Extending Die Life and Enhancing Performance with Advanced Laser Cladding Techniques

This technical brief is based on the academic paper "Renovation of moulds for high-pressure casting of aluminium by laser cladding" by Janette Brezinová and Miroslav Džupon, published in INTERNATIONAL SCIENTIFIC JOURNAL "MACHINES. TECHNOLOGIES. MATERIALS" (2023). It is summarized and analyzed for HPDC professionals by the experts at STI C&D.

Keywords

- Primary Keyword: Laser Cladding for HPDC Mould Repair

- Secondary Keywords: High-Pressure Die Casting (HPDC), Mould Renovation, Dievar Steel (1.2343), Microhardness of Welds, Surface Wettability, Contact Angle Measurement, Aluminum Die Casting

Executive Summary

- The Challenge: Moulds used in high-pressure die casting (HPDC) of aluminum alloys are subjected to extreme thermal and mechanical stresses, leading to wear, cracking, and a shortened operational life.

- The Method: Researchers employed laser cladding with a TruDisk 4002 solid-state disk laser to repair and refurbish mould parts made from 1.2343 (Dievar) steel. Three different additive wire materials were evaluated: 1.2343 (Dievar), 1.6356 (Dratec), and 1.6356 (UTPA 702).

- The Key Breakthrough: The study successfully demonstrated that laser cladding can produce high-quality, defect-free repair welds. The choice of additive material significantly impacts the final properties, with the Dievar clad layer achieving a surface microhardness of up to 700 HV0.5.

- The Bottom Line: Laser cladding is a highly effective and viable technology for renovating HPDC moulds, offering a data-driven path to restoring and potentially enhancing the performance and lifespan of critical tooling.

The Challenge: Why This Research Matters for HPDC Professionals

In the demanding world of high-pressure aluminum die casting, the mould is the heart of the operation. However, it's also the component most susceptible to failure. The process involves injecting molten aluminum at temperatures around 700 °C into a preheated mould (approx. 400 °C). This massive and rapid temperature gradient, combined with high injection pressures and mechanical stresses, inevitably leads to degradation mechanisms.

As shown in the paper, these effects cause thermal fatigue, resulting in the initiation and propagation of cracks on the mould surface (Fig. 1). This wear not only compromises the quality of the cast parts but also leads to costly downtime for mould repair or replacement. Finding a reliable and effective method to refurbish these worn moulds is crucial for maintaining productivity and profitability. This research directly addresses this challenge by investigating laser cladding as a high-precision renovation technique.

The Approach: Unpacking the Methodology

To find a robust solution for mould repair, the researchers conducted a systematic investigation using state-of-the-art laser technology.

The experimental setup involved preparing welds on a base material of grade 1.2343 (Dievar) steel, a common tool steel for HPDC moulds, which was refined to a hardness of 44-48 HRC. A TruDisk 4002 solid-state disk laser was used for the surfacing process.

Three different filler materials were tested to evaluate their performance:

- Mat.No.1.2343 (Dievar): A matching material to the mould base.

- Mat.No.1.6356 (Dratec): A nickel-based alloy.

- Mat.No.1.6356 (UTPA 702): Another nickel-based alloy with a slightly different composition.

The quality of the resulting clad layers was meticulously analyzed using light and scanning electron microscopy (SEM), EDX microanalysis for chemical composition, and Vickers microhardness testing. Furthermore, the study explored the interaction of a release agent (SafetyLube 7815) with laser-textured surfaces by measuring the contact angle to simulate real-world lubrication performance.

The Breakthrough: Key Findings & Data

The investigation yielded clear, data-backed results on the effectiveness of laser cladding and the performance of different additive materials.

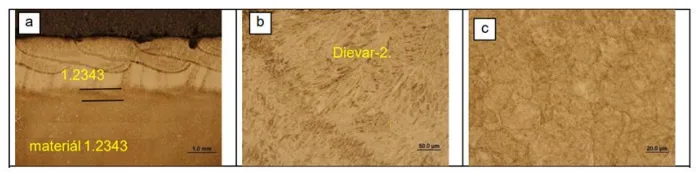

- Finding 1: High-Quality, Defect-Free Welds: Across all three additive materials, the laser cladding process produced welds without integrity defects or anomalies. The heat-affected zone (HAZ) was well-defined, with a gradual transition from the base material to the clad layer (Fig. 2, Fig. 3, Fig. 4).

- Finding 2: Material-Dependent Hardness Profiles: The choice of filler material had a direct and significant impact on the microhardness of the repaired surface.

- The 1.2343-Dievar clad exhibited the highest surface hardness, starting at 600 HV0.5 and peaking around 700 HV0.5 at a depth of 0.8 mm, making it exceptionally wear-resistant at the surface (Fig. 8a).

- The 1.6356-Dratec and 1.6356-UTPA 702 clads showed a different profile. Their surface hardness was lower (approx. 400 HV0.5), but it increased to 600-700 HV0.5 at a deeper level (1.6-2.0 mm), suggesting a tougher, more ductile surface with a hard sub-layer (Fig. 8b, 8c).

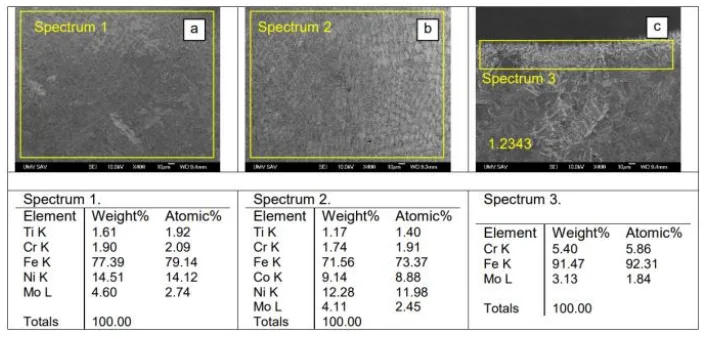

- Finding 3: Alloy Distribution and Microstructure: EDX analysis revealed uniform distribution of alloys in the 1.2343-Dievar deposit (Fig. 5). In the nickel-based UTPA 702 and Dratec deposits, some variation in cobalt and nickel concentrations was observed between the first and second clad layers (Fig. 6, Fig. 7).

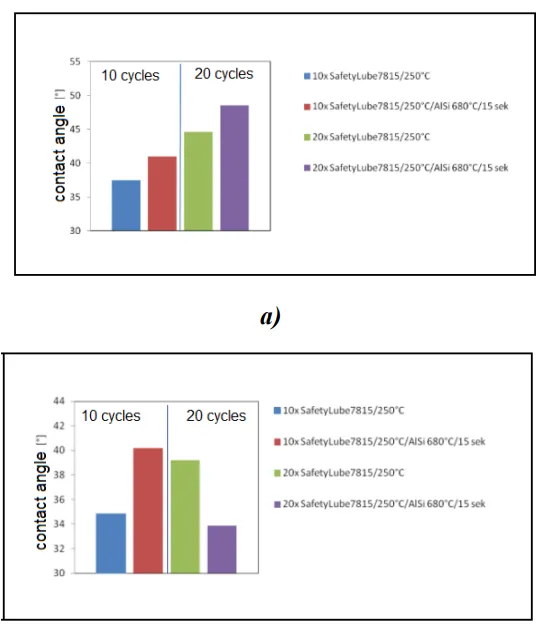

- Finding 4: Enhanced Lubricant Interaction: The study on surface wettability showed that laser texturing can influence the behavior of release agents. The contact angle of SafetyLube 7815 was measured after repeated spray cycles and immersion in molten aluminum, providing valuable data on how surface modification can improve lubricant retention during the initial run-in phase of a new or refurbished mould (Fig. 9).

Practical Implications for Your HPDC Operations

The findings from this paper offer tangible benefits and strategic considerations for manufacturing and maintenance teams in the die-casting industry.

- For Process Engineers: This research confirms that laser cladding is a reliable repair method. The choice of filler material can be tailored to specific needs. For applications requiring maximum surface wear resistance, a Dievar-on-Dievar clad is ideal. For situations where surface toughness is more critical, a nickel-based alloy like Dratec or UTPA 702 could be more suitable.

- For Quality Control: The detailed microhardness profiles (Fig. 8) provide a clear benchmark for validating the quality of a laser-clad repair. This data allows for precise quality control, ensuring that refurbished moulds meet the required specifications for hardness and durability before returning to production.

- For Die Design and Maintenance: The study on surface texturing and wettability (Fig. 9) opens the door to advanced mould surface engineering. By incorporating laser texturing into the refurbishment process, it may be possible to improve the adhesion and effectiveness of release agents, potentially reducing sticking issues, improving part release, and extending the time between mould cleanings.

Paper Details

Renovation of moulds for high-pressure casting of aluminium by laser cladding

1. Overview:

- Title: Renovation of moulds for high-pressure casting of aluminium by laser cladding

- Author: Janette Brezinová, Miroslav Džupon

- Year of publication: 2023

- Journal/academic society of publication: INTERNATIONAL SCIENTIFIC JOURNAL "MACHINES. TECHNOLOGIES. MATERIALS"

- Keywords: LASER CLADDING, DIE CASTING, CASTING DIES, ALUMINIUM, CONTACT ANGLE

2. Abstract:

The paper presents the results of an investigation focused on the analysis of the wear of moulds for high-pressure casting with Al alloy. In order to repair and refurbish the mould parts of moulds for high-pressure casting of aluminium alloys, samples of experimental welds were prepared on the base material of grade 1.2343 (Dievar) of dimensions 150x130x30 mm refined to the hardness value of 44-48 HRC. A TruDisk 4002 solid-state disk laser with BEO D70 focusing optics was used for surfacing. Mat.No.1.2343 (Dievar), Mat.No.1.6356 (Dratec) and Mat.No.1.6356 (UTPA 702 and NIFIL NiCu7/Dievar) wires were used as additional material. Light microscopy technique was used to inspect the microstructures on the cross-sections of the welds. Microhardness measurements were performed with a Vickers indenter at a load of 500 g and a mutual indentation distance of 0.4 mm between the indenter impressions.

3. Introduction:

High-pressure die casting is a critical manufacturing process for aluminum components in the automotive and aerospace industries. The process involves injecting molten aluminum (670-710 °C) at high speed and pressure into a mould. Before each cycle, a release agent is applied to prevent sticking. The mould itself is preheated to around 400 °C, but the contact with molten aluminum creates a significant temperature gradient, inducing compressive and tensile stresses. These thermal and mechanical stresses lead to degradation mechanisms and wear, as depicted in Fig. 1, necessitating refurbishment to extend the mould's life.

4. Summary of the study:

Background of the research topic:

Moulds for high-pressure aluminum die casting are subject to severe operating conditions, including high temperatures, thermal cycling, and mechanical stresses, which cause them to wear and fail over time. Refurbishment is a critical process to restore functionality and extend the service life of these expensive tools. Laser cladding is a promising technology for this application due to its precision and control over heat input.

Status of previous research:

The paper cites previous work [1-8] that establishes the context for using cladding and other surface modification techniques to improve the life of tooling. This study builds upon that foundation by specifically applying laser cladding with different filler materials for the renovation of HPDC moulds.

Purpose of the study:

The study aimed to investigate and compare the quality of repaired mould surfaces using laser cladding with three different additive materials. The primary goals were to analyze the resulting microstructure, measure the microhardness profiles, and evaluate the surface wettability with a release agent to determine the viability and effectiveness of this renovation technique.

Core study:

The core of the study involved creating experimental welds on 1.2343 Dievar steel plates using a TruDisk 4002 laser. Three filler wires—1.2343 (Dievar), 1.6356 (Dratec), and 1.6356 (UTPA 702)—were used with specific laser parameters. The resulting clads were sectioned and analyzed for microstructural integrity, chemical composition (via EDX), and microhardness. Additionally, the interaction between a commercial release agent and laser-textured surfaces was tested using contact angle measurements to simulate performance in a production environment.

5. Research Methodology

Research Design:

The experiment was designed to compare three different weld overlay materials on a standardized base material. Samples of 1.2343 (Dievar) steel (150x130x30 mm, 44-48 HRC) were used as the substrate. Laser cladding was performed using a TruDisk 4002 laser with BEO D70 optics.

Data Collection and Analysis Methods:

- Microscopy: Light microscopy and Scanning Electron Microscopy (SEM) were used to examine the cross-sections of the welds for defects, microstructure, and the heat-affected zone (HAZ).

- EDX Microanalysis: Semi-quantitative Energy-Dispersive X-ray Spectroscopy (EDX) was used to analyze the distribution of alloying elements within the clad layers and the HAZ.

- Microhardness Testing: A Vickers indenter with a 500 g load was used to measure microhardness profiles from the surface down into the base material, with indentations spaced 0.4 mm apart.

- Contact Angle Measurement: The wettability of laser-textured surfaces by a release agent (SafetyLube 7815) was tested to assess lubricant interaction after simulated operational cycles (heating and spraying).

Research Topics and Scope:

The research focused on the renovation of HPDC moulds for aluminum casting. The scope included:

- Application of laser cladding with three different filler materials.

- Characterization of the resulting weld's microstructure and integrity.

- Measurement of microhardness profiles of the clad layers.

- Verification of surface wettability with a release agent on textured surfaces.

6. Key Results:

Key Results:

The study found that all three additive materials produced sound, defect-free welds.

- Material 1.2343-Dievar: Resulted in a clad with a sorbitic microstructure and a maximum HAZ of 0.5 mm. It showed the highest surface hardness, reaching ~700 HV0.5 (Fig. 8a). EDX analysis confirmed a uniform distribution of alloys (Fig. 5).

- Material 1.6356-UTPA 702: Produced a clad with a casting microstructure and a 1.0 mm HAZ. The surface hardness was ~400 HV0.5, increasing to 600-700 HV0.5 at a depth of 1.6-2.0 mm (Fig. 8c). EDX showed no cobalt in the second clad layer (Fig. 6).

- Material 1.6356-Dratec: Also showed a casting microstructure and a 1.0 mm HAZ. The hardness profile was similar to UTPA 702 (Fig. 8b). EDX analysis indicated reduced cobalt and nickel concentrations in the second layer compared to the first (Fig. 7).

- Wettability Tests: Contact angle measurements on textured surfaces demonstrated the methodology for evaluating lubricant performance, showing changes after repeated spray cycles and immersion in molten aluminum (Fig. 9).

Figure Name List:

- Fig. 1 Initiation and propagation of cracks due to thermal gradient of the mould surface

- Fig. 2 Material 1.2343-Dievar, a) disposition; b) detail of the outline; c) background material

- Fig. 3 Material 1.6356 - UTPA 702, a) disposition; b) detail of HAZ and construction material; c) detail of HAZ

- Fig. 4 Material 1.6356 - Dratec, a) disposition; b) TOZ detail and melting zone; c) detail of HAZ

- Fig. 5 Microstructure of material 1.2343; a) 2nd layer of clad; b) 1st layer of clad; c) HAZ

- Fig. 6 Microstructure of material 1.6356-UTPA 702; a) 2nd layer of clad; b) 1st layer of clad; c) HAZ

- Fig. 7 Microstructure of material 1.6356-Dratec; a) 2nd layer of clad; b) 1st layer of clad; c) HAZ

- Fig. 8 Microhardness from surface, indentation distance 0,4 mm; a) material 1.2343 - Dievar; b) material 1.6356 - Dratec; c) material 1.6356 - UTP 702 A

- Fig. 9 Contact angle vs. number of spray cycles lubricant Safety Lube 7815. a) Surface Punch + texture random, b) Surface Dievar + laser random + duplex NaCRo4 coat

7. Conclusion:

The paper successfully demonstrates that laser cladding is a high-quality method for renovating moulds used in high-pressure aluminum casting. The welds produced with Dievar, Dratec, and UTPA702 filler materials showed high structural quality with uniform alloy distribution. The use of surface texturing was also shown to be a viable method for improving the lubrication of moulds, particularly during the critical run-in phase. The authors conclude that further research should focus on the high-temperature corrosion resistance of these welds in molten aluminum.

8. References:

- M. Sadeghian, M. Shamanian, A. Shafyei:. Materials & Design 60 (2014), pp. 678-684.

- L. Binglin, J. Y. Richard Liew, A. L. Hoang: Engineering Structures 200 (2019), pp. 256-263.

- A. Behera: Materials Today: Proceedings (2020), pp. 1-5.

- C. Zhu, J. Cheon, X. Tang, S. Na, F. Lu, H. Cui Effect of swing arc on molten pool behaviors in narrow-gap GMAW of 5083 Al-alloy J. Mater. Process. Technol., 259 (2018), pp. 243-258

- D. Chen, M. Chen, C. Wu Effects of phase difference on the behavior of arc and weld pool in tandem P-GMAW J. Mater. Process. Technol., 225 (2015), pp. 45-55

- K. Wu, T. Yin, N. Ding, M. Zeng, Z. Liang Effect of phase on the behavior of metal transfer in double-wire pulsed GMAW Int. J. Adv. Manuf. Technol., 97 (2018), pp. 3777-3789

- K. Wu, N. Ding, T. Yin, M. Zeng, Z. Liang Effects of single and double pulses on microstructure and mechanical properties of weld joints during high-power double-wire GMAW J. Manuf. Process., 35 (2018), pp. 728-734

- J. Chen, Y. Zhang, C. Wu, G. Padhy Suppression of undercut defects in high-speed GMAW through a compound magnetic field J. Mater. Process. Technol., 274 (2019), p. 116288

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing mould life and performance in HPDC. The findings offer a clear, data-driven path toward improving quality, reducing defects, and optimizing production through advanced renovation techniques.

STI C&D is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the problem discussed in this white paper aligns with your research goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your research.

Expert Q&A:

- Q1: Which laser cladding material is best for repairing a high-wear area on an HPDC mould?

- A: Based on the study, the 1.2343 (Dievar) filler material is the best choice for maximizing surface hardness. It achieved a microhardness of 600-700 HV0.5 directly at the surface, which is ideal for resisting abrasive wear. This is supported by the data in Figure 8a of the paper "Renovation of moulds for high-pressure casting of aluminium by laser cladding".

- Q2: How does the laser cladding process affect the original mould material?

- A: The process creates a Heat-Affected Zone (HAZ) in the base material adjacent to the weld. For the Dievar clad, the HAZ was minimal at 0.5 mm thick. For the Dratec and UTPA 702 clads, the HAZ was thicker at 1.0 mm. In all cases, the transition was gradual and the microstructure remained free of defects, indicating a well-controlled process.

- Q3: Can laser cladding improve the performance of mould release agents?

- A: Yes, the paper suggests it can. The research explored using laser texturing on the mould surface, which can alter its wettability. The contact angle measurements with SafetyLube 7815 (Figure 9) show that surface topography can be modified to improve lubricant retention, which is especially beneficial during the initial run-in cycles of a refurbished mould.

- Q4: What were the key laser parameters used for the successful cladding?

- A: The paper specifies the parameters for each material. For the Dievar additive, the laser power was 1500W with a welding speed of 6 mm/s and a feed rate of 10 mm/s. For the Dratec additive, the power was 1600W with the same speeds. These parameters, detailed in the "Experimental methodology and material" section, were proven to create high-quality, defect-free welds.

- Q5: Were the chemical compositions of the clad layers consistent?

- A: For the 1.2343-Dievar deposit, the distribution of alloys was uniform throughout the clad layers (Figure 5). For the nickel-based 1.6356-UTPA 702 and 1.6356-Dratec deposits, there were some variations, with the second layer showing no cobalt (UTPA 702) or reduced cobalt and nickel (Dratec) compared to the first layer (Figures 6 and 7). This highlights the importance of material selection and process control.

Copyright

- This material is an analysis of the paper "Renovation of moulds for high-pressure casting of aluminium by laser cladding" by Janette Brezinová and Miroslav Džupon.

- Source of the paper: WEB ISSN 1314-507X; PRINT ISSN 1313-0226

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 STI C&D. All rights reserved.