Boosting Tool Life: How Duplex PVD Coatings Revolutionize Aluminum Die Casting

This technical summary is based on the academic paper "Use of Duplex PVD Coatings to Increase the Life of Moulds and Cores for die Casting of Aluminium Alloys in the Automotive Industry" by Janette Brezinová et al., published in Acta Mechanica Slovaca (2022). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: Duplex PVD Coatings

- Secondary Keywords: Die Casting, Mould Life, Aluminum Alloys, Laser Surface Remelting, Automotive Industry, Tool Steel

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: Moulds and cores used in high-pressure aluminum die casting suffer from severe thermal fatigue, erosion, and soldering, which drastically shortens their operational life and impacts productivity.

- The Method: Researchers applied an innovative duplex treatment to Uddeholm Dievar tool steel, combining local impulse laser heating for surface preparation with the subsequent deposition of advanced nACRo³ PVD coatings.

- The Key Breakthrough: The duplex-treated surface demonstrated significantly increased hardness and excellent adhesion, forming a compact, intact barrier that resisted corrosion from molten Al-Si alloy at 680 ± 20°C for up to 300 minutes.

- The Bottom Line: Combining laser surface pre-treatment with advanced PVD coatings is a highly effective strategy to enhance the durability and significantly extend the service life of critical die casting tooling.

The Challenge: Why This Research Matters for HPDC Professionals

In the high-stakes world of automotive manufacturing, the longevity of die casting moulds is a critical factor for productivity and profitability. Moulds and cores for aluminum alloys are subjected to extreme conditions: intense thermal cycles (from 80°C to over 600°C), high pressures (up to 120 MPa), and the erosive, corrosive action of turbulent molten metal.

These harsh conditions lead to a cascade of failure mechanisms. Thermal fatigue is the most common culprit, manifesting as a network of fine cracks on the tool surface. This cracking, along with erosion and the local adhesion of the casting alloy (soldering), leads to the loss of surface material, degradation of the casting's quality and dimensions, and ultimately, premature tool failure. For HPDC professionals, finding a robust solution to delay this degradation is a constant pursuit to improve efficiency and reduce operational costs.

The Approach: Unpacking the Methodology

This study focused on an innovative duplex surface treatment designed to fortify die casting tools against these failure modes.

- Base Material: The research was conducted on Uddeholm Dievar, a hot-work tool steel renowned for its high toughness, hot strength, and resistance to thermal stress, making it a common choice for demanding die casting applications.

- Surface Pre-treatment: A 400 W solid-state laser was used to apply local impulse heating to the steel's surface. This step was performed in the recrystallization temperature range without melting the material. The goal was to modify the surface properties to improve the adhesion of the subsequent coating. Researchers tested various laser scan speeds (20, 30, 40, and 60 mm/s) to determine the optimal heating depth.

- Coating Deposition: Two advanced PVD coatings were applied using Larc technology: a conventional AIXN³ coating and a newly designed nACRo³ nanocomposite coating. The nACRo³ coating consists of AlCrN nanocrystalline grains embedded in an amorphous Si₃N₄ matrix, a structure known for its exceptional toughness and resistance to high temperatures (up to 1100°C).

- Quality Evaluation: The integrity and performance of the duplex-treated surfaces were rigorously tested.

- Adhesion: The Scratch test and the Mercedes test (Rockwell C indentation with a 1500 N load) were used to evaluate the coating's adhesion to the substrate.

- Hardness: Microhardness (HV0.025) was measured in a cross-section from the coating surface down into the base material.

- Corrosion Resistance: Coated samples were immersed in a molten Al-Si alloy at 680 ± 20°C for 120 and 300 minutes to simulate real-world casting conditions.

The Breakthrough: Key Findings & Data

The experimental work confirmed that the duplex treatment significantly enhanced the mould surface's durability.

Finding 1: Superior Hardness and Adhesion Achieved with Duplex Treatment

The combination of laser pre-treatment and PVD coating created a highly robust surface. Microhardness measurements revealed an increase of about 18.6 - 25% HV0.025 in the coated area on the laser-treated substrate compared to the base material. As shown in the hardness profile in Figure 10, the hardness gradually decreased from the surface towards the substrate, demonstrating a well-integrated hardened zone. Furthermore, adhesion tests confirmed the coating's exceptional quality. The Scratch test recorded satisfactory adhesion, with substrate failure occurring only at high critical loads of around 50 N. The Mercedes test (Figures 12 and 13) resulted in an adhesion rating of HF 1-2, indicating only small, isolated cracks with minimal disruption to the coating integrity, confirming excellent adhesion.

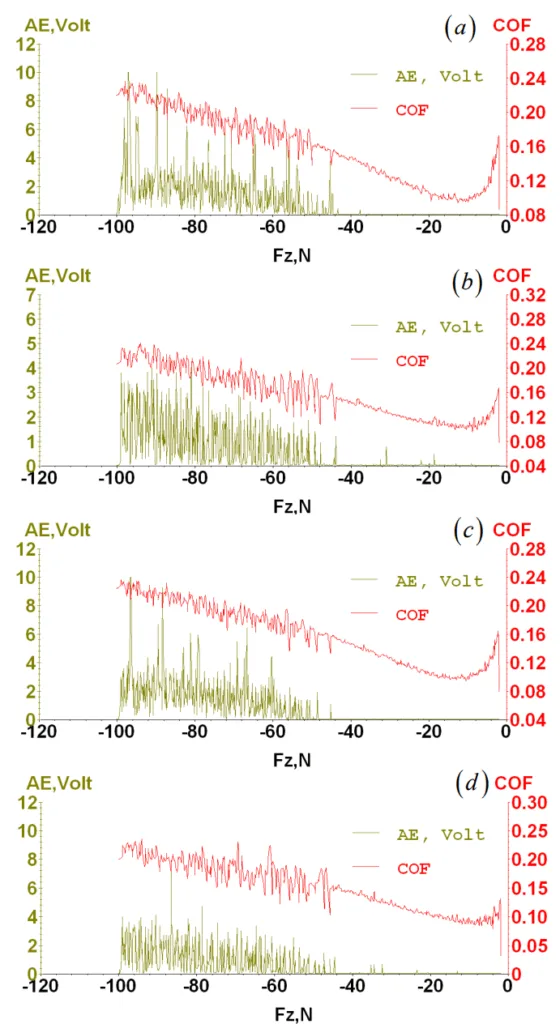

Finding 2: Duplex Coatings Form an Impenetrable Barrier Against Molten Aluminum

The most critical test was the high-temperature immersion in molten Al-Si alloy. The results were definitive. As shown in Figure 14, after being submerged for up to 300 minutes at 680 ± 20°C, both the AIXN³ and nACRo³ duplex coatings remained compact, intact, and formed a continuous barrier between the tool steel and the molten aluminum. This demonstrates the treatment's effectiveness in preventing the chemical interactions (corrosion and soldering) that are a primary cause of mould degradation in production environments. The surface microgeometry, evaluated according to ISO 25 178, was also not significantly affected by the laser pre-treatment, ensuring the final surface finish meets casting requirements.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that incorporating a laser surface heating step prior to PVD coating can significantly improve tool life. The parameters in Figure 7, which correlate laser scan speed to heating depth (e.g., 20 mm/s to 160 µm), provide a valuable starting point for optimizing this pre-treatment process to enhance coating adhesion.

- For Quality Control Teams: The data from the Mercedes test (Table 3) and the Scratch test (Figure 11) establishes clear benchmarks for what constitutes "good adhesion" (HF 1-2 rating, critical load > 40 N). These methods can be adopted as standard QC protocols for evaluating new or refurbished tooling with advanced coatings.

- For Design Engineers: The findings confirm that a duplex surface treatment is a powerful tool for mitigating common failure modes like thermal fatigue and corrosion. This allows for greater confidence in designing moulds for long production runs, especially for complex automotive components where tool reliability is paramount.

Paper Details

Use of Duplex PVD Coatings to Increase the Life of Moulds and Cores for die Casting of Aluminium Alloys in the Automotive Industry

1. Overview:

- Title: Use of Duplex PVD Coatings to Increase the Life of Moulds and Cores for die Casting of Aluminium Alloys in the Automotive Industry

- Author: Janette Brezinová, Ján Viňáš, Miroslav Džupon, Dagmar Jakubeczyová, Jakub Brezina, Henrich Sailer, Ján Hašuľ, Michal Považan

- Year of publication: 2022

- Journal/academic society of publication: Acta Mechanica Slovaca

- Keywords: PVD coatings, laser surface remelting, die casting of aluminium, tribology

2. Abstract:

The paper presents the results of research aimed at increasing the life of moulds and cores for high-pressure aluminium casting. The castings produced are intended for the automotive industry. Local impulse heating was applied to the surface of the base material of the Uddeholm Dievar moulds. Three heating rates were used. After surface treatment, structural analysis was performed. PVD coating nACRo³ was applied to the surface treated in this way. Coating deposition was performed by Larc technology. The quality of the coating was evaluated on the basis of the Scratch test and the Mercedes test. After laser treatment of the material surface and application of nACRo³ coating, the surface microgeometry was evaluated according to ISO 25 178. The coated surface was then immersed in an Al – Si-based alloy melt at a temperature of 680 ± 20°C and remaining in the melt for 120 and 300 min. Experimental work has confirmed that the resistance of the mould surface has significantly increased.

3. Introduction:

Aluminium and plastic castings are of great importance in the automotive industry. They are usually produced in metal moulds for die casting and injection moulding. Die casting moulds are made of chrome or tool steel and are heat treated to a hardness between 29 and 48 HRC. Mould life is a major factor in the die casting process and this strongly affects the productivity of mass production. Depending on the application of the casting or mould, different types of mould damage occur. Cracking caused by thermal fatigue is the most common mistake in the life cycle of a mould. Thermal fatigue cracking is often observed on the tool surface as a network of fine cracks or as individual and distinct cracks. The formation of thermal fatigue cracks leads to the loss of surface material in the form of small fragments. Other common reasons for damage are tensile cracks caused by structural notches, local adhesion of the casting alloy to the tool, i.e. soldering, and steel erosion supported by the casting of molten metal or plastic. The mould parts and mould cores for casting aluminium alloys must have suitable physical and mechanical properties at elevated temperatures. These properties are essentially defined by thermal and mechanical stress, as well as the interaction at the interface between the mould and the aluminium alloy melt.

4. Summary of the study:

Background of the research topic:

The research addresses the significant challenge of mould and core degradation in high-pressure die casting of aluminum alloys for the automotive industry. Failure mechanisms like thermal fatigue, erosion, abrasion, and corrosion shorten tool life and impact productivity.

Status of previous research:

Previous work has identified the main mechanisms of mould damage and the factors influencing wear. While surface treatments are common, there is a need for new, progressive technologies that can better withstand the adverse conditions of the die casting process. One potential solution is laser hardening of thermally treated tools prior to PVD coating to improve surface adhesive properties.

Purpose of the study:

The study aimed to develop and validate an innovative duplex surface treatment to increase the life of moulds and cores. The goal was to combine local intensive laser heating with the deposition of chemically stable PVD coatings to create a surface highly resistant to the thermal and chemical stresses of aluminum die casting.

Core study:

The core of the study involved applying local laser heating to Uddeholm Dievar tool steel samples, followed by grinding and deposition of two PVD coatings (AIXN³ and nACRo³). The researchers then conducted a comprehensive evaluation of the treated surfaces, including structural analysis, hardness testing, adhesion testing (Scratch and Mercedes tests), surface microgeometry evaluation, and a high-temperature corrosion test by immersing the samples in molten Al-Si alloy.

5. Research Methodology

Research Design:

The research followed an experimental design to test the effectiveness of a duplex surface treatment. This involved preparing control samples (ground surface only) and test samples (laser-treated and ground surface), applying PVD coatings to both sets, and then subjecting them to a series of mechanical and chemical tests to compare their performance.

Data Collection and Analysis Methods:

- Laser Treatment: A 400 W solid-state laser was used for surface heating.

- Coating: AIXN³ and nACRo³ PVD coatings were deposited using Larc technology.

- Microscopy: Cross-sections were analyzed using a Focused Ion Beam (FIB) device and SEM microscopy.

- Adhesion Testing: A Rockwell C indentation test (Mercedes test) with a 1500 N load and a Scratch test with a linearly increasing force up to 200 N were performed.

- Hardness Testing: Microhardness (HV0.025) was measured on the cross-section.

- Surface Geometry: Surface parameters were evaluated according to ISO 25 178.

- Corrosion Test: Samples were immersed in an Al-Si melt at 680 ± 20°C for 120 and 300 minutes.

Research Topics and Scope:

The research focused on increasing the life of Uddeholm Dievar moulds and cores for high-pressure aluminum casting. The scope included developing a laser pre-treatment process, applying and characterizing duplex PVD coatings, and evaluating their resistance to conditions mimicking the die casting environment.

6. Key Results:

Key Results:

- An innovative duplex treatment method was developed, consisting of local laser heating, finishing grinding, and deposition of PVD coatings.

- The PVD coatings demonstrated high quality, confirmed by Scratch and Mercedes tests, showing excellent adhesion (HF 1-2).

- After immersion in molten Al-Si alloy at 680 ± 20°C, the coatings remained compact and intact, forming an effective barrier against the melt.

- The surface microgeometry parameters (per ISO 25 178) were not significantly affected by the laser pre-treatment, indicating the process preserves the required surface finish.

- The laser-affected zone showed a hardness increase of 18.6 - 25% HV0.025 compared to the substrate.

Figure Name List:

- Figure 1: Cross section of AIXN³ coating made on a FIB (Focused lon Beam) device

- Figure 2: Cross section of nACRo³ coating performed on a FIB device

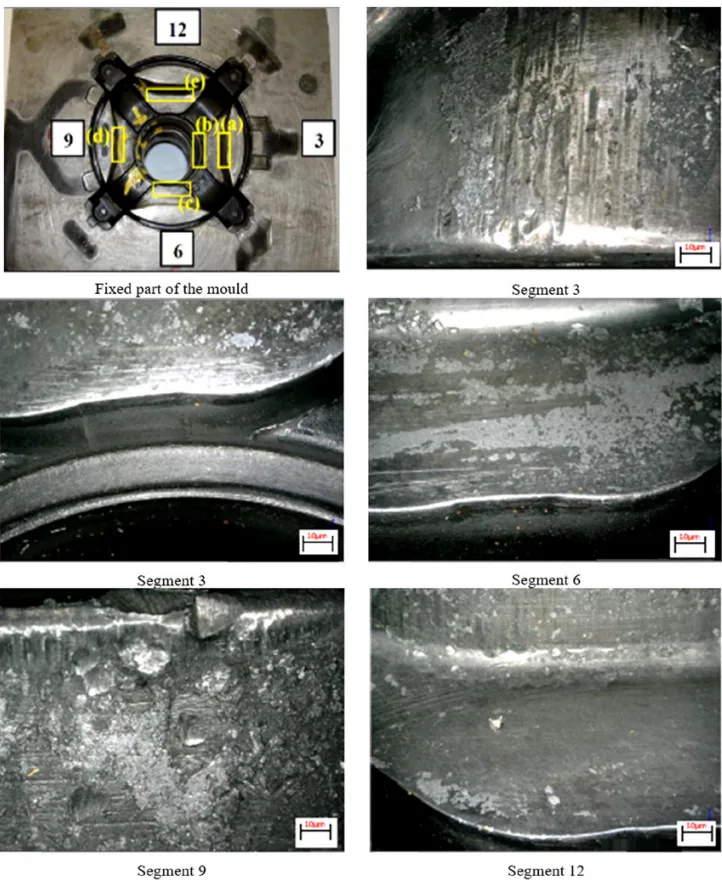

- Figure 3: Worn solid half of the mould part - mould insert

- Figure 4: Shaped part of the mould after capillary testing

- Figure 5: Appearance of cracks at the bottom of the mould

- Figure 6: Detail of the worn form; a) Crack around the ejector and the core cavity b) Separating means on the surface of the moulded part c) Contact of the movable core and the moulded part

- Figure 7: Laser surface hardening

- Figure 8: Surface of PVD coatings of control samples and samples after laser treatment and deposition of coatings

- Figure 9: Indents for the nACRo coated sample

- Figure 10: Hardness test HV0.025 from the surface towards the substrate

- Figure 11: Scratch test systems o PVD coatings - laser heat treated substrate; a) PVD coating duplex AIXN³; b) PVD coating duplex nACRo³; c) PVD coating duplex AIXN³ on a laser terated surface; d) PVD coating duplex nACRo3 on a laser terated surface

- Figure 12: Morphology of indentation impression in AIXN3 coating (X = Cr)

- Figure 13: Morphology of indentation indentation into the coating nACR03, LM

- Figure 14: PVD coatings duplex on laser treated and ground surfaces after exposure in Al mel; a) Duplex AIXN³/120 minutes/680+/-20°C/Al-Si; b) Duplex AIXN³/300 minutes/680 +/-20°C/Al-Si; c) Duplex nACRo³/120 minutes/680+/-20°C/Al-Si; d) Duplex nACRo³/300 minutes/680+/-20°C/Al-Si

7. Conclusion:

The performed experiments confirmed that an innovative method of treating shaped parts of moulds and cores, consisting of local laser heating followed by deposition of duplex PVD coatings, is highly effective. Two types of coatings were applied, a conventional AIXN³ and a newly designed nACRo³ coating. The PVD coatings were of high quality, confirmed by scratch and Mercedes tests. After immersion in a high-temperature Al-Si-based alloy melt, the coatings remained compact and intact, forming a protective barrier. The surface microgeometry was not significantly affected by the laser pre-treatment. This duplex approach significantly increases the resistance of the mould surface.

8. References:

- Changrong Chen et al.: Energy based approach to thermal fatigue life of tool steels for die casting dies. In: International Journal of Fatigue Volume 92, Part 1, November 2016, Pages 166-178.

- J. Lin et al.: Design methodology for optimized die coatings: The case for aluminium pressure die-casting In: Surface and Coatings Technology 201 (2006) pp. 2930-2941.

- K. Domkin, J.H. Hattel, J. Thorborg, Modeling of high temperature- and diffusion-controlled die soldering in aluminium high pressure die casting, J. Mater. Process. Technol. 209 (8) (2009) 4051-4061.

- Sundqvist M., Hogmark S.: Effects of liquid aluminium on hot-work tool steel Tribol. Int. 26 (1993) in International Journal of Fatigue p. 129.

- H. Zhu, J. Guo, J. Jia, Experimental study and theoretical analysis on die soldering in aluminium die casting, J. Mater. Process. Technol. 123 (2) (2002) 229-235.

- Z.W. Chen, M.Z. Jahedi, Die erosion and its effect on soldering formation in high pressure die casting of aluminium alloys, Mater. Des. 20 (6) (1999) 303-309.

- K. Venkatesan, R. Shivpuri, Experimental and numerical investigation of the effect of process parameters on the erosive wear of die casting dies, J. Mater. Eng. Perform. 4 (2) (1995) 166-174. R. Markežič et al. Engineering Failure Analysis 95 (2019) 171-180179.

- A Mohammed, M.B. Marshall, R. Lewis, Development of a method for assessing erosive wear damage on dies used in aluminium casting, Wear 332-333 (2015)1215-1224.

- LF. Hou, Y.H. Wei, Y.G. Li, B.S. Liu, H.Y. Du, C.L. Guo, Erosion process analysis of die-casting inserts for magnesium alloy components, Eng. Fail. Anal. 33 (2013)457-564.

- D.W.C. Baker, K.H. Jolliffe, D. Pearson, The resistance of materials to impact erosion damage, Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 260 (1110) (1966) 193-203.

- A. Persson, S. Hogmark, J. Bergström, Temperature profiles and conditions for thermal fatigue cracking in brass die casting dies, J. Mater. Process. Technol. 152(2) (2004) 228-236.

- C. Rosbrook, Analysis of Thermal Fatigue and Heat Checking in Die-Casting Dies: A Finite Element Approach, PhD thesis Ohio State University, 1992.

- F. Medjedoub, G. Dour, S. Le Roux, P. Lamesle, M. Salem, P. Hairy, F. Rézaï-Aria, Experimental conditions and environment effects on thermal fatigue damage accumulation and life of die-casting steel X38CrMoV5 (AISI H11), Int. J. Microstruct. Mater. Propert. 3 (2-3) (2008).

- P. Hansson, "Modern prehardened tool steels in die-casting applications," Materials and Manufacturing Processes, vol. 24, no. 7-8, pp. 824-827, 2009.

- Uddeholm, "Dievar," 2014, (18.10.2021) internet: http://www.uddeholm.com

- D. Klobčar, J. Tušek, B. Taljat, Thermal fatigue of materials for die-casting tooling, Mater. Sci. Eng. A 472 (1) (2008) 198-207.

- D. Schwam, J. F. Wallace, and S. Birceanu, "Die Materials for Critical Applications and Increased Production Rates," Case Western Reserve University, 2002.

- Methodical measurement and evaluation of adhesive cohesive behavior of thin film - substrate systems, 2005, (19.10.2021) internet: https://www.opi.zcu.cz/adheze.html

- J. Tkáčová, E. Zdravecká, E. Evin, M. Tomáš, D. Jakubéczyová: Koroze a ochrana materiálu 63(4) 159-166 (2019).

- D. Klobčar, et al.: Thermo fatigue cracking of die casting dies. In: Engineering Faliure Analysis Volume 20, March 2012, pp. 43-53.

- D. Jakubéczyová, M. Džupon: Effect of the roughness on the adhesive properties of nanocomposite PVD coatings. In Vrstvy a povlaky 2016: 15. ročník konferencie. Rožnov pod Radhoštěm, 17.-18.10.2016. - Plzeň: Západočeská univerzita, 2016, p. 49-55.(Layers and coatings 2016)

Expert Q&A: Your Top Questions Answered

Q1: Why was Uddeholm Dievar steel specifically chosen as the base material for this study?

A1: The paper states that Uddeholm Dievar was chosen for its excellent mechanical properties, which are ideal for high-pressure die casting. These include good toughness, high hot strength, satisfactory resistance to heat stress and rough cracking, and dimensional stability during heat treatment. These characteristics make it a benchmark material for demanding applications, ensuring the study's findings are relevant to industry practices.

Q2: What is the specific advantage of the nACRo³ coating's nanocomposite structure over a more conventional coating?

A2: The nACRo³ coating, called TripleCoatings3, has a unique structure of AlCrN nanocrystalline grains embedded in an amorphous Si₃N₄ matrix. This nanocomposite design, as described in the paper, results in a coating that is very tough and highly resistant to abrasion at extreme temperatures, up to 900/1100°C. This is superior to many conventional coatings and is critical for withstanding the thermal shocks and abrasive wear seen in aluminum die casting.

Q3: The paper mentions a network of shallow surface cracks after laser treatment. Isn't this detrimental to the final product?

A3: The paper notes that a network of shallow surface cracks is "typical for rapid heating and rapid cooling of the material surface." While cracks are generally a concern, the subsequent steps of grinding and PVD coating deposition still resulted in a final surface with excellent adhesion (HF 1-2) and integrity. This implies that these micro-cracks are superficial and are effectively sealed or rendered non-critical by the tough, overlying duplex PVD coating.

Q4: How does the "Mercedes test" provide a different insight into coating quality compared to the "Scratch test"?

A4: The two tests evaluate adhesion through different mechanisms. The Scratch test, as described, involves an indenter moving across the surface with continuously increasing force to find the "critical load (Lc)" where the coating fails, measuring resistance to dynamic, shearing stress. The Mercedes test is a static indentation test using a Rockwell indenter under a high load (1500 N). It assesses adhesion by analyzing the pattern and extent of cracking and peeling around the indent, providing a qualitative rating (HF1 to HF6) of the coating's cohesive and adhesive strength under compressive stress.

Q5: According to Table 4, the surface roughness (Sa) is lower for the laser-treated surfaces. What is the practical significance of this?

A5: Table 4 shows that the arithmetic mean roughness (Sa) for laser-treated surfaces (0.29 µm for nACRo³, 0.23 µm for AIXN³) is lower than for the ground-only surfaces (0.82 µm and 0.57 µm, respectively). The paper concludes that the surface microgeometry was "not significantly affected" in a negative way. The lower Sa value is actually beneficial, as a smoother surface can improve metal flow, reduce friction, and decrease the likelihood of soldering, all of which contribute to better casting quality and longer mould life.

Q6: Why was the laser treatment performed without melting the material?

A6: The paper specifies that the laser irradiation was conducted "in the recrystallization temperature range without melting of the material." This is a key distinction. By avoiding melting, the process modifies the surface microstructure and relieves stress without causing significant dimensional changes or creating a cast microstructure, which can have undesirable properties. This solid-state transformation allows for improved surface properties while maintaining the core integrity and precise geometry of the tool.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of extending the life of die casting tooling is a constant battle against thermal fatigue, erosion, and corrosion. This research demonstrates a powerful solution: the use of Duplex PVD Coatings applied over a laser-treated surface. The key breakthrough is the creation of a highly adherent, durable barrier that significantly increases surface hardness and effectively withstands the harsh chemical and thermal environment of high-pressure aluminum casting. For engineers in R&D and operations, these findings provide a clear, data-backed pathway to more reliable and long-lasting moulds, leading to enhanced productivity and higher-quality components.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Use of Duplex PVD Coatings to Increase the Life of Moulds and Cores for die Casting of Aluminium Alloys in the Automotive Industry" by "Janette Brezinová et al.".

- Source: https://doi.org/10.21496/ams.2022.003

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.