Boost Strength and Wear Resistance in AZ91 Die Casting: New Research Reveals Optimal Process Parameters

This technical summary is based on the academic paper "Investigation of Tribological and Mechanical Properties of Biodegradable AZ91 Alloy Produced by Cold Chamber High Pressure Casting Method" by Levent Urtekin, Recep Arslan, Fatih Bozkurt, and Ümit Er, published in Archives of Metallurgy and Materials (2021).

Keywords

- Primary Keyword: AZ91 HPDC Parameters

- Secondary Keywords: AZ91 magnesium alloy, cold chamber die casting, mechanical properties, tribological properties, wear resistance, biodegradable alloy

Executive Summary

- The Challenge: To overcome common process limitations and enhance the mechanical strength and wear resistance of the widely used AZ91 magnesium alloy in high-pressure die casting (HPDC).

- The Method: The study systematically varied key cold chamber HPDC process parameters—casting temperature, in-mold pressure, and gate speed—to produce AZ91 samples and compared their properties against conventionally cast samples.

- The Key Breakthrough: A specific combination of process parameters—a casting temperature of 680°C, an in-mold pressure of 1000 bar, and a gate speed of 30 m/s—produced an AZ91 alloy with the highest tensile strength, hardness, and wear resistance.

- The Bottom Line: Precise control of HPDC parameters is critical for refining the grain structure of AZ91 alloy, directly leading to superior mechanical and tribological properties that significantly outperform those achieved through conventional casting.

The Challenge: Why This Research Matters for HPDC Professionals

Magnesium alloys, particularly AZ91, are highly sought after in aerospace, automotive, and electronics for their exceptional strength-to-weight ratio. High-pressure die casting (HPDC) is the go-to manufacturing method for producing these components at scale. However, the process is not without its challenges.

Engineers frequently grapple with issues like gas porosity and heat treatment difficulties, which can compromise the mechanical integrity of the final part. The final quality of an HPDC component is highly sensitive to process parameters like temperature, pressure, and flow rate. Without a clear understanding of how these variables interact, achieving consistent, high-performance parts is difficult. This research addresses this critical knowledge gap by investigating how to manipulate these parameters to produce a stronger, more durable AZ91 alloy.

The Approach: Unpacking the Methodology

The researchers conducted a rigorous experimental study to isolate the effects of different process parameters on AZ91 alloy properties.

Method 1: Sample Production via HPDC and Conventional Casting

- Material: AZ91 Magnesium alloy ingots (9.0 wt% Al, 0.9 wt% Zn).

- HPDC Equipment: A Metal Pres MP100 (1600 kN) cold chamber die casting machine.

- HPDC Test Groups: Three distinct groups of samples were produced by varying key parameters:

- Group 1: 680°C casting temp, 1000 bar in-mold pressure, 30 m/s gate speed.

- Group 2: 680°C casting temp, 1000 bar in-mold pressure, 45 m/s gate speed.

- Group 3: 640°C casting temp, 1200 bar in-mold pressure, 45 m/s gate speed.

- Control Group: A fourth group of samples was produced using a conventional casting method to serve as a baseline for comparison.

Method 2: Comprehensive Material Testing and Analysis

- Microstructure Analysis: Samples were prepared according to standard metallographic procedures to analyze grain structure and size, calculated using the intercept length method (ASTM E112).

- Mechanical Testing:

- Tensile Test: Performed on a universal testing machine according to ASTM B557M-2016 to determine tensile strength and elongation.

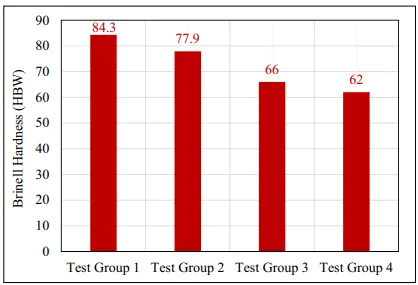

- Hardness Test: Brinell hardness (HBW) was measured using an Emcotest DuraVision 30 model.

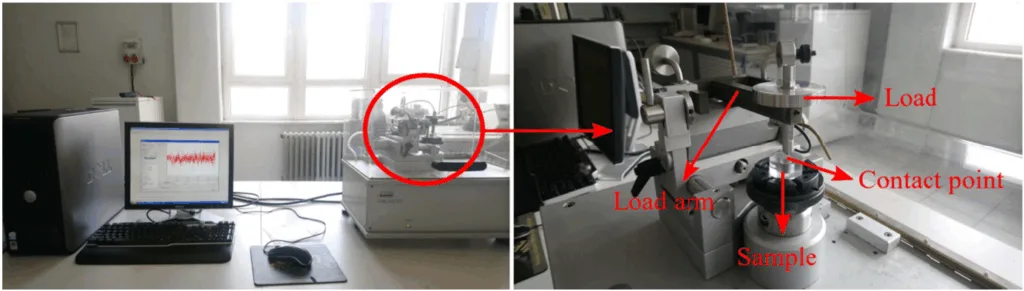

- Tribological Testing: Dry sliding wear behavior was assessed using a ball-on-disc CSM-Tribometer with a WC ball, following the ASTM G99 standard to measure friction coefficient and wear rate.

The Breakthrough: Key Findings & Data

The study revealed a direct and significant link between HPDC process parameters, the resulting microstructure, and the final mechanical and wear properties of the AZ91 alloy.

Finding 1: Optimal Parameters Yield Superior Strength and Hardness

The mechanical properties were found to be highly dependent on the process parameters, which directly influenced the grain size of the alloy. The HPDC samples produced with optimized parameters significantly outperformed the conventionally cast samples.

- As shown in Figure 3 and Figure 4, Test Group 1 (680°C, 1000 bar, 30 m/s) exhibited the highest mechanical properties: a tensile strength of 221 MPa and a Brinell hardness of 84.3 HBW.

- In contrast, the conventionally cast samples (Group 4) showed a much lower tensile strength of 172 MPa and a hardness of 62 HBW. This improvement is attributed to the fine-grained structure (ASTM grain size number 10) achieved with the faster cooling rate of the HPDC process, which hinders dislocation movement and strengthens the material.

Finding 2: Higher Hardness Directly Translates to Better Wear Resistance

The tribological tests confirmed that the mechanical property improvements led to enhanced wear performance. A clear inverse relationship was observed between hardness and wear.

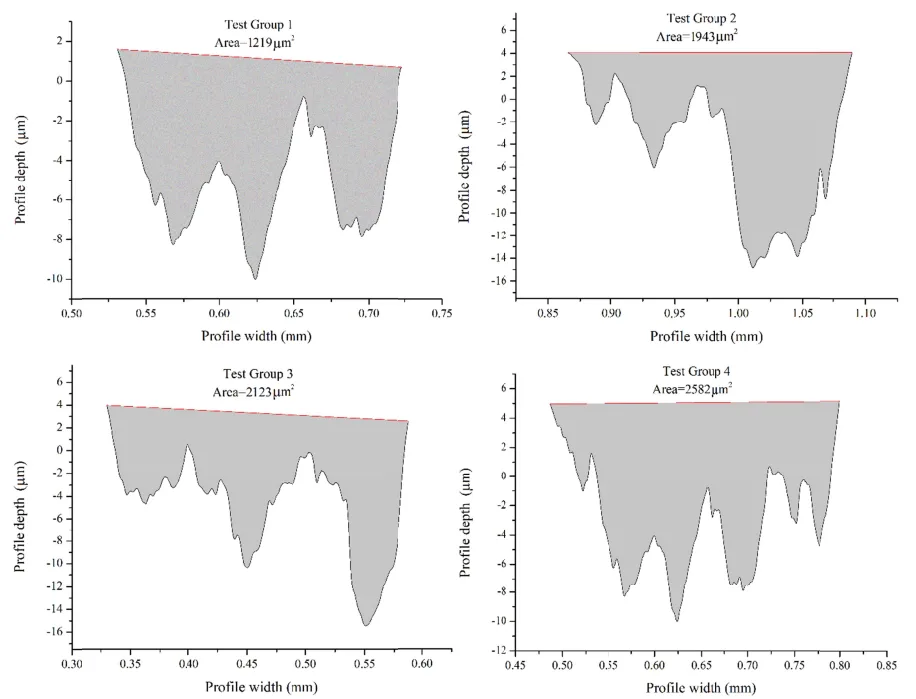

- According to Table 5 and Figure 15, Test Group 1, which had the highest hardness, also demonstrated the best wear performance with the lowest average friction coefficient (0.26) and the lowest specific wear rate (6.095 x 10⁻⁵ mm³/Nm).

- Conversely, the softer, conventionally cast sample (Group 4) experienced the most wear, with the highest friction coefficient (0.33) and a specific wear rate of 12.910 x 10⁻⁵ mm³/Nm—more than double that of the optimized HPDC sample.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting casting temperature to 680°C, in-mold pressure to 1000 bar, and gate speed to 30 m/s may contribute to a significant improvement in the strength and wear resistance of AZ91 components by refining the grain structure.

- For Quality Control Teams: The data in Figure 3 (Tensile Strength) and Figure 4 (Hardness) of the paper illustrates the direct effect of process parameters on key mechanical properties, which could inform new, tighter quality inspection criteria for critical components.

- For Design Engineers: The findings indicate that achieving superior material properties is not just about alloy selection but is heavily dependent on the manufacturing process. This reinforces the need to consider HPDC process capabilities and limitations during the early design phase for parts requiring high strength and durability.

Paper Details

Investigation of Tribological and Mechanical Properties of Biodegradable AZ91 Alloy Produced by Cold Chamber High Pressure Casting Method

1. Overview:

- Title: Investigation of Tribological and Mechanical Properties of Biodegradable AZ91 Alloy Produced by Cold Chamber High Pressure Casting Method

- Author: Levent Urtekin, Recep Arslan, Fatih Bozkurt, Ümit Er

- Year of publication: 2021

- Journal/academic society of publication: Arch. Metall. Mater. 66 (1), 205-216

- Keywords: Die casting, AZ91 magnesium alloy, cold chamber high pressure casting method, mechanical properties of AZ91 magnesium alloy, wear of AZ91 alloy, tribological properties of AZ91 alloy

2. Abstract:

In this study, AZ91 Magnesium alloy is produced by cold chamber high pressure die casting (HPDC) method. Different combinations of the cold chamber HPDC process parameters were selected as; in-mold pressure values of 1000 bar and 1200 bar, the gate speed of 30 m/s and 45 m/s, the casting temperatures of 640°C and 680°C. In addition, the test samples were produced by conventional casting method. Tensile test, hardness test, dry sliding wear test and microstructure analysis of samples were performed. The mechanical properties of the samples produced by the cold chamber HPDC and the conventional casting method were compared. Using these parameters; the casting temperature 680°C, in-mold pressure 1000 bar and the gate speed 30 m/s, the highest tensile strength and the hardness value were obtained. Since the cooling rate in the conventional casting method is slower than that of the cold chamber HPDC method, high mechanical properties are obtained by the formation of a fine-grained structure in the cold chamber HPDC method. In dry sliding wear tests, it was observed that there was a decrease in friction coefficient and less material loss with the increase of hardness values of the sample produced by the cold chamber HPDC method.

3. Introduction:

Magnesium is one of the lightest metallic materials, making it desirable for various industrial applications, including aircraft, automotive, and mobile equipment. Among magnesium alloys, AZ91 (containing 9.0 wt% Al, 0.9 wt% Zn) is one of the most preferred and commercially used. High pressure die casting (HPDC) is an efficient, high-capacity manufacturing technique suitable for producing magnesium alloy parts. HPDC machines are classified as cold chamber or hot chamber, with cold chamber machines being suitable for alloys with high melting temperatures like magnesium. The quality and mechanical properties of HPDC products depend on process parameters such as casting temperature, pressure, and gate speed. While HPDC offers advantages like high production rates and fine microstructures, it also has disadvantages like potential gas porosity. Recent research has focused on investigating the influence of process parameters on the mechanical properties of magnesium alloys. This study aims to investigate the effect of casting temperature, in-mold pressure, and gate speed on the mechanical and tribological properties of AZ91 alloy produced by cold chamber HPDC and compare them to conventionally cast samples.

4. Summary of the study:

Background of the research topic:

The study is centered on the AZ91 magnesium alloy, a material valued for its low density and good strength-to-weight ratio. The manufacturing process under investigation is cold chamber high-pressure die casting (HPDC), a method known for its high efficiency and ability to produce parts with fine microstructures due to rapid cooling.

Status of previous research:

Prior research has established that the mechanical properties of die-cast magnesium alloys are influenced by various process parameters. Numerous publications have focused on producing magnesium alloys via the HPDC method and have investigated the influence of different parameters on the properties of AZ and AM series alloys.

Purpose of the study:

The primary objective was to systematically investigate the effect of three key HPDC process parameters—casting temperature, in-mold pressure, and gate speed—on the resulting mechanical (tensile strength, hardness) and tribological (friction, wear) properties of AZ91 magnesium alloy. A secondary objective was to compare the properties of HPDC-produced samples with those made by a conventional casting method.

Core study:

The core of the study involved producing four sets of AZ91 samples. Three sets were manufactured using a cold chamber HPDC machine with different combinations of casting temperature (640°C, 680°C), in-mold pressure (1000 bar, 1200 bar), and gate speed (30 m/s, 45 m/s). A fourth set was produced by conventional casting to serve as a control. All samples were then subjected to a series of tests, including microstructure analysis, tensile tests, hardness tests, and dry sliding wear tests, to correlate the process parameters with the final material properties.

5. Research Methodology

Research Design:

The study employed an experimental research design. It compared multiple experimental groups (produced with varying HPDC parameters) against a control group (produced by conventional casting). This design allowed for a direct assessment of how changes in casting temperature, in-mold pressure, and gate speed affect the properties of the AZ91 alloy.

Data Collection and Analysis Methods:

Data was collected through empirical testing. AZ91 alloy samples were cast using a Metal Pres MP100 HPDC machine and a conventional furnace. The cast samples were then subjected to:

- Metallographic Characterization: Optical microscopy (Nikon Eclipse MA100) was used to analyze the microstructure. Grain size was calculated via the intercept length method per ASTM E112.

- Tensile Testing: An ALSO UTM 100 universal testing machine was used as per ASTM B557M-2016.

- Hardness Testing: Brinell hardness (HBW) was measured with an Emcotest DuraVision 30.

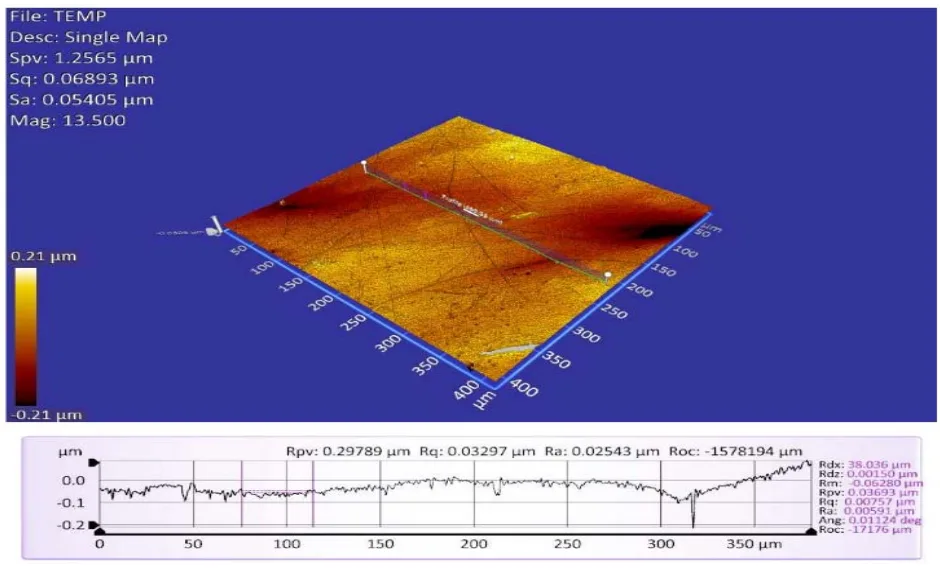

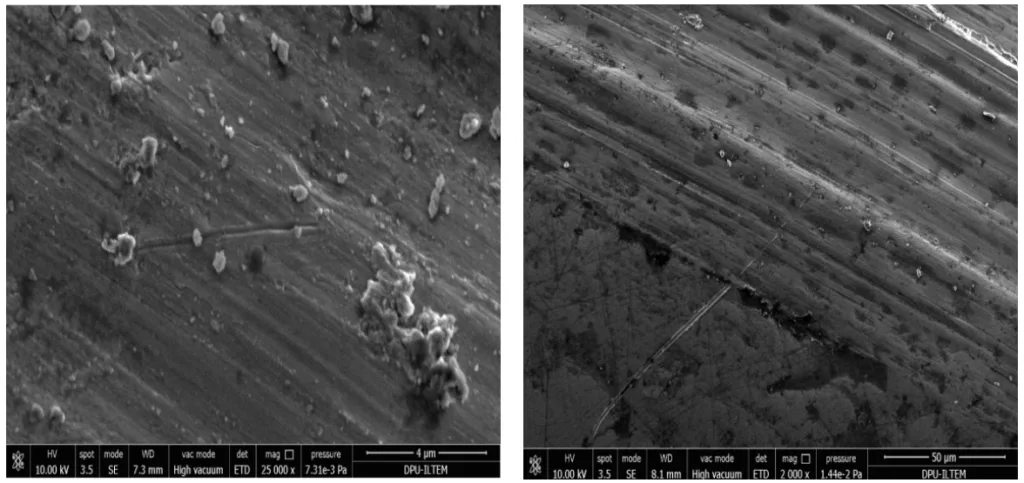

- Wear Testing: A ball-on-disc CSM-Tribometer was used for dry sliding wear tests according to ASTM G99. Wear tracks were examined with SEM, EDS, and a 3D optical profilometer.

Research Topics and Scope:

The research was focused specifically on the AZ91 magnesium alloy. The scope was limited to the investigation of three process variables in a cold chamber HPDC process: casting temperature (640°C and 680°C), in-mold pressure (1000 bar and 1200 bar), and gate speed (30 m/s and 45 m/s). The study evaluated the impact of these variables on tensile strength, elongation, hardness, friction coefficient, and specific wear rate.

6. Key Results:

Key Results:

- The highest tensile strength (221 MPa) and hardness value (84.3 HBW) were obtained for samples produced with a casting temperature of 680°C, in-mold pressure of 1000 bar, and gate speed of 30 m/s (Test Group 1).

- The fine-grained microstructure resulting from the faster cooling rate in the HPDC method led to higher mechanical properties compared to the coarse-grained structure of the conventionally cast samples.

- In dry sliding wear tests, a decrease in friction coefficient and less material loss were observed with an increase in the hardness values of the samples.

- Test Group 1, having the highest hardness, exhibited the lowest average friction coefficient (0.26) and the lowest specific wear rate (6.095 x 10⁻⁵ mm³/Nm).

- The conventionally cast sample (Test Group 4) had the lowest hardness (62 HBW) and the highest specific wear rate (12.910 x 10⁻⁵ mm³/Nm).

- SEM and EDS analysis of the wear tracks indicated the presence of abrasive wear (ploughing) and adhesive wear mechanisms.

Figure Name List:

- Fig. 1. Metal Pres MP100 die cast cold chamber machine

- Fig. 2. CSM tribometer and the view of the wear test setup

- Fig. 3. Tensile strength and elongation result of the samples produced by cold chamber HPDC and conventional casting methods

- Fig. 4. Brinell hardness of the samples produced by cold chamber HPDC and conventional casting methods

- Fig. 5. Mg-Al phase diagram [36]

- Fig. 6. Dry sliding wear behavior of test group 1

- Fig. 7. Dry sliding wear behavior of test group 2

- Fig. 8. Dry sliding wear behavior of test group 3

- Fig. 9. Dry sliding wear behavior of test group 4

- Fig. 10. 3D surface profile of sample from test group 1

- Fig. 11. 3D surface profile of sample from test group 2

- Fig. 12. 3D surface profile of sample from test group 3

- Fig. 13. 3D surface profile of sample from test group 4

- Fig. 14. Worn area of test group 1, test group 2, test group 3 and test group 4 samples

- Fig. 15. Specific wear rate of test group 1, test group 2, test group 3 and test group 4 samples

- Fig. 16. SEM of wear tracks for test group 1

- Fig. 17. SEM of wear tracks for test group 2

- Fig. 18. EDS analysis of the wear track for test group 2

- Fig. 19. SEM of wear tracks for test group 3

- Fig. 20. SEM of wear tracks for test group 4

![TABLE 4

The microstructure and the screenshot of software which shows

the ASTM G number [22,28]](https://castman.co.kr/wp-content/uploads/image-3455.webp)

7. Conclusion:

The study concluded that the dry sliding wear behavior and mechanical properties of AZ91 magnesium alloy can be controlled and optimized by selecting suitable cold chamber HPDC process parameters. The highest mechanical properties (tensile strength and hardness) were achieved for Test Group 1, which was produced at a casting temperature of 680°C, in-mold pressure of 1000 bar, and gate speed of 30 m/s. The superior properties of HPDC samples compared to conventionally cast samples are due to the formation of a fine-grained structure resulting from a faster cooling rate. This fine structure acts as a barrier to dislocation motion, increasing strength. Furthermore, the wear tests demonstrated that increased hardness leads to a decrease in friction coefficient and material loss, thereby improving wear resistance. The study also highlighted that if HPDC parameters are not properly controlled, the resulting mechanical properties can be similar to those of conventional casting, negating the benefits of the more costly HPDC process.

8. References:

- [1] M.A. Ashraf, Z. Liu, W.X. Peng, N. Yoysefi, Progress in Organic Coatings 136, 105296 (2019). DOI: 10.1016/j.porgcoat.2019.105296

- [2] B. Mingo, R. Arrabal, M. Mohedano, A. Pardo, E. Matykina, Surface and Coatings Technology 309, 1023-1032 (2017). DOI: 10.1016/j.surfcoat.2016.10.041

- [3] M. Gobara, M. Shamekh, Anti-Corrosion Meth & Material 61 (5), 319-327 (2014). DOI: 0.1108/ACMM-04-2013-1258

- [4] Y. Xin, C. Liu, X. Zhang, G. Tang, X. Tian, P. K. Chu, 2007, J. Mater. Res. 22 (7), 2004-2011 (2007). DOI: 10.1557/jmr.2007.0233

- [5] Q. Zhang, H. Zhang, Anti-Corrosion Meth & Material 66 (3), 264-273 (2019). DOI: 10.1108/ACMM-07-2018-1964

- [6] P.B. Srinivasan, C. Blawert, W. Dietzel, Materials Characterization 60 (8), 843-847 (2009). DOI: 10.1016/j.matchar.2009.01.014

- [7] P.B. Srinivasan, C. Blawert, W. Dietzel, Wear 266 (11-12), 1241-1247 (2009). DOI: 10.1016/j.wear.2009.03.013

- [8] W. Liu, B. Jiang, Q. Yang, J. Tao, B. Liu, F. Pan, Progress in Natural Science: Materials International 29 (4), 453-456 (2019). DOI: 10.1016/j.pnsc.2019.07.002

- [9] D. Mehra, M.M. Mahapatra, S.P. Harsha, Ind. Lubrication and Tribology 70 (2), 256-263 (2018). DOI: 10.1108/ILT-01-2018-0018

- [10] A. Bordbar-Khiabani, B. Yarmand, M. Mozafari, Materials Letters 258, 126779 (2020) DOI: 10.1016/j.matlet.2019.126779

- [11] S. Candan, M. Unal, E. Koc, Y. Turen, E. Candan, Journal of Alloys and Compounds 509 (5), 1958-1963 (2011). DOI: 10.1016/j.jallcom.2010.10.100

- [12] Y.Z. Lü, Q.D. Wang, W.J. Ding, X.Q. Zeng, Y.P. Zhu, Materials Letters 44 (5), 265-268 (2000). DOI: 10.1016/S0167-577X(00)00041-0

- [13] P. Zak, J. Lelito, J. Suchy, W. Krajewski, K. Haberl, P. Schumacher, World Journal of Engineering 8 (3), 277-282 (2011). DOI: 10.1260/1708-5284.8.3.277

- [14] S. Jayabharathy, P Mathiazhagan, Materials Today Proceedings, DOI: 10.1016/j.matpr.2019.09.142

- [15] Z. Yang, A. Ma, H. Liu, D. Song, Y. Wu, Y. Yuan, J. Jiang, J. Sun, "Managing Strength and Ductility in AZ91 Magnesium Alloy through ECAP Combined with Prior and Post Aging Treatment," Materials Characterization 152, 213-222 (2019). DOI: 10.1016/j.matchar.2019.04.022

- [16] J. Majhi, A.K. Mondal, Microstructure and Impression Creep Characteristics of Squeeze-Cast AZ91 Magnesium Alloy Containing Ca and/or Bi, Materials Science and Engineering: A, 744, 691-703 (2019). DOI: 10.1016/j.msea.2018.12.067

- [17] P.J. Blau, M. Walukas, Tribology International 33 (8), 573-579 (2000). DOI: 10.1016/S0301-679X(00)00108-0

- [18] H. Chen, A.T. Alpas, Wear 246 (1-2), 106-116 (2000). DOI: 10.1016/S0043-1648(00)00495-6

- [19] J. Sun, Z. Yang, H. Liu, J. Han, Y. Wu, X. Zhuo, D. Song, J. Jiang, A. Ma, G. Wu, Materials Science and Engineering: A, 759, 703-707, (2019). DOI: 10.1016/j.msea.2019.05.093

- [20] Y. Xia, Z. Jia, J. Jia, Advanced Tribology, 896-898 (2009). DOI: 10.1007/978-3-642-03653-8_306

- [21] H. Hoche, H.-J.Schroeder, H. Scheerer, E. Broszeit, C. Berger, Advanced Eng,nnering Materials 1, 10 (2002). DOI: 10.1002/1527-2648(20020212)4:1/2<42::AID-ADEM42>3.0.CO;2-E

- [22] R. Arslan, Master's Thesis, Determination of Mechanical Properties of Magnesium Alloys Produced by Cold Chamber Die Casting, Kırşehir Ahi Evran Üniversitesi, Kırşehir/Turkey (2019).

- [23] V.D. Majstorovic, N. Durakbasa, Proceedings of the 12th International Conference on Measurement and Quality Control - Cyber Physical Issue: IMEKO TC 14 2019, Springer International Publishing, Cham. (2019)

- [24] B.L. Mordike, T. Ebert, Materials Science and Engineering A, 302, 37-45 (2001). DOI: 10.1016/S0921-5093(00)01351-4

- [25] E. Gutman, Y. Unigovski, M. Levkovich, Z. Koren, E. Aghion, M. Dangur, Materials Science and Engineering: A, 234-236, 880-883 (1997). DOI: 10.1016/S0921-5093(97)00363-8

- [26] I. Vicario, I. Crespo, D. Val, U. Weiss, D. Cao, I. Martinez de la pera, J.M. Sanchez, J. of Materi. Eng. and Perform. 28 (7), 3935-3940 (2019). DOI: 10.1007/s11665-019-03981-9

- [27] P. Sharifi, J. Jamali, K. Sadayappan, J.Y. Wood, Journal of Materials Science & Technology 34 (2), 324-334 (2018). DOI: 10.1016/j.jmst.2016.09.004

- [28] S. Yazman, U. Koklu, L. Urtekin, S. Morkavuk, L. Gemi, Journal of Manufacturing Processes 57, 136-152 (2020). DOI: 10.1016/j.jmapro.2020.05.050

- [29] C.H. Cáceres, W.J. Poole, A.L. Bowles, C.J. Davidson, Materials Science and Engineering: A, 402 (1-2), 269-277 (2005). DOI: 10.1016/j.msea.2005.04.024

- [30] C.H. Cáceres, C.J. Davidson, J.R. Griffiths, C.L. Newton, Materials Science and Engineering: A, 325 (1-2), 344-355 (2002). DOI: 10.1016/S0921-5093(01)01467-8

- [31] ASM International, Metallography and Microstructures, American Society for Metals, Metals Park, Ohio (2004).

- [32] M.D. Nave, A.K. Dahle, D.H. StJohn, Magnesium Technology 2000, 233-242 (2000). DOI: 10.1002/9781118808962.ch33

- [33] D.G. Leo Prakash, D. Regener, W.J.J. Vorster, Journal of Alloys and Compounds 470 (1-2), 111-116 (2009). DOI: 10.1016/j.jallcom.2008.02.051

- [34] Y. Wei, L. Hou, L. Yang, B. Xu, M. Kozuka, H. Ichinose, Journal of Materials Processing Technology 209 (7), 3278-3284 (2009). DOI: 10.1016/j.jmatprotec.2008.07.034

- [35] C.D. Lee, J. Mater. Sci. 42 (24), 10032-10039 (2007). DOI: 10.1007/s10853-007-2003-1

- [36] I.J. Polmear, J.F. Nie, M. Qian, D. StJohn, Light Alloys: Metallurgy of the Light Metals, Butterworth-Heinemann, an imprint of Elsevier, Oxford (2017).

Expert Q&A: Your Top Questions Answered

Q1: What was the primary strengthening mechanism responsible for the improved mechanical properties in the optimal HPDC samples?

A1: The paper identifies grain boundary strengthening as the main mechanism. The rapid cooling rate inherent to the HPDC process produces a fine-grained microstructure. These smaller grains create more grain boundaries, which act as barriers to dislocation movement within the metal's crystal lattice, thus increasing the material's overall strength and hardness, a principle described by the Hall-Petch equation.

Q2: How did increasing the gate speed from 30 m/s to 45 m/s affect the alloy's properties?

A2: Comparing Test Group 1 (30 m/s) and Test Group 2 (45 m/s), where temperature and pressure were constant, the results showed that increasing the gate speed led to a decrease in tensile strength from 221 MPa to 201 MPa. The paper attributes this to the effect of grain size coarsening, even though the measured grain size was slightly finer. This suggests that while faster gate speeds can influence grain refinement, there may be other competing factors at play that negatively impact tensile properties under these specific conditions.

Q3: Why were the properties of the conventionally cast samples so much lower than the HPDC samples?

A3: The difference is primarily due to the cooling rate. In conventional casting, the cooling rate is much slower. This allows more time for grains to grow, resulting in a coarse-grained microstructure (ASTM grain size number 5.5). As explained by the principles of material science, a coarser grain structure has fewer boundaries to impede dislocation motion, leading to lower strength and hardness (172 MPa and 62 HBW) compared to the fine-grained HPDC samples.

Q4: What were the dominant wear mechanisms identified during the tribological tests?

A4: The paper identifies two primary wear mechanisms. The first is abrasive wear, characterized by ploughing and the formation of micro-valleys and hills on the wear track, which is expected given the high hardness of the WC ball compared to the AZ91 alloy. The second is adhesive wear, where particles of the magnesium substrate transferred to the WC ball due to high pressure and temperature at the contact point. EDS analysis confirmed the oxidation of this transferred material during sliding.

Q5: The paper mentions that improperly controlled HPDC can yield results similar to conventional casting. Which parameters in the study demonstrated this?

A5: Test Group 3 (640°C, 1200 bar, 45 m/s) provides an example of this. The tensile strength of this group was 175 MPa, which is very close to the 172 MPa of the conventionally cast Group 4. This finding underscores a critical point: simply using the HPDC process is not a guarantee of superior properties. The investment in HPDC technology only pays off when process parameters are carefully optimized; otherwise, the resulting part quality may not justify the higher cost of the method.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and actionable roadmap for enhancing the performance of AZ91 magnesium alloy components. The core challenge of achieving consistent, high-quality parts is directly addressed by demonstrating the profound impact of AZ91 HPDC Parameters. The key breakthrough is the identification of an optimal process window—680°C casting temperature, 1000 bar in-mold pressure, and 30 m/s gate speed—that doubles the wear resistance and significantly boosts the tensile strength and hardness compared to conventional methods.

For R&D and operations teams, these findings are not just academic; they are a practical guide to unlocking higher performance, reducing defects, and maximizing the value of the HPDC process.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Investigation of Tribological and Mechanical Properties of Biodegradable AZ91 Alloy Produced by Cold Chamber High Pressure Casting Method" by "Levent Urtekin, Recep Arslan, Fatih Bozkurt, Ümit Er".

Source: https://doi.org/10.24425/amm.2021.134777

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.