Unlocking Structural Performance: A Guide to High Integrity Diecasting for Automotive Applications

This technical summary is based on the presentation "High Integrity Diecasting for Structural Applications" by Martin Hartlieb of VIAMI INTERNATIONAL INC., presented at the iMdc meeting, WPI, Worcester, MA (2013).

Keywords

- Primary Keyword: High Integrity Diecasting

- Secondary Keywords: Structural Aluminum Die Castings, HPDC Process Control, Vacuum Die Casting, Low Porosity Casting, Automotive Die Casting, Aluminum Die Casting Alloys

Executive Summary

- The Challenge: Traditional High Pressure Die Casting (HPDC) processes produce castings with high porosity and poor mechanical properties (due to high Fe content), making them unsuitable for demanding structural applications.

- The Method: A holistic approach is required, integrating advanced process control, high vacuum systems, optimized die and gating design, superior melt treatment, and specialized low-iron alloys.

- The Key Breakthrough: By controlling the entire process chain and using new low-Fe/high-Mn alloys, it's possible to produce weldable, heat-treatable structural die castings with low porosity, high ductility, and excellent fatigue life.

- The Bottom Line: The inherent advantages of die casting (speed, precision, thin walls) can now be leveraged for high-quality structural components at competitive costs, overcoming the limitations of traditional methods.

The Challenge: Why This Research Matters for HPDC Professionals

The automotive industry's drive for lightweighting has led to a dramatic increase in aluminum content, with projections showing continued growth for structural components like body-in-white structures, shock towers, and engine cradles (Source: Ducker Worldwide 2011). While HPDC is the lowest-cost mass production casting process, its traditional application for structural parts has been severely limited.

The core challenges stem from inherent process disadvantages:

* High Porosity: Standard HPDC often results in significant gas and shrinkage porosity, which acts as an initiation point for cracks and drastically reduces fatigue life.

* Detrimental Alloying: To prevent die soldering, traditional HPDC alloys rely on high levels of iron (Fe). This high Fe content leads to the formation of brittle, needle-like Al5FeSi phases, which destroy ductility and fracture toughness.

* Inability to Heat Treat: The high level of entrapped gases causes blistering and distortion if the parts undergo subsequent heat treatment, preventing the enhancement of mechanical properties.

These limitations have historically relegated HPDC to non-structural or less critical components. To meet the demands of modern structural applications—which require high strength, ductility (≥10% elongation), crashworthiness, and weldability—a fundamental shift in the die casting process is necessary.

The Approach: Unpacking the Methodology

To overcome the limitations of conventional HPDC, the presentation advocates for a "holistic approach" that treats die casting not as a single step but as an integrated system of technologies. This approach requires meticulous control over every stage of the process, from raw material to finished part.

The key elements of this complete die casting process technology include:

* Melt Treatment & Transfer: Implementing proper temperature control, degassing, fluxing, and filtering to ensure the molten metal is free of oxides, hydrogen, and other inclusions before it even reaches the machine.

* Simulation & Design: Utilizing numerical simulation to optimize gating, runner, and overflow design, ensuring a continuous, non-turbulent flow path that minimizes entrapped air. Die design must also incorporate advanced thermal control and sealing for vacuum integrity.

* Process Control & Monitoring: Employing real-time, closed-loop control of all critical parameters. This includes shot monitoring for precise and repeatable injection profiles, cycle-to-cycle die temperature monitoring, and advanced vacuum monitoring to ensure low cavity pressure.

* Advanced Equipment: Utilizing high-performance die casting machines, effective vacuum systems (valves and controls), and optimized die release chemistry and application.

* Specialized Alloys: Moving away from high-Fe secondary alloys to high-purity, low-Fe (<0.25%) primary alloys with controlled additions of elements like Mn and Sr to improve ductility, toughness, and castability.

* Post-Casting Processes: Integrating controlled part extraction, quenching, and low-distortion heat treatment into the production cycle to achieve final mechanical properties.

This systematic approach transforms HPDC from an art into a science, enabling the production of high-integrity castings with predictable and reliable performance.

The Breakthrough: Key Findings & Data

By implementing this holistic approach, die casters can achieve breakthroughs in quality and performance, making HPDC a viable solution for structural components.

Finding 1: The Critical Link Between Iron Content, Microstructure, and Toughness

The presentation provides clear evidence that reducing iron content is paramount for structural performance. Traditional alloys with high Fe form brittle, needle-like intermetallic phases (Al5FeSi) that severely compromise mechanical properties.

The research cited from John Campbell quantifies this effect directly. As shown in the graph on slide 22, an aluminum alloy with 0.15% Fe exhibits significantly higher fracture toughness across all dendrite arm spacings compared to alloys with 0.30% and 0.40% Fe. This demonstrates that minimizing iron is a non-negotiable requirement for high-integrity castings. Furthermore, the presentation highlights that replacing Fe with Mn helps correct the Fe phase and minimize soldering without the same negative impact on ductility (slide 51).

Finding 2: Drastically Reducing Porosity with Vacuum and Process Control

Porosity is a primary determinant of fatigue life. The presentation illustrates a clear hierarchy of casting quality based on process control (slide 15). While standard die casting can have porosity levels of 2.5% or more, a "High vacuum high integrity Diecasting for Structural Castings" process can achieve levels below 0.16%.

This reduction is achieved primarily through high vacuum systems that evacuate air from the die cavity and shot sleeve before and during injection, preventing gas entrapment. Advanced monitoring techniques (slide 39) are used to ensure proper vacuum levels, detect leaks, and even identify issues like excessive moisture from die lubricant, which is "not compatible" with a good vacuum (slide 44). This meticulous control over cavity atmosphere is essential for producing sound, heat-treatable, and weldable castings.

Practical Implications for R&D and Operations

The insights from this presentation have direct, actionable implications for engineering and management teams in the die casting industry.

- For Process Engineers: This study suggests that adjusting the slow shot velocity profile is critical for preventing air entrapment (slide 36). Implementing real-time shot monitoring systems (slide 35) allows for precise, repeatable injection control, which is fundamental to achieving consistent quality.

- For Quality Control Teams: The data in the fracture toughness graph (slide 22) illustrates the effect of Fe content on a key mechanical property, which could inform new material inspection criteria for incoming alloys. The clear visual difference in porosity between standard and high-integrity castings (slide 15) provides a benchmark for quality assessment.

- For Design Engineers: The findings indicate that runner and gating design has a direct impact on entrapped air (slide 32). Utilizing flow simulation in the early design phase is a must to ensure a robust casting process and a high-quality final part.

Paper Details

High Integrity Diecasting for Structural Applications

1. Overview:

- Title: High Integrity Diecasting for Structural Applications

- Author: Martin Hartlieb, VIAMI INTERNATIONAL INC.

- Year of publication: 2013

- Journal/academic society of publication: iMdc meeting, WPI, Worcester, MA, December 12, 2013

- Keywords: High Integrity Diecasting, Structural Applications, Die Casting Quality, Aluminum, Automotive

2. Abstract:

Traditional die casting processes have struggled to produce high-integrity (low porosity) castings suitable for structural applications, largely due to a reliance on high iron (Fe) levels to reduce die soldering, which negatively impacts mechanical properties. This presentation outlines a holistic approach to overcome these limitations. By integrating new low-Fe alloys with advanced process control, high vacuum systems, and proper die design, it is now possible to produce die castings with superior quality and mechanical properties (heat treatable, weldable, crashworthy, high fatigue life). This allows the inherent advantages of die casting—such as high freezing rate, thin walls, and high precision—to be leveraged for producing high-quality structural castings at competitive costs.

3. Introduction:

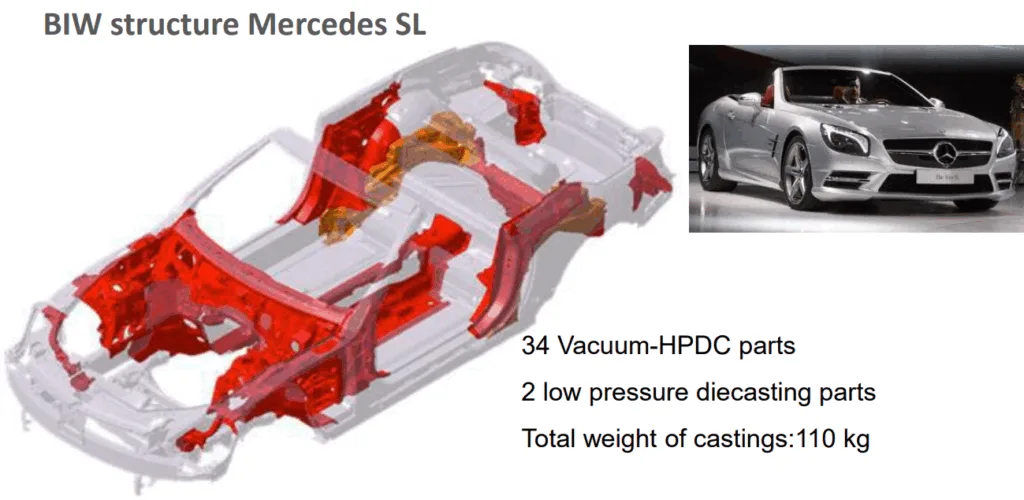

The use of aluminum in the automotive industry is steadily increasing to save weight and improve performance. Structural aluminum die castings are replacing heavier materials, thicker-walled parts, and complex steel assemblies. Applications range from body-in-white (BIW) structures like A-pillars and shock towers to suspension parts and engine cradles. The Mercedes SL is presented as a key example, featuring 34 vacuum-HPDC parts totaling 110 kg, contributing to a significant weight advantage over a conventional steel design. However, to meet the stringent requirements of these applications (e.g., high mechanical properties, crash performance, weldability), the known disadvantages of conventional HPDC, such as high porosity and defects, must be overcome.

4. Summary of the study:

Background of the research topic:

The increasing demand for lightweight vehicles has driven a significant rise in the aluminum content per vehicle, particularly for structural components.

Status of previous research:

Conventional HPDC is recognized as a low-cost, high-volume process but is plagued by disadvantages, including expensive tooling, high porosity, and the use of high-Fe secondary alloys that yield poor mechanical properties and fatigue life. Casting defects like porosity, oxides, and intermetallic particles are known to be the primary limiting factors for fatigue performance.

Purpose of the study:

The purpose is to present a holistic approach to improve die casting quality, enabling the production of "high integrity" die castings that meet the demanding requirements for structural applications in the automotive and other industries.

Core study:

The core of the study is the detailed examination of all factors affecting die casting quality. This includes a comprehensive review of the entire process chain, from alloy composition and melt treatment to die design, machine control (shot profile, vacuum), and post-casting heat treatment. The study highlights the technologies, alloys, and control strategies necessary to move from standard die casting to high-integrity structural casting.

5. Research Methodology

Research Design:

The presentation does not follow a single experimental design but rather presents a comprehensive overview and synthesis of best practices and technologies required for high-integrity die casting. It functions as a technical guide based on industry experience and existing research.

Data Collection and Analysis Methods:

The methodology is a holistic review of the complete die casting process. The factors affecting quality are systematically broken down and analyzed, including:

- Alloy composition and metal quality.

- Melt treatment and transfer methods.

- Die-casting machine and control systems (shot end, monitoring).

- Tooling (die design, gating, vacuum system, lubricant).

- Part design and post-processing steps (heat treatment).

A complete process chain is outlined, emphasizing quality gates (Q-Gates) at each critical step.

Research Topics and Scope:

The scope covers the entire process of producing structural aluminum die castings. Key topics include: applications, advantages and disadvantages of HPDC, types of defects, requirements for structural parts, factors affecting quality, melt treatment, product development and simulation, process control (die temperature, shot monitoring), vacuum systems, and specialized alloys.

6. Key Results:

Key Results:

- Traditional die casting is unsuitable for structural parts due to high porosity and the use of high-Fe alloys which destroy mechanical properties, especially elongation.

- A holistic approach covering the entire process chain—from melt quality to heat treatment—is necessary to achieve high integrity.

- Reducing Fe content below 0.25% and using Mn to control soldering is critical for improving fracture toughness and ductility.

- Advanced process controls, including high vacuum systems, closed-loop shot control, and die thermal management, are essential for minimizing porosity and ensuring part consistency.

- New Al-Si and Al-Mg-Si alloy families have been developed specifically for high-integrity die casting, offering excellent castability and mechanical properties, making them heat treatable, weldable, and crashworthy.

- With these new processes and alloys, the inherent advantages of die casting (high freezing rate, thin walls, precision) can be used to produce high-quality structural castings at competitive costs.

Figure Name List:

- Aluminum content in automotive

- Relationship Between Dendrite Cell Size and Solidification Rate for Aluminum Alloys

- Porosity in High Pressure Die Casting

- Fracture Toughness depends on Fe content & dendrite arm spacing

- A „holistic“ approach is needed! Complete Die Casting Process Technology

- Typical process chain for structural high integrity die castings

- "Sludge" Factor chart and Fluidity vs. Temperature graph

- Numerical simulation (1st flow vs. Optimized runner design)

- Die design, thermal balance and process control (Thermal image)

- Shot monitoring and control (Visi-Trak graph)

- Example: The slow shot (diagrams and Visi-Trak graph)

- High vacuum die casting (diagrams and Visi-Trak graph)

- Efficiency comparison with bench test (CASTvac vs. others)

- Vacuum and moisture are not compatible! (graphs)

- Effect of Iron on Fatigue Curve for XK360

- The influence of Mn (replacing Fe) mechanical properties (graphs)

- The influence of Si and Mg on mechanical properties in the F temper (graphs)

- AA 365 - Silafont 36 property chart

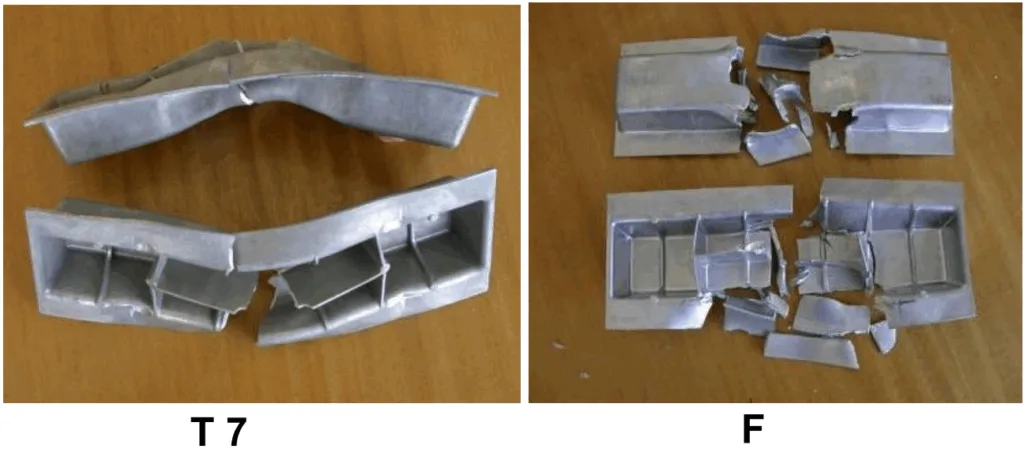

- Force vs time curves, T7 and F conditions (CALYPSO 61D)

- Heat treatment of high integrity die castings (temperature profile)

7. Conclusion:

- Traditional diecasting processes had difficulty in achieving high integrity (low porosity) castings and were therefore unusable for structural applications.

- Traditional diecasting has relied upon high levels of Fe in Al to reduce die soldering. As known, Fe also destroys mechanical properties (especially elongation).

- New diecasting processes applying process control, high vacuum, proper die design, etc. and new alloys allow production of diecastings with high quality / mechanical properties (heat treatable, weldable, crash worthy, high fatigue life, etc.).

- The inherent advantages of diecasting (high freezing rate, thin walls, high precision, etc.) can now be used to produce high quality structural castings at competitive costs.

8. References:

- Source: Ducker Worldwide 2011 (slide 3)

- Source: Daimler AG, Dr. Lutz Storsberg, Mercedes-Benz Cars, Structural Symposium Bühler AG, Hamilton, Canada, October 1, 2013 (slides 6, 7)

- After Spear and Gardner (slide 12)

- See also Modern Casting Article “Predicting the Fatigue Life of Aluminum Castings (May 2013) based on research paper 13-1342 from P. Jones & Q. Wang (GM) presented at the 2013 AFS Metalcasting Congress (slide 14)

- Source: John Campbell: CASTING [1991 edition], page 266, figure 8.3. (slide 22)

- Courtesy of Magna BDW GmbH & Co. KG, Markt Schwaben, Germany (slides 25, 30)

- Courtesy of Visi-Trak Worldwide, LLC (slides 33, 35, 37, 39, 45, 46)

- Courtesy of MERCURY MARINE, a division of BRUNSWICK CORPORATION (slides 21, 50)

- See May 2013 edition of Diecasting Engineer http://www.diecasting.org/dce/issues/0513/51340.pdf (slide 48)

Expert Q&A: Your Top Questions Answered

Q1: Why is iron (Fe) content so detrimental in aluminum die castings, and what is the modern approach to mitigate its effects?

A1: High iron content is detrimental because it promotes the formation of brittle, needle-like Al5FeSi intermetallic phases during solidification (slide 17). These phases act as stress risers, drastically reducing the ductility, fatigue life, and fracture toughness of the casting (slide 22). The modern approach for high-integrity castings is to use primary alloys with very low iron content (<0.25%) and to add manganese (Mn), which helps minimize die soldering and modifies the iron phase into a less harmful morphology (slides 48, 49, 51).

Q2: The presentation emphasizes a "holistic approach." What are the key components of this approach as shown in the process technology cycle?

A2: The holistic approach is a continuous cycle of interdependent technologies. As shown on slide 25, the key components are: Simulation, Die Concept, Gating System, Melt Treatment, Shot Monitoring and Control, Vacuum, Die Release Chemistry, Die Release Application, and Humidity Monitoring. This demonstrates that achieving high quality is not about perfecting one step, but about optimizing and controlling the entire integrated system.

Q3: How does improper slow shot velocity lead to defects, and what does an optimized profile look like?

A3: An improper slow shot velocity can directly cause air entrapment. If the shot is too slow, the wave front of the molten metal can fold over on itself, trapping a pocket of air in the sleeve (slide 36). If it is too fast, it can create a wave that splashes and traps air against the end of the sleeve. The ideal profile, as suggested by the process control graph on slide 37, is a constant, smooth acceleration that pushes a flat metal front, effectively evacuating air ahead of it without turbulence.

Q4: What are the primary advantages of using a high vacuum system in die casting, and what is a critical factor for its effectiveness?

A4: The primary advantages of high vacuum die casting are reduced porosity, which allows for subsequent heat treatment without blistering and significantly improves mechanical properties. It also enables the casting of thinner walls and more complex parts (slide 38). A critical factor for its effectiveness is controlling moisture. As shown on slide 44, high humidity (e.g., 90%) severely limits the achievable vacuum level (120 mbar), whereas low humidity (15%) allows for a much deeper vacuum (< 50 mbar). Therefore, managing die lubricant application and ambient humidity is essential.

Q5: The presentation shows a significant difference in crash behavior between F (as-cast) and T7 tempers for the CALYPSO 61D alloy. What properties account for this?

A5: The difference in crash behavior is due to the change in mechanical properties induced by the T7 heat treatment. The F (as-cast) condition has higher ultimate tensile strength (270-290 MPa) but lower elongation (10-12%). In contrast, the T7 temper results in lower UTS (215-225 MPa) but significantly higher elongation (14-18%) and a higher yield strength (155-165 MPa vs 120-140 MPa). This increased ductility allows the T7 part to absorb more energy by deforming plastically without catastrophic failure, as shown by the bent part in slide 58, whereas the F temper part shatters.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing lightweight, high-performance structural components has pushed the boundaries of traditional manufacturing. As this presentation clearly demonstrates, conventional die casting, with its inherent issues of porosity and material limitations, is no longer sufficient. The future belongs to High Integrity Diecasting, a scientifically managed, holistic process that transforms HPDC into a reliable method for creating critical structural parts. By combining advanced process control, vacuum technology, and specialized low-impurity alloys, manufacturers can now deliver heat-treatable, weldable, and crashworthy components that meet the highest industry standards.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "High Integrity Diecasting for Structural Applications" by "Martin Hartlieb".

- Source: Presentation at the iMdc meeting, WPI, Worcester, MA, December 12, 2013.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.