A Deep Dive into the Manufacturing, Strengthening, and Application of Advanced Aluminum Composites

This technical brief is based on the academic paper "Review on Nano Particle Reinforced Aluminum Metal Matrix Composites" by Endalkachew Mosisa, V. Yu Bazhin, and Sergey Savchenkov, published in the Research Journal of Applied Sciences (2016). It is summarized and analyzed for industry professionals by the experts at STI C&D.

Keywords

- Primary Keyword: Nano Particle Reinforced Aluminum Metal Matrix Composites (AMMCs)

- Secondary Keywords: Aluminum Metal Matrix Composites, Strengthening Mechanisms in Composites, Stir Casting Process, Squeeze Casting, Powder Metallurgy, Wettability in MMCs, Aerospace and Automotive Materials

Executive Summary

- The Challenge: Standard lightweight alloys like aluminum often lack the high strength-to-weight ratio, hardness, and wear resistance required for demanding aerospace and automotive applications.

- The Method: This paper reviews the state-of-the-art in producing nano-particle reinforced aluminum metal matrix composites (AMMCs), focusing on manufacturing processes, strengthening mechanisms, and the critical factor of particle wettability.

- The Key Breakthrough: The mechanical properties of AMMCs are not determined by a single factor but by a combination of the manufacturing route (e.g., stir casting, squeeze casting, powder metallurgy), the successful integration of reinforcement particles (wettability), and a synergistic effect of multiple strengthening mechanisms (Orowan, Hall-Petch, thermal mismatch, etc.).

- The Bottom Line: By carefully selecting the processing method and reinforcement phase, engineers can design AMMCs with a superior and tailored combination of physical and mechanical properties unattainable with monolithic alloys.

The Challenge: Why This Research Matters for Industry Professionals

Since the invention of the airplane, the demand for materials that are both lightweight and exceptionally strong has been a primary driver of innovation. While monolithic aluminum, magnesium, and titanium alloys are light, they often fall short in providing the necessary strength, hardness, and wear resistance for next-generation components. This inadequacy led to the development of Metal Matrix Composites (MMCs).

As detailed in the paper, introducing a hard ceramic reinforcement phase (like Silicon Carbide or Aluminum Oxide) into a metal matrix creates a composite with an attractive blend of properties. Specifically, nano-particle reinforced Aluminum Metal Matrix Composites (AMMCs) are gaining significant attention for their potential in engineering applications due to their superior strength-to-weight ratio and fatigue resistance. However, successfully manufacturing these advanced materials presents significant challenges, including ensuring a uniform distribution of reinforcement particles, achieving good bonding between the particle and the matrix, and controlling interfacial reactions. This review consolidates critical knowledge on overcoming these hurdles.

The Approach: Unpacking the Methodology

This paper provides a comprehensive review of the primary techniques and underlying principles for fabricating high-performance AMMCs. The authors synthesize findings from numerous studies to create a clear picture of the critical factors involved. The review is structured around three core areas:

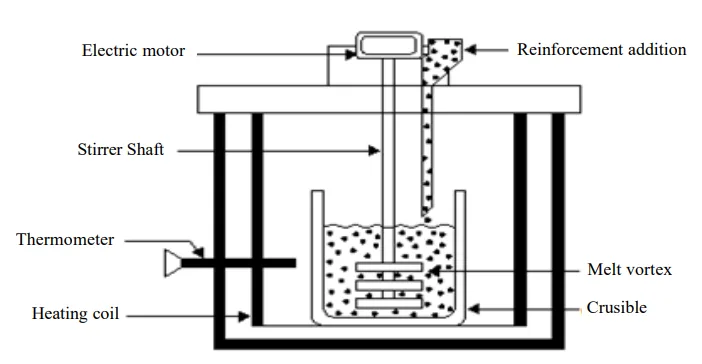

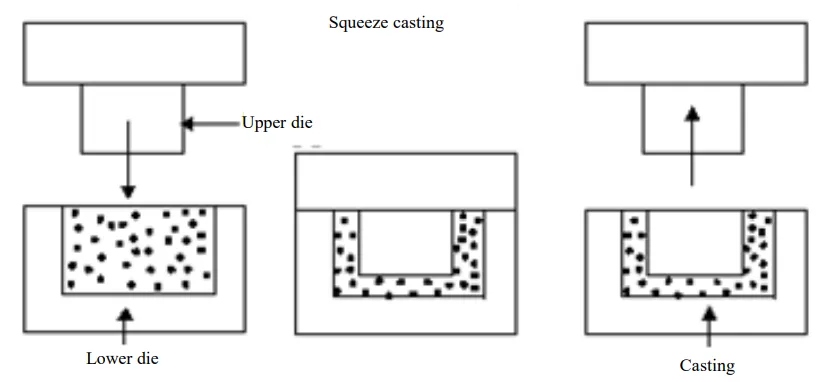

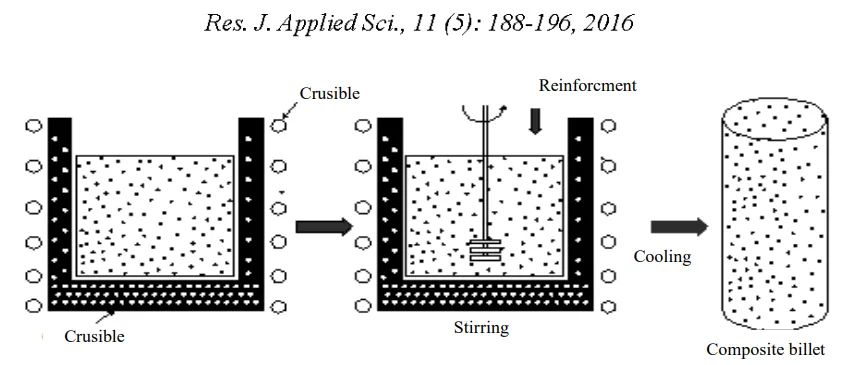

- Manufacturing Processes: The paper analyzes the most common liquid-state and solid-state processing techniques, including stir casting, squeeze casting, compo-casting, and powder metallurgy. It highlights the advantages and disadvantages of each method, as shown in Figures 1, 2, 3, and 4.

- Wettability: A major challenge in liquid-state processing is the poor wettability of ceramic particles by molten aluminum. The study explains the physics of wettability using the contact angle concept (Figure 5) and discusses methods to improve it, such as particle coatings and the use of alloying elements like magnesium.

- Strengthening Mechanisms: The paper breaks down the complex ways nanoparticles enhance the mechanical properties of the aluminum matrix. It details several key mechanisms, including Orowan strengthening, Hall-Petch strengthening, thermal mismatch strengthening, and load transfer, providing the governing equations for each.

The Breakthrough: Key Findings & Data

The review highlights that the final properties of an AMMC are a direct result of carefully controlled processing and the interplay of several microstructural phenomena.

- Finding 1: Processing Route is Paramount: The choice of manufacturing method directly impacts the final microstructure and defect levels.

- Stir Casting (Figure 1) is a simple, flexible, and commercially viable route but can suffer from non-uniform particle distribution and poor wettability.

- Squeeze Casting (Figure 2) applies high pressure during solidification, yielding a pore-free, fine-grain casting with properties approaching those of wrought products.

- Powder Metallurgy (Figure 4) offers excellent control over composition and enables the creation of complex alloy combinations, but it involves higher tooling costs and can have limitations on part geometry.

- Finding 2: Wettability is a Non-Negotiable Prerequisite: For strong interfacial bonding, the liquid aluminum matrix must effectively "wet" the solid reinforcement particles. The paper explains that a low contact angle (θ < 90°) signifies good wetting (Figure 5). Poor wettability leads to particle rejection and clumping. Adding magnesium to the melt is identified as an effective strategy to improve wettability with SiC particles by reducing the SiO₂ layer on the particle surface.

- Finding 3: Strength is a Multi-faceted Enhancement: The remarkable increase in strength in AMMCs is not from a single source but from the cumulative effect of several mechanisms:

- Orowan Strengthening: Hard, non-shearable nanoparticles act as obstacles, forcing dislocations to bow around them, which requires higher stress (Eq. 4).

- Hall-Petch Strengthening: Nanoparticles can act as grain refiners. A smaller grain size creates more grain boundaries, which impede dislocation motion and increase strength (Eq. 7).

- Thermal Mismatch Strengthening: A significant difference in the coefficient of thermal expansion between the aluminum matrix and ceramic particles generates a high density of dislocations near the particles during cooling, increasing strength (Eq. 8).

- Load Transfer: The stiff, strong reinforcement particles carry a portion of the applied load, effectively shielding the softer matrix and increasing the overall strength of the composite (Eq. 11).

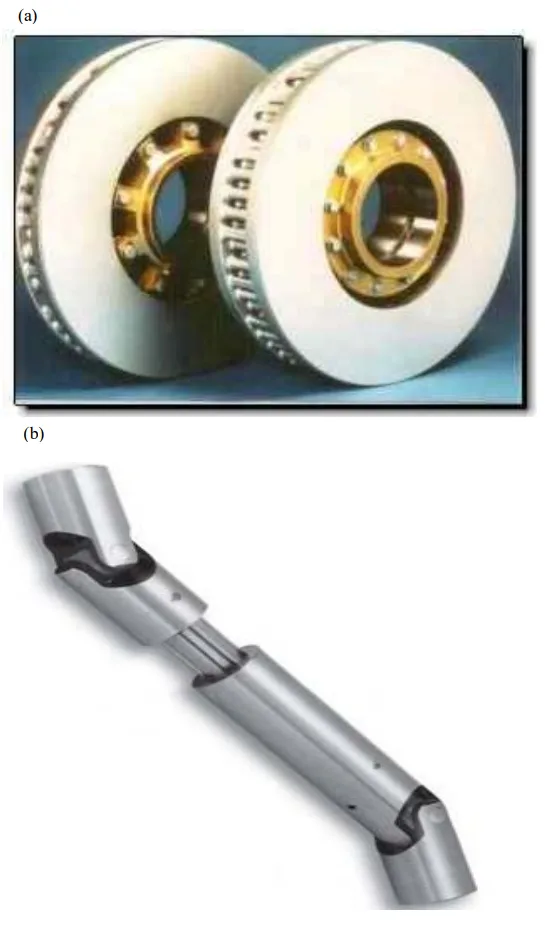

- Finding 4: Broad Application Potential: The superior properties of AMMCs make them suitable for a wide range of high-performance applications, including brake systems for trains, automotive drive shafts (Figure 6), aerospace components (fan exit guide vanes), and electronic packaging.

Practical Implications for Your Operations

The insights from this review can be directly applied to improve the design, manufacturing, and performance of components in various industries.

- For Process Engineers: The paper underscores that there is no one-size-fits-all manufacturing process. The findings suggest that for components requiring minimal porosity and maximum mechanical properties, Squeeze Casting is a superior choice over conventional Stir Casting. The review also highlights critical process parameters for stir casting, such as stirring rate, time, and temperature, which must be optimized to ensure homogeneous particle distribution.

- For Materials Scientists & R&D: The detailed explanation of strengthening mechanisms provides a clear roadmap for material design. This research suggests that to maximize strength, a strategy combining grain refinement (Hall-Petch) with a uniform dispersion of fine nanoparticles (Orowan) is highly effective. Furthermore, understanding the role of magnesium in improving wettability is a key takeaway for developing robust liquid-state processing routes.

- For Design Engineers: This study confirms that AMMCs offer a viable path to creating lighter and stronger components. The data implies that replacing monolithic alloys with AMMCs in applications like drive shafts, brake systems, and suspension arms (Figure 6) can lead to significant weight savings and performance improvements, which is critical in the automotive and aerospace sectors.

Paper Details

Review on Nano Particle Reinforced Aluminum Metal Matrix Composites

1. Overview:

- Title: Review on Nano Particle Reinforced Aluminum Metal Matrix Composites

- Author: Endalkachew Mosisa, V. Yu Bazhin and Sergey Savchenkov

- Year of publication: 2016

- Journal/academic society of publication: Research Journal of Applied Sciences

- Keywords: Metal matrix, reinforcement particle, metal matrix composites, strengthening mechanism, methods

2. Abstract:

The need for lightweight, high strength materials has been recognized since the invention of the airplane. The inadequacy of lightweight metals and alloys in providing high strength to weight ratio led to the development of Metal Matrix Composites (MMCs). The introduction of a ceramic material into the matrix produces a composite material that results in an attractive combination of physical and mechanical properties which cannot be obtained with monolithic alloys. Nowadays different types of metals matrix predominately Al, Mg and Cu have been employed for the production of composite reinforced by nano sized ceramic particle such as carbides, nitrides and oxides. Wide range of property combinations also can be obtained by appropriate selection of metal matrix material, processing methods and the reinforcement phase. Comparatively among all MMCs, aluminium based particle reinforced MMCs have a large potential for a number of engineering applications, due to the fact that nano sized particle reinforced Aluminium Metal Matrix Composite (AMMCs) possess superior high strength to weight ratio, high hardness, fatigue strength and wear resistance. Hence, strengthening mechanisms and property improvement of aluminium based metal matrix composite have attracted the attention of researchers. This work aims to review the most popular processing methods, strengthening mechanisms and wettability of nano particle reinforced aluminium MMCs.

3. Introduction:

In a metal matrix composite, three features determine its characteristics: the matrix, the reinforcement, and the interface. The properties of the continuous matrix phase are improved by introducing a hard secondary reinforcement phase (e.g., whiskers, particles). The goal is to produce a composite whose properties are superior to those of monolithic lightweight alloys. The paper reviews the processing methods, strengthening mechanisms, and wettability of nano-particle reinforced aluminum MMCs, which have gained extensive application in automotive and aerospace industries.

4. Summary of the study:

Background of the research topic:

The research is grounded in the persistent engineering need for materials that are both lightweight and strong. Monolithic alloys often cannot meet these dual requirements, which has driven the development of Metal Matrix Composites (MMCs), particularly aluminum-based composites (AMMCs) reinforced with ceramic nanoparticles.

Status of previous research:

Previous research has established various manufacturing techniques for MMCs, broadly categorized into liquid-state and solid-state processing. Studies have identified key challenges, such as achieving homogeneous particle distribution, ensuring good wettability between the matrix and reinforcement, and understanding the complex interplay of strengthening mechanisms that give these composites their enhanced properties.

Purpose of the study:

This work aims to review and consolidate the existing knowledge on the most popular processing methods (e.g., stir casting, squeeze casting, powder metallurgy), the critical strengthening mechanisms (e.g., Orowan, Hall-Petch), and the issue of wettability for nano-particle reinforced aluminum MMCs.

Core study:

The core of the study is a comprehensive review that examines:

- Aluminum Alloys and Reinforcements: Classifies the types of aluminum alloys and common reinforcement particles (SiC, Al₂O₃, B₄C).

- Manufacturing Processes: Details liquid-phase processes (stir casting, squeeze casting, compo-casting) and solid-phase processes (powder metallurgy), outlining their procedures, advantages, and disadvantages.

- Wettability: Explains the concept of wettability and its importance for creating a strong interfacial bond, discussing methods for its improvement.

- Strengthening Mechanisms: Analyzes the primary mechanisms responsible for the enhanced mechanical properties of AMMCs, including Orowan, Hall-Petch, thermal mismatch, and load transfer strengthening.

- Applications: Lists current and potential applications in industries like automotive, aerospace, and electronics.

5. Research Methodology

Research Design:

As a review paper, the research design involves the systematic collection, synthesis, and analysis of existing academic literature and research findings related to nano-particle reinforced aluminum metal matrix composites.

Data Collection and Analysis Methods:

The authors collected data from a wide range of published studies. The analysis involves comparing different manufacturing techniques, explaining the theoretical basis for various strengthening mechanisms with their corresponding mathematical models, and summarizing the consensus on key challenges like wettability and their solutions.

Research Topics and Scope:

The scope is focused on aluminum metal matrix composites reinforced with nano-sized particles. The key topics covered are:

- Manufacturing processes.

- Reinforcement particles and their interaction with the matrix.

- Wettability phenomena.

- Strengthening mechanisms.

- Current and potential applications.

6. Key Results:

Key Results:

The review concludes that the superior properties of AMMCs are achieved through careful control of processing and leveraging multiple strengthening effects. Key results include:

- Liquid-state processes like squeeze casting produce high-integrity, pore-free parts, while stir casting is a more economical but technically challenging route.

- Solid-state processing via powder metallurgy allows for unique material combinations but at a higher cost.

- Wettability is a critical barrier in liquid processing that can be overcome by adding active elements like Mg or by pre-treating the reinforcement particles.

- The overall strength of the composite is a sum of contributions from several mechanisms, including dislocation impediment (Orowan), grain refinement (Hall-Petch), and internal stress generation (thermal mismatch).

- The enhanced properties of AMMCs have led to their adoption in demanding applications like automotive brake systems, drive shafts, and aerospace structural components.

Figure Name List:

- Fig. 1: Stir casting process

- Fig. 2: Squeeze casting

- Fig. 3: Compo-casting process

- Fig. 4: Powder metallurgy processes

- Fig. 5: Interaction of liquid droplet with solid substrate; a) partially wetting; b) completely wetting and c) completely non-wetting

- Fig. 6: Some potential applications of AMMCs; a) brake systems of trains and b) drive shafts

7. Conclusion:

The current review reveals that extensive work has been reported to improve the properties of aluminium based MMCs reinforced with various ceramic particle materials such as: Al₂O₃, SiC and B₄C. The selection of appropriate processing route and process parameters during the reinforcement plays vital role for better achievement of mechanical properties of AMMCs. Wettability between the matrix and reinforcement improved by increasing the surface energies of the solid, decreasing the surface tension of the matrix alloy and decreasing of the solid/liquid interfacial energy. The strength and ductility of particle reinforced aluminium metal matrix composite enhanced by hall-petch, orowan, particle shearing and thermal mismatch strengthening mechanisms. Among the various types of MMCs, particle reinforced AMMCs constitutes largest quantity of composites produced and utilized in different engineering applications such as cylinder block liners, vehicle drive shafts, automotive pistons, brake systems of trains, bicycle frames, rotating blade sleeves for helicopters, etc.

8. References:

- Chawla, N. and Y.L. Shen, 2001. Mechanical behavior of particle reinforced metal matrix composites. Adv. Eng. Mater., 3: 357-370.

- Dieter, G.E., 1988. Mechanical Metallurgy. 1st Edn., McGraw-Hill, New York, ISBN: 0071004068.

- Ellis, M.B.D., 1996. Joining of Al-based metal matrix composites-a review. Mater. Manuf. Process., 11: 45-66.

- Flemings, M.C., 1991. Behavior of metal alloys in the semisolid state. Metall. Trans. A., 22: 957-981.

- Ham, R.K., 1969. Strengthening by ordered precipitates. Proceedings of the 3rd Bolton Landing Conference on Ordered Alloys Structural Applications and Physical Metallurgy, September 8-10, 1969, Lake George, New York, pp: 365-374.

- Hashim, J., L. Looney and M.S.J. Hashmi, 2001. The wettability of SiC particles by molten aluminium alloy. J. Mater. Process. Technol., 119: 324-328.

- Jayalakshmi, S. and M. Gupta, 2015. Metallic Amorphous Alloy Reinforcements in Light Metal Matrices. Springer International Publishing, New York, ISBN: 978-3-319-15015-4, Pages: 112.

- Kainer, K.U., 2006. Metal Matrix Composites: Custom-made Materials for Automotive and Aerospace Engineering. Wiley, New York, ISBN: 978-3-527-31360-0, Pages: 330.

- Lloyd, D.J., H. Lagace, A. McLeod and P.L. Morris, 1989. Microstructural aspects of aluminium-silicon carbide particulate composites produced by a casting method. Mater. Sci. Eng.: A, 107: 73-80.

- Modi, O.P., A.H. Yegneswaran, R. Asthana and P.K. Rohatgi, 1988. Thermomechanical processing of aluminium-based particulate composites. J. Mater. Sci., 23: 83-92.

- Moon, J., S. Kim, J.I. Jang, J. Lee and C. Lee, 2008. Orowan strengthening effect on the nanoindentation hardness of the ferrite matrix in microalloyed steels. Mater. Sci. Eng., 487A: 552-557.

- Murty, S.V.S.N., B.N. Rao and B.P. Kashyap, 2003. On the hot working characteristics of 6061 Al-SiC and 6061-Al₂O₃particulate reinforced metal matrix composites. Compos. Sci. Technol., 63: 119-135.

- Nardone, V.C. and K.M. Prewo, 1986. On the strength of discontinuous silicon carbide reinforced aluminum composites. Scripta Metallurgica, 20: 43-48.

- Sanaty-Zadeh, A., 2012. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall-Petch effect. Mater. Sci. Eng.: A, 531: 112-118.

- Shankar, M.C.G., P.K. Jayashree, R. Shetty, A. Kinia and S.S. Sharma, 2013. Individual and combined effect of reinforcements on stir cast aluminium metal matrix composites-a review. Int. J. Curr. Eng. Technol., 3: 922-934.

- Skoglund, P., M. Kejzelman and I. Hauer, 2002. High Density PM Components by High Velocity Compaction. In: Advances in Powder Metallurgy and Particulate Materials, Arnhold, V. and C.L. Chu (Eds.). Metal Powder Industries Federation, USA., pp: 85-95.

- Yang, L.J., 2003. The effect of casting temperature on the properties of squeeze cast aluminium and zinc alloys. J. Mater. Process. Technol., 140: 391-396.

- Zhang, H., K.T. Ramesh and E.S.C. Chin, 2004. High strain rate response of aluminum 6092/B₄C composites. Mater. Sci. Eng.: A, 384: 26-34.

- Zhang, H., M.W. Chen, K.T. Ramesh, J. Ye, J.M. Schoenung and E.S.C. Chin, 2006. Tensile behavior and dynamic failure of aluminum 6092/B₄C composites. Mater. Sci. Eng.: A, 433: 70-82.

- Zhang, Z. and D.L. Chen, 2008. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites. Mater. Sci. Eng.: A, 483: 148-152.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the performance of aluminum composites. The findings offer a clear, data-driven path toward improving material properties, reducing defects, and optimizing production for high-value applications.

STI C&D is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the challenges discussed in this paper align with your goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your components.

Expert Q&A:

- Q1: What are the main manufacturing processes for aluminum metal matrix composites (AMMCs)? A1: The paper categorizes the processes into two main groups: liquid-state and solid-state. The most popular liquid-state processes reviewed are stir casting, squeeze casting, and compo-casting. The primary solid-state process discussed is powder metallurgy. Each has distinct advantages, with squeeze casting offering excellent part integrity and powder metallurgy providing compositional flexibility, as detailed in the "MANUFACTURING PROCESSES OF MMCS" section.

- Q2: Why is "wettability" so important in producing AMMCs, and how can it be improved? A2: Wettability is the ability of the liquid aluminum matrix to spread over and bond with the solid reinforcement particles. As explained in the "WETTABILITY" section, poor wettability (a high contact angle, see Figure 5) prevents the formation of a strong interface, leading to particle clumping and weak mechanical properties. The paper states that wettability can be improved by coating the particles (e.g., with Ni or Cu) or by adding active elements like magnesium (Mg) to the molten aluminum, which helps reduce the oxide layer on particles like SiC.

- Q3: What are the primary ways that nanoparticles strengthen the aluminum matrix? A3: The paper outlines several key strengthening mechanisms in the "STRENGTHENING MECHANISMS IN PARTICLE REINFORCED ALUMINUM ALLOYS" section. The primary mechanisms are: 1) Orowan strengthening, where particles block dislocation movement; 2) Hall-Petch strengthening, where particles refine the grain structure; 3) Thermal mismatch strengthening, where differences in thermal expansion create a higher dislocation density; and 4) Load transfer, where the strong particles carry a portion of the applied stress.

- Q4: What is the difference between large particle composites and dispersion-strengthened composites? A4: According to the "REINFORCEMENT PARTICLE FOR ALUMINUM ALLOYS" section, the distinction is based on the strengthening mechanism. In large particle composites, the particle-matrix interaction is not on an atomic level, and the properties are a bulk average of the constituents, predictable by the rule of mixtures (Eq. 1 and 2). In dispersion-strengthened composites, the particles are much smaller (typically < 0.1 µm) and they increase strength by blocking the movement of dislocations within the matrix.

- Q5: What are some key applications for these advanced composites? A5: The paper lists numerous applications in the "APPLICATIONS OF AL METAL MATRIX COMPOSITES" and "CONCLUSION" sections. Due to their high strength-to-weight ratio and wear resistance, they are used in the automotive industry for brake systems, drive shafts, and pistons; in aerospace for fan exit guide vanes and structural components; and in electronics for microprocessor lids and heat sinks. Figure 6 visually depicts their use in train brake systems and drive shafts.

Copyright

- This material is an analysis of the paper "Review on Nano Particle Reinforced Aluminum Metal Matrix Composites" by Endalkachew Mosisa, V. Yu Bazhin, and Sergey Savchenkov.

- Source of the paper: https://www.researchgate.net/publication/306208052

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 STI C&D. All rights reserved.