This technical brief is based on the academic paper "Overview on aluminium alloys as sinks for end-of-life vehicle scrap" by Stefan Pogatscher and Sebastian Samberger, published in IOP Conference Series: Materials Science and Engineering (2024). It is summarized and analyzed for HPDC professionals by the experts at CASTMAN.

Executive Summary

- The Challenge: The increasing use of recycled aluminum from sources like end-of-life vehicles (ELVs) introduces impurities that form brittle intermetallic phases (IMPs), which traditionally degrade the metal's mechanical properties.

- The Method: This research reviews advanced metallurgical strategies that go beyond simple impurity removal. It focuses on manipulating these "detrimental" IMPs through controlled solidification, thermomechanical processing, and strategic alloy design.

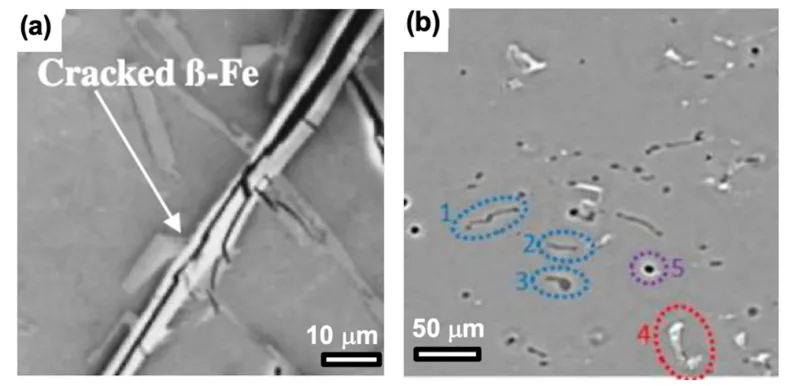

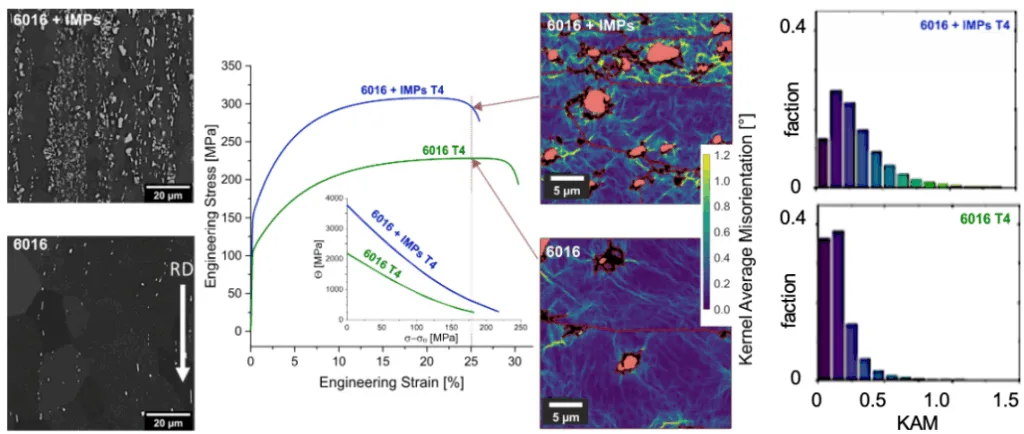

- The Key Breakthrough: The paper demonstrates that by creating "heterostructured alloys," the supposedly harmful IMPs can be transformed into assets. These phases can be used to create unique microstructures that significantly enhance both strength and ductility, a combination previously unattainable in conventional alloys.

- The Bottom Line: This work challenges the long-held belief that purity equals performance. It provides a scientific basis for "upcycling" low-value mixed aluminum scrap into high-performance, next-generation materials, paving the way for a more sustainable and circular economy.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, engineers have operated under a fundamental metallurgical principle: the higher the purity of a metal, the better its performance. In aluminum alloys, impurities like iron (Fe) are particularly problematic. They have low solubility and tend to form brittle, needle-like intermetallic phases (IMPs) that act as crack initiation sites, reducing ductility and fracture toughness.. As the manufacturing world, especially the automotive industry, pushes towards greater sustainability, the reliance on recycled aluminum scrap from ELVs is skyrocketing..

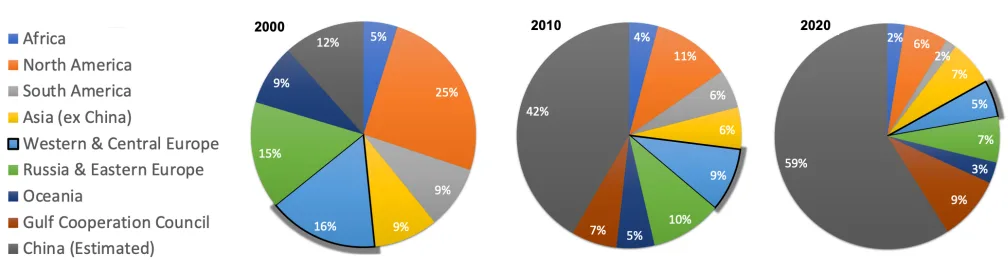

This presents a significant hurdle. ELV scrap is a complex mix of various wrought and cast alloys, leading to an unavoidable accumulation of impurities.. Furthermore, the rise of electric vehicles is projected to decrease the demand for cast aluminum engine blocks, which have historically been the primary "sink" for lower-quality scrap.. This situation creates a looming challenge: an excess of mixed, impure aluminum scrap with no clear high-value application. The traditional solution—diluting the scrap with high-purity primary aluminum—is not only costly but also environmentally unsustainable, as primary production consumes about 2% of the world's total energy.. This research directly confronts this industry-wide problem by asking a revolutionary question: What if we could turn these impurities from a liability into an asset?

The Approach: Unpacking the Methodology

The paper provides a comprehensive overview of both established and cutting-edge techniques for managing impurities in aluminum alloys. The research methodology is a synthesis of existing literature and new experimental concepts, focusing on how to control and leverage IMPs rather than simply avoiding them.

The approach can be broken down into three key areas:

- Compositional Control: The study reviews the use of "Fe-corrector" elements like manganese (Mn). Adding an optimal amount of Mn can modify the morphology of Fe-containing IMPs from harmful needles into more compact, less detrimental shapes..

- Process-Based Control: The researchers highlight the critical role of solidification rate. Casting techniques with high cooling rates, such as high-pressure die casting (HPDC) and twin-roll casting, can refine the size of IMPs, dramatically reducing their negative impact.. For example, Fe-rich IMPs can be reduced from over 100 µm to less than 1 µm..

- Microstructure-Based Design: The most innovative concept explored is the strategic creation of heterostructured alloys. This involves using advanced thermomechanical processing (fast solidification followed by homogenization) to deliberately manipulate IMPs. The goal is to create a material with controlled variations in strength throughout its microstructure, where the "hard" IMPs and "soft" aluminum matrix work together to produce superior overall properties..

The Breakthrough: Key Findings & Data

The paper presents compelling evidence that impurities can be harnessed to create superior alloys. The key findings demonstrate a clear path from understanding the problem to engineering a solution.

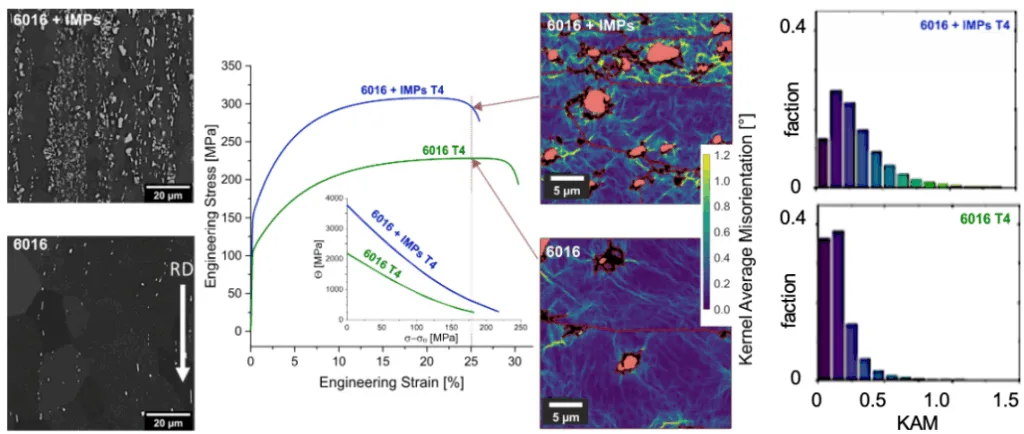

- Finding 1: The Morphology of IMPs is Critical. The shape of IMPs is more important than their mere presence. As shown in Figure 2, Fe-containing IMPs often form as brittle, cracked plates (β-particles), which are highly detrimental to performance..

- Finding 2: Chemical "Correctors" Can Mitigate Harm. Adding elements like manganese (Mn) can transform the harmful, needle-like β-Al5FeSi phase into a more compact α-Al15(FeMn)3Si2 phase. As detailed in Figure 3, an optimal Mn content minimizes the formation of microcracks under load. However, this method has limitations, as it can increase the total fraction of IMPs..

- Finding 3: High Cooling Rates Drastically Refine IMP Size. The solidification speed has a profound effect on IMP size. Figure 4 provides a stunning visual comparison: in gravity die casting (slow cooling), Fe-rich IMPs are massive (100 µm), while in additive manufacturing (extremely fast cooling), they are reduced to less than 1 µm. This refinement leads to significantly improved elongation.. This principle is directly applicable to HPDC.

- Finding 4: Heterostructures Turn IMPs into Strength Enhancers. By using fast solidification and heat treatment, a commercial 6016 alloy doped with 10 vol.% IMPs was created. Figure 5 shows that this "dirty" alloy exhibits significantly higher strength and strain hardening than the standard alloy, without sacrificing ductility. The IMPs create geometrically necessary dislocations (GNDs), leading to a high back-stress that strengthens the material..

- Finding 5: Mixed Automotive Scrap Can Be Upcycled into High-Performance Wrought Alloys. The culmination of this research is shown in Figure 6. The study demonstrates that alloys created from mixed ELV scrap, when subjected to fast solidification and a two-step homogenization treatment, can be processed into sheet material. These upcycled alloys exhibit an exceptional combination of high strength (200-350 MPa) and high elongation (19-27%), comparable to premium commercial 5xxx series alloys..

Practical Implications for Your HPDC Products

The findings presented in this paper are not merely academic; they have direct, actionable implications for real-world manufacturing environments, particularly in High-Pressure Die Casting.

- For Process Engineers: The research strongly suggests that maximizing the cooling rate during casting is a powerful tool for managing impurities.. The data in Figure 4 provides clear evidence that the rapid solidification inherent to HPDC can be leveraged to refine IMP morphology and improve mechanical properties, even when using secondary aluminum with higher impurity levels. The findings in the "Known strategies for mitigating the negative effects of IMPs" section suggest that adjusting composition with Fe-correctors like Mn could further reduce defects..

- For Quality Control: The correlation shown in Figure 3 between Mn content, IMP morphology, and crack initiation provides a new potential indicator for quality. Instead of only measuring the elemental composition of Fe, analyzing the Mn/Fe ratio and characterizing IMP morphology could lead to a more accurate prediction of mechanical performance and earlier defect detection.

- For Die Design: This study on heterostructured alloys implies that design choices have a measurable impact on final part performance. The concept of leveraging IMPs for strengthening, as detailed in the paper's conclusion, opens new possibilities. While the paper focuses on wrought alloys, the principles of controlled solidification and microstructure design are relevant. Future die designs could potentially be optimized to create specific cooling profiles that promote the formation of beneficial, refined IMPs in critical areas of a casting.

Paper Details

Overview on aluminium alloys as sinks for end-of-life vehicle scrap

1. Overview:

- Title: Overview on aluminium alloys as sinks for end-of-life vehicle scrap

- Author: Stefan Pogatscher and Sebastian Samberger

- Year of publication: 2024

- Journal/academic society of publication: IOP Conference Series: Materials Science and Engineering

- Keywords: aluminium alloys, recycling, end-of-life vehicles, scrap, intermetallic phases (IMPs), heterostructured alloys, sustainable metallurgy

2. Abstract:

A fundamental principle in metallurgy is that the higher the purity of metals and alloys, the more favourable their properties will be. However, as the recycling of materials in production becomes increasingly significant, the levels of impurities are also on the rise. In the case of aluminium, the consequences can be detrimental due to the low solubility of most elements in this metal, which leads to the formation of brittle intermetallic phases (IMPs). Moreover, once impurities have entered aluminium, it is difficult to remove them. In 2017, almost 100 million cars were produced worldwide. Historically, vehicle design prioritised performance, resulting in a multi-material mix to utilise the best materials for each application. This included over 40 different wrought and cast aluminium alloys, Cu-based materials for electrics, and steels for high-strength applications. In the recycling of end-of-life vehicles (ELVs), high purity wrought Al alloys are today down-cycled to low purity cast engine blocks. However, recent advancements show that the drawback of increase IMP-fractions can be turned into benefits through the strategic design of heterostructured alloys. A first successful alloy example from this approach enables interesting forming properties, previously only found in 5xxx series wrought aluminium alloys, in combination with a matrix composition and age-hardening potential known from 6xxx series wrought aluminium alloys. A second examples reviews compositions directly resulting from ELV scrap. By manipulating IMPs it is feasible to create heterostructures with an interesting balance of strength and ductility. These approaches challenge traditional views, allowing for a greater volume fraction of intermetallic phases. Understanding the formation and role of intermetallic particles is crucial. This work gives an overview to the current problem and the state of the art and addressed the potential of upcycled aluminium alloys that tolerate high impurity levels by using intermetallic phases as impurity sinks.

3. Introduction:

The paper introduces the global push for sustainable consumption and the critical role of recycling, especially in regions like Europe that are dependent on imported raw materials. It highlights the growing challenge of aluminum recycling: an increasing volume of scrap, compositional incompatibility between different alloy classes, and the accumulation of detrimental impurities. The introduction sets the stage by explaining that traditional scrap sinks, like cast combustion engines, are declining with the rise of electric vehicles, creating an urgent need for new methods to handle mixed, impure aluminum scrap.

4. Summary of the study:

Background of the research topic:

The research is set against the backdrop of increasing aluminum recycling and the associated problems with impurities (tramp elements). These elements form brittle intermetallic phases (IMPs) that degrade mechanical properties, a significant issue as today's advanced alloys demand high purity.

Status of previous research:

Previous research focused on mitigating the negative effects of IMPs, primarily in casting alloys. Strategies included adding "Fe-corrector" elements like Mn and Cr to change the shape of Fe-bearing IMPs, and using high-cooling-rate casting processes like HPDC to refine their size. However, these methods have limitations and do not prevent the formation of IMPs altogether.

Purpose of the study:

The study aims to challenge the traditional paradigm that impurities are always detrimental. It seeks to provide an overview of a new approach where impurities are strategically used to create novel "heterostructured" alloys with enhanced properties, effectively "upcycling" scrap material.

Core study:

The core of the study is a review and synthesis of research demonstrating how to control and leverage IMPs. This includes analyzing the effect of cooling rates, chemical additions, and thermomechanical processing. The paper culminates in presenting a new concept where mixed automotive scrap is successfully processed into a high-performance wrought alloy, proving that impurities can be engineered into beneficial microstructural components.

5. Research Methodology

Research Design:

The paper is a comprehensive review and perspective article. It synthesizes findings from a wide range of existing studies and combines them with new conceptual approaches developed by the authors to form a cohesive argument for a new recycling paradigm.

Data Collection and Analysis Methods:

The authors draw on data from numerous sources, including metallurgical literature, industry reports, and experimental studies. The analysis involves comparing different impurity mitigation strategies, from compositional adjustments (e.g., Mn additions) to advanced processing techniques (e.g., fast solidification, twin-roll casting, homogenization treatments). The paper uses micrographs, stress-strain curves, and compositional data to illustrate key concepts.

Research Topics and Scope:

The scope covers the entire lifecycle of aluminum recycling, from the generation of ELV scrap to the production of new, high-performance alloys. Key topics include the detrimental effects of tramp elements, strategies to mitigate these effects (e.g., HPDC), and the novel design of heterostructured wrought alloys that contain high fractions of IMPs.

6. Key Results:

Key Results:

- Impurities in recycled aluminum form brittle intermetallic phases (IMPs) that traditionally degrade mechanical properties.

- The morphology (shape) of IMPs can be controlled by adding corrector elements (e.g., Mn) or by increasing the solidification cooling rate.

- High cooling rates, such as those in HPDC or additive manufacturing, can refine IMPs to a sub-micron size, significantly improving ductility.

- A novel approach, creating "heterostructured alloys," uses IMPs as strengthening agents, leading to materials with a superior balance of strength and ductility.

- Mixed automotive scrap can be successfully "upcycled" into high-performance wrought alloys with properties comparable to premium commercial alloys.

Figure Name List:

- Figure 1: Proportion of primary aluminium production by region in 2000, 2010 and 2020.

- Figure 2: Examples of detrimental IMPs in commercial Al-alloys.

- Figure 3: Principal crack initiation in high-pressure die casting alloys with low, optimal and high Mn content as an Fe-corrector.

- Figure 4: Casting alloy AlSi9Cu3MgFeZn with 1.2% Fe; (a) gravity die casting, (b) additive manufacturing.

- Figure 5: Microstructure and stress-strain curves of commercial alloys 6016 and 6016 doped with 10 vol.% IMPs.

- Figure 6: Automotive scrap compositions in different scenarios with varying dismantling operations.

7. Conclusion:

The paper concludes that the traditional view of impurities as purely harmful is outdated. By strategically designing heterostructured alloys, it is possible to transform impurities into beneficial components that enhance mechanical properties. This approach allows for the creation of upcycled aluminum alloys from mixed scrap that exhibit a superior balance of strength and ductility. This innovation is critical for sustainable manufacturing, especially in the automotive industry, as it reduces dependence on energy-intensive primary aluminum. Future work must focus on refining these processing techniques to ensure they are scalable for industrial application.

8. References:

- [The full list of 82 references is provided in the original paper, from pages 11 to 15.]

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving the properties of alloys made from scrap?

A1: The study concluded that the most critical factor is the strategic manipulation of intermetallic phases (IMPs) through a combination of fast solidification and thermomechanical processing to create a "heterostructured" alloy. This approach transforms impurities from defects into strengthening components, as detailed in the "Conclusions and Outlook" and demonstrated by the data in Figure 5 and Figure 6.

Q2: How does this research compare to traditional methods for addressing impurities in scrap?

A2: The paper's Introduction and Conclusion sections note that traditional methods focus on mitigating or minimizing impurities through dilution with pure aluminum or by using chemical correctors to make them less harmful.. This research introduces a fundamentally new approach: harnessing the impurities to create a unique heterostructure that delivers superior mechanical properties, such as the exceptional strength and elongation shown in Figure 6.

Q3: Is this finding applicable to all types of alloys, or a specific one?

A3: The research was conducted on several aluminum systems, but its most groundbreaking finding relates to creating new, purpose-designed alloys from mixed automotive scrap. The Methodology and results in Figure 6 specifically detail creating high-performance alloys from compositions derived from mixed ELV scrap, which includes a blend of cast and wrought alloys. The principles are also demonstrated on a 6016 series alloy..

Q4: What specific measurement or simulation technique did the researchers use to arrive at this conclusion?

A4: The researchers utilized a combination of advanced processing and characterization techniques. The "Heterostructured wrought aluminium alloys" section highlights the use of fast solidification (at a rate of ~60 K/s) and a "two-stage homogenization treatment".. The results were analyzed using stress-strain curves and Kernel Average Misorientation (KAM) analysis to reveal the formation of geometrically necessary dislocations around the IMPs, as shown in Figure 5.

Q5: According to the paper, what is the main limitation or area for future research?

A5: The authors state in the Conclusions and Outlook that a key area for future research is the refinement of these processing techniques to ensure "scalability and industrial applicability." Specifically, the paper notes that the required high cooling rate and the "relatively long homogenization process" require significant energy input, and these aspects are the subject of current research efforts to make the process more efficient..

Q6: What is the direct, practical takeaway from this paper for a die casting facility?

A6: The core takeaway is that by optimizing process parameters—particularly maximizing the cooling rate inherent to HPDC—it is possible to refine the microstructure of alloys containing high levels of impurities and achieve superior mechanical properties. This opens the door to using a wider range of lower-cost secondary aluminum sources without compromising part quality, a conclusion strongly supported by the overall results of the paper, "Overview on aluminium alloys as sinks for end-of-life vehicle scrap".

Conclusion & Next Steps

This research provides a valuable roadmap for turning the industry's biggest recycling challenge into a competitive advantage. By moving beyond the outdated purity-performance paradigm, the findings offer a clear, data-driven path toward improving component strength and ductility while embracing sustainable, circular manufacturing principles. The ability to upcycle mixed scrap into high-performance material is a genuine breakthrough for the aluminum industry.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals—such as improving performance while using more sustainable materials—contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "Stefan Pogatscher and Sebastian Samberger". Based on "Overview on aluminium alloys as sinks for end-of-life vehicle scrap".

- Source of the paper: https://doi.org/10.1088/1757-899X/1315/1/012008

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.