Unlocking Flawless Castings: A Taguchi-Based Guide to ADC12 Porosity Reduction

This technical summary is based on the academic paper "Optimization of process parameters of High Pressure Die Casting process for ADC12 Aluminium alloy using Taguchi method" by Veeresh G Balikai, I G Siddlingeshwar, and Mahesh Gorwar, published in the International Journal of Pure and Applied Mathematics (2018). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: ADC12 Porosity Reduction

- Secondary Keywords: High Pressure Die Casting, HPDC Process Optimization, Taguchi Method, Aluminium Die Casting Defects, Casting Process Parameters

Executive Summary

- The Challenge: Porosity is the most common defect in ADC12 aluminium high pressure die castings, increasing rejection rates and reducing productivity.

- The Method: Researchers applied the Taguchi L25 orthogonal array method to systematically investigate the effects of four key process parameters—pouring temperature, injection pressure, and two phases of plunger velocity—on porosity.

- The Key Breakthrough: Plunger velocity in the 1st phase (34.012% contribution) and 2nd phase (31.602% contribution) were identified as the most significant factors influencing porosity formation.

- The Bottom Line: By optimizing specific process parameters to their ideal levels, manufacturers can achieve a significant reduction in porosity, leading to higher quality castings and improved operational efficiency.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive world of high pressure die casting (HPDC), particularly for automotive, aerospace, and electronics applications, quality is paramount. For components made from ADC12 aluminium alloy, porosity remains the most persistent and costly defect. Caused by entrapped air, gas, or solidification shrinkage, porosity compromises the mechanical properties and pressure tightness of castings. This directly leads to higher scrap rates, increased rejections, and a significant drop in overall productivity.

For small and large-scale manufacturers alike, controlling the numerous independent process parameters that influence porosity formation is a constant challenge. This research addresses this critical industry pain point by providing a systematic, data-driven approach to identify and optimize the most influential parameters, offering a clear path to achieving good quality castings with minimal defects.

The Approach: Unpacking the Methodology

To isolate the most critical process parameters, this study employed the robust Taguchi parameter design methodology. The core of the experiment was to optimize the HPDC process for ADC12 aluminium alloy with the objective of minimizing porosity.

- Material: ADC12 Aluminium Alloy.

- Equipment: 400T HMT model high pressure die casting machine.

- Experimental Design: A Taguchi L25 orthogonal array was selected, allowing for the systematic testing of 25 unique combinations of parameter levels.

- Key Process Parameters Investigated:

- Pouring Temperature (T): Ranged from 660°C to 700°C.

- Injection Pressure (P): Ranged from 160 kg/m³ to 200 kg/m³.

- Plunger Velocity - 1st Phase (V₁): Ranged from 0.26 m/s to 0.3 m/s.

- Plunger Velocity - 2nd Phase (V₂): Ranged from 2.6 m/s to 3.0 m/s.

- Data Analysis: The quality of each casting was assessed by measuring its density using Archimedes' principle and calculating the percentage of porosity. An Analysis of Variance (ANOVA) was then performed on the Signal-to-Noise (S/N) ratios to determine the statistical significance and percentage contribution of each parameter to porosity formation.

The Breakthrough: Key Findings & Data

The experimental results clearly demonstrated that variations in process parameters have a significant effect on porosity in ADC12 die castings. The ANOVA provided a quantitative breakdown of which factors matter most.

Finding 1: Plunger Velocity is the Dominant Factor in Porosity Formation

The most critical finding from the ANOVA (Table 4) is the overwhelming influence of plunger velocity. Together, the two phases of plunger velocity account for over 65% of the variation in porosity.

- Plunger Velocity (1st phase) was the single most significant parameter, with a 34.012% contribution to porosity.

- Plunger Velocity (2nd phase) was the second most significant, contributing 31.602%.

- In contrast, Pouring Temperature had a moderate effect (11.245%), and Injection Pressure had the least significant impact (2.134%) within the tested ranges.

Finding 2: The Optimal Process Window for Minimum Porosity

The study successfully identified the specific parameter levels that yield the lowest porosity. The best result achieved in the experiments (Trial 21 in Table 3) produced a casting with a remarkably low porosity of just 0.01738%. Based on the analysis, the optimal combination of parameters for achieving minimum porosity is:

- Pouring Temperature: 660°C (1st Level)

- Intensification Pressure: 190 kg/cm² (4th Level)

- Plunger Velocity (1st phase): 0.3 m/s (5th Level)

- Plunger Velocity (2nd phase): 3.0 m/s (5th Level)

This provides a clear, validated recipe for achieving superior casting quality.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting plunger velocity (both 1st and 2nd phase) and pouring temperature to the identified optimal levels may contribute directly to reducing porosity defects and improving casting consistency.

- For Quality Control Teams: The data in Table 3 of the paper illustrates the vast difference in outcomes, from a worst-case porosity of 4.07% (Trial 6) to a best-case of 0.017% (Trial 21). This underscores the sensitivity of the process and highlights the need for tight monitoring of these key parameters.

- For Design Engineers: The findings, rooted in the problem of turbulent flow causing air entrapment (as noted in the introduction), reinforce that component design should always aim to facilitate smooth, non-turbulent metal flow during cavity filling to complement an optimized casting process.

Paper Details

Optimization of process parameters of High Pressure Die Casting process for ADC12 Aluminium alloy using Taguchi method

1. Overview:

- Title: Optimization of process parameters of High Pressure Die Casting process for ADC12 Aluminium alloy using Taguchi method

- Author: Veeresh G Balikai, I G Siddlingeshwar, Mahesh Gorwar

- Year of publication: 2018

- Journal/academic society of publication: International Journal of Pure and Applied Mathematics

- Keywords: Optimisation, DOE, Taguchi Method, HPDC, Process parameters, Porosity

2. Abstract:

A study has been carried out to optimize the die casting process parameters in order to achieve the improved quality of high pressure die casting (HPDC) products, which is the challenge for the small and large scale manufacturers of HPDC products. In this study the approach used is the experimental study to optimize the die casting process parameters for the ADC12 aluminum alloys. The ADC12 aluminum alloy components were chosen for the study and objective was to reduce the porosity in these components which help to obtain the good quality castings. The porosity is the most common defect frequently encountered in aluminium high pressure die castings, which increases the rejection rate and scrap rate and reduces the productivity. Porosity formation is closely related to die casting process parameters. Hence in order to minimize the porosity, this paper investigated the effect of process parameters on porosity formation in HPDC of ADC12 alloys and optimization of process parameters carried out using Taguchis parameter design approach. Experiments were conducted by varying selected process parameters with different levels as per Taguchi method. ANOVA was performed to find the significance of parameters on porosity formation in die castings. Results indicated that selected process parameters have significant effect on porosity formation. The optimum process parameters were obtained for minimum porosity in HPDC of ADC12 alloy.

3. Introduction:

High pressure die casting (HPDC) process is an efficient manufacturing process to produce complex, thin and thick wall components economically with high productivity and high dimensional accuracy for automotive, aerospace, defence and other industries [9,13]. In aluminium high pressure die casting process, molten aluminium alloy is injected into a metal mould at high speed and allowed to solidify under high holding pressure [10]. ADC12 based alloys have been widely used in the field of HPDC process to produce lightweight components with low cost, good mechanical properties and high corrosion resistance for electric, electronic and automobile and other applications [5]. In high pressure die casting of ADC12 aluminium alloys, Porosity is the most common defect caused due to entrapment of air/gas and oxides due to the turbulent flow of metal during the cavity filling [8]. This defect is classified as gas porosity (caused due to air trapped air in sleeve), shrinkage porosity (due to solidification of the metal in the gate before solidification in other areas of the casting) and flow porosity (caused due to insufficient pressure towards the end of cavity filling). The mechanical properties and pressure tightness are affected due to presence of porosity in castings. Porosity in a high pressure die casting varies both with part geometry of component and casting parameters of the process [9].

4. Summary of the study:

Background of the research topic:

Porosity is a major defect in high pressure die casting (HPDC) of ADC12 aluminium alloys, leading to increased rejection rates and reduced productivity. The formation of this defect is closely linked to several independent process parameters.

Status of previous research:

Previous literature has investigated the influence of various process parameters on porosity. G.O. Verran et al. (2008) optimized injection parameters for SAE 305 alloys. V. D. Tsoukalas (2003) studied the effect of machine parameters on porosity in complex aluminium die-casting. Lars Arnberg et al. (2015) reviewed the effect of injection parameters on Al-Si alloys. G.P.Syrcos (2003) optimized the aluminium alloy die casting process using the Taguchi method.

Purpose of the study:

The study's objective was to investigate the effects of selected process parameters on casting porosity and to minimize porosity formation in die castings of ADC12 aluminium alloy by selecting the optimum process parameters for the HPDC process using the Taguchi method.

Core study:

The study experimentally tested the effects of four process parameters (pouring temperature, injection pressure, plunger velocity 1st phase, and plunger velocity 2nd phase) at five different levels on the porosity of ADC12 aluminium alloy castings. Using a Taguchi L25 orthogonal array and ANOVA, the researchers identified the percentage contribution of each parameter and determined the optimal settings for minimum porosity.

5. Research Methodology

Research Design:

The study used an experimental design based on Taguchi's parameter design approach. An L25 orthogonal array was chosen to accommodate the four selected process parameters, each with five levels. This design allows for a systematic investigation of the parameters' effects with a manageable number of experiments (25 trials). The quality characteristic chosen was porosity, with a "Lower the better" objective.

Data Collection and Analysis Methods:

For each of the 25 experimental combinations, three castings were produced. The density of each casting was measured using Archimedes' principle. The porosity percentage was then calculated using the formula: porosity(%) = [(ρ_apparent - ρ_th) / ρ_th] * 100, where ρ_th is the theoretical density of ADC12 (2.67 gm/cm³). The Signal-to-Noise (S/N) ratio was computed for each trial. Finally, an Analysis of Variance (ANOVA) was performed on the S/N ratios to determine the significance and percentage contribution of each process parameter.

Research Topics and Scope:

The research focused exclusively on the HPDC process for ADC12 aluminium alloy. The scope was limited to four specific process parameters: pouring temperature, injection pressure, 1st phase plunger velocity, and 2nd phase plunger velocity. The study's primary outcome was the identification of optimal parameter levels to minimize porosity.

6. Key Results:

Key Results:

- The ANOVA results (Table 4) showed that plunger velocity (1st phase) has the highest contribution to porosity at 34.012%, followed by plunger velocity (2nd phase) at 31.602%.

- Pouring temperature contributed 11.245%, and intensification pressure had the lowest contribution at 2.134%.

- The optimal process parameters for minimum porosity were determined to be:

- Pouring temperature: 660°C (1st level)

- Intensification pressure: 190 kg/cm² (4th level)

- Plunger velocity (1st phase): 0.3 m/s (5th level)

- Plunger velocity (2nd phase): 3.0 m/s (5th level)

- The combination of these optimal parameters resulted in "satisfactory results by reducing the porosity and improving the quality of the castings."

Figure Name List:

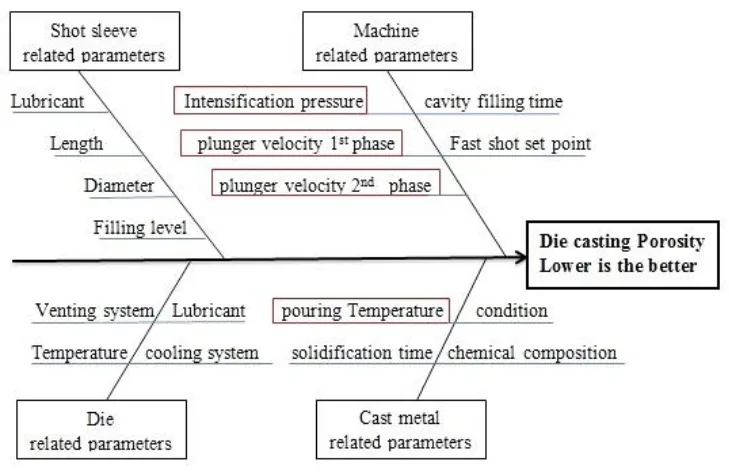

- Fig.1. Cause and effect diagram (Ishikawa diagram) for casting porosity

7. Conclusion:

The Experimental results shows that variations in die casting process parameters have significantly effects on the porosity formation of aluminium alloy die casting. Pouring temperature, intensification pressure, plunger velocity (1st phase), plunger velocity (2nd phase) are the influential process parameters which are affecting the formation of porosity in ADC12 aluminium alloy castings. The percentage contribution of each parameter and optimum process parameters with their levels for the optimum casting porosity in high pressure die castings of ADC12 aluminium alloy was as follows:

- Pouring temperature: 11.245% (Optimal: 660°C, 1st level)

- Intensification pressure: 2.134% (Optimal: 190 kg/cm², 4th level)

- Plunger velocity (1st phase): 34.012% (Optimal: 0.3 m/s, 5th level)

- Plunger velocity (2nd phase): 31.602% (Optimal: 3.0 m/s, 5th level)

The Taguchi Method parameter design approach for the optimisation of the process parameters in HPDC for ADC12 alloy has given the satisfactory results by reducing the porosity and improving the quality of the castings. The parts have been validated through the microscopic studies.

8. References:

- [1] S. W. Choi, Y. C. Kim, J. I. Cho & C. S. Kang (2008), Influence of die casting process parameters on castability and properties of thin walled aluminium housings, International Journal of Cast Metals Research, 21:1-4, pp.330-333.

- [2] Murray, M.T. (2011) High pressure die casting of aluminium and its alloys, M Murray & Associates Pty Ltd, Australia.

- [3] G.O. Verran, R.P.K. Mendes, L.V.O. Dalla Valentina (2008), DOE applied to optimization of aluminium alloy die castings journal of materials processing technology, 200 pp.120125.

- [4] G.P.Syrcos (2003), Die casting process optimization using Taguchi method, journal of materials processing technology, 135, pp.68-74.

- [5] M.A. Irfan, D. Schwam, A. Karve, R. Ryder (2012), Porosity reduction and mechanical properties improvement in die cast engine blocks, Materials Science and Engineering A 535, pp.108 114.

- [6] V. D. Tsoukalas (2003), The effect of die casting machine parameters on porosity of aluminium die castings, International Journal of Cast Metals Research, 15:6, pp.581-588.

- [7] Guilherme Ourique Verran, Rui Patrick Konrad Mendes, Marco Aurelio Rossi, Influence of injection parameters on defects formation in die casting Al12Si1.3Cu alloy: Experimental results and numeric simulation, Journal of Materials Processing Technology, 179 (2006) pp.190195.

- [8] Anilchandra R. Adamane, Lars Arnberg, Elena Fiorese, Giulio Timelli, Franco Bonollo, (2015), Influence of Injection parameters on the porosity and tensile properties of High pressure die cast Al-Si Alloys: A Review, International Journal of Metalcasting, Volume 9, Issue 1.

- [9] Laihua Wang, Peter Turnley, Gary Savage (2011), Gas content in high pressure die castings, Journal of Materials Processing Technology 211, pp.15101515.

- [10] V.D. Tsoukalas (2008), Optimization of porosity formation in AlSi9Cu3 pressure die castings using genetic algorithm analysis, Materials and Design 29, pp.20272033.

- [11] Roy, R. K. Design of Experiments Using the Taguchi Approach: 16 Steps to Product and Process Improvement, 2001 (J. Wiley, New York).

- [12] Taguchi, G. and Konishi, S. Orthogonal Arrays and Linear Graphs, 1987 (American Supplier Institute, Dearborn, Michigan).

- [13] Quang-Cherng Hsu and Anh Tuan Do (2013), Minimum Porosity Formation in Pressure Die Casting by Taguchi Method, Mathematical Problems in Engineering.

- [14] Taguchi G. Introduction to quality engineering. 1st ed. New York: Asian Productivity Organization, UNIPUB; 1986.

- [15] Logothetis N. Total quality control. 2nd ed. UK: Prentice-Hall International Limited; 1992.

- [16] K.Ch.Apparao and Anil Kumar Birru, Optimization of Die casting process based on Taguchi approach, Materials Today: Proceedings 4 (2017) pp.18521859.

Expert Q&A: Your Top Questions Answered

Q1: Why were pouring temperature, injection pressure, and plunger velocities chosen as the key parameters for this study?

A1: These four parameters were selected after a review of existing literature and the construction of a cause-and-effect (Ishikawa) diagram, as shown in Figure 1. This process identified them as the most significant process parameters that may affect porosity in the high pressure die castings of ADC12 aluminium alloy, making them the logical focus for optimization.

Q2: The ANOVA table (Table 4) shows injection pressure has a very low contribution (2.134%). Does this mean it's not an important parameter?

A2: Within the experimental range of 160-200 kg/m³, the effect of injection pressure on porosity was found to be less significant relative to the powerful influence of plunger velocity. However, the study still identified an optimal level for pressure (190 kg/m², the fourth of five levels), indicating that it is part of the ideal process recipe. Its lower contribution suggests that fine-tuning plunger velocity offers a greater opportunity for porosity reduction.

Q3: What is the purpose of using the Signal-to-Noise (S/N) ratio in this analysis?

A3: The paper states that the Taguchi technique uses the S/N ratio to study the variation of the response. For a "Lower the better" quality characteristic like porosity, the goal is not only to achieve a low average porosity but also to make the process robust against uncontrollable process variations. The S/N ratio analysis helps identify parameter settings that minimize this variability, leading to more consistent and reliable casting quality.

Q4: The optimal pouring temperature was found to be the lowest one tested (660°C). Why would a lower temperature reduce porosity?

A4: The study empirically determined that 660°C, the first level tested, was the optimal setting for minimizing porosity. While the paper does not elaborate on the specific physical mechanism, lower melt temperatures are generally associated with a reduced capacity for dissolved gas and can influence solidification rates and patterns. Both of these factors are directly related to the formation of gas and shrinkage porosity.

Q5: How was the porosity percentage in Table 3 calculated?

A5: The porosity percentage was calculated based on a quantitative analysis of the casting's density. First, the apparent density of sample castings was measured using Archimedes' principle, as described by the formula in equation (1). This measured density was then compared to the theoretical density of a fully dense ADC12 alloy (2.67 gm/cm³) using the formula in equation (2) to determine the final porosity percentage.

Q6: Does this study apply to other aluminium alloys or just ADC12?

A6: This study was specifically designed and conducted for ADC12 aluminium alloy. While the principles of optimizing process parameters to reduce porosity are broadly applicable across the HPDC industry, the specific optimal values (e.g., 660°C pouring temperature) are validated only for ADC12 under the conditions of this experiment and may need to be re-evaluated for other alloys.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and actionable framework for tackling one of the most persistent challenges in high pressure die casting: porosity. By systematically applying the Taguchi method, the study moves beyond guesswork and pinpoints the precise process parameters that have the greatest impact on casting quality. The key takeaway is that a focused strategy for ADC12 porosity reduction, centered on the meticulous control of 1st and 2nd phase plunger velocities, can yield dramatic improvements. The identified optimal settings offer a validated starting point for manufacturers to enhance component integrity, reduce scrap, and boost overall productivity.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Optimization of process parameters of High Pressure Die Casting process for ADC12 Aluminium alloy using Taguchi method" by "Veeresh G Balikai, I G Siddlingeshwar, Mahesh Gorwar".

- Source: http://www.acadpubl.eu/hub/

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.