Smart Castings in a Single Step: A Breakthrough in In-Process Embedding for HPDC

This technical summary is based on the academic paper "In-Process Embedding of Piezo Sensors and RFID Transponders into Cast Parts for Autonomous Manufacturing Logistics" by Dipl.-Wi.-Ing. Christoph Pille, published in Smart Systems Integration (2010). It has been analyzed and summarized for technical experts by CASTMAN.

![Fig. 1: Effect of induction current on the magnetic field [6] (left) and destructive interference by reflection of the electromagnetic wave (right)](https://castman.co.kr/wp-content/uploads/image-3073.webp)

![Fig. 2: RFID cast part with integrated RFID transponder (left) and design of a glass transponder [7] (right)](https://castman.co.kr/wp-content/uploads/image-3072.webp)

Keywords

- Primary Keyword: In-Process Embedding

- Secondary Keywords: Smart Castings, RFID in Die-Casting, Piezo Sensors in Castings, Autonomous Manufacturing Logistics, HPDC Innovation, Functional Integration

Executive Summary

- The Challenge: Conventional methods for adding electronic components to cast parts are complex, costly, and can compromise performance, especially in large-scale production.

- The Method: The research investigates a new technology for integrating electronic components, like sensors and RFID transponders, directly into the part during the die-casting process itself.

- The Key Breakthrough: The study successfully demonstrated the in-process embedding of both RFID transponders into zinc castings and piezoceramic sensors into aluminum castings, proving the technology's viability.

- The Bottom Line: This in-process embedding technology enables the mass production of intelligent cast parts that can self-monitor, store data, and be uniquely identified from the moment of their creation.

The Challenge: Why This Research Matters for HPDC Professionals

In modern manufacturing, particularly in the automotive sector, there is a growing demand for "smart" components that can sense their environment, monitor their own health, and communicate product-related data. Traditionally, enhancing cast parts with electronic components like sensors or RFID tags is a state-of-the-art but cumbersome process. It relies on secondary assembly operations like screwing or bonding.

These conventional methods introduce several pain points:

* Added Complexity & Cost: They represent an additional, often complex, production step, which extends the process chain and reduces added value.

* Performance Issues: For sensors, adhesive layers used for bonding can act as a buffer, distorting measurements and degrading over time due to aging.

* Durability Concerns: Surface-mounted components are vulnerable to damage, contamination, or loss during subsequent machining, assembly, and operational use.

This research was necessary to overcome these limitations by developing a method to create intelligent cast parts in a single, integrated production step.

The Approach: Unpacking the Methodology

The core challenge of in-process embedding is protecting sensitive electronics from the extreme temperatures and pressures of the die-casting process. The research team developed a methodology to address this for two distinct electronic components: RFID transponders and piezo sensors.

1. Embedding RFID Transponders:

The goal was to create a cast part with an inseparable, unique digital identity for autonomous logistics.

* Component Selection: A glass transponder (Sokymat SID153) operating at a low frequency (125 kHz) was chosen to minimize interference from the surrounding metal.

* Thermal Protection: Numerical simulations were used to calculate the heat input during mold filling and solidification (Figure 3). Based on this, a protective polymer-based insulation layer was designed to keep the transponder below its maximum thermal endurance (+120 °C).

* Positioning & Casting: The encapsulated transponder was fixed in a dedicated slot within the die-casting mold (Figure 4). The experimental work was conducted on a FRECH DAW 315 die-cast unit using a ZL0410 zinc alloy teemed at 420°C.

2. Embedding Piezo Sensors:

The objective was to integrate sensors capable of measuring compressive and tensile stresses for structural health monitoring.

* Component Selection: A robust piezo-ceramic stack actuator (CeramTec SP505) was selected for its ability to generate strong sensor signals. A critical parameter was its Curie Temperature (CT) of 205 °C, above which it permanently loses functionality.

* Thermal Protection: Similar to the RFID approach, the heat input was calculated. A high-heat resistant polymer-based insulation layer (2 mm thickness) was designed to protect the sensor. Crucially, the front ends of the sensor were left exposed to create a positive connection with the casting for accurate stress measurement, requiring extra compensation in the side insulation.

* Positioning & Casting: A patented fixing construction involving V2A steel plates and a pluggable metal core was used to position the encapsulated sensor system in the mold (Figure 7, left). The experiment used a BÜHLER SCN/66 die-cast unit with an AlSi9Cu3 (226) aluminum alloy teemed at 710° C.

The Breakthrough: Key Findings & Data

The research successfully demonstrated that in-process embedding is a viable manufacturing technology for both zinc and aluminum alloys.

Finding 1: RFID Transponders Can Be Successfully Integrated for Permanent Identification

The study proved that an encapsulated RFID transponder could survive the die-casting process and remain functional. The final cast part, an automotive reflector made of zinc alloy, contained a fully integrated and operational RFID transponder. As shown in Figure 5, the process moved from the die-cast unit and mold to a final, intelligent component, inseparable from its digital identity. This provides a tamper-proof method for part identification right from its "birth."

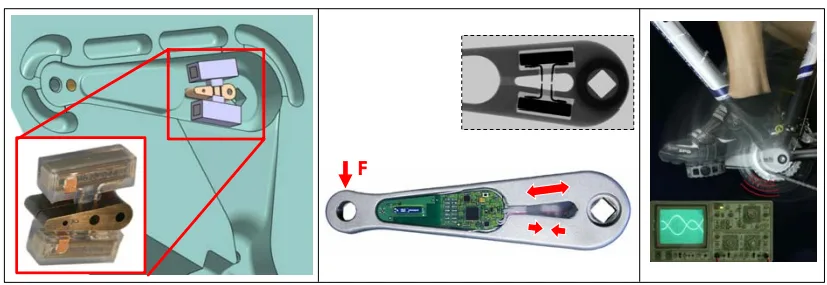

Finding 2: Piezo Sensors Can Be Embedded for Real-Time Structural Health Monitoring

The experiment with the aluminum pedal crank was also successful. The embedded piezo sensors survived the significantly higher temperatures of aluminum die-casting and formed a positive, functional connection with the metallic structure. The x-ray image in Figure 7 (center) confirms the precise integration of the sensors. The analysis of the sensor signals (Figure 7, right) validated that the embedded sensors could effectively measure the compressive and tensile stresses induced in the part, enabling capabilities like active vibration damping and real-time health monitoring.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that integrating electronic functionality can be moved from a secondary assembly process into the primary casting step. This has the potential to significantly shorten the overall production chain and reduce manufacturing complexity.

- For Quality Control Teams: The data from embedded RFID transponders provides a robust solution for unique part identification and seamless traceability throughout the entire manufacturing and product lifecycle, as highlighted in the paper. This is a crucial advantage for safety-critical components.

- For Design Engineers: The findings indicate that parts can be designed from the outset to include integrated intelligence. The research provides a foundational methodology for calculating insulation requirements and designing positioning features (as seen in Figure 4 and Figure 7) to ensure the survivability and functionality of embedded components.

Paper Details

In-Process Embedding of Piezo Sensors and RFID Transponders into Cast Parts for Autonomous Manufacturing Logistics

1. Overview:

- Title: In-Process Embedding of Piezo Sensors and RFID Transponders into Cast Parts for Autonomous Manufacturing Logistics

- Author: Dipl.-Wi.-Ing. Christoph Pille

- Year of publication: 2010

- Journal/academic society of publication: Smart Systems Integration, Como, Italy, 23 - 24 March 2010

- Keywords: Piezo Sensors, RFID Transponders, Cast Parts, Autonomous Manufacturing Logistics, In-Process Embedding, Die-Cast Process

2. Abstract:

The paper presents a new technology for the in-process embedding of electronic components like piezo sensors and RFID transponders directly into metal parts during the casting process. This approach aims to create "smart" and "intelligent" cast parts capable of sensing loads, monitoring structural health, and retaining product-related data for autonomous logistics. The method protects the electronics from damage and improves the connection to the material structure. The paper details the development of this technology through two demonstrators: a cast part with an integrated RFID transponder for identification and a "function integrated pedal crank" with embedded piezo sensors for stress measurement.

3. Introduction:

Casting is a primary manufacturing technology for metal components. Enhancing these parts with electronic components is typically a complex and costly post-processing step, especially in large-scale automotive production. This research explores an in-process embedding method where functional components (sensors, actuators, RFID transponders) are integrated directly during casting. This protects the electronics from contamination, damage, or loss during subsequent machining and use, and improves the connection of sensor and actuator elements to the material structure.

4. Summary of the study:

Background of the research topic:

The demand for intelligent cast parts with sensing, actuating, and data-carrying capabilities is increasing. These parts can monitor their own health, control material distortion, and transfer data for autonomous manufacturing logistics.

Status of previous research:

Conventional joining technologies like screwing or bonding are the state-of-the-art for adding electronics to castings. However, these methods add production steps and can introduce inaccuracies, such as an adhesive layer buffering sensor signals. While research into integrating piezoelectrical components exists, a method for well-directed, local integration without affecting the cast structure was lacking.

Purpose of the study:

To develop and demonstrate a technology for the in-process embedding of electronic functional components directly into parts during the die-cast process, creating intelligent cast parts in a single production step.

Core study:

The study addresses the fundamental challenges of in-process embedding: protecting sensitive electronics from high temperatures and pressures, ensuring proper positioning within the mold, and enabling communication with the embedded component. The development is illustrated through two exemplary demonstrators: embedding an RFID transponder in a zinc die-cast part and embedding piezo sensors in an aluminum die-cast part.

5. Research Methodology

Research Design:

The research followed a structured development process for each component type:

1. Characterization and selection of a suitable electronic component (RFID transponder, piezo sensor).

2. Numerical simulation of the thermal loads during the die-casting process.

3. Designing and testing suitable thermal-mechanical insulation layers.

4. Developing a methodology for positioning and fixing the encapsulated component within the die-cast mold.

5. Conducting experimental casting trials to validate the entire process.

Data Collection and Analysis Methods:

- Numerical simulation was used to calculate heat input into the electronic components.

- Experimental research was conducted to measure heat input during polymer encapsulation.

- Real-world die-casting was performed using industrial machinery (FRECH DAW 315 for zinc, BÜHLER SCN/66 for aluminum).

- Post-casting analysis included functional testing of the embedded components and x-ray imaging to verify integration.

Research Topics and Scope:

The research focused on the in-process embedding of two specific types of electronic components:

1. RFID transponders for identification and data storage in zinc die-casting.

2. Piezo-ceramic sensors for stress and vibration measurement in aluminum die-casting.

The scope covered the entire technology development chain from component selection and protection to final casting and functional validation.

6. Key Results:

Key Results:

- A technology was successfully developed to embed functional RFID transponders and piezo sensors into castings during zinc and aluminum die-cast processes.

- The process involves determining thermal/mechanical loads, sealing the component with a specific protective insulation layer, and fixing it within the casting mold using positioning techniques.

- The embedded RFID transponder in the zinc casting survived the process and was functional for component identification.

- The embedded piezo sensors in the aluminum casting survived the process and were able to measure mechanical loads (compressive and tensile stresses).

Figure Name List:

- Fig. 1: Effect of induction current on the magnetic field [6] (left) and destructive interference by reflection of the electromagnetic wave (right)

- Fig. 2: RFID cast part with integrated RFID transponder (left) and design of a glass transponder [7] (right)

- Fig. 3: Numerical simulation of the heat input into the RFID transponder during filling of the mold and solidification of the melt (without insulation encapsulation)

- Fig. 4: Positioning and fixing of the RFID transponder with insulation encapsulation in the die casting mold

- Fig. 5: Die-cast unit FRECH DAW 315 (left), die casting mold (center) and final cast part with integrated RFID transponder (right)

- Fig. 6: Piezoelectric sensor of type SP505 7x7x32.4 mm³ (left) and structural-mechanical calculation of a load of 1800 N (right)

- Fig. 7: Encapsulated piezo sensors fixed in die-cast mold (left), casted pedal crank with embedded sensors and x-ray image (center) and analysis of the sensor signals (right)

7. Conclusion:

The presented work has shown that the in-process embedding of electronic functional components, such as RFID transponders and piezoceramic sensors, into castings via the die-cast process is feasible. The developed technology, which involves determining loads, applying a protective insulation layer, and using positioning techniques, was successfully demonstrated in both zinc and aluminum die-cast processes.

8. References:

- [1] Eisenegger, Christian: Lückenlos rückverfolgbar. Beschriften von Gussteilen im Produktionsprozess, in: Giesserei-Erfahrungsaustausch 2008, Nr. 7+8, pp. 4-5

- [2] Kim, K.Y.; et al., in: Sensors and Actuators 2005, Vol. 120, pp. 123-129

- [3] Rübner, Matthias; Körner, Carolin; Singer, Robert F.: Integration of Piezoceramic Modules into Die Castings - Procedure and Functionalities, in: Advances in Science and Technology 2008, Vol. 56, pp. 170-175

- [4] Meißner, Knut; Brahmann, Martin: Markierung von Gussteilen während des Urformprozesses und deren Anwendung zur Rückverfolgbarkeit und Prozessoptimierung bei der Komponentenfertigung, in: Druckguss 2009, Vol. 5-6, pp. 161-166

- [5] Harbauer, Frank: Bauteilkennzeichnung - Markierverfahren im Überblick, in: BDG-Fachtagung Gussteilkennzeichnung - Methoden und Datenmanagement - Praxisberichte, VDG Akademie (2009), pp. IV/1-IV/9

- [6] Bovelli, S., Neubauer, F., Heller, Ch.: Mount-on-Metal RFID Transponders for Automatic Identification of Containers, in: Proceedings of the 36th European Microwave Conference 2006, pp. 726-727

- [7] Kern, Christian: Anwendung von RFID-Systemen, 2. Auflage, Springer-Verlag, Berlin, Heidelberg, 2006

Expert Q&A: Your Top Questions Answered

Q1: How did the research protect sensitive electronics from the extreme heat and pressure of molten metal?

A1: The core of the solution was an application-specific protective insulation layer. The researchers first used numerical simulation to predict the heat input into the component during mold filling and solidification. Based on this thermal load profile, they designed an encapsulation layer (made of high-heat resistant polymer-based compounds) with a specific material and wall thickness to ensure the electronics never exceeded their maximum thermal endurance.

Q2: Why was a low-frequency (125 kHz) RFID transponder chosen over a high-frequency one?

A2: The metallic environment of a cast part severely disrupts radio waves. As shown in Figure 1, high-frequency waves are reflected by metal, causing destructive interference that prevents communication. Low-frequency systems, however, use a magnetic field. While the metal part can deflect magnetic flux lines and induce eddy currents, a low-frequency transponder with a ferrite core is designed to improve performance in these environments and maintain a functional connection with the reader.

Q3: What is the "Curie Temperature" and why was it so critical for embedding the piezo sensors?

A3: The Curie Temperature (CT) is the specific temperature at which a piezoceramic material loses its piezoelectric properties and therefore its functionality permanently. For the selected SP505 sensor, the CT is 205 °C. The entire thermal protection strategy had to be designed to guarantee that the sensor's internal temperature remained below this critical threshold during the 710° C aluminum casting process.

Q4: How were the components held firmly in place inside the mold to resist the high pressures of die-casting?

A4: The researchers developed specific positioning techniques for each component. For the RFID transponder, the insulation encapsulation was designed with features that allowed it to be slotted securely into the die casting mold (Figure 4). For the more complex piezo sensor, a special patented construction was developed using V2A steel plates and a pluggable metal core to fix the sensor system rigidly within the mold of the pedal crank (Figure 7, left).

Q5: The paper mentions creating a "positive fitting connection" for the piezo sensor. What does this mean and why is it important?

A5: A "positive fitting connection" means the sensor is not just surrounded by metal, but is mechanically interlocked with the metallic structure of the casting. This was achieved by leaving the front ends of the piezo sensor exposed to the molten metal. This direct, inseparable bond is essential for accurately transferring the mechanical stresses and vibrations from the part to the sensor, which is necessary for it to function correctly for health monitoring.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of creating truly intelligent, durable, and traceable cast components has been a significant hurdle for the HPDC industry. This research demonstrates a powerful solution by tackling the problem at its source: the casting process itself. The successful demonstration of In-Process Embedding for both RFID transponders and piezo sensors marks a significant step towards manufacturing smart components in a single, efficient step. This eliminates costly and complex secondary operations while enhancing the durability and performance of the final product.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "In-Process Embedding of Piezo Sensors and RFID Transponders into Cast Parts for Autonomous Manufacturing Logistics" by "Dipl.-Wi.-Ing. Christoph Pille".

- Source: [https://ieeexplore.ieee.org/document/5451082]

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.