A Comprehensive Guide to Optimizing Your HPDC Die Design and Manufacturing Workflow

This technical brief is based on the academic paper "Review Paper on design of Single Cavity Pressure Die Casting Die Using CAD Tool & Its Manufacturing by HPDC Technology" by Rakesh Bandane and Vaibhav Bankar, published in the Journal Publication of International Research for Engineering and Management (JOIREM) (2022). It is summarized and analyzed for HPDC professionals by the experts at STI C&D..

Keywords

- Primary Keyword: HPDC Die Design

- Secondary Keywords: Single Cavity Pressure Die Casting, CAD for Die Casting, HPDC Process Flow, Casting Defects, Die Design Guidelines, Material Planning for Casting

Executive Summary

- The Challenge: Designing and manufacturing High-Pressure Die Casting (HPDC) dies is a complex process where numerous factors must be precisely controlled to produce successful, economical castings and avoid costly defects and production delays.

- The Method: The research provides a comprehensive review of best practices and outlines a systematic, integrated workflow for HPDC die development. This includes detailed design considerations, material and process planning, and final inspection, supported by a survey of relevant literature.

- The Key Breakthrough: The paper establishes a clear, structured process flow, from quotation to dispatch, that integrates design (CAD), manufacturing (CAM), and analysis (CAE). This holistic approach ensures all aspects, from part geometry to material properties and machine parameters, are considered upfront.

- The Bottom Line: By adopting the systematic guidelines and integrated workflow presented, manufacturers can significantly shorten lead times, reduce defects, and produce high-quality, defect-free components more consistently and economically.

The Challenge: Why This Research Matters for HPDC Professionals

For manufacturers relying on HPDC for mass production, the die is the heart of the operation. As the paper's introduction states, "The designer must incorporate numerous manufacturability-related factors into the design of a die to produce successful castings economically." A poorly designed die leads to a cascade of problems: incomplete filling, inconsistent solidification, difficult part ejection, and a high rate of defects like porosity, which can reach 15-20% in bulk production (Ref. [1]).

These issues not only create waste but also increase lead times and manufacturing costs. The challenge is to move from a trial-and-error approach to a predictive, systematic methodology. This research addresses this by compiling critical design considerations and process steps into a single, actionable framework, aiming to achieve a "zero-defect environment" (Ref. [6]).

The Approach: Unpacking the Methodology

This paper presents a comprehensive review and a structured methodology for the entire lifecycle of an HPDC die. The authors synthesized information from existing literature and established best practices to create a holistic guide. The core of their approach is a detailed process flow that begins with the initial quotation and extends to the final dispatch of the tool.

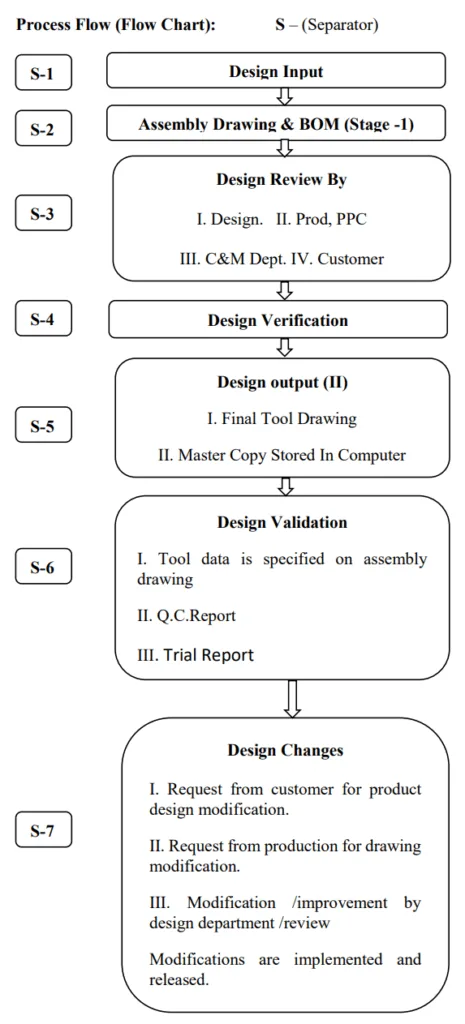

This workflow, illustrated in the Process Flow (Flow Chart) on page 5, is broken down into key stages:

- Design Input & Review: Defining requirements and conducting a multi-departmental review.

- Design Verification & Output: Creating final tool drawings using CAD software.

- Design Validation: Cross-referencing tool data with assembly drawings, QC reports, and trial reports.

- Material & Process Planning: Systematically planning for materials (Section 4) and manufacturing steps (Section 5).

- Inspection & Assembly: Ensuring all components meet specifications before and during final assembly (Sections 6 & 7).

This structured approach ensures that critical factors like material selection, runner/gate design, cooling layout, and ejection systems are addressed logically and sequentially.

The Breakthrough: Key Findings & Data

The paper consolidates extensive knowledge into actionable guidelines and processes. The key breakthroughs are not from a single experiment but from the structured synthesis of industry best practices.

Finding 1: Comprehensive Design Checklists: The paper provides detailed checklists for design considerations across Press Tools, Moulds, and Die Casting Dies (Section 3.1). These lists cover everything from the component's material and shape to shrinkage calculations, runner/gate types, cooling channel placement, and ejection systems. Following these ensures no critical factor is overlooked during the initial design phase.

Finding 2: A Structured, Verifiable Workflow: The flowchart presented on page 5 provides a clear, step-by-step process for die manufacturing. It emphasizes crucial feedback loops like "Design Review" (S-3) and "Design Validation" (S-6), which involve input from production, quality control, and the customer. This ensures the design is manufacturable, meets quality standards, and aligns with customer requirements before significant resources are committed.

Finding 3: The Importance of Integrated Planning: The research highlights that die design cannot exist in a vacuum. Success depends on integrated Material Planning (Section 4) to ensure the right materials are available at the right time, and detailed Process Planning (Section 5) to define the most efficient sequence of manufacturing operations (e.g., CNC machining, heat treatment). This integration is critical for maintaining delivery schedules and controlling costs.

Finding 4: Defect Mitigation Through Parameter Control: The literature review (Section 2) reinforces the link between process parameters and defects. For instance, controlling injection metal temperature is shown to be critical for reducing rejection rates (Ref. [1]), and proper vent design is essential for preventing porosity by allowing air to escape the cavity (Ref. [2]). This underscores the need for a design that facilitates precise process control.

Practical Implications for Your HPDC Operations

The findings in this paper offer a practical blueprint for refining your die design and manufacturing processes.

For Process Engineers: The literature review (Section 2) provides data-driven insights. For example, the finding that injection metal temperature is more critical than melting temperature (Ref. [1]) suggests that process monitoring should be focused at the shot sleeve. The emphasis on laminar flow and optimized pouring speed (Ref. [1]) provides clear targets for process optimization to reduce defects.

For Quality Control: The paper's focus on a structured inspection process (Section 6) and final die try-out (Section 6.1) provides a framework for robust quality assurance. The recommendation to check critical dimensions against the customer's approved drawing ensures that the final product meets all specifications, leading to higher customer satisfaction.

For Die Design: The "Guidelines for Design" (Section 3.2) serve as an invaluable checklist. Principles like "Specify thin sections," "Keep sections as uniform as possible," and "Provide sufficient draft on side walls" are fundamental rules that, when followed, directly lead to more robust, cost-effective, and higher-quality castings. The paper explicitly states that following these guidelines minimizes costs, machining, and flash removal.

Paper Details

Review Paper on design of Single Cavity Pressure Die Casting Die Using CAD Tool & Its Manufacturing by HPDC Technology

1. Overview:

- Title: Review Paper on design of Single Cavity Pressure Die Casting Die Using CAD Tool & Its Manufacturing by HPDC Technology

- Author: Rakesh Bandane, Vaibhav Bankar

- Year of publication: 2022

- Journal/academic society of publication: Journal Publication of International Research for Engineering and Management (JOIREM)

- Keywords: Single Cavity Pressure Die Casting Die

2. Abstract:

Manufacturers can create a sharply defined textured or smooth surface of metal parts by using a manufacturing process described in high-pressure die-casting technology. The mechanism under this technology forces and injects molten metal into a reusable metal die at a speed of 27-45 m/s. The manufacturers will use the hot chamber or cold chamber method to inject the metal into the die on the basis of the type of metal chosen to fabricate the part. The designer must incorporate numerous manufacturability-related factors into the design of a die to produce successful castings economically. To achieve this overall design goal, the die fills completely with molten metal, quickly & consistent solidification of molten metal, the part ejects easily from the die without damage, the part requires a minimum of die construction and die maintenance difficulties, the part meets the customer's tolerance requirement. Proper estimation of part manufacturing is essential for tender procurement & reduction in manufacturing lead time. The project gives a brief introduction of design considerations in manufacturing single cavity pressure die casting die. It explains the process flow from quotation to dispatch of the PDC tool. CAD software will be used for doing the work accomplished in design.

3. Introduction:

This project provides information on the design and manufacturing of dies for High-Pressure Die Casting (HPDC). Unlike permanent mould casting which relies on gravity, HPDC forces molten metal into moulds (dies) under high pressure and velocity. This allows for the production of more complex shapes. The process involves a cycle of closing the die, injecting molten metal, applying pressure during solidification, opening the die, and ejecting the casting. The paper aims to outline the critical design considerations and process flow required to manufacture a single cavity pressure die casting die effectively.

4. Summary of the study:

Background of the research topic:

For high-volume mass production, processes like sand casting are too slow. High-Pressure Die Casting (HPDC) is a necessary alternative, but its success hinges on a critically designed and manufactured die. The design phase is crucial, requiring expertise in CAD and CAE to handle challenges and arrive at an optimal configuration.

Status of previous research:

The literature review (Section 2) summarizes key findings from various researchers:

- Bharat Sharma [1]: Highlighted that controlling injection metal temperature is more critical than melting temperature and can significantly reduce a 15-20% rejection rate.

- Nouri-Borujerdi & J. A. Goldak [2]: Developed an analytical model for air venting, showing that improper venting leads to porosity, a major defect in die casting.

- Franco Bonollo et al. [6]: Discussed the industry challenge of moving towards a "zero-defect environment" by implementing real-time process control and making optimization an acknowledge-based issue.

- Shuhua Yue et al. [10]: Showed that an integrated CAD/CAE/CAM system shortens the die design and manufacture cycle, leading to higher quality castings in less time.

Purpose of the study:

The objectives of the study, as listed in Section 1.1, are to:

- Study the process to determine the die layout.

- Identify key parameters for die design.

- Identify potential casting defects and their areas of concern.

- Decide on the optimal type and location of the gate/runner/feeder system.

- Design a die capable of producing a high-quality, defect-free component.

Core study:

The core of the paper is a systematic breakdown of the entire die design and manufacturing process. It covers detailed design considerations for tools and moulds (Section 3.1), specific design guidelines for die-cast parts (Section 3.2), a complete process flow from quotation to dispatch (Section 3.3 and Flow Chart), and dedicated sections on Material Planning (4), Process Planning (5), Inspection (6), and Assembly (7).

5. Research Methodology

Research Design:

As a review paper, the research design involves the synthesis of existing academic literature and established industry best practices. It formulates a structured, systematic workflow for the design and manufacturing of an HPDC die, rather than conducting a new physical experiment.

Data Collection and Analysis Methods:

The methodology is based on collecting and analyzing information from previous studies (as seen in the Literature Review) and organizing best-practice principles into a coherent, step-by-step guide. This guide is presented through checklists, procedural descriptions, and a process flowchart.

Research Topics and Scope:

The scope covers the complete lifecycle of a single cavity pressure die casting die, from initial design considerations using CAD tools to its final manufacturing and inspection. It focuses on the practical steps and knowledge required to produce a successful die for HPDC technology.

6. Key Results:

Key Results:

The paper's primary result is a comprehensive, structured framework for HPDC die design and manufacturing. Key outputs include:

- Detailed Design Checklists (Section 3.1): Specific, actionable lists for press tools, moulds, and die casting dies, covering aspects like material, shrinkage, runner systems, cooling, and ejection.

- Process Flowchart (Page 5): A visual representation of the end-to-end process from "Design Input" to "Design Changes," emphasizing review and validation stages.

- Specific Design Guidelines (Section 3.2): A list of 15+ best-practice rules for designing die-cast parts to improve quality and reduce cost (e.g., "Keep sections as uniform as possible," "Provide sufficient draft").

- Integrated Planning Framework: A clear explanation of how Material Planning (Section 4), Process Planning (Section 5), and Inspection (Section 6) must be integrated with the design phase to ensure a smooth and efficient production cycle.

Figure Name List:

- Figure 1: High Pressure Die Casting Die

7. Conclusion:

The paper concludes that HPDC is a versatile and preferred casting process for many applications due to its ability to produce complex parts at a high rate. However, its advantages can only be fully realized through a systematic and precise approach to die design and manufacturing. By following the outlined principles of integrated planning, detailed design, and structured process control, limitations can be overcome, making the process more precise and efficient. This comprehensive approach, covering material planning, manufacturing process planning, inspection, and assembly, is essential for success in the HPDC industry.

8. References:

- [1] Bharat Sharma, Hidden Parameter in High Pressure Die Casting, International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 07 Issue: 10 | Oct 2020.

- [2] A. Nouri-Borujerdi, J. A. Goldak, Modeling of Air Venting in Pressure Die Casting Process, Journal of Manufacturing Science and Engineering AUGUST 2004, Vol. 126 Copyright © 2004 by ASME.

- [3] Raimo Helenius a, *, Otto Lohne a, Lars Arnberg a, Hans I. Laukli b, The heat transfer during filling of a high-pressure die-casting shot sleeve, Received in revised form 21 July 2005, Materials Science and Engineering A 413-414 (2005) 52–55.

- [4] Paul Robbins, Plunger Design-A Key to the Successful Die Casting System, 11the Metal Casting Congress, May 15-18, 2007, Houston, Texas, NADCA, 241 Holbrook, Wheeling, Illinois, 60090.

- [5] Bing Zhou, Yonglin Kang *, Mingfan Qi, Huanhuan Zhang and Guoming Zhu, R-HPDC Process with Forced Convection Mixing Device for Automotive Part of A380 Aluminum Alloy, Materials 2014, 7, 3084-3105; doi:10.3390/ma7043084.

- [6] Franco Bonollo, Nicola Gramegna, and Giulio Timelli, High-Pressure Die-Casting: Contradictions and Challenges, The Journal of The Minerals, Metals &Materials Society (TMS), SSN 1047-4838Volume 67 Number 5, JOM (2015) 67:901-908DOI 10.1007/s11837-015-1333-8

- [7] X.P. Niu (Chair.), B.H. Hu, I. Pinwill, H. Li,"Vacuum assisted HPDC of Al alloys", Journal of Materials Processing Technology 105 (2000) 119-127, 2000.

- [8] Rajesh Rajkolhe, J. G. Khan, "Defects, Causes and Their Remedies in Casting Process", 2014.

- [9] Mohammad B. NDALIMAN and Akpan P. PIUS, "Behavior of Aluminum Alloy Castings under Different Pouring Temperatures and Speeds", 2017.

- [10] Shuhua Yue, Guoxiang Wang, Fei Yin, Yixin Wang, Jiangbo Yang,2003, “Application of an integrated CAD/CAE/CAM system for die casting dies", Journal of Materials Processing Technology 139 (2003) 465-468.

- [11] Vaibhav Ingle, MadhukarSorte, "Defects, Root Causes in Casting Process and Their Remedies: Review", 2017

- [12] DR. Ch. S., Naga Prasad, 2017, "Temperature Defects on Compressor Housing Die Casting Method"

- [13] Acceptance Criteria's, Book, author IGTR, AURANGABAD.

- [14] Steel Solutions, Author, STEEL-DEAL.

- [15] Industrial Steels (Reference Book), Author, S.N.Bagachi, Kuldip Prakash.

- [16] Text book P.N.Rao, Manufacturing Technology (Tata McGraw Hill)

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing die design and manufacturing in HPDC. The findings offer a clear, data-driven path toward improving quality, reducing defects, and optimizing production by adopting a systematic, integrated workflow.

STI C&D is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the problem discussed in this white paper aligns with your research goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your research.

Expert Q&A:

Q1: What are the primary objectives when designing an HPDC die?

- A1: According to the paper's "Objectives" (Section 1.1), the primary goals are to determine the die layout based on the process, identify key design parameters and potential defects, decide on the optimal gate/runner system, and ultimately design a die that produces a high-quality, defect-free component.

Q2: What are some critical design guidelines to minimize defects and costs in die casting?

- A2: Section 3.2, "Guidelines for Design," provides a detailed list. Key guidelines include: keeping wall sections thin and uniform, using gradual transitions to avoid stress concentration, providing sufficient draft for easy part removal, using fillets at inside corners, and designing cores for easy withdrawal to avoid complicated die construction. Following these helps minimize material usage, flash, and post-processing costs.

Q3: What is the recommended process flow for designing and manufacturing a die casting tool?

- A3: The paper outlines a structured workflow in the "Process Flow (Flow Chart)" on page 5. The key stages are: 1. Design Input, 2. Assembly Drawing & BOM (Stage 1), 3. Design Review by multiple departments, 4. Design Verification, 5. Design Output (Final Tool Drawing), 6. Design Validation (using QC and trial reports), and 7. Managing Design Changes. This systematic flow ensures multiple checkpoints for quality and accuracy.

Q4: Why is material planning so important in the die casting process?

- A4: As detailed in Section 4, "MATERIAL PLANNING," its importance is multifaceted. The objectives listed in Section 4.1 include reducing material cost, ensuring a uniform flow of material for production, controlling inventory, and ensuring the right quality at the right price. Effective material planning, including a detailed Bill of Materials, is essential for cost reduction and the efficient handling of materials at all stages.

Q5: How does this paper suggest improving quality and reducing defects based on the literature?

- A5: The "LITERATURE REVIEW" (Section 2) synthesizes several key strategies. For example, it cites Bharat Sharma [1], who found that controlling injection metal temperature is crucial and can reduce rejection rates that are often as high as 15-20%. It also references Nouri-Borujerdi & Goldak [2], who showed that proper air vent design is critical to prevent porosity. The overall message is that quality improvement comes from a combination of good design (e.g., vents, gates) and tight process parameter control (e.g., temperature, speed).

Copyright

- This material is an analysis of the paper "Review Paper on design of Single Cavity Pressure Die Casting Die Using CAD Tool & Its Manufacturing by HPDC Technology" by Rakesh Bandane and Vaibhav Bankar.

- Source of the paper: https://www.joirem.com/Vol.10,Issue04,July-2022/JIR-V10I04-01.pdf

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 STI C&D. All rights reserved.