This technical summary is based on the academic paper "Effect of water flow rate, casting speed, alloying elements and pull distance on tensile strength, elongation percentage and microstructure of continuous cast copper alloys" published by Bagherian, E-R., Fan, Y., Cooper, M., Frame, B., & Abdolvand, A. in Metallurgical Research and Technology (2016). It was analyzed and summarized for HPDC experts by CASTMAN with the support of AI.

Keywords

- Primary Keyword: Casting Process Optimization

- Secondary Keywords: Copper alloy casting, mechanical properties of alloys, solidification microstructure, cooling rate effects, tensile strength and elongation, alloy composition analysis

Executive Summary

- The Challenge: Achieving the ideal balance of tensile strength and ductility (elongation) in cast metal components is a constant challenge. Process parameters directly control the final microstructure, which in turn dictates these mechanical properties.

- The Method: The research systematically investigated the effects of four key parameters—water flow rate, casting speed, alloying elements (Zr), and pull distance—on the properties of continuous cast copper alloys.

- The Key Breakthrough: The study quantifies the direct relationship between process parameters and mechanical outcomes. For instance, increasing the water flow rate from 15 ltrs/min to 45 ltrs/min improved elongation in a CuSnP alloy from 10% to 25% (Table 5). Similarly, adding zirconium (Zr) significantly increased tensile strength in a CuZr alloy, from 201 MPa at 2.67% Zr to 645 MPa at 6.80% Zr (Table 7).

- The Bottom Line: This paper provides a powerful framework for Casting Process Optimization. While focused on continuous casting, its core principles on managing cooling, speed, and chemistry to control grain structure are directly applicable to enhancing quality and performance in High-Pressure Die Casting (HPDC) operations.

The Challenge: Why This Research Matters for HPDC Professionals

In any casting process, including HPDC, the goal is to produce components that meet stringent specifications for strength, ductility, and structural integrity. The final microstructure—specifically the grain size and morphology—is the primary determinant of these properties. This research, although conducted on a continuous casting system, isolates and examines universal variables that every HPDC engineer grapples with: cooling rates (analogous to die thermal management), fill speed (related to casting speed), and alloy composition. Understanding how these levers precisely impact the end product is crucial for reducing defects, improving part performance, and optimizing cycle times.

The Approach: Unpacking the Methodology

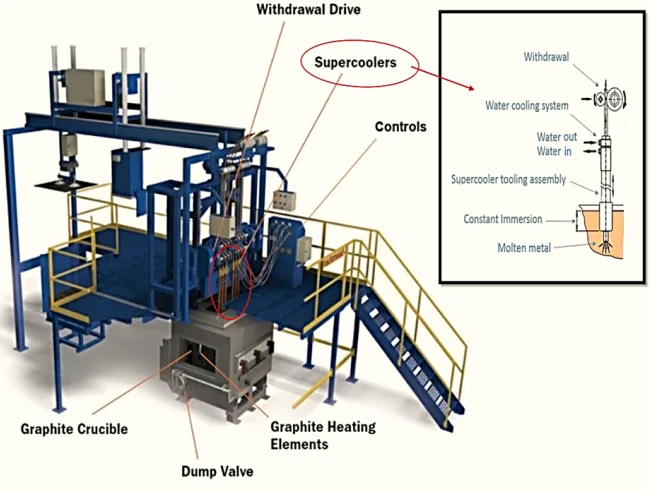

The researchers used a Rautomead RS vertical upwards-continuous casting machine to produce various copper alloy rods. They systematically varied one parameter at a time while keeping others constant to isolate its effect.

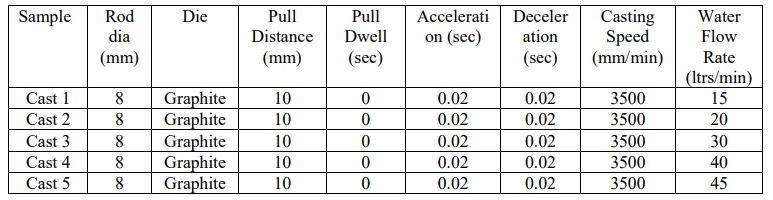

- Water Flow Rate: CuSnP alloy samples were cast at a constant speed (3500 mm/min) while varying the water flow rate from 15 to 45 ltrs/min.

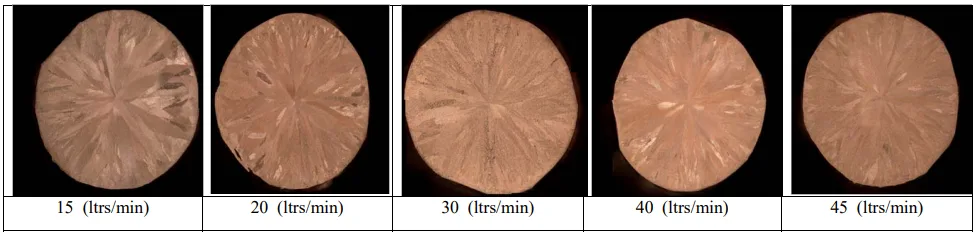

- Casting Speed: OFCu copper samples were cast with a constant water flow rate (45 ltrs/min) at speeds ranging from 2500 to 7800 mm/min.

- Alloying Elements: CuZr alloy samples were produced with zirconium content varying from 2.67% to 6.80%.

- Pull Distance: CuSn samples were cast by varying the pull distance from 3 mm to 6 mm.

For each trial, the resulting samples were analyzed for tensile strength and elongation percentage using an Instron universal testing machine, and their microstructure was examined via metallography.

The Breakthrough: Key Findings & Data

The study delivered clear, data-driven conclusions on how each parameter influences the final cast product.

- Finding 1: Higher Cooling Rates Boost Ductility. For the CuSnP alloy, increasing the water flow rate led to a significant improvement in ductility. The average elongation percentage increased from 10% at a 15 ltrs/min flow rate to 25% at a 45 ltrs/min flow rate. This was accompanied by a finer grain structure, as shown in the micro-graphs (Figure 3).

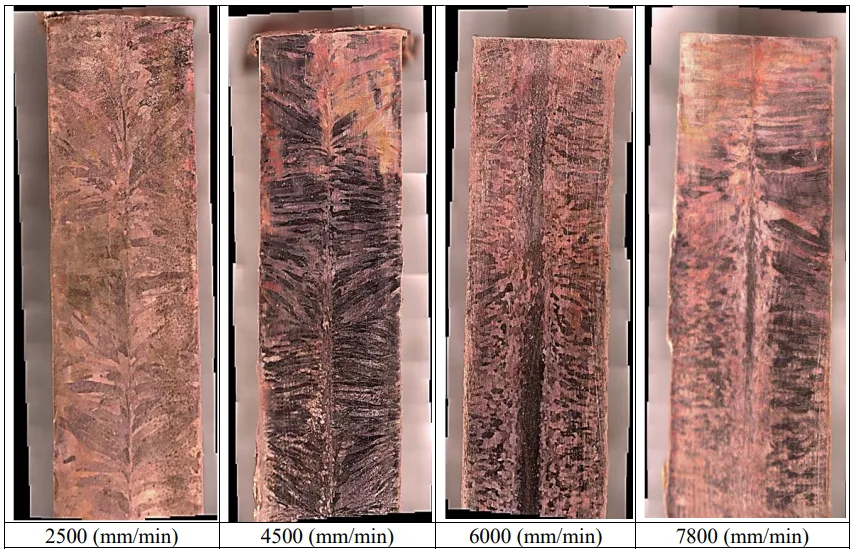

- Finding 2: Faster Casting Speed Refines Grain Structure and Increases Elongation. In OFCu samples, increasing the casting speed from 2500 mm/min to 7800 mm/min resulted in a finer, more refined grain structure (Figure 5). This refinement led to an increase in the average elongation from 34% to 41%, although it slightly decreased the tensile strength from 178 MPa to 168 MPa.

- Finding 3: Zirconium Alloying Dramatically Increases Strength but Reduces Elongation. The addition of zirconium to copper had the most significant effect on tensile strength. Increasing Zr content from 2.67% to 6.80% caused the tensile strength to skyrocket from 201 MPa to 645 MPa. However, this came at the cost of ductility, with elongation dropping from 6% to 2% (Table 7). The addition of Zr also refined the microstructure by reducing the secondary dendrite arm spacing (SDAS), as detailed in Table 8.

Practical Implications for HPDC Products

While the process is different, the metallurgical principles are universal. This research offers valuable insights for Casting Process Optimization in an HPDC context.

- For Process Engineers: The study’s findings on water flow rate strongly suggest that optimizing die cooling and thermal management in HPDC is critical. The data indicates the potential benefit of employing precisely controlled cooling channels to achieve faster solidification, which could lead to finer grain structures and improved ductility in the final cast part, as seen in Figure 3.

- For Quality Control: The inverse relationship between tensile strength and elongation shown in the CuZr alloy tests (Figure 7) is a key insight. This research suggests that when specifying mechanical properties for HPDC parts, it is crucial to understand this trade-off. Demanding extreme strength may inherently limit the part's ductility. The data provides a quantitative example of this principle.

- For Die Design: The study links faster casting speeds to finer grain structures (Figure 5). This suggests that HPDC gate and runner design, which controls melt flow velocity and fill time, could be a powerful tool for microstructural engineering. The study indicates the potential benefit of designing for faster, smoother fills to promote rapid solidification and enhance the mechanical properties of the final component.

Paper Details

1. Overview:

- Title: Effect of water flow rate, casting speed, alloying elements and pull distance on tensile strength, elongation percentage and microstructure of continuous cast copper alloys

- Author: Bagherian, Ehsaan-Reza; Fan, Yongchang; Cooper, Mervyn; Frame, Brian; Abdolvand, Amin

- Year of publication: 2016

- Journal/academic society of publication: Metallurgical Research and Technology

- Keywords: Continuous Casting, Copper Alloys, Solidification, Tensile Test

2. Abstract:

Most parameters that control the solidification of castings, and consequently, microstructure and mechanical properties, are: chemical composition, liquid metal treatment, cooling rate and temperature gradient. In this work, characterization of the influence of water flow rate, casting speed, alloying element and pull distance on tensile strength, elongation percentage and microstructure of continuous cast copper alloys has been carried out. A significant difference based on tensile strength, elongation percentage and grain structure has been investigated and it was also found that these parameters could improve the physical and mechanical properties of samples. As a particular example, water flow rate could improve the elongation of samples from 10% to 25%.

3. Introduction:

Copper alloys have been utilized for at least 7,000 years due to beneficial characteristics like excellent conductivity, corrosion resistance, and easy processing. Continuous casting is a key process for producing copper components. While less expensive than thermo-mechanical processes like extrusion, continuous casting typically results in lower mechanical properties. This paper aims to investigate the impact of alloying elements and cooling control on the mechanical properties of continuous cast copper and copper alloys to enhance their performance.

4. Summary of the study:

This study experimentally investigates four primary process parameters in the continuous casting of copper alloys: water flow rate, casting speed, the addition of alloying elements (zirconium), and pull distance. It measures the resulting tensile strength, elongation percentage, and microstructure for each variation. The goal is to establish clear relationships between these controllable process inputs and the final mechanical properties of the cast material, providing a basis for process optimization.

5. Methodology:

The research was conducted using a Rautomead RS080 vertically upwards-continuous casting machine. Different copper alloys (CuSnP, OFCu, CuZr, CuSn) were produced while systematically altering one of the four key parameters:

- Water Flow Rate: Varied from 15 to 45 ltrs/min.

- Casting Speed: Varied from 2500 to 7800 mm/min.

- Alloying Elements: Zirconium content was varied from 2.67% to 6.80%.

- Pull Distance: Varied from 3 to 6 mm.

Test specimens were prepared according to ASTM standards, and tensile tests were performed on an Instron 4204 machine. Microstructural analysis was conducted after sectioning, grinding, polishing, and etching the samples.

6. Key Results:

Key Results:

- Increasing the cooling water flow rate on CuSnP samples from 15 to 45 ltrs/min increased the average elongation percentage from 10% to 25%, while tensile strength decreased from 310 MPa to 248 MPa.

- Increasing the casting speed on OFCu samples from 2500 mm/min to 7800 mm/min increased the average elongation percentage from 34% to 41%, while tensile strength slightly decreased from 178 MPa to 168 MPa.

- Increasing the zirconium (Zr) content in CuZr alloys from 2.67% to 6.80% dramatically increased tensile strength from 201 MPa to 645 MPa but decreased the average elongation percentage from 6% to 2%.

- The addition of zirconium was also found to reduce the size of the secondary dendrite arm space (SDAS) of the continuously cast copper rod.

- Increasing the pull distance from 3 mm to 6 mm for CuSn samples resulted in a slight increase in the elongation percentage from 31% to 37%.

- In all cases, parameters that led to faster cooling (higher water flow, faster casting speed) resulted in a finer grain structure.

Figure Name List:

- Fig. 1. Schematic of Continuous Rod Casting Machine

- Fig. 2. Tensile strength and elongation percentage of CuSnP samples

- Fig.3 Comparison grain structure of CuSnP samples

- Fig. 4. Tensile strength and elongation percentage of OFCu samples

- Fig.5 Comparison grain structure of OFCu samples (Cross section)

- Fig.6 Comparison grain structure of OFCu samples (Longitudinal section)

- Fig. 7. Tensile strength and elongation percentage of CuZr samples

- Fig.8 Grain structure of CuZr samples

- Fig.9 Second dendrite arm space of CuZr samples

- Fig. 10. Tensile strength and average elongation percentage of CuSn samples

- Fig.11 Grain structure of CuSn samples

7. Conclusion:

The study successfully demonstrated that water flow rate, casting speed, alloying elements, and pull distance have significant effects on the mechanical properties of continuous cast copper alloys. Key conclusions include:

- Increased cooling water flow rate improves elongation percentage.

- Increased casting speed leads to significant improvements in physical and mechanical properties.

- The addition of zirconium (Zr) improves tensile strength but decreases elongation.

- The addition of zirconium slightly reduces the size of the SDAS.

8. References

- J.R. Davis et al. (Eds.): Copper and copper alloys, ASM speciality handbook, second ed., ASM International, Materials Park, OH, 2008, pp. 361-363.

- V. Arbabi, Differences in microstructure and tensile properties of brasses produced by Continuous casting and thermo-mechanical processing, EMESEG'10, the 3rd WSEAS international conference on Engineering mechanics, structures, engineering geology, 2010, Pages 83-88

- M.M. Wolf, "History of Continuous Casting," in Steelmaking Conference Proceedings, 75, (Iron & Steel Society, Warrendale, PA, 1992), 83-137

- Thomas, B.G., “Continuous Casting,” The Encyclopedia of Materials: Science and Technology, Vol. 2, 2001, pp. 1595-1599

- H. SOMMERHOFER, P. SOMMERHOFER, Proc. 5th Int. Cong. Con. Cas. New York (2006), p. 368

- V. PLOCHIKHINE, V. KARKHIN, and H. BERGMANN, Int. Cong. Cont. cast. New York (2000), p. 109

- Zhiming Yan, Meiling Chen, Jun Yang, Grain Refinement of CuNi10Fe1Mn Alloy by SiC Nanoparticles and Electromagnetic Stirring, Journal of Materials and Manufacturing Processes, Volume 28, Issue 8, 2013, pp. 957–961

- ZHAO HUI WANG, YONG LIN KANG, WENCHAO DONG, Study of Grain Refinement and SiC Nanoparticle Reinforced Magnesium Alloys, Journal of MATERIALS SCIENCE FORUM, Volumes 488 – 489, 2005, pp. 889–892.

- Tadeusz Knych, Beata Smyrak, and Monika Walkowicz, Research on the influence of the casting speed on the structure and properties of oxygen-free copper wires, AGH University of Science and Technology, Poland. 2011

- M. Haissig, Horizontal Continuous Casting - A Technology for the Future, Iron and Steel Engineer, vol. 61, pp. 65-70,1984

- P. Voss-Spilker and W. Reichelt, A Review of Horizontal continuous Casting of Metals with Special Reference to Steel, Metals Forum, vol. 7" pp. 79-97, 1984

- Dmitri Kopeliovich, Horizontal continuous casting in graphite mold, Foundry technologies, 2012

- Barry Sadler, The Influence of Casting Speed in The As Cast Strip Mechanical Properties of 8079 AND 8006 Alloys, Light Metals 2013 book, TMS (The Minerals, Metals & Materials Society), 2013

- Naokuni Muramatsu, Development and Microstructure of CuZr Alloy Wire with Ultimate Tensile Strength of 2.2 GPa, Materials Transactions, Vol. 53, No. 6 (2012) pp. 1062 to 1068

- Qing Liu, Control Technology of Solidification and Cooling in the Process of Continuous Casting of Steel, Science and Technology of Casting Processes, Published: September 26, 2012

- J. Sengupta, The use of water cooling during the continuous casting of steel and aluminum alloys, Metallurgical and Materials Transactions A, January 2005, Volume 36, Issue 1, PP. 187-204

- J. Sengupta, B. G. Thomas, M. A. Wells, The use of water cooling during the continuous casting of steel and aluminum alloys, Metallurgical and Materials Transactions A, January 2005, Volume 36, Issue 1, pp 187-204

- W.O. Alexander, G.J. Davies, K.A. Reynolds and E.J. Bradbury: Essential metallurgy for engineers, p63-71. 1985. Van Nostrand Reinhold (UK) Co. Ltd. ISBN: 0-442-30624-5

- Zhao Jingchen The Effect of Cooling Rate of Solidification on hlICROSTRI CTIIKE: And Alloy Element Segregation of As Cast Alloy 718, Central Iron and Steel Research Institute Beijing, Clina, 2015

- L.A. Dobrzański, The effect of cooling rate on microstructure and mechanical properties of AC AlSi9Cu alloy, International Scientific Journal, Volume 28 Issue 2 February 2007 Pages 105-112

- Zhiliang NING, Effect of Cooling Conditions on Grain Size of AZ91 Alloy, Journal of Materials Science and Technology, Vol.23 No.5, 2007]

- N.H. PRYDS, The Effect of Cooling Rate on the Microstructures Formed during Solidification of Ferritic Steel, journal of Metallurgical and Materials Transactions A, 2000, Volume 31, Issue 12, pp 3155-3166

- Adrian P Mouritz, Introduction to Aerospace Materials, 2012

- Jr Alfred E Beck, Matti J Saarivirta, Copper-zirconium alloys, US Patent 2842438, 1958

- James M. Boileau; Jacob W. Zindel; John E. Allison, The effect of solidification time on the mechanical properties in a cast A356-T6 aluminum alloy, Technical Paper Series 970019, Applications of Aluminum in Vehicle Design, SAE International, 1997

- J.R.Davis, Solidification structures of copper alloy ingots, ASM Specially Handbook: Copper and Copper Alloys, 2001

- Z Mei, Effects of cooling rate on mechanical properties of near-eutectic tin-lead solder joints, Journal of Electronic Materials, October 1991, Volume 20, Issue 10, pp 599-608

Expert Q&A: Your Top Questions Answered

Q1: The paper highlights that a higher water flow rate improves elongation. How can this principle be applied to HPDC, where solid dies are used instead of direct water cooling?

A1: This is an excellent question that gets to the heart of applying these findings. In HPDC, the "water flow rate" is analogous to the efficiency of the die's thermal management system. The study's conclusion that faster cooling refines grain structure and boosts ductility (as shown for CuSnP in Table 5) suggests that HPDC dies with optimized cooling channels, conformal cooling designs, or high-conductivity tool steels could achieve similar results. The principle is to extract heat more rapidly and uniformly from the casting, which promotes finer grains and can lead to better mechanical properties, especially ductility.

Q2: The study shows a clear trade-off: adding zirconium to increase tensile strength significantly reduced elongation (Figure 7). How should an HPDC engineer manage this when selecting an alloy?

A2: This finding is critically important for alloy selection in HPDC. The data in Table 7 shows a more than 3x increase in strength (201 MPa to 645 MPa) but a 66% reduction in elongation (6% to 2%) as Zr increases. An HPDC engineer must first define the primary requirement for the component. If the part is a structural element where high strength is paramount and it will experience minimal flexing or impact, a higher-Zr alloy might be suitable. If the component requires some ductility to prevent fracture under load or during assembly (e.g., crimping, bending), then a lower-Zr alloy or an alternative alloy system must be considered. This research provides a quantitative model for that trade-off.

Q3: According to the paper, increasing casting speed improved the elongation of OFCu copper (Table 6). Does this mean faster fill times in HPDC are always better?

A3: Not necessarily, and this is a key distinction. The study found that higher casting speeds in a continuous process led to finer grains and better elongation. In HPDC, a faster fill time can also promote rapid solidification. However, excessively high gate velocities can lead to turbulence, gas entrapment, and die erosion. The insight here is that the rate of solidification is the critical factor. The goal for HPDC professionals is to achieve a fast, non-turbulent fill that allows the molten metal to solidify quickly and uniformly, which this research suggests can refine the microstructure and enhance properties.

Q4: The paper mentions that increasing pull distance is equivalent to increasing casting speed. How does this concept of "pull distance" relate to the HPDC process?

A4: In the continuous casting process described, the "pull distance" is part of an intermittent withdrawal cycle. A larger pull distance in each cycle contributes to a higher overall average casting speed. There isn't a direct one-to-one equivalent in the single-shot HPDC process. However, the underlying principle is that the rate at which the material is processed impacts solidification time. The takeaway for HPDC is that process parameters affecting the overall cycle time and solidification rate, such as injection speed and cooling time, have a cumulative effect on microstructure and properties, similar to how pull distance and casting speed are linked in this study.

Q5: The study concludes that increasing casting speed, water flow rate, and pulling distance leads to a finer grain structure (Conclusion #6). How does this help in diagnosing issues in HPDC production?

A5: This conclusion provides a powerful diagnostic framework. If an HPDC component is failing quality control due to poor mechanical properties (e.g., brittleness) and a microstructural analysis reveals a coarse grain structure, this research points to insufficient cooling as a likely root cause. Based on the paper's findings (Figure 3 and Figure 5), the quality team could investigate issues like clogged cooling lines in the die, incorrect die temperature settings, or an extended cycle time. It reinforces that a fine-grained microstructure is a key indicator of a well-controlled casting process.

Conclusion & Next Steps

This research provides a clear and methodical demonstration of how fundamental process parameters directly control the microstructure and final mechanical properties of cast copper alloys. For professionals in the casting industry, it reinforces the critical importance of a data-driven approach to Casting Process Optimization. The key takeaway is that precise control over cooling rates, processing speed, and alloy chemistry allows for the deliberate engineering of desired material properties.

At CASTMAN, we are committed to applying the latest industry research to help customers achieve higher productivity and quality. If the issues discussed in this paper—such as balancing strength and ductility or refining grain structure—align with your operational goals, contact our engineering team to explore how we can implement these principles in your HPDC components.

Copyright

- This material is a paper by "Bagherian, E-R., Fan, Y., Cooper, M., Frame, B., & Abdolvand, A.". Based on "Effect of water flow rate, casting speed, alloying elements and pull distance on tensile strength, elongation percentage and microstructure of continuous cast copper alloys".

- Source: https://doi.org/10.1051/metal/2016006

- Copyright © 2025 CASTMAN. All rights reserved.