Unlocking Die Longevity: A Technical Guide to Selecting Die Casting Die Materials for Thermal Fatigue Resistance

This technical summary is based on the academic paper "MATERIALS ON DIES FOR PRESSURE DIE CASTING" by E. RAGAN, J. DOBRÁNSKY, P. BARON, T. OLEJÁR, published in METALURGIJA (2012).

Keywords

- Primary Keyword: Die Casting Die Material

- Secondary Keywords: Thermal Fatigue, Die Service Life, High Pressure Die Casting, Tool Steel, Molybdenum Dies, Material Properties

Executive Summary

- The Challenge: Pressure die casting dies fail prematurely due to cyclical thermal stress (thermal fatigue) caused by contact with molten metal, leading to cracking and the end of the die's service life.

- The Method: The paper theoretically defines the thermal stress generated in the die surface and derives a mathematical model that links the die's service life (number of cycles) to the pouring temperature of the cast metal.

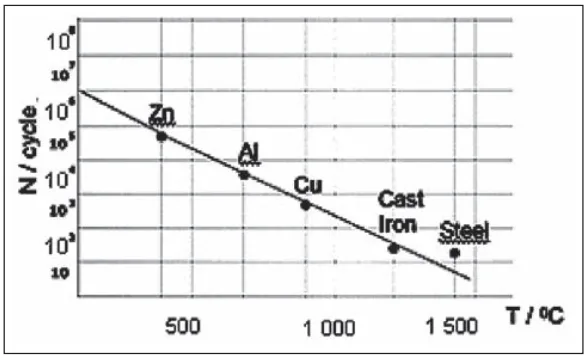

- The Key Breakthrough: The service life of a die material has a logarithmic inverse relationship with the pouring temperature, meaning small increases in temperature drastically reduce the number of cycles a die can withstand before failure.

- The Bottom Line: Selecting die materials with a combination of low thermal expansion, low modulus of elasticity, and high thermal conductivity is critical to minimizing thermal stress and maximizing die life, with materials like molybdenum showing significant promise for casting high-temperature ferrous alloys.

The Challenge: Why This Research Matters for HPDC Professionals

In high pressure die casting, the repeated injection of high-temperature liquid metal into a cooler die creates a severe thermal shock on the die surface. This cyclical heating and cooling generates immense compressive and tensile stresses. Over thousands of cycles, this thermal fatigue leads to the initiation and propagation of cracks, a phenomenon known as heat checking. This degradation ultimately dictates the end of the die's useful service life, causing costly downtime and replacement. Understanding the fundamental material properties that resist this failure mechanism is paramount for improving operational efficiency and reducing tooling costs. This research directly addresses this core challenge by analyzing the physics of thermal stress and evaluating the materials best suited to withstand it.

The Approach: Unpacking the Methodology

The study provides a theoretical framework for understanding and predicting die failure due to thermal fatigue. The methodology is based on fundamental material science and mechanics principles.

Method 1: Quantifying Thermal Stress: The paper begins by modeling the die surface as a layer that attempts to expand when heated by liquid metal. Since this expansion is constrained by the cooler underlying material, compressive stress arises. The extension of this layer is defined as δ = α(T₁ - T₀), where α is the coefficient of thermal expansion and (T₁ - T₀) is the temperature change. This extension generates a stress σ = (δ * m * E) / (m - 1), where E is Young's modulus and m is Poisson's constant. Using typical values for steel, the paper calculates a stress of 1,200 MPa, highlighting the extreme forces at play.

Method 2: Modeling Die Service Life: The research then proposes a relationship where the number of cycles (N) a die can endure is inversely proportional to the pouring temperature (T). This is expressed mathematically as dT = -k(dN/N). By integrating this relationship, the authors derive a logarithmic equation for service life: logN = A – k₁t. This model predicts that as the pouring temperature increases, the achievable number of cycles decreases exponentially, a finding that aligns with empirical observations.

The Breakthrough: Key Findings & Data

The paper's theoretical analysis and review of material properties yield critical insights for die material selection and process control.

Finding 1: The Logarithmic Decline of Die Life with Temperature

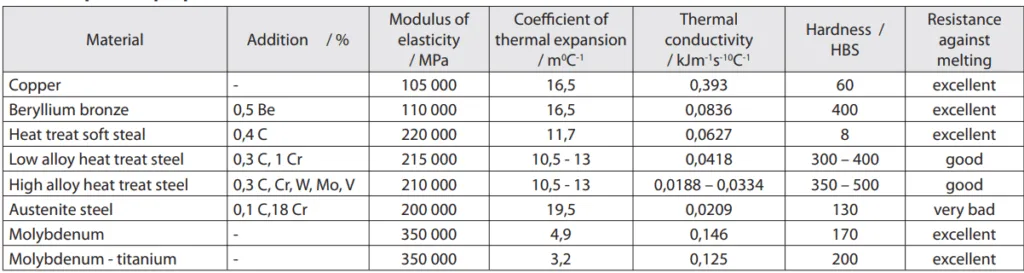

The most significant finding is the quantifiable relationship between pouring temperature and die life. As shown in Figure 2, the service life (N/cycle) drops dramatically as the temperature of the cast alloy increases. For zinc alloys cast at lower temperatures, dies can achieve over 10 million cycles. However, for ferrous alloys (cast iron, steel) cast at temperatures approaching 1,500 °C, the service life plummets to just a few hundred cycles. This logarithmic curve powerfully illustrates why casting high-temperature alloys like copper and steel is so challenging for die longevity.

Finding 2: Molybdenum and Specialized Steels Show Highest Potential

The analysis of material properties in Table 1 reveals the ideal characteristics for resisting thermal fatigue: low thermal expansion, low modulus of elasticity, and high thermal conductivity. While standard steels offer a balance, specialized materials show superior potential. Molybdenum stands out with a very low coefficient of thermal expansion (4.9 m/°C⁻¹) and high thermal conductivity (0.146 kJm⁻¹s⁻¹°C⁻¹). These properties mean it generates significantly less stress under thermal shock compared to steel. However, its brittleness at low temperatures and need for surface protection against sublimation at high temperatures are practical challenges that must be addressed. For casting aluminum, chrome-molybdenum steels are highlighted as effective, while tungsten-chrome steels are noted for their high-temperature hardness and wear resistance, making them suitable for gate areas.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that minimizing pouring temperature, even by a small margin, can yield a significant extension in die life due to the logarithmic relationship shown in Figure 2. Precise thermal management and control are not just for part quality, but are critical for tooling asset management.

- For Quality Control Teams: The data in Table 1 illustrates the direct link between fundamental material properties (thermal expansion, conductivity) and performance. This can inform material certification and incoming inspection criteria for new tool steels, ensuring they meet the required specifications for thermal fatigue resistance.

- For Design Engineers: The findings indicate that die design should aim to mitigate thermal stress concentrations. The high potential of molybdenum suggests that for casting ferrous alloys, designing dies with molybdenum inserts in high-heat-load areas could be a viable strategy, provided its brittleness and surface protection requirements are managed.

Paper Details

MATERIALS ON DIES FOR PRESSURE DIE CASTING

1. Overview:

- Title: MATERIALS ON DIES FOR PRESSURE DIE CASTING

- Author: E. RAGAN, J. DOBRÁNSKY, P. BARON, T. OLEJÁR

- Year of publication: 2012

- Journal/academic society of publication: METALURGIJA 51 (1) 117-120

- Keywords: stress of material, thermal fatigue, service life, material properties

2. Abstract:

In the contribution the stress of die materials of thermal fatigue is defined and material life is derived theoretically and compared with the measured values. The important properties of the die materials as thermal conductivity, coefficient of thermal expansivity, modulus of elasticity and mechanical properties are described. Binding to it single die materials as carbon steels and chrome-tungsten steels are analyzed. As the perspective die material for pressure die casting of ferrous metals appears molybdenum with regard to advantageous properties.

3. Introduction:

At operation of pressure die casting dies are cyclically stressed on thermal fatigue. After exhausting of material sliding properties the end of die service life comes. For the more profound explanation it is necessary further to analyze thermal conditions and single important properties of die material during the operation of pressure die casting.

4. Summary of the study:

Background of the research topic:

The primary failure mechanism for dies used in pressure die casting is thermal fatigue. This occurs due to the cyclical thermal stresses induced by repeated contact with high-temperature liquid metal, which eventually leads to cracking and the end of the die's operational life.

Status of previous research:

The study builds upon established principles of thermal mechanics, citing references [1, 2] for the foundational equations governing thermal expansion and stress generation in a constrained material layer.

Purpose of the study:

The objective is to define the stress state in die materials resulting from thermal fatigue, to theoretically derive a model for the service life of these materials, and to analyze the critical material properties that govern performance in pressure die casting applications.

Core study:

The paper presents a theoretical derivation of thermal stress based on the coefficient of thermal expansion and Young's modulus. It then develops a mathematical model that establishes a logarithmic relationship between die service life (in cycles) and the pouring temperature of the cast alloy. This model is compared with measured data. The study analyzes key properties—thermal conductivity, thermal expansion, modulus of elasticity, and mechanical properties—for various materials, including carbon steels, alloyed steels (Cr, W, Mo, V), and molybdenum. It discusses the suitability of these materials for casting different alloys (zinc, aluminum, copper, ferrous metals) and explores future development directions, such as the use of molybdenum and composite materials.

5. Research Methodology

Research Design:

The research is an analytical and theoretical study. It employs fundamental equations from physics and material science to model thermal stress and die life. The theoretical derivations are then compared and correlated with existing empirical data on die performance.

Data Collection and Analysis Methods:

The study utilizes established material property data from literature, as presented in Table 1. It also references a graphical representation of measured die service life as a function of pouring temperature (Figure 2) to validate its theoretical model. The analysis involves comparing the properties of different classes of die materials to explain their relative performance and identify promising candidates for demanding applications.

Research Topics and Scope:

The scope of the research includes:

1. The theoretical calculation of compressive and tensile stresses arising from thermal cycling in a die.

2. The derivation of a service life equation linking the number of cycles to failure with the casting temperature.

3. A comparative analysis of die materials, including copper, various steels (carbon, low-alloy, high-alloy, austenitic), and molybdenum, based on their thermal and mechanical properties.

4. Discussion of chemical stress (dissolution, sticking) and development directions for future die materials.

6. Key Results:

Key Results:

- A theoretical model for thermal stress in dies was established, showing stresses can reach up to 1,200 MPa.

- Die service life (N) was found to be logarithmically and inversely proportional to the pouring temperature (T), as described by the equation logN = A – k₁t. This is visually confirmed by Figure 2.

- The ideal properties for a die material to resist thermal fatigue are low coefficient of thermal expansion, low modulus of elasticity, and high thermal conductivity.

- Molybdenum is identified as a highly promising "perspective" material for dies used in casting high-temperature ferrous alloys due to its very low thermal expansion and high thermal conductivity, despite challenges with brittleness and the need for surface protection.

- For aluminum casting, chrome-molybdenum steels are effective, while tungsten-chrome steels are noted for their high-temperature hardness and wear resistance.

Figure Name List:

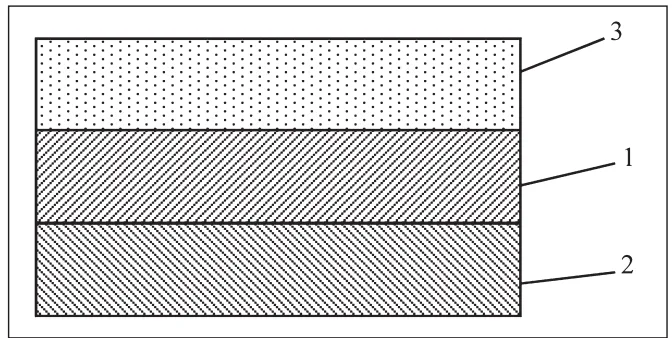

- Figure 1 The surface layer 1 and undersurface layer 2 of the die at filling the die with the liquid metal 3

- Figure 2 Dependence of die material service life at pressure die casting on pouring temperature

7. Conclusion:

The contribution describes the cyclical stresses on thermal fatigue of die materials and derives them analytically. Further, the exhaustion of the material sliding properties is derived with the end of die service life. The single properties of the die materials are also described. The development was very important at the transition from zinc to aluminum and copper alloys at die cast, and it can do service at the transition from research to working of the ferrous alloys die cast.

8. References:

- [1] W. Leis, Tlakové lití, materiály, Slévarenství, 7(2007), 327-333.

- [2] E.J. Vinarcik, High Integrity Die Casting Processes, John Wiley and Sons, New York, 2003.

- [3] J. Nová, I. Nováková, J. Bradáč, Technologie I, TU Liberec, 2006.

- [4] D. Bolibruchová, E. Tillová, Zlievá-renské zliatiny Al-Si, ŽU Žilina, 2005.

- [5] E. Ragan a kol., Liatie kovov pod tlakom, FVT TU Košice so sídlom v Prešove, Prešov, 2007.

- [6] J. Malík, Zlievárenské stroje a zariadenia, HF TU, Košice, 2006.

- [7] E. Ragan, Proces liatia pod tlakom, FVT TU Košice so sídlom v Prešove, Prešov, 1997.

- [8] M. Mihaliková, J. Janek, Metalurgija, 46 (2007) 2, 107-110.

- [9] M. Janák, M. Kočiško, IN-TECH 2010, Prague, 2010, 401-404.

- [10] P. Demeč, M. Varchola, J. Svetlík, Metalurgija, 49 (2010) 2, 604-608.

- [11] H.R. Wang, W. Wang, J.O. Gao, Materials Letters, 64 (2010) 2, 219-222.

- [12] L. Běhálek, Povrcháři, 3 (2008), 4-5.

- [13] I. Orlovský, M. Hatala, Technički Vjesnik, 16 (2009) 2, 27-30.

- [14] P. Demeč, J. Svetlík, Acta Mechanica Slovaca, 13 (2009) 4, 68-73.

- [15] P. Monka, K. Monková, CCT 2007, Parbubice, 2007, 437-444.

- [16] J. Jurko, Applied Mechanics and Materials, 39 (2011), 369-374.

- [17] R. Kreheľ, Tematický magazine, 6 (2009) 1, 20-21.

- [18] J. Jurko, A. Panda, M. Gajdoš, International Journal Machining and Machinability of Materials, 5 (2009) 4, 383-400

- [19] S. Hloch et al., Strojarstvo, 49 (2008) 4, 303 – 309.

- [20] M. Brožek, M. Müller, Strojírenská technologie, 9 (2004) 1, 9-15.

- [21] J. Brychta, R. Čep, J. Nováková, L. Petřkovská, Technologie II, VŠB TU, Ostrava, 2007

- [22] R. Čep, M. Neslušan, B. Barišič, Strojarstvo, 50 (2008) 6, 337-345.

Expert Q&A: Your Top Questions Answered

Q1: Why is molybdenum considered such a promising die material despite its well-known issues with brittleness and high-temperature sublimation?

A1: The paper highlights molybdenum's potential based on its fundamental properties that directly combat thermal fatigue. Its coefficient of thermal expansion (4.9 x 10⁻⁶ /°C) is less than half that of steel, and its thermal conductivity is significantly higher. This combination means that for a given thermal shock, the molybdenum surface will expand less and dissipate heat faster, resulting in much lower internal stress. While its brittleness and need for surface protection (e.g., nitriding) are significant engineering challenges, its inherent resistance to thermal stress makes it a prime candidate for the extreme conditions of ferrous die casting.

Q2: The paper mentions "secondary hardness" in high-alloyed steels. How does this phenomenon impact die material selection for high-temperature applications?

A2: Secondary hardness is a critical property for dies used with high-temperature alloys like aluminum or copper. It refers to the increase in hardness observed when certain high-alloy steels (containing elements like W, Mo, V) are tempered at high temperatures (above 400°C). This occurs because fine, complex carbides precipitate within the steel matrix. This phenomenon allows the die to maintain its strength and wear resistance at the elevated operating temperatures encountered in casting, preventing plastic deformation and premature failure, which would occur in simpler steels whose hardness would decrease at such temperatures.

Q3: What is the practical significance of the logarithmic relationship between die life and pouring temperature shown in Figure 2?

A3: The logarithmic relationship means that die life is not linearly sensitive to temperature; it is exponentially sensitive. For a process engineer, this implies that even a small, seemingly minor increase in the molten metal's pouring temperature can cause a disproportionately large reduction in the die's lifespan. This quantifies the critical importance of precise process control and thermal management, not just for casting quality but as a primary driver of tooling cost and operational uptime.

Q4: The paper discusses "sticking" in aluminum die casting. What is the underlying chemical mechanism described?

A4: The paper explains that sticking is a form of chemical stress caused by the metallurgical interaction between the molten aluminum and the iron-based die steel. According to the Fe-Al equilibrium diagram, at temperatures around 700°C, aluminum reacts with the iron in the die to form brittle intermetallic phases, specifically FeAl₃, Fe₂Al₅, and FeAl. These hard, brittle layers adhere to the die surface, damaging both the casting upon ejection and the die itself, leading to a failure mode often called "soldering" or sticking.

Q5: How does high thermal conductivity directly influence die life, beyond just faster cycle times?

A5: While high thermal conductivity aids in rapidly solidifying the casting for shorter cycles, its primary benefit for die life is stress reduction. The thermal stress is proportional to the temperature difference (ΔT) between the hot surface layer and the cooler die body. A material with high thermal conductivity quickly dissipates heat from the surface into the bulk of the die, lowering the peak temperature (T₁) of the surface layer. This reduction in peak temperature directly minimizes the ΔT, which in turn reduces the amount of thermal expansion and the resulting compressive and tensile stresses that cause thermal fatigue.

Conclusion: Paving the Way for Higher Quality and Productivity

The persistent challenge of thermal fatigue is a primary limiter of productivity and a major cost driver in high pressure die casting. This paper effectively demonstrates that the service life of a tool is fundamentally governed by the properties of the selected Die Casting Die Material. The key breakthrough is the clear, logarithmic link between pouring temperature and die life, underscoring that superior material selection—prioritizing low thermal expansion and high thermal conductivity—is the most effective strategy for maximizing tool longevity. As the industry moves toward casting higher-temperature alloys, materials like molybdenum and advanced chrome-molybdenum steels will become increasingly critical.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "MATERIALS ON DIES FOR PRESSURE DIE CASTING" by "E. RAGAN, J. DOBRÁNSKY, P. BARON, T. OLEJÁR".

Source: The paper was published in METALURGIJA 51 (2012) 1, 117-120. A direct link is not provided in the source document.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.