This technical summary is based on the academic paper "ANALYSIS OF MECHANICAL PROPERTIES AND MICROSTRUCTURE OF MULTIPLE DIE CAVITY PRODUCTS PRODUCED IN VERTICAL AND HORIZONTAL ARRANGEMENT BY GRAVITY DIE CASTING" published by SALEH S SALEH ELFALLAH in Faculty of Mechanical and Manufacturing Engineering Universiti Tun Hussein Onn Malaysia (2012). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

![Figure 1.1: Gravity die mold [3].](https://castman.co.kr/wp-content/uploads/image-2803.webp)

Keywords

- Primary Keyword: Gravity Die Casting

- Secondary Keywords: Mechanical Properties, Microstructure, Vertical Arrangement, Horizontal Arrangement, Multiple Die Cavity, Aluminum Alloy

Executive Summary

- The Challenge: Manufacturers often assume products from vertical and horizontal die casting arrangements have the same quality, lacking data on strength, defects, and microstructure.

- The Method: Researchers compared mechanical properties and microstructure of castings produced in vertical vs. horizontal arrangements using various tests (microhardness, impact, tensile, density, porosity, microscopy).

- The Key Breakthrough: Castings from vertical arrangements exhibit superior mechanical properties (density, hardness, impact strength, tensile strength) compared to horizontal arrangements.

- The Bottom Line: Arrangement significantly impacts product quality; vertical arrangements generally yield mechanically superior castings.

The Challenge: Why This Research Matters for HPDC Professionals

In the gravity die casting industry, a common assumption is that products manufactured using either vertical or horizontal mold arrangements possess equivalent quality. However, this assumption often lacks sufficient data regarding crucial properties such as strength, internal defects, and microstructure. This information gap can lead to inconsistencies in product performance and potential failures, impacting overall manufacturing efficiency and customer satisfaction. For high-pressure die casting (HPDC) professionals, understanding the nuances of mold arrangement is critical for optimizing product quality and minimizing potential risks.

The Approach: Unpacking the Methodology

To investigate the impact of mold arrangement, the researcher compared castings produced using vertical and horizontal arrangements. The methodology involved a comprehensive suite of tests to evaluate mechanical properties and microstructure. These tests included:

- Vickers Microhardness Test: Measures the material's resistance to indentation [Abstract].

- Izod Impact Test: Determines the material's ability to withstand sudden impact [Abstract].

- Tensile Test: Evaluates the material's strength under tension [Abstract].

- Density and Porosity Tests: Quantify the material's compactness and void content [Abstract].

- Optical Microscope Inspection: Examines the material's microstructure for defects and grain structure [Abstract].

These tests were performed on samples produced from both vertical and horizontal arrangements, allowing for a direct comparison of their respective properties [Abstract].

The Breakthrough: Key Findings & Data

The research revealed significant differences in the mechanical properties and microstructure of castings produced using vertical versus horizontal arrangements:

- Density: Vertical arrangement castings exhibited a 1.6117% higher density than horizontal arrangement castings [Abstract].

- Porosity: Vertical arrangement castings showed higher porosity, exceeding horizontal castings by 13.3885% [Abstract].

- Hardness: Vertical arrangement castings displayed hardness values between 115HV and 78.9HV, while horizontal castings ranged from 110HV to 79.1HV. Castings in vertical arrangement showed 7.5442% higher hardness [Abstract].

- Impact Strength: Vertical arrangement castings had impact strength values between 6J and 19J, exceeding horizontal castings (2J to 11J) by 118.4615% [Abstract].

- Tensile Strength: Vertical arrangement castings exhibited ultimate tensile strengths between 122-182 MPa, 11.81% higher than horizontal castings (101-178 MPa) [Abstract].

- Microporosity: Microporosity was 35% lower in vertical arrangement positions compared to horizontal arrangements [Abstract].

Practical Implications for HPDC Products

The research suggests that the choice of mold arrangement has a significant impact on the final product's properties. This has several implications for HPDC operations:

- For Process Engineers: The higher density and tensile strength achieved with vertical arrangements suggest that this configuration may be preferable for components requiring high structural integrity [Abstract].

- For Quality Control: The difference in porosity levels indicates that careful monitoring and control of the casting process are crucial to minimize defects, especially in vertical arrangements where porosity tends to be higher [Abstract].

- For Die Design: The findings highlight the importance of considering the mold arrangement during the design phase to optimize mechanical properties and minimize microporosity [Abstract].

Paper Details

ANALYSIS OF MECHANICAL PROPERTIES AND MICROSTRUCTURE OF MULTIPLE DIE CAVITY PRODUCTS PRODUCED IN VERTICAL AND HORIZONTAL ARRANGEMENT BY GRAVITY DIE CASTING

1. Overview:

- Title: ANALYSIS OF MECHANICAL PROPERTIES AND MICROSTRUCTURE OF MULTIPLE DIE CAVITY PRODUCTS PRODUCED IN VERTICAL AND HORIZONTAL ARRANGEMENT BY GRAVITY DIE CASTING

- Author: SALEH S SALEH ELFALLAH

- Year of publication: JUNE 2012

- Journal/academic society of publication: Faculty of Mechanical and Manufacturing Engineering Universiti Tun Hussein Onn Malaysia

- Keywords: Not provided in the paper.

2. Abstract:

Multiple cavities die casting (Permanent die casting) in vertical arrangement and horizontal arrangement moulds are widely used in industry. However, manufacturers assume that each product produced in either arrangement would have the same quality. Manufacturers do not have enough information about the properties of each product, i.e. strength, internal defect and the microstructure. Furthermore, in actuality the quality of each product might be affected. It is the problem that we found within the market now (pinholes, cracks, misruns and etc.), that is the reason investigation and comparison of the multi product in vertical and horizontal arrangement is needed. This investigation is needed to choose which arrangement is preferred to maintain the quality of the product. The methodology used are vickers microhardness test, izod test, ensile test, density and porosity test and optical microscope inspection for all produced sample. Results of this research show that castings produced at vertical arrangement mould have higher mechanical and properties than castings produced in horizontal arrangement mould. Vertical arrangement castings obtained higher density exceeds %1.6117 than horizontal arrangement castings that ranges between (1.156 and 4.8707 percent). However, vertical arrangement castings obtained higher porosity exceeds %13.3885 than horizontal arrangement castings that ranges between (0.0809 and 7.4629 percent). The hardness values for vertical castings ranges between (115HV and 78.9HV), while ranges between (110HV and 79.1HV) for horizontal castings. Castings in vertical arrangement hardness are %7.5442 higher than hardness for castings in horizontal arrangement. Impact strength values of vertical arrangement casting impact values that ranges between( 6J and 19J ) positions are %118.4615 higher than casting at horizontal arrangement casting positions that range between (2J and 11J). Ultimate tensile strength for castings produced at vertical arrangement mould ranges between (122-182 MPa) are %11.81 higher than castings produced at horizontal arrangement castings (101-178 MPa). The microporosity at vertical arrangement positions are %35 lower than microporoity at horizontal arrangement positions.

3. Introduction:

This chapter will generally present the process, type, problems, and purpose of study. The following area of discussion in this chapter will introduce the problem background, problem statement, objectives, scope of study, and significant of study, hypothesis, expected results and synopsis.

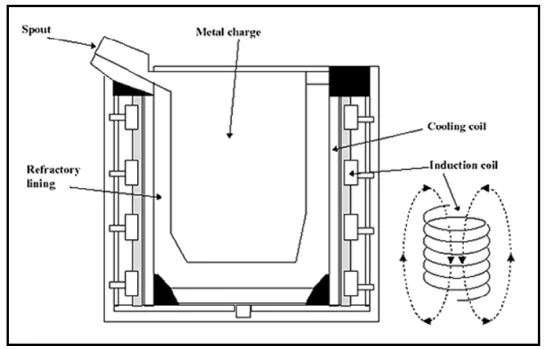

One of the most popular methods of producing parts in metal is by casting [1]. Casting is a manufacturing process by which a molten material such as metal or plastic is introduced into a mold, allowed to solidify within the mold, and then ejected or broken out to make a fabricated part. Casting produced should an exact replica of the mold [1]. Casting is used for making parts of complex shape that would be difficult or uneconomical to make by other methods, such as cutting from solid material [2]. Gravity die casting is a process wherein the liquid metal is poured into metallic moulds without application of any external pressure. The liquid metal enters the cavity by gravity. Gravity die casting (GDC) is different from High Pressure Die Casting (HPDC), where the liquid metal is injected into the metal mould under very high pressures for production of thin walled smaller castings with better dimensional accuracy and surface finish [3]. Like Low Pressure Die Casting (LPDC) dies, the dies used for permanent mold casting are typically coated with a refractory material. Cores can be used and made from high alloy steels or resin bonded sands. Permanent mould casting is typically used for high-volume production of sample metal parts with uniform wall thickness. The minimum wall thickness that can be permanent mould cast is approximately 4 mm because of the limited ability of metal to run into thin sections. The process is used for the volume production ranging from 1000 to more than 100 000 per year. Common permanent mould parts include gears, automotive pistons and car wheels. The alloys commonly cast by permanent mould casting include 319 (AlSi5Cu3), 413 (ALSi12) and A356 (AlSi7Mg). The casting operation ranges from manually-operated die sets) to automatically operated (carousel machines having several dies around 4-10 minutes before the casting can be taken out from the die so the process is relatively slow. If higher production rates are required, multiple die sets have to be employed [4]. Gravity die casting accounts about %30 of all light alloy casting production while high pressure die casting is the most widely used, representing about 50%. and Low pressure die casting currently accounts for about %20 [2]. Gravity die casting is a manufacturing process for producing accurately dimensioned, sharply defined, smooth or textured-surface metal parts. It is accomplished by gently pouring molten metal into reusable metal dies under the force of gravity. The term, "die casting," is also used to describe the finished part.

4. Summary of the study:

Background of the research topic:

Multiple cavities die casting (Permanent die casting) in vertical arrangement and horizontal arrangement moulds are widely used in industry. However, manufacturers assume that each product produced in either arrangement would have the same quality. Manufacturers do not have enough information about the properties of each product, i.e. strength, internal defect and the microstructure. Furthermore, in actuality the quality of each product might be affected. It is the problem that we found within the market now (pinholes, cracks, misruns and etc.), that is the reason investigation and comparison of the multi product in vertical and horizontal arrangement is needed. This investigation is needed to choose which arrangement is preferred to maintain the quality of the product.

Status of previous research:

Not provided in the paper.

Purpose of the study:

This research is to study the mechanical properties of the samples produced by gravity die casting (GDC) in vertical and horizontal arrangement.

Core study:

This research show that castings produced at vertical arrangement mould have higher mechanical and properties than castings produced in horizontal arrangement mould.

5. Research Methodology

Research Design:

The methodology used are vickers microhardness test, izod test, ensile test, density and porosity test and optical microscope inspection for all produced sample.

Data Collection and Analysis Methods:

Results of this research show that castings produced at vertical arrangement mould have higher mechanical and properties than castings produced in horizontal arrangement mould. Vertical arrangement castings obtained higher density exceeds %1.6117 than horizontal arrangement castings that ranges between (1.156 and 4.8707 percent). However, vertical arrangement castings obtained higher porosity exceeds %13.3885 than horizontal arrangement castings that ranges between (0.0809 and 7.4629 percent). The hardness values for vertical castings ranges between (115HV and 78.9HV), while ranges between (110HV and 79.1HV) for horizontal castings. Castings in vertical arrangement hardness are %7.5442 higher than hardness for castings in horizontal arrangement. Impact strength values of vertical arrangement casting impact values that ranges between( 6J and 19J ) positions are %118.4615 higher than casting at horizontal arrangement casting positions that range between (2J and 11J). Ultimate tensile strength for castings produced at vertical arrangement mould ranges between (122-182 MPa) are %11.81 higher than castings produced at horizontal arrangement castings (101-178 MPa). The microporosity at vertical arrangement positions are %35 lower than microporoity at horizontal arrangement positions.

Research Topics and Scope:

To study the mechanical properties and microstructure of each specimen in casting. To make comparison between each specimen produced. Tensile test will be included to test each specimen. Aluminum 356 will be the material to be casted. The mold will be used is made from the mild steel.

6. Key Results:

Key Results:

- Vertical arrangement castings obtained higher density exceeds %1.6117 than horizontal arrangement castings that ranges between (1.156 and 4.8707 percent).

- Vertical arrangement castings obtained higher porosity exceeds %13.3885 than horizontal arrangement castings that ranges between (0.0809 and 7.4629 percent).

- The hardness values for vertical castings ranges between (115HV and 78.9HV), while ranges between (110HV and 79.1HV) for horizontal castings.

- Castings in vertical arrangement hardness are %7.5442 higher than hardness for castings in horizontal arrangement.

- Impact strength values of vertical arrangement casting impact values that ranges between( 6J and 19J ) positions are %118.4615 higher than casting at horizontal arrangement casting positions that range between (2J and 11J).

- Ultimate tensile strength for castings produced at vertical arrangement mould ranges between (122-182 MPa) are %11.81 higher than castings produced at horizontal arrangement castings (101-178 MPa).

- The microporosity at vertical arrangement positions are %35 lower than microporoity at horizontal arrangement positions.

![Figure 1.2: principle of gravity die casting [3]](https://castman.co.kr/wp-content/uploads/image-2804.webp)

Figure Name List:

- Figure 1.1: Gravity die mold [3].

- Figure 1.2: principle of gravity die casting [3].

- Figure 1.3: Example of multiple die cavities

- Figure 2.1: Electric Induction Furnace (Coreless)

- Figure 2.2: Typical Cupola Furnace.

- Figure 2.3: Direct Arc Furnace.

- Figure 2.4: Crucible Furnace.

- Figure 2.5: Rotating Furnace [5].

- Figure 2.6: Example of gas porosity defect [10].

- Figure 2.7: Example of misrun defect [10].

- Figure 2.8: Example of cold shut defect [10].

- Figure 2.9: Example of hot tear defect [10].

- Figure 2.10: Example of shrinkage porosity [10].

- Figure 2.11: Cooling curve for a pure metal of eutectic-composition [1].

- Figure 2.12: Cooling curve depicting undercooling and subsequent recalescence [1].

- Figure 2.13: Schematic illustration of three shrinkage regimes.

- Figure 2.14: Solidification model for an unfed sphere [12].

7. Conclusion:

Results of this research show that castings produced at vertical arrangement mould have higher mechanical and properties than castings produced in horizontal arrangement mould.

8. References:

- Degarmo, E. P., Black, J. T. & Kohser, R. A. (2003). Materials and Processes in Manufacturing. 9th ed. USA: Wiley.

- Gravity Die Casting: Introduction. Retrieved 2011. from ZheJiang Dongrun Casting Industry&Trade Co,.Ltd: http://www.dongruncasting.com/Capabilities/Gravity_Die_Casting.htm

- Gravity Die Casting, Retrieved Dec 3, 2011, from IndiaMART InterMESH Limited: http://www.industrialmetalcasting.com/gravity-die-casting.html

- Lumley, R. (2011). Fundumentls of Aluminum Metallurgy. Cambridge: woodhead Publishing Limited.

- Copula Furnace, Retrieved Dec 6, 2011, from IndiaMART InterMESH Limited: http://www.industrialmetalcasting.com/cupola-furnaces.html

- Posinasetti Nageswara, R. (1999). Manufacturing technology: foundry, forming and welding. 2nd ed. USA: Tata McGraw-Hill.

- Singh, N., Sikkenga, S. & Shankar, G. (2004). Atlas of Casting Defects. Montvale, NJ: Investment Casting Institute.

- Waters, T. F. (2003). Manufacturing For Engineers. 2nd edition. London: Taylor &Francis.

- Colton, J. S. (2011). Casting Defects and Design Issues, Manufacturing Processes and Systems. US: Georgia Institute of Technology.

- Apelian, D. (2009). Aluminum Cast Alloys: Enabling Tools for Improved Performance. Wheeling, Illinois: North American Die Casting Association.

- Campell, J. (2003). Castings, 2nd ed. University of Birmingham. UK: Elsevier.

- Castings Problems. Retrieved Jan, 2011, from Key To Metal: http://www.keytometals.com/Article83.html

- Permenant Mold Casting. Retrieved Jan, 2011, from Substance and Technologies: http://www.substech.com/dokuwiki/doku.php?id=permanent_mold_casting

- Design for Manufacturability (DFM) Tips for Die Cast Parts. Retrieved 2010, from Magic precision: http://www.mgprecision.com/resources/design-for-manufacturability-tips-for-die-cast-parts.html

- Janagan, Shamasundar, S., & Gopalakrishna, V. (2010). Gravity Die Casting Process: Die Design and Process Optimisation. Chennai: Ennore Foundries Limited.

- Permenant Mold Casting. Retrieved 2009, from Custom Part Net: http://www.custompartnet.com/wu/permanent-mold-casting

- Gravity die cast aluminum. Retrieved 2011, from G.W.P. Manufacturing Services AG: http://www.gwp-ag.com/en/services/series-production/cast-metal/gravity-diecasting/gravity-diecast-aluminum/index.html

- Andresen, B. (2005). Die Casting Engineering. New York: Marcel Dekker.

- Die Cast Samples. Retrieved 2011, from Vikram Engineering Works: http://www.vikramenggworks.co.in/die-cast-samples.html

- Reynolds number. Retrieved May 22, 2009, from Glenn Research Center: http://www.grc.nasa.gov/WWW/BGH/reynolds.html

- Chakrabartti, S. (1969). Investigation of flow-phenomenon invarious running and gating system. UK: The British Foundrymen.

- Kaufman, J. G., Rooy, E. L., 2004. Aluminum Alloy Castings: Properties, Processes, and Applications, American Foundry. Society Material Park, OH: ASM International.

- A.M. Kliauga, E.A. Vieira and M. Ferrante, The influence of impurity level and tin addition on the ageing heat treatment of the 356 class alloy. Elsevier. 2008. A 480: 5-16.

- Ong Chin Yee, Analysis of Mechanical Properties and Microstructure of Miltiple products Produced in Vertical and Horizontal Arrangement by Gravity Die Casting, UTHM, Batu Pahat, 2011.

- Determination of Impact Energy Using the Izod Test. Retrieved Mar 17, 2005, from AZOM: http://www.azom.com/article.aspx?ArticleID=2765

- Izod Impact Test. Retrieved 2002, from About: Metals: http://metals.about.com/library/bldef-Izod-Impact-Test.html

- American Society for Testing and Materials, Standard Test Methods for Notched Bar Testing of Metallic Materials, US, ASTM E23-07a, 2010.

- Vickers Hardness Test. Retrieved 2001, from CALCE and the University of Maryland: http://www.calce.umd.edu/TSFA/Hardness_ad_.htm#rf11%22

- Vickers Hardness Testing Machine. Retrieved 2011, from UK Calibration: http://www.ukcalibrations.co.uk/vickers_htm.html

- Vickers hardness test. Retrieved Nov 2011, from Gordon England: http://www.gordonengland.co.uk/copyright.html

- American Society for Testing and Materials (2010). Standard test method for microindentation hardness of materials. US: ASTM E384-05a.

- Vickers Hardness Testing. Retrieved 2011, from Mat Web material propertiy data: http://www.matweb.com/reference/vickers-hardness.aspx

- Vickers Test. Retrieved 2008, from Instron: http://www.instron.us/wa/corporate/profile.aspx

- American Society for Testing and Materials (2010). Standard test method for tension testing wrought and cast aluminum and magnesium alloy products. US: ASTM B557-06.

- Density and Specific Gravity. Retrieved 2011, from Intertek Plastics Technology Laboratories: http://www.ptli.com/testlopedia/tests/density-specgrav-d792.asp

- Optical Microscope. Retrieved Oct 2008, from Wikipedia: http://en.wikipedia.org/wiki/Optical_microscope

- Vander Voort, G. F. & Manilova, E. P. (1999). Metallographic Etching of Aluminum and Its Alloys. Lake Bluff, Illinois: Buehler Ltd.

- Khursheed, A. (2011). Scanning Electron Microscope Optics and Spectrometers. Singapore: National University of Singapore.

- Ndaliman, B & Pius, P. A. (2007). Behavior of Aluminum Alloy Castings under Different Pouring Temperatures and Speeds. Leonardo Electronic Journal of Practices and Technologies. 6(11), pp. 71-80.

- TASH, M., Khalifa, W& El Hashash, A. (2008). Effect of metallurgical differences between 356 and 384 alloys on their mechanical properties, proc. Of the ninth Int. Conf. om Mechanical Design and Production. Cairo. University of Cairo. pp. 8-10.

- ASM International. (2009). Casting Design and Performance. 1st ed. Ohio: ASM International.

- Monroe, R. (2005). Porosity in Castings. American Foundry Society. 05-245(04), pp. 1-28.

- Kliauga, A. M., Vieura, E. A. & Ferrante, M. (2008). The influence of impurity level and tin addition on the ageing heat treatment of the 356 class alloy. Elsevier, 480(A), pp. 5-16.

Expert Q&A: Your Top Questions Answered

Q1: Why should HPDC professionals care about the mold arrangement (vertical vs. horizontal) in gravity die casting?

A1: The mold arrangement significantly affects the mechanical properties of the final casting. This research demonstrates that vertical arrangements generally yield higher density, hardness, impact strength, and tensile strength compared to horizontal arrangements [Abstract]. Understanding these differences allows for informed decisions to optimize product quality and performance.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing mechanical properties in gravity die casting. The findings offer a clear, data-driven path toward improving quality, reducing defects, and optimizing production.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "SALEH S SALEH ELFALLAH". Based on "ANALYSIS OF MECHANICAL PROPERTIES AND MICROSTRUCTURE OF MULTIPLE DIE CAVITY PRODUCTS PRODUCED IN VERTICAL AND HORIZONTAL ARRANGEMENT BY GRAVITY DIE CASTING".

- Source of the paper: Not provided in the paper.

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.