Mega-Casting: The High-Pressure Die Casting Revolution for Automotive Body-in-White

This technical summary is based on the academic paper "Chancen und Risiken von Mega-Casting in der Fahrzeugproduktion - Die Karosserie aus dem Aluminium-Druckguss" by G. Schuh, G. Bergweiler, L. Dworog, and F. Fiedler, published in WT WERKSTATTSTECHNIK (2022). It has been analyzed and summarized for technical experts by CASTMAN.

![Bild 1. Einordnung der Karosseriebauweise „Mega-Casting“ und dessen Konzepte mit beispielhaften OEM und Modellen im Rahmenwerk der etablierten Karosseriebauweisen (Eigenleistung). Rahmenwerk und Teil-Darstellungen in Anlehnung an Birkert et al. [3], Stellantis [14], Land Rover [15], Tesla [5]. Grafik: WZL](https://castman.co.kr/wp-content/uploads/image-2970-1024x668.webp)

Keywords

- Primary Keyword: Mega-Casting

- Secondary Keywords: Giga-Casting, High Pressure Die Casting, Automotive Body in White, Aluminum Die Casting, Tesla

Executive Summary

- The Challenge: Traditional automotive body-in-white (BIW) construction involves assembling hundreds of individual stamped steel parts, a complex and capital-intensive process that new EV manufacturers are seeking to disrupt.

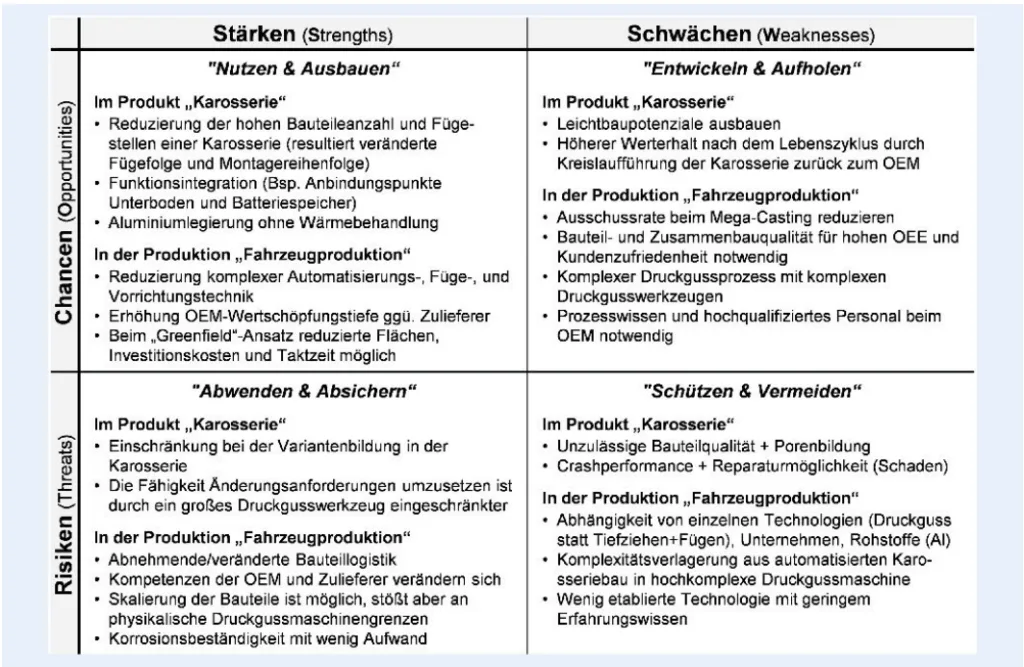

- The Method: An expert team from the Laboratory for Machine Tools and Production Engineering (WZL) at RWTH Aachen University conducted a comprehensive SWOT analysis to evaluate the opportunities, risks, strengths, and weaknesses of the Mega-Casting approach.

- The Key Breakthrough: Mega-Casting enables the production of large sections of a car body—or even the entire underbody—in a single aluminum high-pressure die casting, drastically reducing part count, simplifying assembly, and lowering investment costs for "greenfield" factories.

- The Bottom Line: While Mega-Casting presents a paradigm shift with significant production advantages, it introduces substantial new challenges in tooling complexity, crash performance, repairability, and process control that require deep HPDC expertise to overcome.

The Challenge: Why This Research Matters for HPDC Professionals

In the age of electromobility, established automotive OEMs are under pressure to fundamentally rethink their production processes to compete with agile new market entrants. The conventional body shop, built around steel monocoque construction, is a prime target for disruption. For years, aluminum die-cast components have been integrated into BIW structures to reduce part count in complex areas like shock towers.

Tesla's patented Mega-Casting approach represents the next evolutionary step: manufacturing entire front sections, rear sections, or even a complete unibody in a single HPDC shot. This approach is diametrically opposed to the established, multi-stage assembly process. This paper investigates the profound implications of this shift, analyzing the opportunities and risks for the entire automotive and supplier industry.

The Approach: Unpacking the Methodology

The research team from WZL at RWTH Aachen University systematically analyzed the impact of Mega-Casting on both the product (the car body) and the production process. The core of their methodology was a multi-expert SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis to provide a balanced and comprehensive view from an OEM's perspective.

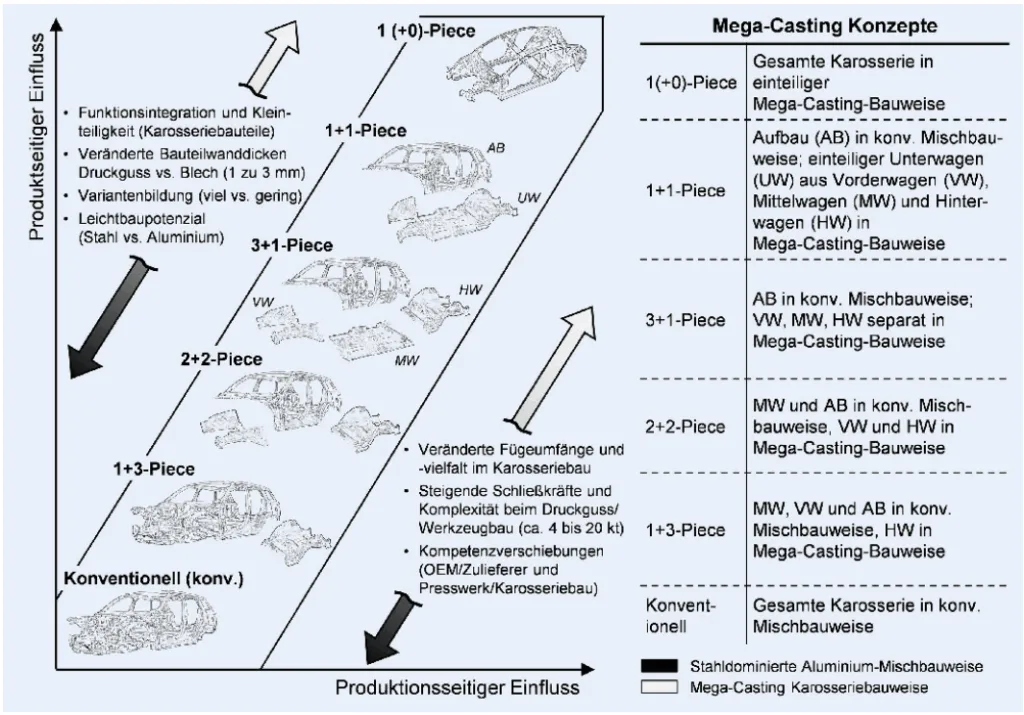

To structure their analysis, the researchers defined five distinct Mega-Casting concepts, illustrating the progressive replacement of conventional body parts with large-scale die castings (Figure 2):

- 1+3 Piece: One large casting (e.g., rear section), with three other major sections built conventionally.

- 2+2 Piece: Front and rear sections are mega-cast, connected by a conventional mid-section.

- 3+1 Piece: Front, rear, and middle (structural battery pack) sections are mega-cast, with only the upper body built conventionally.

- 1+1 Piece: The entire underbody is a single casting, with the upper body built conventionally.

- 1(+0) Piece: The ultimate vision of a complete car body produced in a single casting.

This framework allowed for a nuanced evaluation of the technological and business implications at each stage of adoption.

The Breakthrough: Key Findings & Data

The SWOT analysis revealed a clear trade-off: Mega-Casting simplifies downstream assembly at the cost of creating an extremely complex and demanding upstream die-casting process.

Finding 1: Radical Simplification of the Body Shop

A primary strength of Mega-Casting is the dramatic reduction in component count and joining operations. The paper highlights that this leads directly to a reduction in complex automation, joining, and fixture technology in the body shop. For a "greenfield" factory approach, this translates into reduced factory footprint, lower investment costs, and faster cycle times. Furthermore, the integration of features like connection points and battery housing directly into the casting eliminates entire process steps.

Finding 2: A Massive Shift in Complexity and Technical Risk

The simplification of the body shop comes at a price. The complexity is shifted almost entirely to the die-casting process. The paper identifies several critical weaknesses and threats:

- Crash Performance & Repairability: Aluminum die castings have limited formability, making crash energy absorption and post-accident repair significant challenges that must be solved at the design and alloy level.

- Process Control: The risk of porosity and ensuring consistent quality across such a large component is a major hurdle. The paper notes that achieving high Overall Equipment Effectiveness (OEE) and customer satisfaction requires deep process knowledge.

- Tooling and Flexibility: The massive, complex dies required for Mega-Casting make product design changes extremely difficult and expensive. This severely limits the ability to produce different vehicle variants from a single tool, a key weakness compared to flexible sheet metal processes.

- Dependency: Adopting Mega-Casting creates a strong dependency on a few key technologies (HPDC machines), suppliers, and raw materials (aluminum), which is a significant strategic risk.

Practical Implications for R&D and Operations

The paper's findings offer actionable insights for technical teams in the HPDC and automotive industries.

- For Process Engineers: This study suggests that the focus of process optimization shifts from managing hundreds of robotic joining operations to mastering the thermal management and flow dynamics within a single, massive die. The successful implementation of Mega-Casting depends on achieving low scrap rates for these high-value components.

- For Quality Control Teams: The data in the SWOT analysis (Figure 4) highlights that traditional BIW quality checks are insufficient. New non-destructive testing (NDT) methods and criteria must be developed to identify internal porosity and ensure the structural integrity required for crash performance, as post-production repairs are nearly impossible.

- For Design Engineers: The findings indicate that function integration (e.g., incorporating battery trays or suspension mounting points) is a major advantage. However, designers are constrained by HPDC principles like wall thickness (2-3 mm for die-cast vs. ~0.7 mm for sheet steel) and the need for draft angles. Early-stage collaboration between design and process teams is more critical than ever to avoid costly tool modifications.

Paper Details

Opportunities and Risks of Mega-Casting in Automotive Production - The Aluminum Die-Casted Body in White

1. Overview:

- Title: Chancen und Risiken von Mega-Casting in der Fahrzeugproduktion - Die Karosserie aus dem Aluminium-Druckguss (Opportunities and Risks of Mega-Casting in Automotive Production - The Aluminum Die-Casted Body in White)

- Author: G. Schuh, G. Bergweiler, L. Dworog, F. Fiedler

- Year of publication: 2022

- Journal/academic society of publication: WT WERKSTATTSTECHNIK BD. 112 (2022) NR. 9

- Keywords: Giga-Casting, Tesla, High pressure die casting

2. Abstract:

The electric car manufacturer Tesla granted a patent for Mega-Casting in 2018. This new manufacturing method should make it possible in the future to produce a car body in one process using aluminum high pressure die casting (HPDC). The approach is contrary to the established body shop. What does Mega-Casting mean for the automotive and supplier industry? A team of experts from the Laboratory for Machine Tools and Production Engineering (WZL) at RWTH Aachen University has examined the opportunities and risks of Mega-Casting in a SWOT-analysis.

3. Introduction:

In the course of electromobility, established automotive manufacturers (OEMs) must realign their production and face competition from new market participants. Both new and established players have the opportunity to completely rethink their corporate structures and consider new manufacturing processes. With Mega-Casting, Tesla aims to take the next step in large-format aluminum die-cast components, where entire car body parts, or even whole car bodies, are to be produced in a single casting. This paper shows how Mega-Casting fits into the overall picture of established car body construction methods, which Mega-Casting concepts are conceivable, and what product- and production-side opportunities and risks exist.

4. Summary of the study:

Background of the research topic:

The study traces the historical development of car body construction, from the early body-on-frame designs to the now-dominant steel monocoque (shell) construction. It charts the increasing use of aluminum in mixed-material designs, which serves as the direct predecessor to the aluminum-die-cast-dominant Mega-Casting approach.

Status of previous research:

The paper acknowledges Tesla's 2018 patent as the catalyst for this new production method. It also notes that other OEMs, including Volkswagen (Project "Trinity"), Volvo, and Mercedes-Benz (EQXX), as well as several Chinese OEMs (XPeng, Nio), have announced plans to adopt Mega-Casting. This indicates a growing industry trend and validates the need for a structured analysis of its implications.

Purpose of the study:

The purpose is to systematically evaluate the opportunities and risks of Mega-Casting from both a product (car body) and production perspective. The study aims to provide a framework for understanding this disruptive technology and its potential impact on OEMs and the supplier ecosystem.

Core study:

The core of the study is a comprehensive SWOT analysis performed by a team of experts. The analysis is broken down into two main areas: the product ("Karosserie") and the production process ("Fahrzeugproduktion"). For each area, the study identifies key strengths to leverage, weaknesses to overcome, opportunities to seize, and threats to mitigate. This is visualized in Figure 4. The study also categorizes Mega-Casting into five evolutionary concepts (Figure 2), from a single large cast part to a fully cast body, to analyze the progressive impact of its adoption.

5. Research Methodology

Research Design:

The research is designed as an expert-led qualitative analysis. It uses a structured framework to classify and evaluate a new manufacturing technology within the context of established industry practices.

Data Collection and Analysis Methods:

The primary analysis method is the SWOT analysis. A team of six project members at the WZL conducted individual SWOT analyses, which were then consolidated to form the final results presented in Figure 4. This approach combines multiple expert perspectives to create a robust assessment. The study also synthesizes information from patents, industry news, and existing technical literature on automotive body construction.

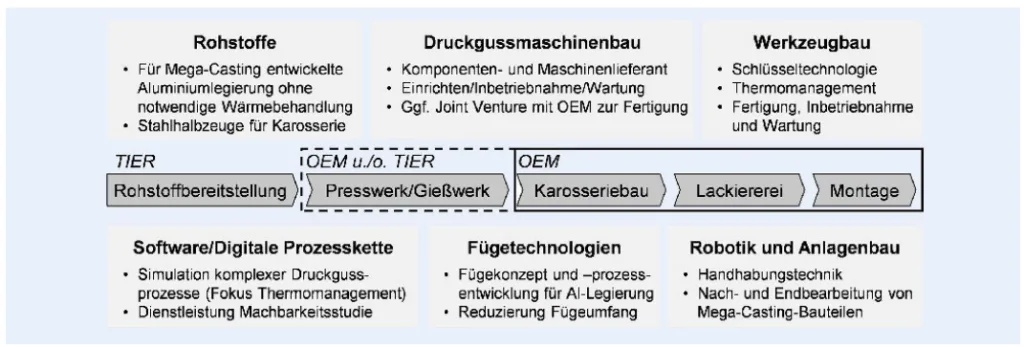

Research Topics and Scope:

The scope covers the entire automotive production chain affected by Mega-Casting, from raw material supply and die-casting machine manufacturing to the OEM's press shop, body shop, and final assembly. It examines the impact on the final product's characteristics (e.g., lightweighting potential, crash performance, variants) and the production system's attributes (e.g., logistics, process complexity, investment costs).

6. Key Results:

Key Results:

- Product Strengths: Reduction of part count and joining points, potential for function integration (e.g., battery housing), and the use of a new aluminum alloy that does not require heat treatment.

- Production Strengths: Reduction of complex automation in the body shop, increased vertical integration for the OEM, and potential for reduced factory footprint, investment, and cycle time in "greenfield" scenarios.

- Product Weaknesses/Threats: Limited lightweighting potential (thicker walls offset material density advantage), challenges in crash performance and repairability, and reduced ability to manage design changes and vehicle variants due to expensive, monolithic tooling.

- Production Weaknesses/Threats: High dependency on a single technology and supplier, a massive shift of complexity into the die-casting process, and a limited industry knowledge base for this new technology.

Figure Name List:

- Bild 1: Einordnung der Karosseriebauweise „Mega-Casting" und dessen Konzepte mit beispielhaften OEM und Modellen im Rahmenwerk der etablierten Karosseriebauweisen (Eigenleistung). Rahmenwerk und Teil-Darstellungen in Anlehnung an Birkert et al. [3], Stellantis [14], Land Rover [15], Tesla [5].

- Bild 2: Einteilung der Karosseriebauweise Mega-Casting in fünf Konzepte mit steigendem Anteil des Einsatzes von Aluminium-Druckguss (1+3 Piece bis 1 (+0)-Piece).

- Bild 3: Unternehmensarten und Beispiele im Themenfeld Mega-Casting in der automobilen Prozesskette und Zuliefererpyramide (TIER).

- Bild 4: Produkt- und produktionsseitige SWOT-Analyse zum Mega-Casting in der Fahrzeugproduktion.

7. Conclusion:

Mega-Casting is a new car body construction method that differs significantly from established methods in terms of manufacturing and material use. The SWOT analysis shows that while building the car body from a single component can likely reduce cycle time and complexity, it also creates new challenges regarding crash performance and repair solutions. Production processes, machinery, and resource management must be further developed. Specifically, die-casting machines for such large components (e.g., the 1(+0)-Piece concept) need to be developed with high qualitative reliability.

8. References:

- [1] Kallas M. K.: Multi-Directional Unibody Casting Machine For A Vehicle Frame And Associated Methods, US 2019/0217380 A1, 2018

- [2] Friedrich, H. E.: Leichtbau in der Fahrzeugtechnik, Springer Fachmedien Wiesbaden, Wiesbaden, 2013

- [3] Birkert et al.: Umformtechnische Herstellung komplexer Karosserieteile, Springer Berlin Heidelberg, Berlin, Heidelberg, 2013

- [4] Stucki, J.; Patinson, G.; Hamill, Q.; Prabhu, A.; Palanivel, S.; Lopez-Garrity, O.: Die cast aluminium alloys for structural components, PCT/US2021/014177, 2021

- [5] Tesla, Video: Battery Day, 2020. Internet: https://tesla-cdn.thron.com/ static/JIXJRM_2020-Battery-Day-2000_WBRTSS.mp4?xseo=. Zugriff am 04.07.2022

- [6] Rai, A.; Sawant, S.; Winberg, P.; Burgess, M.; Spencer, T.; Kornmayer, P.; Pattinson, G.; Edwards, P.; Rinaldi, C.; Reikher, A.; Kuehmann, C.; Moll, D.: Integrated energy absorbing castings, WO 2022/031991 A1, 2022

- [7] Verein Deutscher Ingenieure: Gießen von Fahrwerks- und Karosseriekomponenten, VDI 2318, VDI Verlag, 2018

- [8] Electrek: Tesla produces first Model Y megacast in gigafactory in Texas. Stand:2022. Internet: https://electrek.co/2021/05/17/tesla-produces-first-model-y-megacast-gigafactory-texas/. Zugriff am 04.07.22

- [9] Insideevs: VW's project Trinity To Use Giga-Casting & Automation to compete with Tesla. Stand 2022. Internet: https://insideevs.com/ news/577128/volkwagen-compete-tesla-gigapress-robots/. Zugriff am 04.07.22

- [10] Volvo Car Switzerland AG: Mega casting. Stand:2022. Internet: https://www.media.volvocars.com/ch/de-ch/media/photos/294346/me ga-casting-1. Zugriff am 04.07.22

- [11] Rakoto, B.; Ling, L.: Mega-Casting Trends for Automotive Manufactures, Mai 2022

- [12] YZweekly: Nios erstes Modell der ET5 mit "integrierter Druckgusstechnologie" wird in Serie produziert und ausgeliefert. Stand 2022. Internet: http://www.yzweekly.com/xyzd/zhengche/7604.htm. Zugriff am 02.09.2022

- [13] Phate Zhang/CnEVPost: HiPhi becomes latest Chinese EV startup to use large die-casting technology. Stand 01.03.2022. Internet: https://cnevpost.com/2022/03/01/hiphi-becomes-latest-chinese-ev-start up-to-use-large-die-casting-technology/. Zugriff am 06.09.2022

- [14] Stellantis: Lambda (historisch). Stand 2022. Internet: https://www.me dia.stellantis.com/de-de/lancia/gallery/1376. Zugriff am 02.09.2022

- [15] Land Rover, Land Rover Leichtbau Strategie, 2014. Stand 2022. Internet: https://media.landrover.com/dede/news/2014/05/land-rover-leichtbau-strategie. Zugriff am 21.02.2022

- [16] Idra: NEΟ 5500 – ΝΕΟ 6100 – ΝΕΟ 8000 – ΝΕΟ 9000. Stand 2022. Internet: https://www.idragroup.com/de/gigapress. Zugriff am 04.07.2022.

- [17] Bühler Group: Umfassendes Know-how rund um die Produktion von Megacasting. Stand 2022 Internet: https://www.buhlergroup.com/content/buhlergroup/global/ de/industries/die-casting/megacasting.html. Zugriff am 04.07.2022.

- [18] Spotlightmetal: LK Group introduces the World's First 6000T & 9000T Giant Die Casting Machine. Stand: 2022. Internet: https://www.spot lightmetal.com/lk-group-introduces-the-worlds-first-6000t-9000t-giant-die-casting-machine-a-1036839/. Zugriff am 04.07.2022

- [19] Alu-Web: Handtmann investiert in Megacasting-Lösung von Bühler. Stand 2022.Internet: https://alu-web.de/handtmann-investiert-in-mega casting-loesung-von-buehler/. Zugriff am 04.07.2022

- [20] Idra: The great success of Giga Press. Stand: 2022. Internet: https://www.idragroup.com/en. Zugriff am 04.07.2022

- [21] Fuchs: Mega-Casting: Druckgussverfahren revolutioniert Automobil-bau. Stand: 2022. Internet: https://www.fuchs.com/de/de/produkte/ schmierstoffe-und-services/schmierstoffe-fuer-spezialanwendungen/ umformschmierstoffe/mega-casting/. Zugriff am 04.07.2022

- [22] Home of Foundry: Think Big... Giga-Castings. Stand: 2022. Internet: https://www.home-of-foundry.de/news/think-biggiga-castings-1002. Zugriff am 04.07.2022

- [23] Briskham, P.: Joining of aluminium alloys with low ductility. 2022.

- [24] Paul, H.; Wollny, V.: Instrumente des strategischen Managements, De Gruyter Oldenbourg 2014.

- [25] Pischinger, S.; Seiffert, U.: Vieweg Handbuch Kraftfahrzeugtechnik, Springer Fachmedien Wiesbaden, Wiesbaden, 2021

- [26] Fuchslocher, G.: Gigacasting ist geeignet, den Karosseriebau neu zu denken, Automobil Produktion, 2022. Internet: https://www.automobil-produktion.de/interviews-734/gigacastingistgeeignet-den-karosserie bau-neu-zu-denken-501.html. Zugriff am 27.02.2022

Expert Q&A: Your Top Questions Answered

Q1: The paper mentions a new aluminum alloy that doesn't require heat treatment. Why is that so important for Mega-Casting?

A1: The paper cites a Tesla patent for such an alloy. This is critical because heat-treating a component as large and complex as a car's underbody is extremely challenging. It would require massive ovens and sophisticated fixtures to prevent distortion and warping during the heating and quenching process. Eliminating this step significantly reduces factory complexity, energy consumption, and capital investment, making the entire Mega-Casting process more viable.

Q2: How does Mega-Casting impact the lightweighting potential of using aluminum?

A2: The paper points out a key trade-off. While aluminum is about three times lighter than steel by density, HPDC parts require a minimum wall thickness of 2-3 mm, compared to about 0.7 mm for stamped steel sheets. This factor of three in thickness largely offsets the density advantage, meaning the direct lightweighting potential is less significant than one might assume. The main benefit comes from part consolidation rather than pure mass reduction.

Q3: What are the five different Mega-Casting concepts outlined in Figure 2, and what do they represent?

A3: The five concepts represent a gradual, evolutionary path to a fully cast car body. They are: 1+3 Piece (e.g., only the rear is cast), 2+2 Piece (front and rear cast), 3+1 Piece (front, rear, and middle/battery pack cast), 1+1 Piece (entire underbody is one casting), and 1(+0) Piece (the entire body is a single casting). This framework allows analysts and OEMs to assess the risks and benefits at each stage of adoption, rather than viewing it as an all-or-nothing transition.

Q4: According to the SWOT analysis, what is the single biggest "threat" to an OEM adopting Mega-Casting?

A4: The analysis in Figure 4 identifies a "complexity shift" as a major threat. OEMs would be moving away from a well-understood, decades-old process (stamping and joining) to a highly complex die-casting process. This creates a dependency on a few specialized machine manufacturers and a need for in-house expertise that is currently scarce. It's a shift from managing automated body shops to managing high-tech foundries, which represents a significant operational and strategic risk.

Q5: How does Mega-Casting affect the automotive supply chain?

A5: Figure 3 illustrates the new ecosystem. It creates huge opportunities for suppliers of large-tonnage die-casting machines (like Idra's "Gigapress"), advanced tooling, and simulation software. However, it disrupts the business of traditional Tier 1 suppliers who provide stamped sub-assemblies. The OEM's role also changes, as they may bring the casting process in-house or form joint ventures with casting specialists, thereby increasing their own value-add.

Conclusion: Paving the Way for Higher Quality and Productivity

The research from RWTH Aachen University confirms that Mega-Casting is more than a fleeting trend; it is a transformative production strategy with the potential to redefine automotive manufacturing. By replacing hundreds of parts with a single, intricate aluminum die casting, OEMs can achieve unprecedented simplification in their body shops. However, this simplification comes with a massive transfer of complexity to the casting process itself, demanding new solutions for material science, process control, and quality assurance. The success of this revolution hinges on mastering the intricacies of high-pressure die casting on an unprecedented scale.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Chancen und Risiken von Mega-Casting in der Fahrzeugproduktion - Die Karosserie aus dem Aluminium-Druckguss" by "G. Schuh, G. Bergweiler, L. Dworog, F. Fiedler".

- Source: DOI 10.37544/1436-4980-2022-09-52

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.