Reusable Molds for Die Casting: A Breakthrough with Alkali-Activated Concrete

This technical summary is based on the academic paper "Ultra-high performance alkali-activated slag as a re-usable mold for light metal casting" by Janna Link, Alexander Wetzel, Sebastian Müller, and Bernhard Middendorf, published in ce/papers (2023).

Keywords

- Primary Keyword: Reusable Molds for Die Casting

- Secondary Keywords: Alkali-Activated Slag, Ultra-High Performance Concrete (UHPC), Aluminum Casting, Thermal Resistance, Light Metal Casting, HPDC Molds

Executive Summary

- The Challenge: Conventional steel molds used in aluminum die casting often lead to metal corrosion and hydrogen porosity in the final component, reducing quality and increasing scrap rates.

- The Method: Researchers developed and tested a reusable mold made from an advanced ceramic-like material: ultra-high performance concrete based on alkali-activated slag (AAM-UHPC).

- The Key Breakthrough: The AAM-UHPC molds successfully withstood multiple casting cycles with molten aluminum at over 700°C without explosive failure, maintained significant structural integrity, and produced castings with a surface quality equivalent to those from steel molds.

- The Bottom Line: AAM-UHPC is a viable alternative to steel for reusable molds, offering improved casting quality by eliminating metal corrosion and enabling the cost-effective production of complex, thin-walled geometries, particularly for smaller production quantities.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of light metal casting, particularly aluminum die casting, steel molds are the industry standard. However, they are not without significant drawbacks that directly impact quality and cost. The paper highlights two core problems:

- Hydrogen Porosity: To prevent the molten aluminum from sticking to the mold, water-based release agents are sprayed onto the steel die. At casting temperatures above 600°C, this water vaporizes and reacts with the molten aluminum, forming aluminum oxide and releasing elemental hydrogen. This hydrogen gets trapped as gas pores during solidification, leading to a deterioration in mechanical properties, fatigue resistance, and overall component durability. This forces manufacturers into costly secondary processes like melt purification or extensive non-destructive testing, increasing scrap rates and production costs.

- Metal Corrosion: The direct interaction between the aluminum melt and the steel mold leads to metal corrosion. This negatively impacts the surface quality of the cast component, requiring additional finishing or leading to part rejection.

These persistent issues create a clear need for an alternative mold material that can withstand extreme temperatures while eliminating the root causes of these common casting defects.

The Approach: Unpacking the Methodology

To address these challenges, the researchers developed and tested a novel mold material based on alkali-activated slag. The methodology was rigorous, covering material science, manufacturing, and real-world application testing.

Method 1: Advanced Material Formulation (AAM-UHPC)

The core of the innovation is the mold material itself—an ultra-high performance concrete based on alkali-activated materials (AAM-UHPC). The formulation was precisely engineered for thermal stability and strength:

- Binder: Granulated ground blast furnace slag and silica fume were used as the primary solid precursors.

- Activator: A potassium waterglass solution was used to activate the precursors, forming a durable, amorphous binder structure (C-A-S-H and N-A-S-H phases) that is more thermally stable than traditional Portland cement.

- Aggregates: Quartz sand and quartz powder provided the structural matrix.

- Key Additives: Regenerated cellulose (RC) fibers were added (0.4 Vol.-%). These fibers decompose at around 300°C, creating a network of micro-channels. This increases the material's permeability, allowing any trapped water vapor to escape during heating and preventing explosive spalling—a common failure mode for high-strength concrete. A hydrophobic agent was also added to improve the fresh material's wettability and achieve a low-defect surface.

Method 2: Mold Manufacturing and Casting Experiments

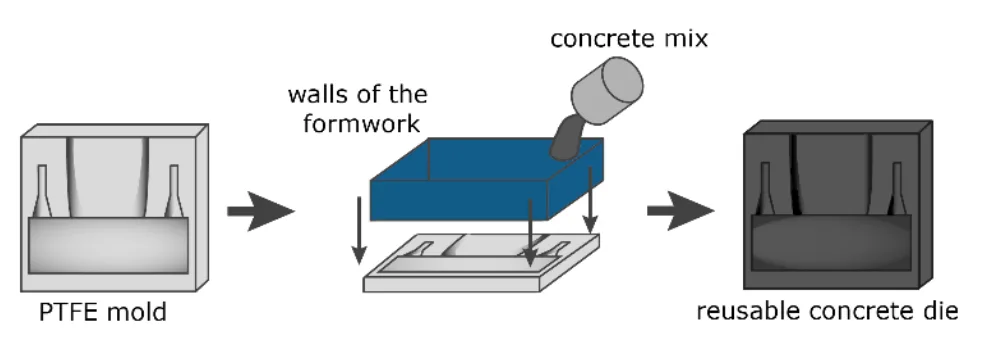

The AAM-UHPC mixture was poured into milled polytetrafluorethylene (PTFE) molds to create the final die halves. These concrete dies were then used in a real-world casting process:

- Equipment: An Indutherm VC 650 V casting unit was used.

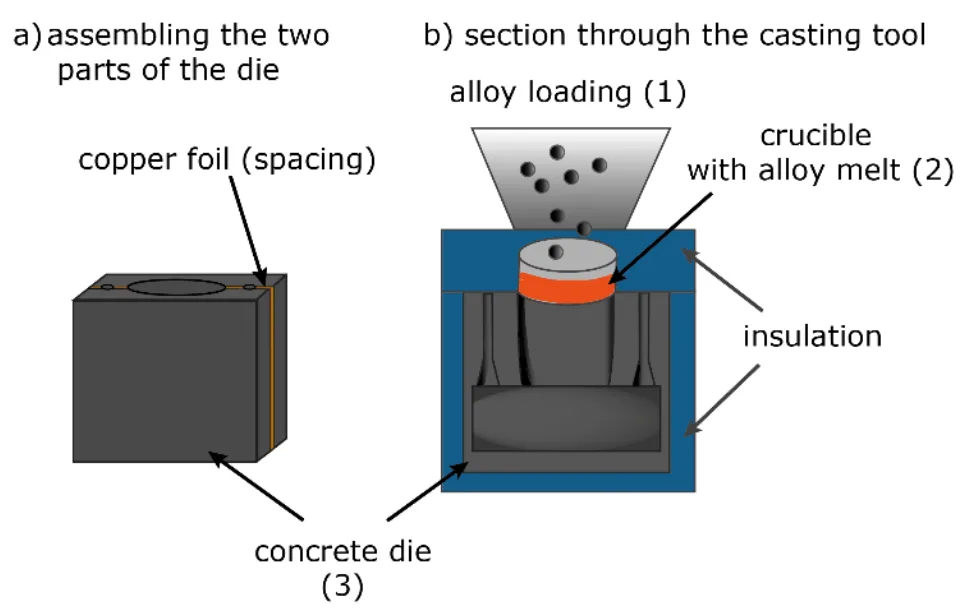

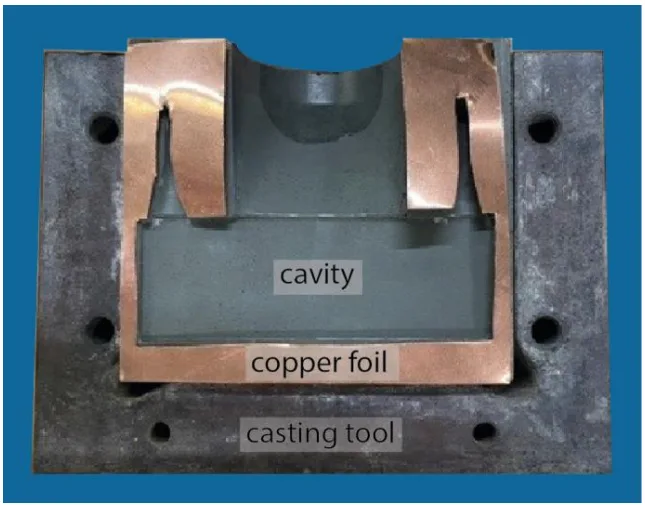

- Process: The AAM-UHPC dies were preheated to 300°C to release physically bound water and reduce thermal shock. Molten aluminum at 720°C was then poured into the assembled die cavity under a pressure of 3 bar to produce the final cast component. A 2 mm copper foil was used as a spacer between the die halves to ensure even pressure distribution and prevent leakage.

The Breakthrough: Key Findings & Data

The experimental results demonstrate the remarkable performance of the AAM-UHPC molds under extreme thermal stress.

Finding 1: Exceptional Thermal Stability and Strength Retention

The material exhibited impressive strength both before and after thermal shock. The AAM-UHPC achieved a compressive strength of 136.6 N/mm² after 7 days. More importantly, after being subjected to a severe thermal shock (moved from room temperature directly into a 700°C oven for one hour), the material retained a compressive strength of 22.6 N/mm². While this is a reduction, the residual strength is still comparable to that of normal construction-grade concrete, and crucially, no explosive spalling occurred, proving the material's resilience to extreme temperature gradients.

Finding 2: Engineered Porosity Prevents Catastrophic Failure

The data reveals how the material was engineered to survive the casting process.

- Pore Structure Evolution: As shown in Figure 3, the pore structure of the AAM-UHPC changes significantly after heat treatment. The porosity in the 2 to 20 µm range increases sharply. This is a direct result of the RC fibers degrading, leaving behind a network of channels that allow water vapor to escape safely, preventing the buildup of internal pressure that causes spalling in conventional concrete.

- Thermal Stabilization: Thermogravimetric analysis (Figure 4) showed that while the material loses almost 15% of its mass during the first heating cycle to 720°C (due to evaporation of incorporated water), a second heating cycle on the same sample resulted in a mass loss of less than 1%. This demonstrates that after an initial "bake-out," the material becomes thermally stable and its strength-forming phases do not continue to degrade, making it suitable for repeated use.

Finding 3: Successful Casting Cycles in a Real-World Test

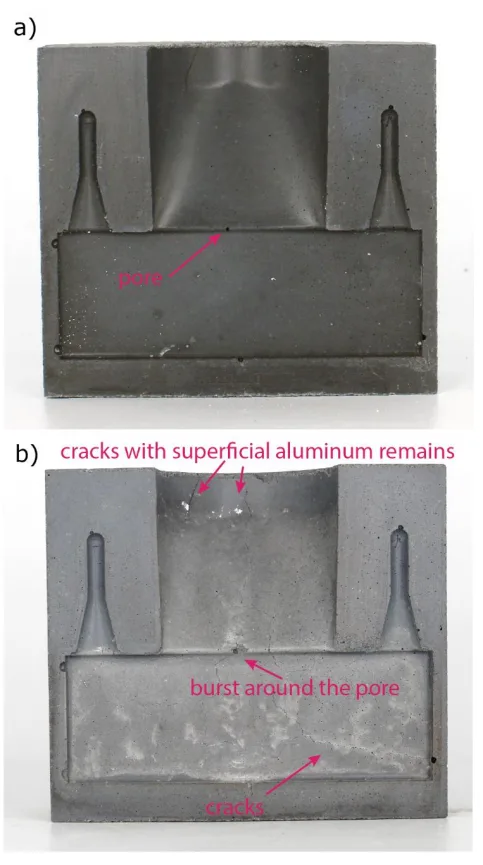

The AAM-UHPC dies were successfully used for multiple aluminum casting cycles. Figure 6 shows a die after manufacturing and after three casting cycles. While irreversible surface defects like fine cracks and some spalling around a central pore were observed, the die remained structurally intact and did not fail. The aluminum adhesions were superficial and easily detached. This test proved that the AAM-UHPC mold can function as a reusable die and produce components with a surface quality within the range of conventional steel molds.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that the lower thermal conductivity of AAM-UHPC molds compared to steel decelerates the solidification of the aluminum melt. This may allow for casting with lower pressure or even gravity-fed processes, reducing equipment strain and energy consumption. It also opens the door to producing complex, thin-walled geometries that are difficult to fill with fast-cooling steel molds.

- For Quality Control Teams: The data in the paper illustrates that AAM-UHPC molds eliminate the risk of metal corrosion and reduce the source of hydrogen incorporation (from water-based release agents). This could directly lead to cast components with lower porosity and improved mechanical properties, potentially allowing for a relaxation of certain NDT inspection criteria or a reduction in scrap rates.

- For Design Engineers: The findings indicate that AAM-UHPC molds can be produced relatively simply and cost-effectively compared to machined steel dies. This makes the material an excellent candidate for prototyping and small-series production, allowing for more design iterations and the creation of intricate geometries that would be prohibitively expensive to tool in steel.

Paper Details

Ultra-high performance alkali-activated slag as a re-usable mold for light metal casting

1. Overview:

- Title: Ultra-high performance alkali-activated slag as a re-usable mold for light metal casting

- Author: Janna Link, Alexander Wetzel, Sebastian Müller, Bernhard Middendorf

- Year of publication: 2023

- Journal/academic society of publication: ce/papers, Ernst & Sohn

- Keywords: Aluminum casting, alkali-activated materials, ultra-high performance concrete, thermal resistance

2. Abstract:

Light metal die casting is usually performed using steel molds. However, these lead to a reduced quality of the casting due to the occurrence of metal corrosion on the surface and the incorporation of hydrogen into the casting as a result of required process chemistry. Ultra-high performance concrete based on alkali-activated slag can be used to produce mineral molds for aluminum casting. The use of reusable mineral molds not only enables the production of various thin-walled geometries. The risk of metal corrosion is eliminated and the concrete molds can withstand multiple cycles due to their thermal stability and high strength, making them potentially superior to the already common lost mineral molds.

3. Introduction:

The production of light metal components, particularly through aluminum die casting, is of growing importance in industries such as automotive, aerospace, and civil engineering. Conventional die casting processes utilize steel dies, which, despite being standard, present several disadvantages. The high thermal conductivity of steel necessitates high pressures to fill molds before the melt solidifies, especially for thin-walled geometries. A significant problem is the formation of hydrogen porosity. Water-based release agents, required for demolding, react with the molten aluminum to form hydrogen gas, which becomes trapped in the cast, degrading its mechanical properties. Furthermore, the interaction between the aluminum melt and steel molds leads to metal corrosion, negatively affecting the surface quality of the final component. These issues lead to increased scrap rates and production costs. This context establishes the need for an alternative, reusable mold material that can overcome these limitations. A mineral-based, high-strength, and temperature-resistant material like ultra-high performance concrete (UHPC) is proposed as a potential solution.

4. Summary of the study:

Background of the research topic:

The study is situated within the field of light metal casting, addressing the inherent limitations of using steel molds for aluminum die casting. These limitations include process-induced defects such as hydrogen porosity and metal corrosion, which compromise the quality and durability of cast components.

Status of previous research:

Previous research has established the properties of ultra-high performance concrete (UHPC), characterized by high compressive strength (150-200 N/mm²) achieved through packing density optimization. It is also known that alkali-activated materials (AAM) can form thermally stable binders (C-A-S-H and N-A-S-H phases) that contain less chemically bound water than ordinary Portland cement (OPC). The addition of regenerated cellulose (RC) fibers to mineral-bonded materials has been shown to improve thermal resistance by creating permeability upon their decomposition at elevated temperatures, which allows water vapor to escape and prevents spalling.

Purpose of the study:

The purpose of this study was to develop and evaluate an ultra-high performance concrete based on alkali-activated slag (AAM-UHPC) as a material for a reusable mold in aluminum casting. The research aimed to determine if such a mineral mold could withstand the extreme thermal and mechanical stresses of the casting process over multiple cycles while offering advantages over traditional steel molds.

Core study:

The core of the study involved the formulation of an AAM-UHPC mixture containing RC fibers for thermal stability. The researchers manufactured both cube specimens for material characterization and die molds for casting experiments. The material's properties, including compressive strength, pore size distribution, and mass loss upon heating, were analyzed before and after subjecting it to a 700°C thermal shock. Finally, the AAM-UHPC dies were used in an actual aluminum casting process to assess their durability, failure modes, and the quality of the resulting cast components over several cycles.

5. Research Methodology

Research Design:

The study employed an experimental research design. It began with the formulation of the AAM-UHPC material, followed by the fabrication of test specimens (5 cm cubes) and functional casting dies. The methodology included subjecting the specimens to controlled thermal loading to simulate casting conditions and then conducting mechanical and physical property tests. The dies were used in a practical casting setup to evaluate their performance in a real-world application.

Data Collection and Analysis Methods:

- Compressive Strength Testing: Cubes were tested for compressive strength after 7 days of curing and after being subjected to a 700°C shock temperature loading test.

- Mercury Intrusion Porosimetry (MIP): MIP was used to analyze the pore size distribution of the AAM-UHPC before and after heat treatment to understand changes in the material's microstructure.

- Thermogravimetric Analysis (TGA): TGA was conducted to measure the mass loss of the material as a function of temperature, providing insight into its thermal stability and the decomposition of its phases.

- Casting Trials: AAM-UHPC dies were used in an Indutherm VC 650 V casting unit to cast an aluminum alloy. The dies were visually inspected for defects after multiple casting cycles.

Research Topics and Scope:

The research was focused on a single formulation of AAM-UHPC. The investigation covered its mechanical and thermal properties, specifically its response to severe thermal shock representative of aluminum casting. The scope of the casting experiments was to demonstrate proof-of-concept and initial durability over a small number of cycles (3 to 10). The study did not investigate the influence of the AAM-UHPC die on hydrogen incorporation into the cast component.

6. Key Results:

Key Results:

- The AAM-UHPC formulation achieved a compressive strength of 136.6 N/mm² after 7 days at standard climate.

- After a shock temperature loading at 700°C, the AAM-UHPC retained a residual compressive strength of 22.6 N/mm², and no spalling was observed.

- Mercury Intrusion Porosimetry (Figure 3) revealed a significant increase in porosity in the 2 to 20 µm range for heat-treated samples, which is attributed to the thermal degradation of the incorporated RC fibers.

- Thermogravimetric Analysis (Figure 4) showed a mass loss of nearly 15% upon initial heating to 720°C. However, a subsequent heating of the same sample showed a mass loss of less than 1%, indicating the material stabilizes after the first thermal cycle.

- The AAM-UHPC dies successfully withstood 3-10 casting cycles with molten aluminum. The dies exhibited irreversible surface defects, including fine cracks and spalling around a central pore, but did not fail catastrophically (Figure 6).

- The use of a 2 mm copper foil as a spacer was found to be critical in preventing premature die failure by ensuring even pressure distribution.

Figure Name List:

- Figure 1 Manufacturing process of the AAM-UHPC dies

- Figure 2 Casting process with the AAM-UHPC dies

- Figure 3 Pore size distribution of AAM-UHPC stored at room temperature (blue) and heat-treated at 700°C (grey), determined with Mercury Intrusion Porosimetry

- Figure 4 Weight loss of AAM-UHPC after storage at room temperate (a) and heat-treated at 700°C (b)

- Figure 5 Copper foil as a spacer on one side of the AAM-UHPC die

- Figure 6 AAM-UHPC-die after manufacturing (a) and after three casting-cycles with aluminum (b)

7. Conclusion:

The study concludes that AAM-UHPC is a suitable material for producing reusable molds for light metal casting. The material demonstrates adequate thermal stability, proven by its ability to withstand thermal shock loading up to 700°C without spalling and retaining a compressive strength over 20 N/mm². The absence of chemically bound water in the AAM binder contributes significantly to this thermal stability. The use of RC fibers is effective in creating permeability that prevents explosive failure. While the AAM-UHPC dies show surface degradation over multiple cycles, they produce cast components of equivalent surface quality to steel molds and eliminate the issue of metal corrosion. The lower thermal conductivity compared to steel may allow for casting with less pressure, enabling the production of thin-walled geometries. Further investigations are required to analyze the interaction between the melt and the mineral die, particularly regarding hydrogen incorporation, and to improve the stability of the die for a higher number of casting cycles.

8. References:

- [1] Hartmann, G.; Herrmann, C.; Heinemann, T.; Hoffmann, T.; Jordi, U.; Pithan, A.; Pries, H. (2013) Aluminiumdruckguss – Potentiale und Handlungsfelder. in: Energie- und ressourceneffiziente Produktion von Aluminiumdruckguss. Springer-Verlag. Berlin Heidelberg.

- [2] Tiryakioğlu, M. (2020) The Effect of Hydrogen on Pore Formation in Aluminum Alloy Castings - Myth Versus Reality. Metals. 10 H. 3, p. 368.

- [3] Fankhänel, B.; Hubálková, J.; Aneziris, C. G.; Stelter, M.; Charitos, A. (2022), Influencing the Hydrogen Porosity in Aluminum Casting by (Re)active Filter Materials. Adv. Eng. Mater., 24.

- [4] Shih, T. S.; Tu, S. H., (2007) Interaction of steel with pure Al, Al-7Si and A356 alloy. Mater. Sci. Engine. A, 454 H. 8, pp. 349-356.

- [5] Fehling, E.; Schmidt, M.; Walraven, J.; Leutbecher, T.; Fröhlich, S. (2014) Ultra-High Performance Concrete UHPC – Fundamentals, Design, Examples. Ernst, Wilhelm & Sohn.

- [6] Scheffler, B.; Wetzel, A.; Sälzer, P.; Middendorf, B. (2019) Thermische Stabilität von UHPC. Beton- und Stahlbetonbau 114 H. 9, pp. 674-682.

- [7] Wetzel, A.; Middendorf, B. (2019) Influence of silica fume on properties of fresh and hardened ultra-high performance concrete based on alkali-activated slag. Cement and Concrete Composites 100, pp. 53-59.

- [8] Singh, N. B.; Middendorf, B. (2020) Geopolymers as an alternative to Portland cement - An overview. Construction and Building Materials 237.

- [9] Duxson, P.; Fernández-Jiménez, A.; Provis, J. L.; Lukey, G. C.; Palomo, A.; van Deventer, J. S. J. (2007) Geopolymer technology: the current state of the art. J Mater Sci. 42. pp. 2917-2933.

- [10] Bernal, S. A.; Provis, J. L.; Rose, V.; de Gutierrez, R. M. (2011) Evolution of binder structure in sodium silicate-activated slag-metakaolin blends. Cement Concrete Composites 33, pp. 46-54.

- [11] Mastali, M.; Kinnunen, P.; Dalvand, A.; Mohammadi Firouz, R.; Illikainen, M. (2018) Drying shrinkage in alkali-activated binders – A critical review. Construction and Building Materials 190, pp. 533-550.

- [12] Wetzel, A.; Göbel, D.; Schleiting, M.; Wiemer, N.; Middendorf, B. (2022) Bonding Behaviour of Steel Fibres in UHPFRC Based on Alkali-Activated Slag. Materials 15 H. 5.

Expert Q&A: Your Top Questions Answered

Q1: Why were regenerated cellulose (RC) fibers added to the AAM-UHPC mix instead of other types of fibers?

A1: The paper explains that RC fibers were added specifically to increase the material's thermal resistance. These fibers decompose at elevated temperatures (around 300°C), forming cavities and a network of channels within the dense concrete matrix. This engineered permeability is critical because it allows physically and chemically bound water to escape as vapor during rapid heating, preventing the buildup of internal pore pressure that would otherwise cause explosive spalling and catastrophic failure of the mold.

Q2: What was the purpose of the 700°C shock temperature loading test, and what does the result imply?

A2: The shock temperature loading test was designed to simulate the extreme thermal gradient the mold experiences during the casting process when molten aluminum (at over 700°C) is introduced. The fact that the AAM-UHPC cubes survived this test without spalling and retained a residual compressive strength of 22.6 N/mm² is a key finding. It demonstrates the material's fundamental suitability for high-temperature applications and confirms the effectiveness of the RC fibers in mitigating thermal stress.

Q3: The paper mentions a copper foil was used as a spacer. Why was this necessary for the concrete dies?

A3: The copper foil was essential to compensate for small geometric deviations on the mating surfaces of the two die halves. Unlike precisely machined steel molds, the concrete dies had minor imperfections in the range of tenths of a millimeter. Without the soft copper foil to act as a sealing gasket, these uneven edges would create high point-loads when the dies are pressed together, leading to punctual mechanical stresses that accelerate the destruction of the dies and cause premature failure. The foil ensures even pressure distribution and prevents the molten aluminum from leaking out.

Q4: How does the thermal stability of this AAM-UHPC compare to traditional Portland cement-based UHPC (OPC-UHPC)?

A4: The paper implies that AAM-UHPC is superior in thermal stability. It states that in contrast to C-S-H phases in OPC-based systems, the C-A-S-H and N-A-S-H phases formed in AAM contain less to no chemically bound water. The degradation of strength-bearing C-S-H phases and the resulting high water vapor pressure are what cause OPC-UHPC to fail explosively at high temperatures (250-300°C). The AAM-UHPC, having a more inherently stable binder, does not suffer this same catastrophic failure mechanism.

Q5: What is the main advantage of AAM-UHPC molds over steel molds for producing thin-walled geometries?

A5: The primary advantage stems from thermal conductivity. Steel has high thermal conductivity, causing the molten aluminum to cool and solidify very quickly. To produce thin-walled parts, this requires very high pressure to force the metal into the entire cavity before it freezes. The AAM-UHPC has a lower thermal conductivity, which decelerates the melt solidification. This slower cooling provides a wider processing window, allowing the melt to fill intricate and thin sections completely with less pressure, making the production of such geometries more feasible and less demanding on the casting equipment.

Q6: What were the observed failure modes of the AAM-UHPC dies after several casting cycles?

A6: The dies did not fail catastrophically but showed progressive surface degradation. As seen in Figure 6, the failure modes included fine cracks distributed across the cavity surface that was in contact with the melt, as well as spalling and bursting around stress concentration points like the central pore. The paper also notes superficial aluminum adhesions in the cracked areas. This indicates that while the bulk material is stable, the surface is subject to wear from repeated thermal and mechanical stresses during casting and demolding.

Conclusion: Paving the Way for Higher Quality and Productivity

The research presented offers a compelling solution to long-standing challenges in aluminum casting. By replacing traditional steel molds with Reusable Molds for Die Casting made from AAM-UHPC, manufacturers can directly address the root causes of defects like hydrogen porosity and metal corrosion. The key breakthrough is a material that not only survives the extreme thermal shock of the casting process but also becomes more stable with each cycle after an initial heat treatment.

For R&D and operations teams, this technology opens up new possibilities for producing higher quality components, especially those with complex, thin-walled geometries that are difficult to achieve with conventional methods. The potential for lower-pressure casting and the cost-effectiveness for smaller production runs make AAM-UHPC a technology to watch.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Ultra-high performance alkali-activated slag as a re-usable mold for light metal casting" by "Janna Link, Alexander Wetzel, Sebastian Müller, and Bernhard Middendorf".

Source: https://doi.org/10.1002/cepa.2772

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.