Unlocking Peak Performance in AlMg10 Alloy: How Casting and Heat Treatment Maximize Mechanical Properties

This technical summary is based on the academic paper "Influence of the conditions of casting and heat treatment on the structure and mechanical properties of the AlMg10 alloy" by P. Kordas, published in Journal of Achievements in Materials and Manufacturing Engineering (2017).

Keywords

- Primary Keyword: AlMg10 Mechanical Properties

- Secondary Keywords: Aluminium-magnesium alloys, Heat treatment, Liquid-state pressing, Casting technology, Tensile strength, Precipitation hardening, Microstructure analysis

Executive Summary

- The Challenge: To overcome limitations in the strength and elongation of AlMg10 alloy by understanding how different casting technologies and heat treatments affect its final microstructure and performance.

- The Method: The study systematically evaluated AlMg10 alloy castings produced by three methods—gravity sand casting, gravity metal mold casting, and liquid-state press molding—both in their raw (as-cast) state and after precipitation hardening heat treatment.

- The Key Breakthrough: Liquid-state pressing combined with heat treatment produced superior results, achieving a tensile strength (Rm) of approximately 330 MPa and an elongation (A5) greater than 10%, significantly outperforming other methods.

- The Bottom Line: The selection of casting technology is a critical factor that, when paired with optimized heat treatment, can unlock the full potential of AlMg10, making it a highly viable material for demanding structural components.

The Challenge: Why This Research Matters for HPDC Professionals

For engineers working with structural components in the automotive and shipping industries, cast aluminum-magnesium alloys like AlMg10 are highly valued for their good mechanical properties, excellent corrosion resistance, and good fluidity. However, achieving the high strength and high elongation required for structural applications is a significant challenge. The final performance of a cast part is not just a function of its chemical composition; it is decisively influenced by factors like grain size, morphology, secondary phase decomposition, and the cooling rate during solidification.

AlMg10, with up to 10.5% magnesium, has very good mechanical properties but is also sensitive. For instance, improper cooling during heat treatment can lead to deformation or cracking. This research was necessary to create a clear roadmap for controlling the alloy's structure by systematically choosing the right casting and heat treatment methods, thereby maximizing its mechanical performance and reliability.

The Approach: Unpacking the Methodology

The research was conducted on a commercial AlMg10 cast alloy, with its chemical composition detailed in Table 1.

Casting Methods: The researchers produced 200 mm x 100 mm x 25 mm plate-shaped castings using three distinct technologies to create varying solidification conditions:

- Gravity Sand Casting: Using a sand form made of pulp O.B.B. Sand „E".

- Gravity Metal Mold Casting (Die Casting): Using the lower half of a press machine's form, heated to approximately 150°C.

- Liquid-State Press Molding: Using a PHM - 250C hydraulic press, the alloy was poured and then pressed at 60 MPa for 30 seconds.

Heat Treatment: To investigate the effects of precipitation hardening, samples from each casting method were subjected to a specific heat treatment process:

- Supersaturation: Heating the cast at 445°C for 30 hours.

- Quenching: Cooling in hot water with a temperature of 100°C to prevent cracking.

- Aging: Spontaneous aging for 10 days.

Analysis: Samples from both the as-cast (raw) and heat-treated states were mechanically processed for tensile testing according to PN-EN ISO 6892-1:2016-09 standards. Metallographic observations were also performed to analyze the microstructure.

The Breakthrough: Key Findings & Data

The study revealed a clear correlation between the manufacturing process, the resulting microstructure, and the final mechanical properties of the AlMg10 alloy.

Finding 1: Casting Method Dictates As-Cast Properties and Microstructure

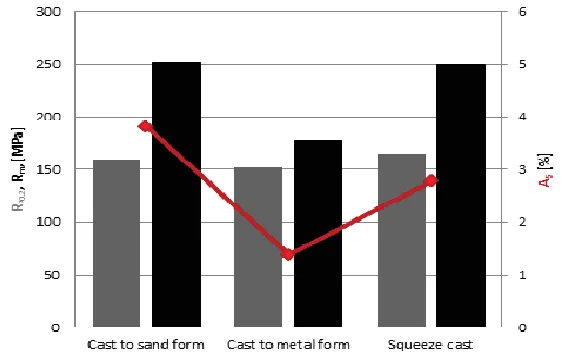

In the raw, non-heat-treated state, the casting method had a profound impact on performance. While sand-cast and press-molded samples showed similar high tensile strengths, the gravity die-cast sample was significantly weaker.

- Tensile Strength (Rm): As shown in Table 2, the sand-cast (251.9 MPa) and liquid-state pressed (250.5 MPa) castings exhibited high strength. In contrast, the metal mold casting had a much lower tensile strength of only 177.1 MPa, which the study attributes to significant internal heat and shrinkage stresses.

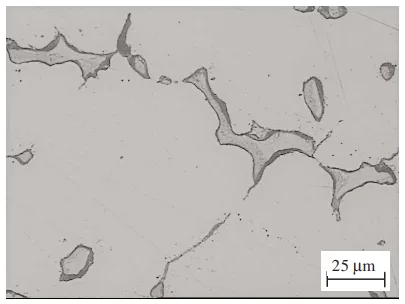

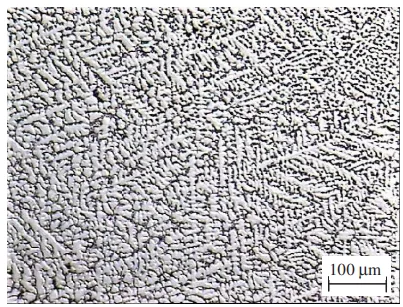

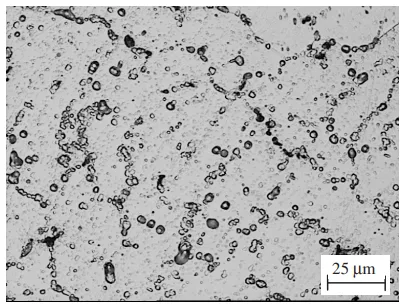

- Microstructure: The cooling rate of each method produced distinct microstructures. Sand castings showed a globular structure (Fig. 3), while die and press castings showed a typically dendritic structure (Fig. 5, 7). The dendritic crystals in the pressed castings were much smaller than in the die castings, indicating a faster cooling rate.

Finding 2: Heat Treatment Dramatically Enhances Mechanical Properties Across All Methods

Precipitation hardening (supersaturation and aging) resulted in a significant improvement in all mechanical indexes for all casting types, unlocking the alloy's true potential. The liquid-state pressing method, when combined with heat treatment, yielded the best overall results.

- Yield and Tensile Strength: After heat treatment, the yield strength (Rp0.2) increased by approximately 60% (Fig. 12). The ultimate tensile strength (Rm) of the pressed castings reached 328.1 MPa, the highest value recorded (Table 4).

- Elongation (Plasticity): The most significant change was in plasticity. As detailed in Table 5, the elongation (A5) for pressed castings increased from 2.78% to 10.38%. For die castings, the improvement was even more dramatic, increasing almost six-fold from 1.38% to 8.10% (Fig. 14), as the heat treatment also served to reduce or eliminate the internal stresses present in the as-cast state.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for high-performance AlMg10 components, liquid-state pressing technology is the most advantageous method. It also highlights the critical importance of avoiding slag inclusion, shrinkage, and magnesium oxidation during the casting process to prevent a decrease in mechanical properties.

- For Quality Control Teams: The data in Tables 2-5 provides clear benchmarks for the expected mechanical properties (Rp0.2, Rm, A5) based on the manufacturing process. The paper's finding that gravity die castings can have significantly lower tensile strength (approx. 80 MPa lower than sand or pressed castings) due to internal stresses is a critical insight for setting quality inspection criteria.

- For Design Engineers: The findings confirm that AlMg10 is sensitive to cooling rates and can crack or deform if quenched improperly. The use of hot water or oil for quenching, as noted in the paper, is a key process consideration. Furthermore, the issue of internal stresses in plate-type die castings suggests that part geometry should be carefully considered in the early design phase to minimize stress concentration.

Paper Details

Influence of the conditions of casting and heat treatment on the structure and mechanical properties of the AlMg10 alloy

1. Overview:

- Title: Influence of the conditions of casting and heat treatment on the structure and mechanical properties of the AlMg10 alloy

- Author: P. Kordas

- Year of publication: 2017

- Journal/academic society of publication: Journal of Achievements in Materials and Manufacturing Engineering

- Keywords: Aluminium-magnesium alloys, Mechanical properties, Heat treatment

2. Abstract:

Assessment of the possibilities of shaping the structure and improvement of mechanical properties of casting from AlMg10 alloy through a selection of casting technology and precipitation hardening. The work evaluated the impact of casting and heat treatment technology on the mechanical properties and structure of AlMg10 alloy castings. The tests were performed on plate castings produced by gravity casting methods for sand and metal moulds and by a liquid state press moulding technology. Metallographic and strength tests were performed on raw castings and after heat treatment. The changes in the morphology and size of primary crystals and the dispersion of the reinforcing phase according to the casting solidification rate and the precipitation hardening treatment were analyzed. In castings which were not heat-treated, the reinforcing phase of Al3Mg2 occurs in interdendritic spaces. After supersaturation and ageing treatments, the phase a has a grain structure in all samples. The largest dispersion of reinforcing molecules is characterized by press castings. Heat treatment of AlMg10 alloy castings significantly influences the increase of mechanical indexes. The highest features of Rm are approx. 330 MPa and A5 above 10% is obtained in castings made by the press method.

3. Introduction:

Cast aluminum alloys with magnesium have wide application in industries like automotive and shipping due to good mechanical properties, good fluidity, and excellent corrosion resistance. For structural components, high strength and high elongation are required. The microstructure, including grain size, morphology, and secondary phase decomposition, are decisive factors influencing these properties. The microstructure depends on chemical composition, melting process, and cooling rate. Heat treatment, specifically dispersion strengthening (supersaturation and aging), is used to increase mechanical properties. AlMg10 alloys are sensitive to water cooling and can deform or crack, necessitating cooling in an oil bath or hot water. This study aims to determine the influence of the casting method and heat treatment on the structure and properties of AlMg10 alloys.

4. Summary of the study:

Background of the research topic:

AlMg10 alloys are used for structural components that require high strength, high elongation, and corrosion resistance. The mechanical properties are heavily influenced by the microstructure, which is in turn shaped by the casting process and subsequent heat treatment.

Status of previous research:

Previous research has established that factors like chemical composition, melting process, and cooling rate are critical in determining the microstructure of aluminum alloys. It is also known that AlMg10 alloys are suitable for heat treatment but are sensitive to thermal shock during quenching.

Purpose of the study:

To assess the possibilities of shaping the structure and improving the mechanical properties of AlMg10 alloy castings by selecting different casting technologies (sand mold, metal mold, liquid-state pressing) and applying precipitation hardening.

Core study:

The study involved manufacturing plate-shaped castings using three different methods to achieve substantially different solidification conditions. These castings were then tested for mechanical properties (yield strength, tensile strength, elongation) in both the as-cast state and after a full precipitation hardening heat treatment cycle. The microstructures were also analyzed to correlate structural changes with mechanical performance.

5. Research Methodology

Research Design:

The study used a comparative experimental design. Three groups of AlMg10 alloy plates were produced using different casting methods: gravity casting into a sand mold, gravity casting into a metal mold, and liquid-state press molding. Each group was then divided, with one subgroup tested as-cast and the other tested after heat treatment.

Data Collection and Analysis Methods:

Mechanical properties were determined using a standardized tensile test according to PN-EN ISO 6892-1:2016-09. Metallographic observations were conducted using a NIKON EPIPHOT light microscope at 100x and 400x magnification to analyze the microstructure.

Research Topics and Scope:

The research focused on a commercial AlMg10 alloy. The scope included melting, casting via three methods, a specific precipitation hardening heat treatment process (445°C for 30 hours, 100°C water quench, 10 days aging), and subsequent mechanical and microstructural analysis of the resulting samples.

6. Key Results:

Key Results:

- In the as-cast state, sand mold and pressed castings showed the highest tensile strength (~251 MPa), while metal mold castings were significantly weaker (177 MPa) due to internal stresses.

- Heat treatment significantly increased all mechanical properties. The yield strength increased by approximately 60%.

- The highest performance was achieved with liquid-state pressed castings after heat treatment, reaching a tensile strength of ~330 MPa and an elongation over 10%.

- Heat treatment dramatically improved the elongation of die castings, increasing it nearly six-fold to 8.1%, by relieving internal stresses.

- Microstructure varied with cooling rate: sand casting produced a globular structure, while die and press casting produced a dendritic structure. Heat treatment resulted in a grain structure and a large dispersion of the reinforcing Al3Mg2 phase.

Figure Name List:

- Fig. 1. Mechanical properties of AlMg10 alloy in molten state according to the casting method

- Fig. 2. Mechanical properties of heat treated AlMg10 alloy depending on the casting method

- Fig. 3. Microstructure of AlMg10 alloy cast into a sand form, etched with 4% HF

- Fig. 4. Microstructure of AlMg10 alloy cast into a sand form, etched with 4% HF

- Fig. 5. Microstructure of AlMg10 alloy cast into a metal form, etched with 4% HF

- Fig. 6. Microstructure of AlMg10 alloy cast into a metal form, etched with 4% HF

- Fig. 7. Microstructure of AlMg10 alloy cast into a metal form, etched with 4% HF

- Fig. 8. Microstructure of a pressed AlMg10 alloy, etched with 4% HF

- Fig. 9. Microstructure of AlMg10 alloy cast into a sand mold and heat treated, etched with 4% HF

- Fig. 10. Microstructure of AlMg10 alloy cast into a metal mold and heat treated, etched with 4% HF

- Fig. 11. Microstructure of pressed and heat treated AlMg10 alloy, etched with 4% HF

- Fig. 12. Apparent yield strength of cast AlMg10 alloys made in sand, metal and pressed form, in molten state and after thermal treatments

- Fig. 13. Tensile strength of AlMg10 alloy castings made in sand, metal and pressed mold, in motlen state and after heat treatments

- Fig. 14. Relative elongation of AlMg10 castings made in sand, metal and pressed mold, in molten state and after heat treatments

7. Conclusion:

The mechanical properties of as-cast AlMg10 alloy are dependent on the casting method, with sand and pressed castings showing the highest durability. After heat treatment, the influence of the initial casting method is lessened, but the highest mechanical properties—Rm at 330 MPa and elongation over 10%—are obtained in heat-treated castings made using the liquid-state press method. Heat treatment causes a transformation of the cast matrix from dendritic to grain structure and ensures the release of the Al3Mg2 curing phase with large dispersion, leading to a significant increase in all mechanical indicators.

8. References:

- [1] A.A. Canales, E. Carrera, J. Talamantes-Silva, S. Valtierra, R. Colas, Mechanical properties in as-cast and heat treated Al-Si-Cu alloys, International Journal of Microstructure and Materials Properties 7/4 (2012) 281-300.

- [2] S. Jayalakshmi, Q, Dezhi, S. Sankaranarayanan, M. Gupta, Microstructure and mechanical properties of Mg-Al alloys with in situ Al4C3 phase synthesised by CO2 incorporation during liquid state processing, International Journal of Microstructure and Materials Properties 8/4-5 (2013) 283-298.

- [3] Y. Kaygisiz, N. Marasli, Microstructural, mechanical and electrical characterization of directionally solidified Al-Si-Mg eutectic alloy, Journal of Alloys and Compounds 618 (2015) 197-203.

- [4] Y. Shu-qing, L. Xing-fu, The effect of Si morphology on the microstructure and wear property of ZA48 alloy, International Journal of Microstructure and Materials Properties 9/1 (2014) 88-96.

- [5] I. Luna, H. Molinar, M. Roman, J. Bocardo, M. Trejo, Improvement of the tensile properties of an Al-Si-Cu-Mg aluminium industrial alloy by using multi stage solution heat treatments, Materials Science and Engineering 561 (2013) 1-6.

- [6] A. Shokuhfar, O. Nejadseyfi, A comparison of the effects of severe plastic deformation and heat treatment on the tensile properties and impact toughness of aluminium alloy 6061, Materials Science and Engineering 594 (2014) 140-148.

- [7] M. Krupiński, K. Labisz, T. Tański, B. Krupińska, M. Król, M. Polok-Rubiniec, Influence of Mg addition on crystallisation kinetics and structure of the Zn-Al–Cu alloy, Archives of Metallurgy and Materials 61/2 (2016) 785-790.

- [8] M. Król, T. Tański, G. Matula, P. Snopiński, A.E. Tomiczek, Analysis of crystallisation process of cast magnesium alloys based on thermal derivative analysis, Archives of Metallurgy and Materials 60/4 (2015) 2993-3000.

- [9] S. Xia, M. Ma, J. Zhang, W. Wang, W. Liu, Effect of heating rate on the microstructure, texture and tensile properties of continuous cast AA 5083 aluminium alloy, Materials Science and Engineering 609 (2014) 168-176.

- [10] Z. Górny, J. Sobczak, Modern casting materials based on non-ferrous metal, Ed. ZA-PIS, Cracow, 2005 (in Polish).

- [11] Polish Standard PN-EN ISO 6892-1:2016-09 Metallic materials - Tensile testing - Part 1: Method of test at room temperature.

- [12] B. Wierzbicka, M.S. Soiński, Casting technology, Publishing House Politechnika Częstochowska, Częstochowa, 1996.

Expert Q&A: Your Top Questions Answered

Q1: Why was the tensile strength of the as-cast metal mold (die) casting so much lower than the sand and pressed castings?

A1: The paper states that during the manufacturing of castings in metal molds, "significant heat and shrinkage stresses occur, which cause uneven distribution of mechanical properties in the casting." As shown in Table 2, this resulted in a tensile strength of only 177 MPa, which is about 80 MPa lower than the other two methods. This highlights that for raw, non-heat-treated components, gravity die casting can introduce detrimental internal stresses.

Q2: The paper mentions AlMg10 is sensitive to cracking during quenching. How was this addressed in the methodology?

A2: The introduction explicitly notes that "AlMg10 alloy castings are sensitive to water cooling and may be deformed or cracked." To prevent this, the researchers followed the recommended practice of using a milder quench. The methodology specifies that after the supersaturation step, the castings were cooled in hot water with a temperature of 100°C, avoiding the thermal shock of a cold water quench.

Q3: What was the most significant microstructural difference between the casting methods before heat treatment?

A3: The primary difference was in the morphology of the primary crystals, driven by the cooling rate. The findings state that castings solidified in a sand mold exhibited a "globular structure" (Fig. 3). In contrast, the faster cooling rates of the metal mold and press methods produced a "typically dendritic structure" (Fig. 5 and 7), with the dendrites in the pressed castings being much smaller than in the die castings.

Q4: How did heat treatment specifically affect the plasticity (elongation) of the die-cast samples?

A4: The effect was dramatic. The as-cast die samples had the lowest elongation at just 1.38%. However, after heat treatment, the elongation "increased almost six-fold, reaching 8.1%" (Fig. 14). This substantial improvement is not only due to the precipitation of the strengthening phase but also because the heat treatment cycle reduces or eliminates the internal stresses that made the as-cast part brittle.

Q5: What is the reinforcing phase in this alloy, and how did its distribution change with the process?

A5: The paper identifies the reinforcing intermetallic phase as Al3Mg2. In the as-cast state, this phase "occurs in interdendritic spaces, and its dispersion increases with the rate of cooling." After supersaturation and aging, the heat treatment caused a "large dispersion of these particles," which is key to the strength increase. The pressed castings, in particular, showed the largest dispersion of these reinforcing molecules (Fig. 11).

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and actionable framework for optimizing AlMg10 Mechanical Properties. The study demonstrates that while as-cast performance is heavily dependent on the casting method, a properly executed precipitation hardening treatment can unlock significant gains in strength and ductility across the board. The key breakthrough is the identification of liquid-state pressing combined with heat treatment as the superior process, yielding tensile strengths of ~330 MPa and elongations over 10%—metrics that meet the demands of high-performance structural applications. By understanding the interplay between solidification rate, internal stress, and microstructural evolution, manufacturers can push the boundaries of what's possible with this versatile alloy.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Influence of the conditions of casting and heat treatment on the structure and mechanical properties of the AlMg10 alloy" by "P. Kordas".

- Source: [http://www.journalamme.org/papers_vol83_1/8314.pdf]

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.