Unlocking Superior Aluminum Castings: How Advanced Grain Refining Slashes Defects and Boosts Mechanical Strength

This technical summary is based on the academic paper "THEORY AND PRACTICE OF GRAIN REFINING FOR ALUMINIUM ALLOYS - UTILIZING COVERAL MTS 1582" by Brian Began, Foseco USA & Pascaline Careil, Foseco Europe, published in Foundry Practice No. 268.

Keywords

- Primary Keyword: Aluminum Grain Refining

- Secondary Keywords: COVERAL MTS 1582, mechanical properties, casting defects, thermal analysis, foundry practice, Al-Si alloys

Executive Summary

- The Challenge: The persistent need for smaller, more uniform grains in cast aluminum alloys to achieve high mechanical properties, ensure pressure tightness, and improve structural soundness.

- The Method: Implementing a novel, granulated flux grain refiner (COVERAL MTS 1582) that forms nuclei in-situ within the melt, and assessing its effectiveness using advanced thermal analysis and optical microscopy.

- The Key Breakthrough: COVERAL MTS 1582 delivers demonstrably superior grain refinement at lower addition rates compared to traditional TiBor rods, resulting in significantly improved mechanical properties and a "perfect" Grain Fineness score of 9.0/9.0.

- The Bottom Line: Adopting this advanced flux-based system provides a direct path to higher-quality castings, reduced scrap from leaks, and significant operational cost savings with an equipment payback period of just over six months.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of high-performance aluminum casting, grain size isn't just a detail—it's the foundation of quality. Whether you're producing critical automotive safety components, aerospace parts, or pressure-tight sand castings, the goal is the same: a fine, equiaxed grain structure. Coarse grains lead to a host of problems that directly impact the bottom line, including poor feeding, increased hot tearing, micro-shrinkage, and a higher likelihood of leakers.

Historically, foundries have relied on master alloys, like TiBor rods, to refine grain structure. While effective to a degree, this method has inherent limitations, including the risk of introducing oxides from the rod surface and inconsistent performance. This paper addresses the critical industry need for a more efficient, reliable, and cost-effective method for Aluminum Grain Refining to meet today's stringent quality and performance demands.

The Approach: Unpacking the Methodology

The study presents a comprehensive comparison between the traditional master alloy approach and a modern, flux-based system.

Method 1: Advanced Flux-Based Grain Refining

The core of the new approach is COVERAL MTS 1582, a granulated flux highly concentrated in titanium and boron. Unlike master alloys that introduce pre-formed nuclei, this flux is added directly into the melt vortex using a FOSECO MTS 1500 automated treatment station. This process forms fresh, highly efficient titanium diboride (TiB₂) and aluminum boride nuclei in-situ. This method ensures a clean, vigorous, and complete reaction, resulting in finely dispersed nuclei throughout the melt.

Method 2: High-Fidelity Performance Assessment

To move beyond simple chemical analysis, the research employed more sophisticated evaluation techniques to accurately measure the effectiveness of the grain refinement:

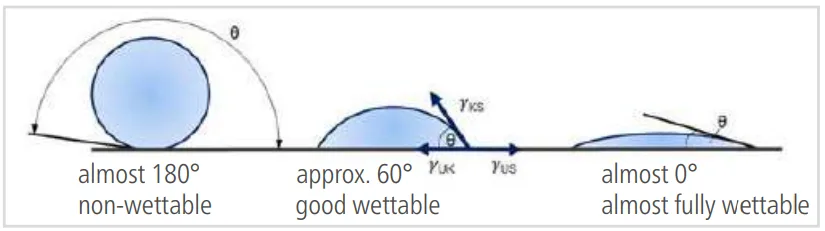

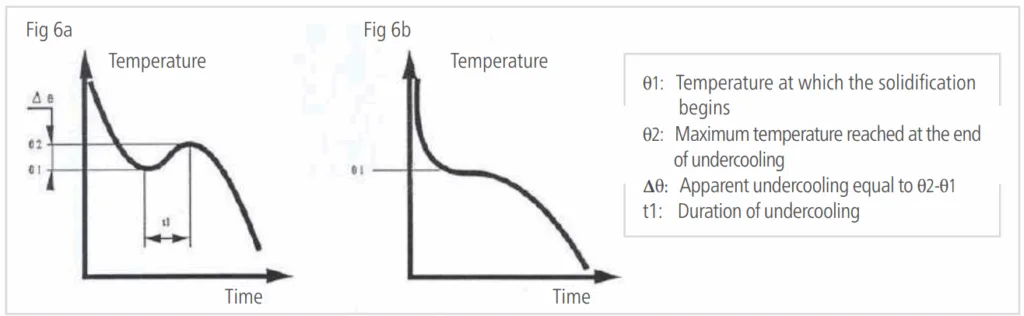

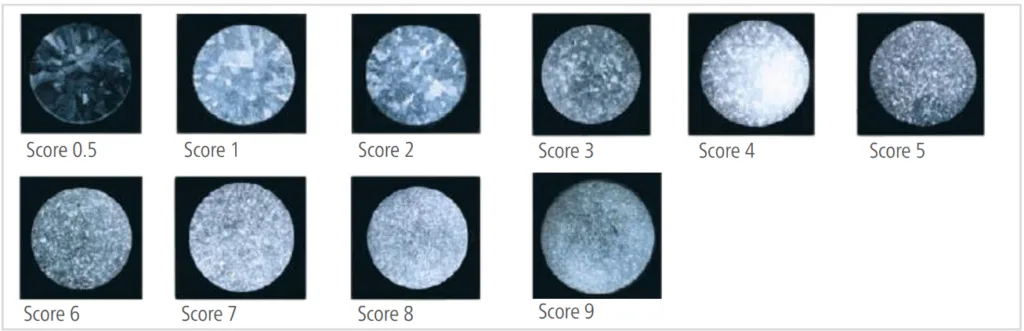

- Thermal Analysis: Using a THERMATEST 5000 NG III unit, researchers analyzed the cooling curve of solidifying metal samples. This provides a rapid, quantitative "Grain Fineness" (GF) score from 1 to 9, offering a far more accurate assessment of refinement than elemental spectroscopy alone.

- Optical Microscopy: The Barker test was used to prepare samples for microscopic evaluation. This "gold standard" method provides direct visual confirmation of the reduction in grain size, allowing for precise measurement and comparison.

The Breakthrough: Key Findings & Data

The data from industrial case studies reveals a clear and significant performance advantage for the COVERAL MTS 1582 system.

Finding 1: Superior Refinement Efficiency at Lower Addition Rates

COVERAL MTS 1582 achieves a more potent refining effect with less material. As shown in Figure 10, an addition rate of just 0.05% of COVERAL MTS 1582 produced a grain size of 237 µm, whereas a higher addition rate of 0.08% of traditional AlTi5B1 rods resulted in a much coarser grain size of 422 µm. This demonstrates a more powerful and efficient refining mechanism.

Finding 2: Quantifiable Improvements in Quality and Mechanical Properties

In a high-production American sand foundry, the implementation of COVERAL MTS 1582 yielded dramatic, measurable improvements.

- Perfect Grain Fineness: As detailed in Table 3, the thermal analysis GF score improved from an insufficient 5.8 (untreated) and an acceptable 6.8 (with TiBor rods) to a perfect 9.0 with COVERAL MTS 1582.

- Enhanced Mechanical Strength: This superior grain structure translated directly into better performance. Table 4 shows that Ultimate Tensile Strength (UTS) increased from 40,000 to 41,290 psi, Yield Strength (YS) rose from 34,500 to 35,100 psi, and Elongation improved from 4% to 5%.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that transitioning from manual TiBor rod additions to an automated flux injection system like the MTS 1500 with COVERAL MTS 1582 can significantly improve process consistency, reduce material consumption, and lower defect rates associated with poor feeding and leaks.

- For Quality Control Teams: The data in Table 3 illustrates that relying on elemental spectroscopy for Ti and B levels is not enough. Implementing thermal analysis to track the Grain Fineness (GF) score provides a rapid, reliable, and more accurate metric for ensuring optimal melt treatment before casting.

- For Procurement Specialists: The economic analysis on page 8 is compelling. The switch resulted in annual savings of over $69,000 in grain refiner and flux costs, coupled with a ten-fold reduction in impregnation costs for sealing leaky castings. This presents a clear business case for investing in advanced melt treatment technology.

Paper Details

THEORY AND PRACTICE OF GRAIN REFINING FOR ALUMINIUM ALLOYS - UTILIZING COVERAL MTS 1582

1. Overview:

- Title: THEORY AND PRACTICE OF GRAIN REFINING FOR ALUMINIUM ALLOYS - UTILIZING COVERAL MTS 1582

- Author: Brian Began, Foseco USA & Pascaline Careil, Foseco Europe

- Year of publication: Not explicitly stated. Published as Foundry Practice No. 268.

- Journal/academic society of publication: Foundry Practice

- Keywords: grain refining, aluminium alloys, COVERAL MTS 1582, thermal analysis, mechanical properties, master alloys, flux treatment

2. Abstract:

The need for smaller grains is vital to achieving the required properties when pouring most cast aluminum alloys. Whether the desired results are high mechanical properties, leaker free castings, a cosmetic appearance or improved structural soundness, smaller grains are impactfully beneficial. Accordingly, there is a desire to improve both grain refining and the ability to quickly and effectively assess grain refinement effectiveness. This paper discusses both the need for smaller grains and the principle fundamentals of grain refining. Moreover, the paper reviews commercially-available grain refiner forms and currently available methods for assessing grain refinement. Finally, the paper introduces a new and improved flux form grain refiner (COVERAL MTS 1582) and documents two recently successful case studies where the COVERAL MTS 1582 was utilized to improve castings in both a low pressure wheel foundry and a high production sand moulding foundry, respectively.

3. Introduction:

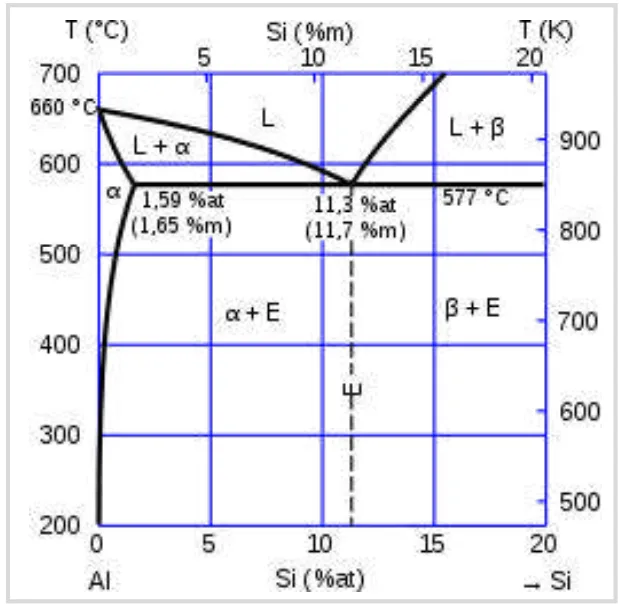

Grain refining is an essential part of the aluminium casting process aimed at reducing the size of primary aluminium grains during solidification. This process offers numerous benefits for most hypoeutectic aluminium alloys, including improved feeding, elongation, mechanical properties, fatigue resistance, and machinability, as well as reduced hot tears and porosity. While historically achieved with master alloys releasing Titanium diboride, grain refining is particularly critical in processes with slower cooling rates like investment, sand, gravity die, and low pressure die casting. The paper identifies key segments where grain refining is crucial: wheel foundries, safety-critical automotive castings, general automotive castings (to prevent leakers), aerospace and military castings, and sand/investment castings.

4. Summary of the study:

Background of the research topic:

The research is predicated on the fundamental principle that smaller grain size in cast aluminum alloys is directly beneficial to achieving desired outcomes, including high mechanical properties, pressure tightness (leaker-free castings), and overall structural soundness.

Status of previous research:

The paper acknowledges the established practice of using master alloys (e.g., AlTi5B1 rods) which contain pre-formed TiB₂ nuclei to induce grain refinement. It also reviews the conventional methods for assessing refinement, noting that elemental spectroscopy is common but less effective than more advanced techniques like thermal analysis and optical microscopy.

Purpose of the study:

The primary purpose is to introduce and validate a new, improved flux-based grain refiner, COVERAL MTS 1582. The study aims to discuss the theoretical fundamentals of grain refining, compare the new flux-based method to traditional master alloys, and document its successful implementation and benefits in two distinct industrial foundry settings.

Core study:

The core of the study is a comparative analysis of COVERAL MTS 1582 against standard TiBor master alloy rods. The performance is evaluated based on grain refinement effectiveness, measured quantitatively via thermal analysis (Grain Fineness score) and optical microscopy (grain size in µm), and its subsequent impact on the mechanical properties (UTS, YS, Elongation) of AlSi7Mg alloy castings. The study is supported by two case studies: one in a European low-pressure wheel foundry and another in an American high-production sand foundry.

5. Research Methodology

Research Design:

The study employs a comparative research design, evaluating an incumbent melt treatment process using TiBor master alloy rods against a new process using COVERAL MTS 1582 flux. The comparison is conducted in industrial environments to assess real-world performance and economic impact.

Data Collection and Analysis Methods:

- Thermal Analysis: A THERMATEST 5000 NG III unit was utilized to record the cooling curve of solidifying samples. The unit's algorithm analyzes the liquidus curve to determine undercooling (Δθ) and compute a Grain Fineness (GF) score on a scale of 1-9.

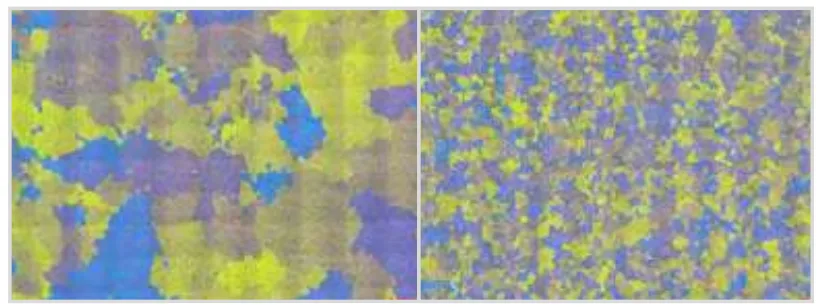

- Optical Microscopy: The Barker test method was used for electrolytic etching of polished test specimens. This allowed for the visualization of the grain structure under polarized light and the measurement of the average grain size (dm [µm]).

- Mechanical Testing: Standard test bars were cast and subjected to tensile testing to determine Ultimate Tensile Strength (UTS), Yield Strength (YS), and percentage Elongation.

Research Topics and Scope:

The research covers the theory of heterogeneous nucleation in aluminium alloys, the mechanism of grain refinement by TiB₂ nuclei, and a comparison of in-situ nuclei formation (from chemical flux) versus the addition of pre-formed nuclei (from master alloys). The scope is focused on hypoeutectic Al-Si alloys (specifically AlSi7Mg) and includes the practical application, assessment, and economic benefits of using COVERAL MTS 1582 in conjunction with an MTS 1500 treatment station.

6. Key Results:

Key Results:

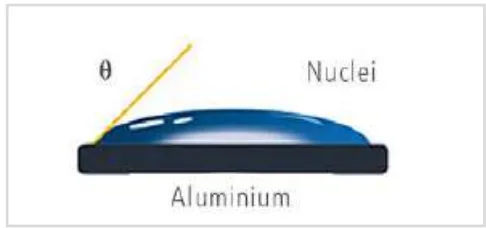

- COVERAL MTS 1582, a chemical flux, demonstrates superior grain refining performance compared to pre-formed nuclei from master alloys due to the in-situ formation of fresh TiB₂ nuclei, which exhibit a lower contact angle and higher surface energy.

- At a lower addition rate of 0.11%, COVERAL MTS 1582 showed a more significant reduction in liquidus undercooling, indicating stronger grain refinement, than 0.2% of AlTi5B1 rods (Figure 8).

- Optical microscopy confirmed that a 0.05% addition of COVERAL MTS 1582 resulted in a grain size of 237 µm, significantly finer than the 422 µm grain size achieved with a 0.08% addition of AlTi5B1 rods (Figure 10).

- In an industrial sand foundry, treatment with COVERAL MTS 1582 increased the average Grain Fineness (GF) score from 6.8 (with TiBor rods) to 9.0 (Table 3).

- The improved grain structure led to enhanced mechanical properties: UTS increased to 41,290 psi (285 MPa), YS to 35,100 psi (242 MPa), and Elongation to 5% (Table 4).

- The implementation of the new process resulted in projected annual savings of over $69,000 from reduced grain refiner and flux consumption, and a ten-fold reduction in impregnation costs for sealing leakers.

Figure Name List:

- Figure 1: Al-Si phase diagram

- Figure 2: Nuclei needs a good wettability by melt

- Figure 3: Heterogeneous nucleation as a function of wetting angle

- Figure 4: Young's equation

- Figure 5: Photograph of a THERMATEST 5000 NG III unit

- Figure 6a and b: Profiles of the cooling curve at the solidification of primary aluminium crystals in case of hypoeutectic alloy

- Figure 7: Test of grain refinement - Standard plate with Grain Fineness (GF)

- Figure 8: Thermal analysis curves

- Figure 9a: Before treatment. Grain size dm [µm] = 984

- Figure 9b: After treatment. Grain size dm [µm] = 206

- Figure 10: Comparison of TiB rods with Coveral MTS 1582: grain size

- Figure 11: Photograph of extremely dry dross in transfer ladle after treatment with COVERAL MTS 1582.

- Figure 12: Microstructure before and after treatment with COVERAL MTS 1582.

- Figure 13: Thermal analysis curves

7. Conclusion:

COVERAL MTS 1582 is a universal grain refining and cleaning flux that forms highly suitable Aluminium boride and Titanium boride nuclei in-situ within aluminium melts. This in-situ creation is more effective than releasing pre-made TiB₂ nuclei from master alloys. While elemental spectroscopy, thermal analysis, and optical microscopy are all methods for assessing grain refinement, the latter two are the most efficient and representative. Industrial experience in both low-pressure wheel and high-production greensand foundries confirms that using COVERAL MTS 1582 with an MTS 1500 unit leads to superior casting mechanical properties and lower overall process costs.

8. References:

- G. Samsonov, A. Panasyuk und G. Kozina, Poroshkovaya Metallurgiya, Nr. 11, pp. 42-48. (1971)

- Careil, P., & Simon, R. MTS 1500 Automated Metal Treatment Station. Foundry Practice Issue 247. p. 15-20. (June 2007)

- Careil, P. & Simon, R. MTS 1500 Automated Metal Treatment Station. Foundry Practice Special Edition for Cast Expo 2018. p. 1-6. (May 2008)

- Stonesifer, J. & Began, B. Degassing and Flux Grain Refining in a Continuous Well at Littlestown Foundry. AFS 123rd Metalcasting Congress Proceedings. Atlanta, GA: American Foundry Society. (2019)

- Careil, P., & Kientzler, P. Thermatest 5000 NG III: thermal analysis equipment designed to predict and control the structure of aluminium alloys before casting. Foundry Practice Issue 250. p. 2-6. (September 2008)

Expert Q&A: Your Top Questions Answered

Q1: Why is the in-situ formation of TiB₂ nuclei from a chemical flux considered more effective than using pre-formed nuclei in master alloys?

A1: According to the paper (pages 3 & 4), in-situ formation is more effective for several reasons. The nuclei are formed with a fresh, clean surface, leading to higher surface energy and a lower contact angle (θ) with the aluminum melt, which promotes better nucleation. Master alloys can have oxides or impurities on the surface of the pre-formed nuclei, which increases the contact angle and reduces their effectiveness. Furthermore, the chemical flux provides an additional cleaning effect on the melt.

Q2: The paper mentions COVERAL MTS 1582 is a "universal" flux. Are there any limitations to its use?

A2: Yes, while it is suitable for a wide range of applications, the paper specifies on page 4 that COVERAL MTS 1582 is suitable for all types of aluminium alloys except hyper-eutectic alloys. It is, however, effective for alloys containing large amounts of magnesium.

Q3: What is the most effective method for assessing grain refinement in a production environment according to this study?

A3: The paper evaluates three methods (page 4). It states that elemental spectroscopy is the most common but least effective method. Optical microscopy is considered the most representative but is time-consuming and resource-intensive. The paper highlights Thermal Analysis, using a device like the THERMATEST 5000 NG III, as perhaps the fastest-growing method because it is quick, more accurate than spectroscopy, and provides a quantitative score (GF) that can be easily used for process control.

Q4: What specific process parameters are required for using COVERAL MTS 1582 effectively?

A4: The paper states on page 4 that COVERAL MTS 1582 is specially designed for use with FOSECO's MTS 1500 rotary degassing equipment, which provides controlled additions and vigorous mixing. It also specifies that the melt temperature should be higher than 720°C. The European wheel foundry case study (page 7, Table 2) provides a specific example of process parameters: a melt temperature of 730-760°C, a 6-minute treatment time, and a rotor speed of 450 rpm.

Q5: The paper claims significant cost savings. Where do these savings primarily come from?

A5: The economic benefits detailed on page 8 come from two main areas. First, there is a direct reduction in material costs, with a projected annual saving of over $69,000 on grain refiners and cleaning flux. Second, and perhaps more significantly, there is a massive reduction in downstream costs related to quality defects. The paper cites a ten-fold reduction in projected impregnation costs, which are incurred to seal porosity in leaky castings, dropping from over $1,500 per month to less than $150 per month.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of consistently producing high-quality aluminum castings with superior mechanical properties and zero leaks is a constant in the foundry industry. This paper demonstrates that a significant leap forward is possible by moving beyond traditional methods. The key breakthrough is clear: advanced Aluminum Grain Refining using an in-situ flux system like COVERAL MTS 1582 provides a more powerful, efficient, and reliable path to achieving a fine-grained microstructure. The resulting improvements in mechanical strength and the drastic reduction in defects offer a direct route to higher productivity and lower operational costs.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "THEORY AND PRACTICE OF GRAIN REFINING FOR ALUMINIUM ALLOYS - UTILIZING COVERAL MTS 1582" by "Brian Began, Foseco USA & Pascaline Careil, Foseco Europe".

Source: Foundry Practice No. 268

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.