This introductory paper is the research content of the paper ["Opportunities and Risks of Mega-Casting in Automotive Production - The Aluminum Die-Casted Body in White"] published by [WT Werkstattstechnik].

![Bild 1. Einordnung der Karosseriebauweise „Mega-Casting" und dessen Konzepte mit beispielhaften OEM und Modellen im Rahmenwerk der etablierten Karosseriebauweisen (Eigenleistung). Rahmenwerk und Teil-Darstellungen in Anlehnung an Birkert et al. [3], Stellantis [14], Land Rover [15], Tesla [5]. Grafik: WZL](https://castman.co.kr/wp-content/uploads/image-1417-1024x664.webp)

1. Overview:

- Title: Opportunities and Risks of Mega-Casting in Automotive Production - The Aluminum Die-Casted Body in White

- Author: G. Schuh, G. Bergweiler, L. Dworog, F. Fiedler

- Publication Year: 2022

- Publishing Journal/Academic Society: WT Werkstattstechnik

- Keywords: Giga-Casting, Tesla, High pressure die casting

2. Abstracts / Introduction

The electric car manufacturer Tesla patented Mega-Casting in 2018, introducing a novel manufacturing method to produce a car body in a single step using aluminum High Pressure Die Casting (HPDC) without subsequent heat treatment. This approach contrasts with established body shop practices. This paper, authored by an expert team from the Laboratory for Machine Tools and Production Engineering (WZL) at RWTH Aachen University, investigates the opportunities and risks of Mega-Casting through a SWOT analysis, exploring its implications for the automotive and supplier industries.

3. Research Background:

Background of the Research Topic:

The rise of electromobility necessitates established Original Equipment Manufacturers (OEMs) to realign their production strategies and compete with new market entrants. This paradigm shift presents opportunities for both emerging and incumbent players to fundamentally rethink their organizational structures and embrace innovative manufacturing processes. In the context of car body construction, the self-supporting shell construction in steel remains the most prevalent method.

Status of Existing Research:

However, the utilization of aluminum die-cast components in structural mixed construction has been steadily increasing for years. This trend is driven by the potential to reduce part counts without increasing material consumption. Furthermore, casting technology enables the creation of complex geometries and shapes, exemplified by strut towers. Tesla's Mega-Casting initiative aims to advance large-format aluminum die-cast components, envisioning the production of entire car body parts, such as front ends or even complete car bodies, in a single casting process. Tesla's patent applications articulate a vision for a reimagined vehicle production paradigm.

Necessity of the Research:

This paper addresses the positioning of Mega-Casting within the broader landscape of established car body construction methods. It explores conceivable Mega-Casting concepts and elucidates the product and production-related opportunities and risks inherent in Mega-Casting.

4. Research Purpose and Research Questions:

Research Purpose:

This contribution aims to categorize Mega-Casting within the overall context of established car body construction methods, to explore conceivable Mega-Casting concepts, and to identify product and production-related opportunities and risks associated with Mega-Casting.

Key Research:

The expert team at WZL Aachen University conducted a SWOT analysis to investigate the opportunities and risks of Mega-Casting.

5. Research Methodology

Research Design:

The research employed a SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis framework to evaluate Mega-Casting.

Data Collection Method:

Six SWOT analyses were independently conducted by individual members of the "Mega-Casting" project team at the WZL of RWTH Aachen University, followed by expert discussions and consolidation.

Analysis Method:

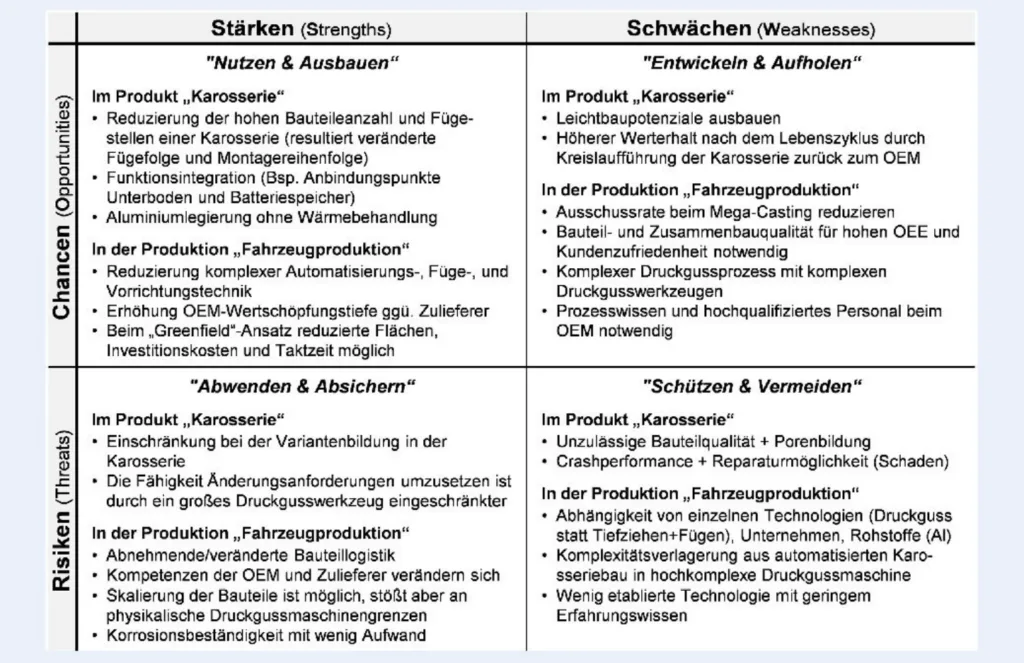

The results of the independently conducted SWOT analyses were consolidated and categorized based on "Product ‘Car body’" and "Production ‘Vehicle production’" from an OEM perspective, as depicted in "Bild 4. Produkt- und Produktionsseitige SWOT-Analyse zum Mega-Casting in der Fahrzeugproduktion. Grafik: WZL".

Research Subjects and Scope:

The study focuses on Mega-Casting within the automotive production domain, specifically from the perspective of OEMs.

6. Main Research Results:

Key Research Results:

The SWOT analysis, summarized in "Bild 4", reveals key strengths of Mega-Casting in "Produkt ‚Karosserie‘" including the reduction of component count and joining operations, functional integration, and the use of heat treatment-free aluminum alloys. Production-related strengths in "Produktion ‚Fahrzeugproduktion‘" include reduced complexity in automation, joining, and fixture technology, increased OEM value creation, and potential for reduced footprint, investment costs, and cycle times in greenfield setups.

Weaknesses in "Produkt ‚Karosserie‘" encompass challenges in leveraging lightweight potential and realizing circular economy benefits. Production weaknesses include the need to reduce scrap rates, ensure component and assembly quality, manage the complex die casting process and tooling, and secure process expertise and qualified personnel at the OEM level.

Opportunities ("Stärken (Strengths) "Nutzen & Ausbauen"") involve capitalizing on component reduction and functional integration, while threats ("Risiken (Threats) "Abwenden & Absichern"") necessitate mitigating limitations in variant flexibility and change management, addressing logistical shifts, and managing evolving OEM-supplier competencies.

Analysis of presented data:

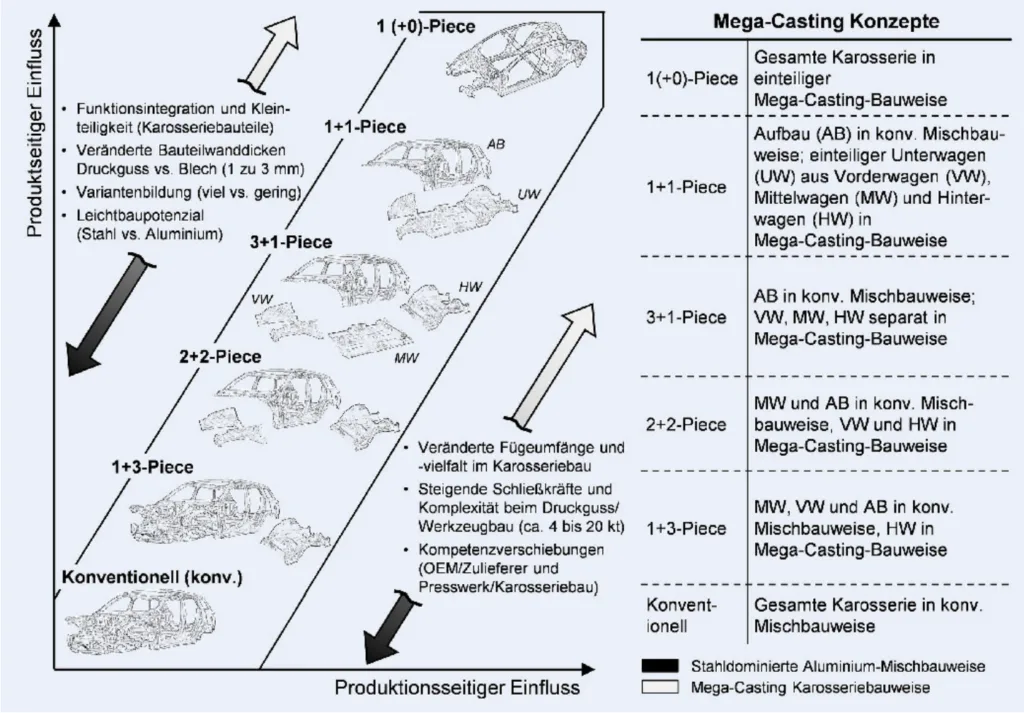

"Bild 2. Einteilung der Karosseriebauweise Mega-Casting in fünf Konzepte mit steigendem Anteil des Einsatzes von Aluminium-Druckguss (1+3 Piece bis 1 (+0)-Piece). Grafik: WZL" categorizes Mega-Casting into five concepts based on increasing aluminum die-casting usage: 1+3-Piece, 2+2-Piece, 3+1-Piece, 1+1-Piece, and 1(+0)-Piece. These concepts range from partial integration of Mega-Casting (1+3 Piece) to the vision of a complete car body cast in a single piece (1(+0)-Piece).

"Bild 4. Produkt- und Produktionsseitige SWOT-Analyse zum Mega-Casting in der Fahrzeugproduktion. Grafik: WZL" details the consolidated SWOT analysis, outlining specific strengths, weaknesses, opportunities, and threats across product ("Karosserie") and production ("Fahrzeugproduktion") dimensions. For instance, strengths like "Reduzierung der hohen Bauteileanzahl und Fügestellen einer Karosserie" (Reduction of high component count and joining points in a car body) and weaknesses such as "Leichtbaupotenziale ausbauen" (Expand lightweight potential) are clearly presented.

Figure Name List:

- Bild 1. Einordnung der Karosseriebauweise „Mega-Casting" und dessen Konzepte mit beispielhaften OEM und Modellen im Rahmenwerk der etablierten Karosseriebauweisen (Eigenleistung). Rahmenwerk und Teil-Darstellungen in Anlehnung an Birkert et al. [3], Stellantis [14], Land Rover [15], Tesla [5]. Grafik: WZL

- Bild 2. Einteilung der Karosseriebauweise Mega-Casting in fünf Konzepte mit steigendem Anteil des Einsatzes von Aluminium-Druckguss (1+3 Piece bis 1 (+0)-Piece). Grafik: WZL

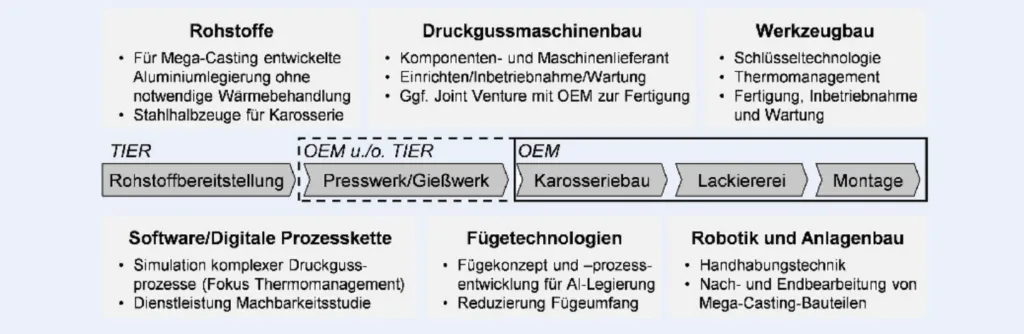

- Bild 3. Unternehmensarten und Beispiele im Themenfeld Mega-Casting in der automobilen Prozesskette und Zuliefererpyramide (TIER). Grafik: WZL

- Bild 4. Produkt- und Produktionsseitige SWOT-Analyse zum Mega-Casting in der Fahrzeugproduktion. Grafik: WZL

7. Conclusion:

Summary of Key Findings:

Mega-Casting represents a novel car body construction method that distinguishes itself from established approaches in manufacturing and material utilization. The SWOT analysis indicates that Mega-Casting offers potential takt time and complexity reductions through single-component car body construction. However, it also introduces challenges concerning crash performance and repair solutions. Production process advancements are necessary, particularly in die casting machine technology for large components with high quality reliability.

Academic Significance of the Study:

This study provides a comprehensive expert-level analysis of Mega-Casting within the automotive body construction domain. The SWOT analysis framework offers a structured evaluation of its opportunities and risks, contributing to the academic understanding of emerging manufacturing technologies in the automotive sector.

Practical Implications:

For OEMs, Mega-Casting necessitates a strategic realignment of production and supply chain management, demanding expertise in large-scale aluminum die casting. Supplier industries, particularly die casting machine manufacturers and material providers, face opportunities in developing and providing enabling technologies and materials for Mega-Casting.

Limitations of the Study and Areas for Future Research:

Further research is warranted to address challenges in crash performance, repair methodologies, and process optimization for Mega-Casting. Ongoing industry collaborations and studies, including consortium research and surveys on automotive production trends focusing on Mega-Casting, are crucial for realizing its full potential.

8. References:

- [1] Kallas M. K.: Multi-Directional Unibody Casting Machine For A Vehicle Frame And Associated Methods, US 2019/0217380 A1, 2018

- [2] Friedrich, H. E.: Leichtbau in der Fahrzeugtechnik, Springer Fachmedien Wiesbaden, Wiesbaden, 2013

- [3] Birkert et al.: Umformtechnische Herstellung komplexer Karosserieteile, Springer Berlin Heidelberg, Berlin, Heidelberg, 2013

- [4] Stucki, J.; Patinson, G.; Hamill, Q.; Prabhu, A.; Palanivel, S.; Lopez-Garrity, O.: Die cast aluminium alloys for structural components, PCT/US2021/014177, 2021

- [5] Tesla, Video: Battery Day, 2020. Internet: https://tesla-cdn.thron.com/static/JIXJRM_2020-Battery-Day-2000_WBRTSS.mp4?xseo=. Zugriff am 04.07.2022

- [6] Rai, A.; Sawant, S.; Winberg, P.; Burgess, M.; Spencer, T.; Kornmayer, P.; Pattinson, G.; Edwards, P.; Rinaldi, C.; Reikher, A.; Kuehmann, C.; Moll, D.: Integrated energy absorbing castings, WO 2022/031991 A1, 2022

- [7] Verein Deutscher Ingenieure: Gießen von Fahrwerks- und Karosseriekomponenten, VDI 2318, VDI Verlag, 2018

- [8] Electrek: Tesla produces first Model Y megacast in gigafactory in Texas. Stand:2022. Internet: https://electrek.co/2021/05/17/tesla-produces-first-model-y-megacast-gigafactory-texas/. Zugriff am 04.07.22

- [9] Insideevs: VW's project Trinity To Use Giga-Casting & Automation to compete with Tesla. Stand 2022. Internet: https://insideevs.com/news/577128/volkwagen-compete-tesla-gigapress-robots/. Zugriff am 04.07.22

- [10] Volvo Car Switzerland AG: Mega casting. Stand:2022. Internet: https://www.media.volvocars.com/ch/de-ch/media/photos/294346/mega-casting-1. Zugriff am 04.07.22

- [11] Rakoto, B.; Ling, L.: Mega-Casting Trends for Automotive Manufactures, Mai 2022

- [12] YZweekly: Nios erstes Modell der ET5 mit "integrierter Druckgusstechnologie" wird in Serie produziert und ausgeliefert. Stand 2022. Internet: http://www.yzweekly.com/xyzd/zhengche/7604.htm. Zugriff am 02.09.2022

- [13] Phate Zhang/CnEVPost: HiPhi becomes latest Chinese EV startup to use large die-casting technology. Stand 01.03.2022. Internet: https://cnevpost.com/2022/03/01/hiphi-becomes-latest-chinese-ev-startup-to-use-large-die-casting-technology/. Zugriff am 06.09.2022

- [14] Stellantis: Lambda (historisch). Stand 2022. Internet: https://www.media.stellantis.com/de-de/lancia/gallery/1376. Zugriff am 02.09.2022

- [15] Land Rover, Land Rover Leichtbau Strategie, 2014. Stand 2022. Internet: https://media.landrover.com/dede/news/2014/05/land-rover-leichtbau-strategie. Zugriff am 21.02.2022

- [16] Idra: NEΟ 5500 – ΝΕΟ 6100 – ΝΕΟ 8000 – ΝΕΟ 9000. Stand 2022. Internet: https://www.idragroup.com/de/gigapress. Zugriff am 04.07.2022

- [17] Bühler Group: Umfassendes Know-how rund um die Produktion von Megacasting. Stand 2022 Internet: https://www.buhlergroup.com/content/buhlergroup/global/de/industries/die-casting/megacasting.html. Zugriff am 04.07.2022.

- [18] Spotlightmetal: LK Group introduces the World's First 6000T & 9000T Giant Die Casting Machine. Stand: 2022. Internet: https://www.spotlightmetal.com/lk-group-introduces-the-worlds-first-6000t-9000t-giant-die-casting-machine-a-1036839/. Zugriff am 04.07.2022

- [19] Alu-Web: Handtmann investiert in Megacasting-Lösung von Bühler. Stand 2022.Internet: https://alu-web.de/handtmann-investiert-in-megacasting-loesung-von-buehler/. Zugriff am 04.07.2022

- [20] Idra: The great success of Giga Press. Stand: 2022. Internet: https://www.idragroup.com/en. Zugriff am 04.07.2022

- [21] Fuchs: Mega-Casting: Druckgussverfahren revolutioniert Automobilbau. Stand: 2022. Internet: https://www.fuchs.com/de/de/produkte/schmierstoffe-und-services/schmierstoffe-fuer-spezialanwendungen/umformschmierstoffe/mega-casting/. Zugriff am 04.07.2022

- [22] Home of Foundry: Think Big… Giga-Castings. Stand: 2022. Internet: https://www.home-of-foundry.de/news/think-biggiga-castings-1002. Zugriff am 04.07.2022

- [23] Briskham, P.: Joining of aluminium alloys with low ductility. 2022.

- [24] Paul, H.; Wollny, V.: Instrumente des strategischen Managements, De Gruyter Oldenbourg 2014.

- [25] Pischinger, S.; Seiffert, U.: Vieweg Handbuch Kraftfahrzeugtechnik, Springer Fachmedien Wiesbaden, Wiesbaden, 2021

- [26] Fuchslocher, G.: Gigacasting ist geeignet, den Karosseriebau neu zu denken, Automobil Produktion, 2022. Internet: https://www.automobil-produktion.de/interviews-734/gigacastingistgeeignet-den-karosseriebau-neu-zu-denken-501.html. Zugriff am 27.02.2022

9. Copyright:

- This material is "G. Schuh, G. Bergweiler, L. Dworog, F. Fiedler"'s paper: Based on "Opportunities and Risks of Mega-Casting in Automotive Production - The Aluminum Die-Casted Body in White".

- Paper Source: https://doi.org/10.37544/1436-4980-2022-09-52

This material was created to introduce the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.