Boost Aluminum Casting Strength: A Deep Dive into Vortex Gate Design

This technical summary is based on the academic paper "THE EFFECTS OF VORTEX GATE DESIGN ON MECHANICAL STRENGTH OF THIN SECTION CASTING OF LM 25 (A—7Si-0.3Mg) ALUMINUM CASTING ALLOY" by Zaid Ali Subhi, submitted in February 2012 to Universiti Tun Hussein Onn Malaysia. It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Vortex Gate Design

- Secondary Keywords: Aluminum Casting Defects, Mechanical Strength, LM25 Alloy, Gating System Design, Molten Metal Flow, Casting Simulation

Executive Summary

- The Challenge: Turbulent molten metal flow in conventional gating systems creates strength-degrading defects like bifilms and porosity in critical aluminum castings.

- The Method: This study compared the mechanical properties and molten metal flow of LM25 aluminum alloy cast using a novel Vortex gate design versus a Conventional gate design, validated by both physical testing and numerical simulation.

- The Key Breakthrough: The Vortex gate design produced a smooth, non-turbulent flow, resulting in a significant reduction in porosity and cracks and an excellent improvement in average flexural strength.

- The Bottom Line: Implementing a Vortex gate design is a highly effective strategy to minimize flow-related defects and enhance the mechanical reliability of thin-section aluminum castings.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive and aerospace industries, the demand for lightweight, high-strength aluminum components is relentless. However, the casting process itself can introduce the very weaknesses we seek to avoid. A primary culprit is the gating system. Improper design leads to high molten metal velocities and turbulence during mold filling.

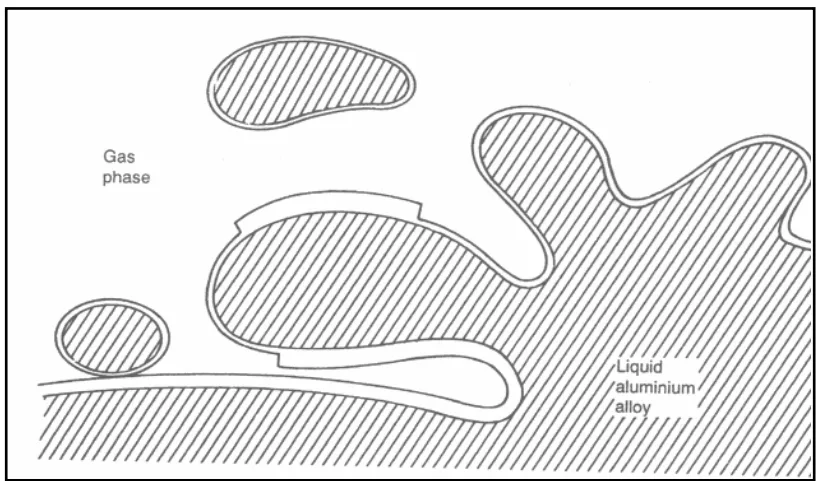

This turbulence folds the surface oxide layer on the liquid metal into the casting, creating crack-like defects known as bifilms. It also entraps air, leading to porosity. These defects, often microscopic, act as stress concentrators and severely limit the final mechanical strength and reliability of the component. For safety-critical parts, this is an unacceptable risk. This research tackles this fundamental problem by investigating a new gating system geometry designed specifically to eliminate the root cause: turbulent flow.

The Approach: Unpacking the Methodology

The study employed a rigorous comparative analysis between a novel Vortex gate and a Conventional gate for thin-section sand casting of LM25 (Al-7Si-0.3Mg) aluminum alloy. The methodology integrated both computational modeling and physical experimentation.

- Computational Simulation: The ADESTEFAN v.10 software package was used to create a 'virtual experiment'. This allowed for detailed visualization of the molten metal flow behavior inside the mold, identifying turbulence and velocity patterns that are impossible to see with the naked eye.

- Physical Casting: Test plates were produced using sand casting with both gate designs at various pouring temperatures (700°C, 720°C, and 740°C).

- Defect Analysis: X-Ray Radiography was used to examine the general distribution of porosity and other defects within the cast plates.

- Mechanical Testing: A 3-Point Bending Test was applied to measure the flexural strength of specimens cut from the cast plates. The scatter in these strength values was then quantified using Weibull statistics to assess material reliability.

- Microstructural Inspection: Optical microscopy and Scanning Electron Machine (SEM) tests were used to observe the grain structure and fracture surfaces, linking defects directly to material failure.

The Breakthrough: Key Findings & Data

The research delivered clear, data-driven evidence of the Vortex gate's superiority in producing higher-quality castings.

Finding 1: Vortex Gate Achieves Smooth, Non-Turbulent Mold Filling

Numerical simulations demonstrated a stark contrast in flow behavior between the two designs. The Conventional gate produced a chaotic, high-velocity fill, promoting the entrapment of oxide films. In contrast, the Vortex gate created a controlled, swirling flow.

As shown in the simulation results (Figures 4.13, 4.14), the Vortex gate design facilitates a smooth, non-turbulent flow. The liquid metal enters the mold cavity with a good free surface condition, significantly reducing the danger of surface film entrapment. The velocity field distribution (Figure 4.15) confirms a more controlled flow compared to the Conventional gate (Figures 4.16, 4.17, 4.18), which showed a much more turbulent pattern. The study successfully aimed to keep the molten metal flow velocity below the critical 0.5 m/s threshold identified by Campbell (2003) as a key factor in preventing surface turbulence.

Finding 2: Superior Mechanical Strength and Drastically Reduced Defects

The smoother fill translated directly into improved mechanical properties and part integrity. The physical experiments confirmed the predictions of the simulation.

Castings produced with the Vortex gate showed a significant reduction in defects. The X-Ray Radiography results (Figure 4.6) visually confirmed a lower porosity distribution in the plates cast with the Vortex gate. Consequently, these castings exhibited superior mechanical strength. The 3-point bending test results for the Vortex gate design (Tables 4.1 and 4.3) consistently showed higher flexural strength values compared to the Conventional gate design (Tables 4.2 and 4.4). Furthermore, the Weibull distribution analysis (Figures 4.9 and 4.10) demonstrated that the Vortex gate castings not only had a higher average strength but also showed less scatter, indicating higher reliability.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that redesigning gating systems to incorporate vortex flow principles is a direct path to reducing turbulence-related defects. The swirling action inside the vortex gate is a key feature for improving melt quality just before it enters the mold cavity.

- For Quality Control Teams: The data in the Weibull plot analysis (Figures 4.9 and 4.10) of the paper illustrates that the Vortex gate not only increases average strength but also improves the Weibull modulus, indicating a more reliable and predictable material. This could inform new, higher standards for quality inspection and component validation.

- For Design Engineers: The findings prove that gating is not merely a means to fill a mold but a critical design feature that dictates the final metallurgical quality of the part. Incorporating a Vortex gate or similar non-turbulent filling system during the initial mold design phase is crucial for producing high-integrity, thin-section castings.

Paper Details

THE EFFECTS OF VORTEX GATE DESIGN ON MECHANICAL STRENGTH OF THIN SECTION CASTING OF LM 25 (A—7Si-0.3Mg) ALUMINUM CASTING ALLOY

1. Overview:

- Title: THE EFFECTS OF VORTEX GATE DESIGN ON MECHANICAL STRENGTH OF THIN SECTION CASTING OF LM 25 (A—7Si-0.3Mg) ALUMINUM CASTING ALLOY

- Author: ZAID ALI SUBHI

- Year of publication: 2012

- Journal/academic society of publication: A thesis submitted to Universiti Tun Hussein Onn Malaysia

- Keywords: Vortex gate, Conventional gate, LM25, Mechanical properties, Porosity distribution, Numerical simulation, ADESTEFAN, X-Ray Radiography, 3-Point bending test, Weibull statistics

2. Abstract:

Aluminum alloy castings are being used progressively more in safety-critical applications in the automotive and aerospace industries. During the production of aluminum ingots and castings, the surface oxide on the liquid is folded in to produce crack-like defects (bifilms), porosities that are extremely thin and tiny or big, but can be extremely extensive, and so constitute seriously detrimental defects. To produce castings of sufficient quality, it is, therefore, important to understand the mechanisms of the formation of defects in aluminum melt flow through the gating system. Gating system design is an essential element in casting process which affects significantly the molten metal flow behavior, heat transfer and solidification of the melt. The good quality casting product could be achieved by using an optimum gating design. This study has employed Vortex gate design of LM25 (Al—7Si-0.3Mg) thin section casting to determine the effect of Vortex and Conventional gate design on mechanical properties and porosity distribution pattern. Numerical simulation by ADESTEFAN v.10 package was used to identify the molten metal flow behavior in the mold cavity which is physically could not be detected by unaided eye. The X-Ray Radiography test used to examine in general the distribution of defects in thin casted part. 3-Point bending test was applied to measure the flexural strength of the casted alloy material. The scattering of flexural strength has been quantified by Weibull statistics approach. The microstructure inspection was observed using both, the optical microscope micrographs and scanning electron machine (SEM) tests. Numerical simulation results showed a smooth and non turbulent flow of the Vortex gate design. The liquid metal in vortex entering the mould cavity is helped by gravity for a good free surface condition during filling, reducing the danger of entrapment of any free surface film. Furthermore, experimental results showed that casting product with vortex gate leads to excellent improvement of average flexural strength and reduction of porosity and cracks defects relying on the feature of swirled flow inside the vortex gate. The ‘virtual' experiment using a computational modeling package and the 'physical' experiment were found to be in reasonable agreement.

3. Introduction:

Castings are objects obtained by allowing molten metal to flow and solidify in a mold. While the process is ancient, modern applications in automotive and aerospace require high-quality aluminum alloys like LM25. However, the casting process, particularly the mold-filling stage, is prone to creating defects. The increasing demand for reliable, lightweight aluminum castings has prompted in-depth research to enhance their mechanical properties by controlling the casting process. The formation of defects is directly related to molten metal flow phenomena during mold filling, where turbulent flows can cause air and inclusion entrapments. This study focuses on the critical role of the gating system design in controlling this flow to improve the final quality of the casting.

4. Summary of the study:

Background of the research topic:

Aluminum-silicon casting alloys like LM25 are widely used in automotive applications for their excellent casting properties and high strength-to-weight ratio. However, their mechanical strength is highly sensitive to defects such as porosity and oxide films (bifilms) that form during the casting process.

Status of previous research:

Previous research has established that gating system design has a significant influence on the flow pattern of molten metal and, consequently, on casting quality. Studies by Dai et al. (2003) and Campbell (2003) have shown that optimizing the gating system can reduce turbulence, minimize air entrapment, and improve mechanical strength. However, a specific, detailed comparison of a Vortex gate design against a conventional one for thin-section LM25 sand castings, combining simulation and extensive physical testing, was the focus of this work.

Purpose of the study:

The main aim was to enhance the mechanical strength of LM25 thin-section castings by using a new Vortex gate system design. The specific objectives were to investigate the effect of the vortex gate on mechanical strength, reduce turbulence and harmful flow velocities (below 0.5 m/s), evaluate the produced castings' properties, and use numerical simulation to identify the flow behavior.

Core study:

The core of the study involved a direct comparison between castings made with a Vortex gate and a Conventional gate. This was achieved through both numerical simulation (ADESTEFAN v.10) to model the fluid dynamics and a comprehensive set of physical experiments. The experiments included producing castings at different temperatures, followed by X-ray inspection for defects, 3-point bend testing for flexural strength, and microstructural analysis to understand the material's internal structure and failure modes.

5. Research Methodology

Research Design:

The study was designed as a comparative experiment. Two gating system designs (Vortex and Conventional) were the primary independent variables. The pouring temperature (700°C, 720°C, 740°C) was a secondary variable. The dependent variables were the mechanical strength (flexural strength), defect distribution (porosity), and molten metal flow characteristics (velocity and turbulence).

Data Collection and Analysis Methods:

- Simulation: Flow behavior, velocity fields, and mold filling sequences were captured from ADESTEFAN v.10 simulations.

- Radiography: X-ray images were used for qualitative assessment of porosity distribution.

- Mechanical Testing: An AG-1 SHIMADZU Universal Testing Machine was used for the 3-point bending tests to collect load-deflection data, from which flexural strength was calculated.

- Statistical Analysis: Weibull statistics were applied to the flexural strength data to determine the characteristic strength and Weibull modulus, quantifying reliability.

- Microscopy: An OLYMPUS BX60M optical microscope and a JSM-6380LA SEM were used to capture images of the microstructure and fracture surfaces.

Research Topics and Scope:

The scope was limited to thin-section sand casting of aluminum alloy LM25 (Al-7Si-0.3Mg). The investigation focused on the effects of two specific gating designs (Vortex and Conventional) and three pouring temperatures. The study did not include heat treatment of the castings. The primary goal was to correlate the gating design with molten metal flow behavior and the resulting mechanical properties and defect levels.

6. Key Results:

Key Results:

- Numerical simulations showed the Vortex gate design produces a smooth and non-turbulent flow, while the Conventional gate design results in a turbulent flow.

- The Vortex gate design helps maintain a good free surface condition during filling, reducing the risk of entrapping surface oxide films.

- Experimental results showed that castings made with the Vortex gate had an excellent improvement in average flexural strength.

- Castings made with the Vortex gate showed a reduction in porosity and crack defects compared to those made with the Conventional gate.

- The simulation results and the physical experiment results were found to be in reasonable agreement.

Figure Name List:

- Figure 2.1: LM 25 (Al-7Si-0.3Mg) aerospace and automotive thin walled products.

- Figure 2.2: The general three runner system designs

- Figure 2.3: Surface turbulence

- Figure 3.1: Overview of the project methodology

- Figure 3.2: The assembled geometry of vortex gate and conventional gate patterns

- Figure 3.3: The new design of non-symmetrical overlapped flask

- Figure 3.4: Electrical Induction Furnace and its crucible at UTHM foundry laboratory used to melt LM25 (Al—7Si-0.3Mg)

- Figure 3.5: The cutting methods of casting samples and the produced specimens will subject to three-point bend test

- Figure 3.6: The experimental work flow progress

- Figure 3.7: X-Ray machine type BOSELLO HT industrial X-Ray used to check the porosity distribution of the products.

- Figure 3.8: Position and dimensions of 3-points bending test specimen

- Figure 3.9: AG-1 SHIMADZU Universal Testing Machine was employed to perform 3-point bending test

- Figure 3.10: Samples preparation for (phenolic-plastic) mounting and microstructure test

- Figure 3.11: (a) Optical microscope type OLYMPUS BX60M. (b) Scanning electron machine type JSM-6380LA.

- Figure 3.12: Geometry and dimension descriptions of the validation work, original geometry

- Figure 4.1: Cause and effect diagram for casting defects (Quality Control)

- Figure 4.2: LM25 Grains Microstructure of (700, 720 and 740) °C pouring temperature and Vortex ingate

- Figure 4.3: LM25 Grains Microstructure of (700, 720 and 740) °C pouring temperature and Conventional ingate

- Figure 4.4: SEM micrographs show the distribution of shrinkage porosities and oxide films on the polished fracture surface of specimen from (Conventional ingate design)

- Figure 4.5: SEM micrographs show the distribution of shrinkage porosities and oxide films on the polished fracture surface of specimen from (Vortex ingate design)

- Figure 4.6: Porosity distribution in casting plate by X-Ray Radiography

- Figure 4.7: Frequency histogram plots of bending strength for horizontal sampling

- Figure 4.8: Frequency histogram plots of bending strength for horizontal sampling.

- Figure 4.9: Weibull plot of LM25 (Al—7Si-0.3Mg) for vertical sampling

- Figure 4.10: Weibull plot of LM25 (Al—7Si-0.3Mg) for horizontal sampling

- Figure 4.11: Benchmark validation for ADESTEFAN software with Flow-3D and Fluent of thin section casting model.

- Figure 4.12: Molten metal entrance velocity, (Campbell, 2003)

- Figure 4.13: 3D - Eagle eyes view of the filling stages for vortex gate mold filling steps.

- Figure 4.14: Front view of the filling stages for vortex gate mold filling steps.

- Figure 4.15: Velocity field distribution inside the vortex gate mold during filling process running till end

- Figure 4.16: 3D - Eagle eyes view of the filling stages for conventional gate mold filling steps.

- Figure 4.17: Front view of the filling stages for conventional gate mold filling steps

- Figure 4.18: Velocity field distribution inside the conventional gate mold during filling process running till end.

7. Conclusion:

This study successfully demonstrated that Vortex gate design significantly enhances the mechanical strength and reduces defects in thin-section castings of LM25 aluminum alloy. The key to this improvement is the creation of a smooth, non-turbulent molten metal flow, which minimizes the entrapment of oxide films and reduces porosity. The strong agreement between numerical simulations and physical experiments validates the use of computational modeling as a predictive tool for optimizing gating system designs. The results confirm that a well-designed gating system is paramount for producing high-quality, reliable aluminum castings for critical applications.

8. References:

- Agrawal, B.K., (1988). Introduction To Engineering Materials. New Delhi: McGraw-Hill.

- Ammen, C.W., (1979). The Complete Handbook of Sand Casting. 1st ed. New York: Mc Graw-Hill.

- Babaei, R., Asgari, A. & Devasmi, P., (2005). Modeling of Air pressure effect in casting moulds. Journal of Modeling And Simulation in Material Science and Engineering , 13, pp.903-917.

- Barkhudarov, M.A. & Hirt, C.W., (1995). Casting Simulation: Mould Filling and Solidification –Benchmark Calculations Using FLOW-3D. Flow Science inc.

- Beeley, P., (2001). Foundry Technology. 2nd ed. Butterworth-Heinnman: Oxford.

- Campbell, J., (2003). Casting. Oxford: Elsevier. pp.13-37, 117-127.

- Dai, X., Yang, X., Campbell, J. & Wood, J., (2003). Effects of runner system design on the mechanical strength of Al-7Si-Mg alloy castings. Materials Science and Engineering, A354, pp.315-325.

- Esparza, C.E., Guerrero Mata, M.P. & Rios Mercdo, R.Z., 2005. Optima Design of gating system by gradient search method. Computional material Science.

- Hsu, F.U., Jolly, M.R. & Campbell, J., (2006). Vortex-gate design for gravity casting. International Journal of Cast Metals Research, 19(1), pp.38-44.

- Hu, B.H., Tong, K.K., Niu, X.P. & Pinwill, I., (2000). Design and opimization of runner and gating system for die casting of thin-walled magenisium telecommunication parts through numerical simulation. Journal of Material Processing Technology, 105, pp.123-133.

- Katzarov, I.H., (2003). Finite element modeling of porosity formation in casting. International Journal of Heat and Mass Transfer, 46, pp.1545-1552.

- Lee, P.D., Chirazi, A. & See, D., (2001). Modeling microporosity in aluminum silicon alloy. Journal of light metal, 1, pp.15-30.

Expert Q&A: Your Top Questions Answered

Q1: Why was the critical velocity of 0.5 m/s chosen as a target for the molten metal flow?

A1: The study references the work of Campbell (2003) and Hsu et al. (2006), which identified 0.5 m/s as a critical velocity threshold for molten aluminum. Exceeding this speed causes the surface oxide film to break and become entrained in the bulk liquid, leading to bifilm defects. The objective of the Vortex gate design was specifically to reduce the flow velocity below this harmful value to maintain a quiescent filling process.

Q2: How did the simulation results from the ADESTEFAN software correlate with the physical casting experiments?

A2: The abstract explicitly states that the "'virtual' experiment using a computational modeling package and the 'physical' experiment were found to be in reasonable agreement." This is a crucial outcome, as it validates the use of ADESTEFAN as a reliable tool for predicting flow behavior. It gives engineers confidence that they can use simulation to optimize gating designs and troubleshoot flow-related problems before committing to expensive and time-consuming physical tooling.

Q3: What is the primary mechanism by which the Vortex gate improves mechanical strength?

A3: The primary mechanism is the reduction of turbulence. The swirling, controlled flow generated by the Vortex gate prevents the chaotic mixing and high velocities seen with the conventional gate. This directly leads to two benefits: 1) it minimizes the folding-in of the surface oxide layer, thus reducing bifilm defects, and 2) it reduces the entrapment of air, leading to lower porosity. Since both bifilms and pores act as initiation sites for cracks, their reduction results in a casting with significantly higher flexural strength and reliability.

Q4: The study notes that the filling time for the Vortex gate was significantly longer (5.4-5.9s) than for the conventional gate (1.9-2.1s). Did this slower fill pose a risk of premature solidification?

A4: The paper focuses on the benefits of the slower, more controlled fill in achieving a non-turbulent flow, which was the primary objective. While a slower fill could theoretically increase the risk of cold shuts in very thin sections, the experimental results showed superior mechanical properties and reduced defects for the Vortex gate. This indicates that for the geometry and temperatures tested, the benefits of eliminating turbulence far outweighed any potential risks from the longer filling time.

Q5: This research was conducted using sand casting. Are the principles of Vortex Gate Design applicable to high-pressure die casting (HPDC)?

A5: This study was specifically scoped to sand casting of LM25 alloy. The paper does not provide data on the performance of this Vortex gate design in an HPDC process. However, the fundamental fluid dynamics principle—that reducing turbulence and controlling flow velocity is critical to preventing oxide film entrapment and porosity—is universally applicable across all casting methods, including HPDC. The specific geometry would likely require adaptation for the much higher velocities and pressures inherent to HPDC, but the core strategy of promoting a more controlled, less chaotic fill remains a valuable goal.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides compelling evidence that addressing the root cause of many casting defects—turbulent molten metal flow—is achievable through intelligent gating system changes. The core problem of bifilms and porosity limiting the strength of critical aluminum components can be effectively mitigated with a Vortex Gate Design. The key breakthrough is the demonstration, through both simulation and physical testing, that a controlled, swirling flow dramatically improves part integrity and mechanical reliability. This work reinforces that the few seconds it takes to fill a mold are the most critical in determining the quality of the final product.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "THE EFFECTS OF VORTEX GATE DESIGN ON MECHANICAL STRENGTH OF THIN SECTION CASTING OF LM 25 (A—7Si-0.3Mg) ALUMINUM CASTING ALLOY" by "Zaid Ali Subhi".

- Source: UTHM Institutional Repository. View metadata, citation and similar papers at core.ac.uk.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.