This introduction paper is based on the paper "Study of two alternative cooling systems of a mold insert used in die casting process of light alloy components" published by "Procedia Structural Integrity".

1. Overview:

- Title: Study of two alternative cooling systems of a mold insert used in die casting process of light alloy components

- Author: Federica Fiorentini, Pellegrino Curcio, Enrico Armentani, Carlo Rosso, Paolo Baldissera

- Year of publication: 2019

- Journal/academic society of publication: Procedia Structural Integrity (Published by Elsevier B.V. on behalf of AIAS 2019 International Conference on Stress Analysis organizers)

- Keywords: Die Casting, Thermomechanical Fatigue, FEM Analysis

2. Abstract:

A mold insert is an important component of the molds commonly used in die casting processes. Its purpose is to realize particular shapes in castings, like cavities and undercuts. It is also used for improving the cooling system in some critical areas. Each insert has at least one simple cooling channel for controlling the thermal state of the mold and for cooling every hot spot efficiently. The severe cyclical thermal conditions, together with the mechanical stresses due at first to the molten metal cast in the shape and then due to the solidified casting, submit the insert to thermomechanical fatigue. The thermomechanical fatigue is the main cause of the cracks observed on insert surfaces after a certain number of cycles, which makes the component unusable and requests its substitution. This circumstance has a negative influence on direct and indirect costs. In this case, the phenomenon has been studied on a mold insert used for realizing an oil drain channel in an aluminum alloy cylinder block made through die casting process. The aim of the present work is to determinate the zones which are mostly subjected to high temperature and high thermal gradients and to design and analyze a more efficient cooling system by using conformal channels on the same insert realized in additive manufacturing.

3. Introduction:

Die casting processes, particularly high pressure die casting (HPDC), are widely used for producing aluminum alloy components, especially in the automotive industry. A major issue in these processes is the durability of dies and their components, which are subjected to high temperatures (molten aluminum at 670 – 710 °C), high injection speeds (30 – 100 m/s), and pressures (50 – 80 MPa). Mold inserts are crucial for creating specific casting features and for enhancing cooling in critical areas. These inserts typically have cooling channels to manage their thermal state and cool hot spots.

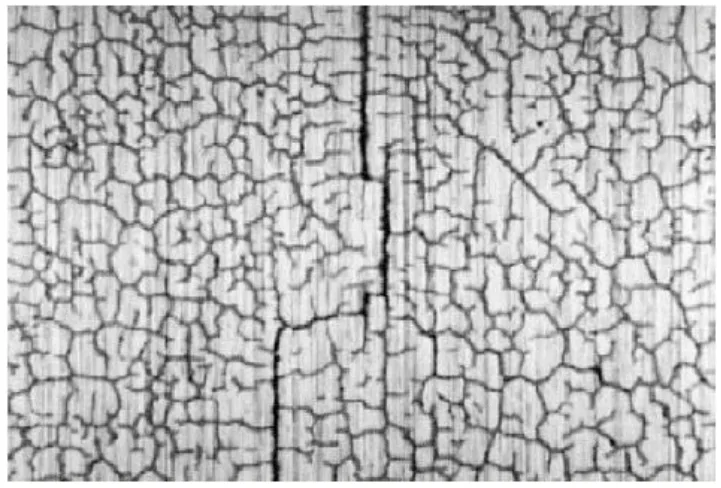

Die casting dies and inserts experience severe cyclical thermal and mechanical loads. These conditions lead to thermomechanical fatigue, which is the primary cause of cracks (often called “heat checks”) on insert surfaces after a number of cycles. This damage renders the insert unusable, necessitating replacement and incurring direct and indirect costs. Macroscopically, cracking initiates from the thermal shock when the die surface is rapidly heated and then quenched by lubricant spray. During heating, compressive stresses arise on the die surface, while cooling induces tensile stresses. The Coffin-Manson equation (1) relates the number of reversals to nucleate cracks to plastic strain amplitude. Thermal strain (equation (2)) and resulting stresses (equation (3)) can lead to plastic deformation (equation (4)) if the yield strength is exceeded. The fatigue life is also influenced by dissipated energy per cycle (equations (5) and (6)).

This paper investigates thermomechanical fatigue in a mold insert used for an oil drain channel in an aluminum alloy cylinder block (HPDC). The study employs finite element analysis (FEM) to identify zones of high temperature and thermal gradients. Based on these findings, a more efficient cooling system using conformal channels, realized through additive manufacturing, is designed and analyzed.

4. Summary of the study:

Background of the research topic:

The durability of die casting dies, particularly mold inserts, is a significant concern due to the harsh operating conditions involving high temperatures and cyclical mechanical loads. Thermomechanical fatigue is the predominant failure mechanism, leading to cracking and reduced service life of inserts, which negatively impacts production costs and efficiency. Effective cooling of inserts is critical to mitigate these issues.

Status of previous research:

Several studies have addressed life prediction and thermomechanical phenomena in die casting dies. Srivastava et al. (2004) presented a methodology using FEM software to predict thermal fatigue cracking, showing that increased temperature and thermal gradients reduce cycles to failure. FEM software has been shown to simulate thermomechanical problems effectively (Astarita et al. (2013), Sepe et al. (2014)). The Coffin-Manson equation (1) is well-known for describing fatigue. Sissa et al. (2014) suggested an energetic criterion for fatigue life prediction. Material properties, such as low thermal expansion and high thermal conductivity, are crucial for thermomechanical fatigue resistance (Lu et al. (2019)). The design of the insert cooling system plays a vital role in temperature control.

Purpose of the study:

The aim of the present work is to determinate the zones which are mostly subjected to high temperature and high thermal gradients and to design and analyze a more efficient cooling system by using conformal channels on the same insert realized in additive manufacturing.

Core study:

The study involves a finite element analysis (FEM) of a mold insert used for producing an oil drain channel in an aluminum alloy cylinder block. A transient thermal analysis was performed to determine the temperature field in the insert with a traditional cooling system. This temperature field was then used as a load in a subsequent structural analysis to evaluate stresses. Based on these results, a new cooling system with conformal channels, designed for additive manufacturing (specifically Select Laser Melting - SLM), was proposed. The performance of this conformal cooling system was then simulated and compared to the traditional system in terms of temperature distribution, thermal gradients, and stress fields.

5. Research Methodology

Research Design:

The research followed a comparative simulation approach.

- A transient thermal finite element analysis was conducted on the mold insert with its existing traditional cooling system to obtain the temperature field over a die-casting cycle.

- The resulting time-dependent temperature field was applied as a load in a structural finite element analysis to determine the stress distribution.

- Based on the findings, a new insert design incorporating conformal cooling channels, suitable for additive manufacturing, was developed.

- The transient thermal and subsequent structural analyses were repeated for the insert with the conformal cooling system under the same boundary conditions.

- The results from both cooling system designs (traditional vs. conformal) were then compared.

The analysis flow is depicted in Figure 3.

Data Collection and Analysis Methods:

Thermal Model (Traditional Cooling):

- The primary heat source was assumed to be the fluctuating temperature of molten metal during solidification.

- Initial insert temperature: 200°C (pre-heating temperature).

- Molten aluminum casting temperature: 700°C.

- A time-variable heat flux, obtained from a previous fluid dynamics simulation, was applied to the insert surface in contact with molten metal, expressed by the polynomial:

q = 3152,8 - 188,8t + 9,5t² - 0,21t³ + 0,0015t⁴(7) - Heat exchange surface: 10.603,5 mm². Cycle time: 45 seconds.

- Cooling: Demineralized water at 25 °C, mass flow rate

ṁ = 0,278 l/s. - Heat removed by water:

Q = hA(Ts - Ti)(8) (Note: paper usesQ = hA(Ts - Ti)but equation (8) in paper isQ = hA(Tw - Ti)). The text refers toTwas wall temperature andTias coolant inlet temperature. - Convective heat transfer coefficient (

hw) calculated using the Dittus-Boelter equation:hw = (kw/D) * Nu(9)

wherekw = 0,60 W/mK(water thermal conductivity),D = 3 mm(cooling channel diameter). - Nusselt number (

Nu):Nu = 0,023Re⁰·⁸ Pr⁰·⁴(10)

Prandtl number (Pr):Pr = (cpμ)/kw = 6,23(11)

Reynolds number (Re):Re = (ρvD)/μ = 4014,8(12)

Resultinghw = 7 kW/m²K. - Material: CrMoV alloyed hot work tool steel Wr. Nr. 1.2343. Temperature-dependent thermal and mechanical properties are listed in Table 1.

- Transient thermal analysis FEM matrix equation:

{p} = [C]{Ṫ} + ([K] + [H]){T}(18)

Structural Analysis:

- The time-variable temperature field from the thermal analysis was applied as a load.

- The model was constrained with fixed joints to simulate assembly in the mold and the bond effect of the alloy during solidification.

- Analysis focused on von Mises equivalent stresses and dissipated energy.

Conformal Cooling Channels Model:

- Designed for additive manufacturing (Select Laser Melting - SLM).

- Material: Maraging steel Wr. Nr. 1.2709. Thermal and mechanical properties are listed in Table 2.

- The transient thermal analysis was conducted under the same boundary conditions as the traditional system for comparison.

- Subsequent structural analysis was also performed.

Research Topics and Scope:

The research focused on:

- Determining temperature distributions and thermal gradients in a die casting mold insert with a traditional cooling system.

- Analyzing the resulting thermomechanical stresses and identifying areas of stress intensification and high dissipated energy.

- Designing an alternative conformal cooling system for the same insert, leveraging additive manufacturing.

- Evaluating the thermal performance and stress response of the conformal cooling system.

- Comparing the effectiveness of the traditional and conformal cooling systems in terms of achieving uniform temperature, reducing thermal gradients, mitigating stresses, and potential for cycle time reduction.

The study was specific to a mold insert used for an oil drain channel in an aluminum alloy cylinder block.

6. Key Results:

Key Results:

Traditional Cooling System:

- Temperature reaches its maximum in every analyzed point nine seconds after the molten metal has been poured (Figure 7).

- Areas distant from the cooling channel maintain higher temperatures at the end of the thermal cycle.

- Significant thermal gradients exist, particularly between the insert surface directly exposed to coolant and the rest of the insert (Figure 8).

- Structural analysis showed stress intensification in areas with high thermal gradients. The maximum von Mises equivalent stress at the end of the cycle was about 370 MPa (Figure 9).

- Large areas of plasticity were detected. The highest dissipated energy observed was

W = 4,81· 10⁻¹ J/mm³in areas where thermal gradients were maximum. - Variable amplitude stresses for the six Cartesian components were obtained (Figure 10).

Conformal Cooling System:

- The thermal field was significantly more uniform across the insert surface compared to the traditional system (Figure 12).

- Thermal gradients were practically absent, and the highest temperature reached was lower.

- The average temperature of the insert returned to approximately its initial value after only 30 seconds (Figure 13), suggesting potential for cycle time reduction. (The paper cites Sachs et al. (1997) who reported cycle time reductions up to 15% with conformal cooling).

- The average temperature in the core of the insert was lower and more uniform with conformal cooling (Figure 14 compared to Figure 6).

- Subsequent structural analysis showed that while the magnitude of equivalent von Mises stresses was similar to the traditional system, there was a lack of stress intensification (Figure 15).

Comparison:

- Conformal cooling channels led to a more uniform thermal field, reduced thermal gradients, and lower peak temperatures compared to traditional drilled channels.

- The conformal system demonstrated faster cooling to the initial average temperature, indicating potential for increased productivity.

- While von Mises stress magnitudes were comparable, the conformal system avoided localized stress intensifications observed with the traditional system.

![Fig. 6. Temperature in the core of the insert [°C].](https://castman.co.kr/wp-content/uploads/image-2291.webp)

![Fig. 8. Thermal fields [°C] at (a) 15 s; (b) 25 s; (c) 35 s; (d) 45 s](https://castman.co.kr/wp-content/uploads/image-2293-1024x403.webp)

![Fig. 15. Comparison of the von Mises stresses [MPa] between (a) traditional cooling channel and (b) conformal cooling channels.](https://castman.co.kr/wp-content/uploads/image-2294.webp)

Figure Name List:

- Fig. 1. Example of heat checks, Srivastava et al. (2004).

- Fig. 2. Cyclical stresses, Persson (2003)

- Fig. 3. Analysis flow chart.

- Fig. 4. Schematization of heat transfer mechanism, Krishnan and Sharma (1996).

- Fig. 5. CAD Model.

- Fig. 6. Temperature in the core of the insert [°C].

- Fig. 7. Temperature plot of eight points on insert' section.

- Fig. 8. Thermal fields [°C] at (a) 15 s; (b) 25 s; (c) 35 s; (d) 45 s.

- Fig. 9. Von Mises stresses on the insert at 45 seconds [MPa].

- Fig. 10. Stresses' spectrum: (a) σxx; (b) σyy; (c) σzz; (d) τxy; (e) τxz; (f) τyz.

- Fig. 11. Insert with conformal cooling system.

- Fig. 12. Comparison of temperature field [°C], after 25 seconds, between (a) traditional cooling channel and (b) conformal cooling channels.

- Fig. 13. Temperature field [°C] after 30 seconds.

- Fig. 14. Thermal field in the core of the insert [°C].

- Fig. 15. Comparison of the von Mises stresses [MPa] between (a) traditional cooling channel and (b) conformal cooling channels.

7. Conclusion:

Injection molding (specifically, die casting in this context) is a frequently used technology for manufacturing automotive parts with high productivity. Optimal thermal management of the injection mold and its components is essential for improving productivity and part quality. This study found that a conformal cooling system is a valid solution for uniformly cooling a mold insert while reducing the effects of thermomechanical fatigue, a common issue in die casting due to high temperatures evolving rapidly.

Two finite element simulations were presented to analyze and compare the temperature and stress fields on an insert with two different cooling systems. The results clearly indicate that conformal cooling channels offer significant improvements, including reductions in mechanical and thermal stresses, and a potential reduction in cycle time.

The advantages of conformal cooling benefit both the product (fewer defects in castings) and the process (less thermomechanical stress on inserts, leading to improved insert duration). Optimal thermal conditioning helps prevent degradation of the steel microstructure caused by prolonged exposure to high temperatures. Furthermore, the faster cooling observed with conformal channels allows for increased productivity.

For future developments, the energetic fatigue criterion expressed by equation (6) will be used to predict and compare the service life (duration) of the insert with the two different cooling system designs.

8. References:

- Abbès, B., Abbès, F., Abdessalam, H., Upganlawar, A. 2019. Finite element cooling simulations of conformal cooling hybrid injection molding tools manufactured by selective laser melting. The International Journal of Advanced Manufacturing Technology 103, 2515-2522.

- Abdulhadi, H.A., Aqida, S.N., Ishak, M., Mohammed, G.R., 2016. Thermal Fatigue of Die-Casting Dies: An Overview. MATEC Web of Conferences 74. 00032.

- Astarita, A., Armentani, E., Ceretti, E., Giorleo, L., Mastrilli, P., Paradiso, V., Scherillo, F., Squillace, A., Velotti, C., 2013. Hot Stretch Forming of a titanium alloy component for aeronautic: mechanical and modeling, Key Engineering Materials 554-557, 647-656.

- Bergström, J., Rézai-Aria, F., 2006. High temperature fatigue of tool steels. In: Rosso M, Actis Grande M, Ugues D, editors. Tool, proceedings of 7th international tooling conference, Torino.

- Dang, X.P., Park, H.S., 2011. Design of U-shape milled groove conformal cooling channels for plastic injection mold. International Journal of Precision Engineering and Manufacturing 12, 73-84.

- Jhavar, S., Paul, C.P., Jain, N.K., 2013. Causes of failure and repairing options for dies and molds: A review. Engineering Failure Analysis 34, 519-535.

- Klobčar, D., Kosec, L., Kosec, B., Tušek, J., 2012. Thermo fatigue cracking of die casting dies. Engineering Failure Analysis 20, 43-53.

- Krishnan, M., Sharma, D.G.R., 1996. Determination of the interfacial heat transfer coefficient h in unidirectional heat flow by Beck's non linear estimation procedure. International Communications in Heat Mass Transfer 23, 203-214.

- Kuo, C.C., Xu, W.C., 2018. Effects of different cooling channels on the cooling efficiency in the wax injection molding process. The International Journal of Advanced Manufacturing Technology 98, 887-895.

- Lu, Y., Ripplinger, K., Huang, X., Mao, Y., Detwiler, D., Luo, A., 2019. A new fatigue life model for thermally-induced cracking in H13 steel dies for die casting. Journal of Materials Processing Tech 271, 444-454.

- Matisková, D., Gašpar, Š., Mura, L., 2013. Thermal Factors of Die Casting and Their Impact on the Service Life of Moulds and the Quality of Castings. Acta Polytechnica Hungarica 10, 65-78.

- Persson, A., 2003. On Tool Failure in Die Casting. Acta Universitatis Upsaliensis.

- Phull, G.S., Kumar, S., Walia, R.S., 2018. Conformal cooling for molds produced by additive manufacturing: a review. International Journal of Mechanical Engineering and Technology 9, 1162-1172.

- Sachs, E., Allen, S., Guo, H., Banos, J., Cima, M., Serdy, J., Brancazio, D., 1997. Progress on Tooling by 3D Printing; Conformal Cooling, Dimensional Control, Surface Finish and Hardness. International Solid Freeform Fabrication Symposium, 115-124.

- Sepe, R., Pozzi, A., Armentani, E., 2014. Finite-element simulation of temperature fields and residual stresses in butt welded joints and comparison with experimental measurements, ASME 12th Biennial Conference on Engineering Systems Design and Analysis 1, 1-6.

- Shayfull, Z., Sharif, S., Ghazali, M.F., Mohd Saad, R., 2014. Potential of Conformal Cooling Channels in Rapid Heat Cycle Molding: A Review. Advances in Polymer Technology 33, 21381.

- Sissa, S., Giacopini, M., Rosi, R., 2014. Low-Cycle Thermal Fatigue and High-Cycle Vibration Fatigue Life Estimation of a Diesel Engine Exhaust Manifold. Procedia Engineering 74, 105-112.

- Srivastava, A., Joshi, V., Shivpuri, R., 2004. Computer modeling and prediction of thermal fatigue cracking in die casting tooling. Wear 256, 38-43.

- Tentardini, E.K., Kunrath, A.O., Aguzzoli, C., Castro, M., Moore, J.J., Baumvol, I.J.R., 2008. Soldering mechanisms in materials and coatings for aluminum die casting. Surface and Coating Technology 202, 3764-3771.

9. Copyright:

- This material is a paper by "Federica Fiorentini, Pellegrino Curcio, Enrico Armentani, Carlo Rosso, Paolo Baldissera". Based on "Study of two alternative cooling systems of a mold insert used in die casting process of light alloy components".

- Source of the paper: https://doi.org/10.1016/j.prostr.2020.02.050

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.