Unlocking Superior Strength: A Deep Dive into AlSi7Mg0.3 Heat Treatment with Zr and Ti Additives

This technical summary is based on the academic paper "Heat Treatment of AlSi7Mg0.3 Aluminium Alloys with Increased Zirconium and Titanium Content" by E. Kantoríková, M. Kuriš, R. Pastirčák, published in ARCHIVES of FOUNDRY ENGINEERING (2021).

Keywords

- Primary Keyword: AlSi7Mg0.3 Heat Treatment

- Secondary Keywords: Aluminum alloys, Zirconium, Titanium, Mechanical properties, Foundry Engineering, Al-Si alloys, Precipitation aging

Executive Summary

- The Challenge: To improve the mechanical properties of the widely used AlSi7Mg0.3 aluminum alloy to meet the increasing demands for lighter and stronger components in the automotive industry.

- The Method: The study investigated the synergistic effect of adding Zirconium (Zr) and Titanium (Ti) to AlSi7Mg0.3, analyzing the alloy's microstructure and mechanical properties after T6 heat treatment and comparing samples cast in shell versus metal molds.

- The Key Breakthrough: The research demonstrated that heat treatment significantly increased hardness by up to 30% and that the casting mold type critically influenced the final microstructure, with the faster cooling of metal molds producing finer, more stable Zirconium phases.

- The Bottom Line: Strategic additions of Zr and Ti, combined with optimized heat treatment and casting methods, can substantially enhance the mechanical performance of AlSi7Mg0.3 alloys, enabling the production of more durable and lightweight components.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive automotive industry, the drive for innovation is relentless. Light aluminum alloys like AlSi7Mg0.3 are essential, but the future depends on enhancing their performance through advanced production and heat treatment technologies. Alloying—the planned addition of elements—is a key strategy to optimize properties, such as increasing ultimate tensile strength to reduce component weight without sacrificing strength.

While common, AlSi7Mg0.3 has limitations. Adding uncommon elements like Zirconium (Zr) offers a path to alter the microstructure, refine grains, and improve the alloy's response to heat treatment. Zr is particularly valuable because its resulting intermetallic phases are resistant to coarsening at high temperatures (above 250°C), a critical advantage for components in demanding environments like engine blocks. This research was necessary to explore how combining Zr and Ti, along with specific casting and heat treatment protocols, could unlock a new level of performance for this foundational alloy.

The Approach: Unpacking the Methodology

The study was designed to evaluate the combined effect of alloying elements, casting method, and heat treatment on AlSi7Mg0.g0.3. The methodology provided a robust comparison of these key variables.

Method 1: Alloy Preparation and Casting

- Base Alloy: AlSi7Mg0.3, a common automotive-grade aluminum alloy.

- Alloying: Three experimental melts were produced with a constant addition of 0.2% Zirconium (Zr) and a gradual addition of Titanium (Ti) at 0.1, 0.2, and 0.3 wt.%.

- Casting: Two distinct casting methods were used to compare the effect of cooling rates: a shell mold and a metal mold. This was a critical variable, as the molds have different heat transfer coefficients, directly impacting solidification and grain structure.

Method 2: Heat Treatment and Mechanical Testing

- Heat Treatment: A T6 hardening procedure was performed according to STN EN 1706. This involved solution annealing at 540°C for 12 hours, followed by a water quench to 20°C, and finally, artificial aging at 150°C for 3 hours.

- Mechanical Testing: The resulting samples were subjected to a series of tests to quantify their properties. Brinell hardness was measured to assess strength, and tensile tests were conducted on a 20 kN universal testing machine to determine ultimate tensile strength (Rm) and elongation (ductility).

- Microstructural Analysis: Standard optical metallography was used to examine the microstructure of the samples before and after heat treatment, focusing on the morphology and distribution of the Zirconium phases.

The Breakthrough: Key Findings & Data

The experiment yielded significant data on how alloying and processing affect the final properties of AlSi7Mg0.3.

Finding 1: Significant Hardness Increase After Heat Treatment

Heat treatment dramatically improved the hardness of all samples. The effect was particularly pronounced in the shell mold castings. As shown in Table 2, the hardness of the shell mold sample with 0.4% Ti increased by over 43% after heat treatment, from 64 HBW to 92 HBW. Samples cast in the metal mold also saw a significant increase, stabilizing around 90-91 HBW, meeting the 90 HBW specification for AC421 alloy. This confirms the effectiveness of the T6 treatment in strengthening the alloy matrix.

Table 2. Brinell hardness

| | Shell Mold | Metal Mold |

| :--- | :---: | :---: | :---: | :---: |

| Ti Content | Non HT | With HT | Non HT | With HT |

| 0.2Ti | 66 | 86 | 75 | 91 |

| 0.3Ti | 61 | 87 | 80 | 90 |

| 0.4Ti | 64 | 92 | 84 | 87 |

Finding 2: Casting Method Dictates Microstructure and Zr Phase Morphology

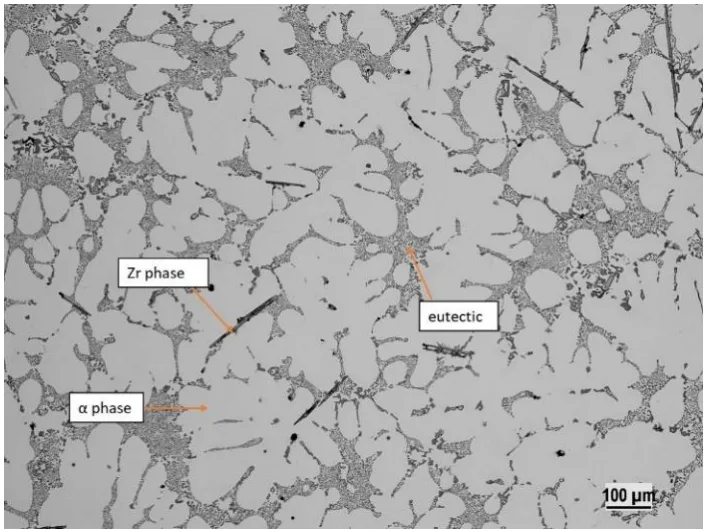

The most striking finding was the difference in microstructure based on the casting mold. Before heat treatment, the alloy showed large, needle-like Zr phases (Figure 3). After heat treatment, the evolution of these phases diverged:

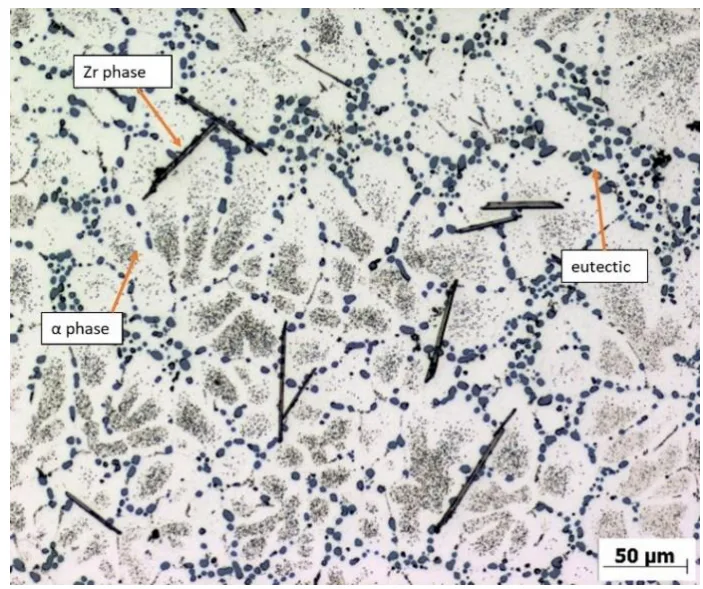

- Shell Mold: In the slower-cooling shell mold, the Zr phases remained as sharp, individually distributed needles (Figure 4).

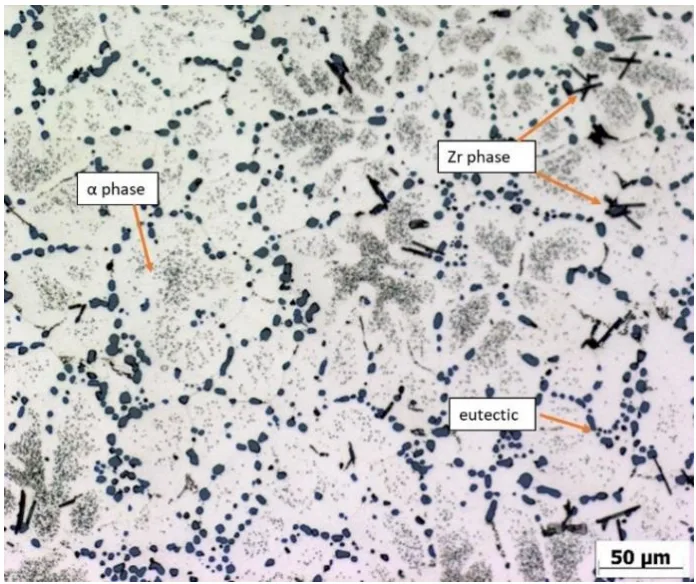

- Metal Mold: In the faster-cooling metal mold, the large needles decomposed into "tiny clusters of small needles with a rounded end" (Figure 5). This finer, more stable, and less stress-concentrating morphology is far more desirable for achieving superior mechanical properties. This demonstrates that the cooling rate during casting is a critical process parameter for controlling the microstructure of Zr-bearing alloys.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the cooling rate by selecting an appropriate casting method (e.g., permanent mold over sand/shell casting) is a powerful tool for refining the microstructure and enhancing the final properties of Zr-bearing aluminum alloys.

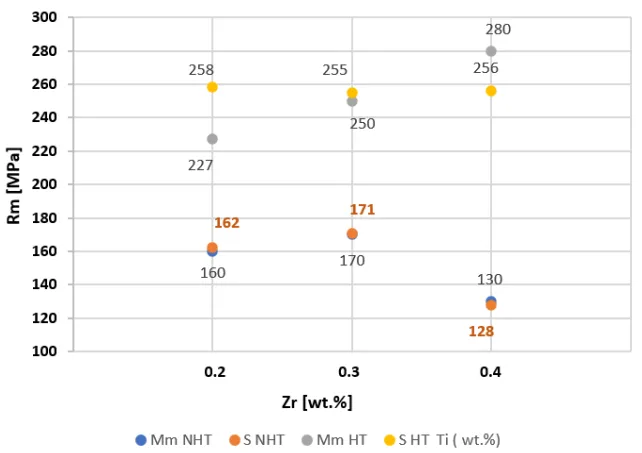

- For Quality Control Teams: The data in Table 2 (Hardness) and Figure 1 (Tensile Strength) illustrates the direct impact of heat treatment and alloy composition on mechanical properties. These results can serve as valuable benchmarks for setting new quality inspection criteria for high-performance components.

- For Design Engineers: The findings indicate that the faster solidification associated with metal molds leads to a more refined and beneficial microstructure. This suggests that component designs that are well-suited for permanent mold or die casting processes could achieve superior mechanical performance when produced with these advanced alloys.

Paper Details

Heat Treatment of AlSi7Mg0.3 Aluminium Alloys with Increased Zirconium and Titanium Content

1. Overview:

- Title: Heat Treatment of AlSi7Mg0.3 Aluminium Alloys with Increased Zirconium and Titanium Content

- Author: E. Kantoríková, M. Kuriš, R. Pastirčák

- Year of publication: 2021

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 21, Issue 2/2021

- Keywords: Heat treatment, Aluminum alloys, Zirconium, Titan, Mechanical properties

2. Abstract:

The paper compares changes in the structure and mechanical properties due to the synergistic effect of alloying elements Zr and Ti. It is assumed that by increasing the content of Zr and Ti in the aluminium alloy, better mechanical properties will be achieved. Paper focuses on description of the differences between the samples casted into the shell mold and the metal mold. Main difference between mentioned molds is a different heat transfer coefficient during pouring, solidification and cooling of the metal in the mold. The main goal was to analyse the influence of Zr and Ti elements and compare the mechanical properties after the heat treatment. Curing and precipitation aging were used during the experiment. The effect of the elements on AlSi7Mg0.3 alloy created differences between the excluded Zr phases after heat treatment. Evaluation of the microstructure pointed to the decomposition of large predominantly needle Zr phases into smaller, more stable formations.

3. Introduction:

The development of new and more sophisticated aluminum alloys is driven by the need for lightweight parts with optimized structural properties, particularly in the automotive industry. Alloying, the planned addition of selected elements, can enhance properties like ultimate tensile strength, allowing for weight reduction without compromising performance. The addition of uncommon elements such as Zirconium (Zr) to Al-Si-Mg alloys can alter the microstructure by forming new intermetallic phases (e.g., Al3Zr), refining grain structure, and improving the material's response to heat treatment. Zr-based phases are notably resistant to dissolution and coarsening at elevated temperatures (above 250 °C), which helps maintain strength after precipitation hardening. This research investigates the combined effects of Zr and Ti additions on the AlSi7Mg0.3 alloy, focusing on how heat treatment and different casting conditions (shell mold vs. metal mold) influence the final structure and mechanical properties.

4. Summary of the study:

Background of the research topic:

The study is situated within the field of materials science and foundry engineering, specifically focusing on the enhancement of Al-Si casting alloys for high-performance applications. The base material, AlSi7Mg0.3, is widely used in the automotive industry for components requiring good castability, corrosion resistance, and pressure tightness.

Status of previous research:

Previous research has established that Zirconium (Zr) is a beneficial alloying element in aluminum alloys. It forms stable Al3Zr intermetallic phases that are resistant to coarsening at high temperatures, thereby increasing and maintaining alloy strength. Zr also acts as a grain refiner. The efficiency of Zr is known to be related to the content of other elements like Mg and Cu.

Purpose of the study:

The primary goal was to analyze the influence of combined Zirconium (Zr) and Titanium (Ti) additions on the microstructure and mechanical properties of AlSi7Mg0.3 alloy after T6 heat treatment. A key objective was to compare these effects in samples produced using two different casting methods—a shell mold and a metal mold—which possess significantly different heat transfer characteristics and thus cooling rates.

Core study:

The core of the study involved an experimental procedure where an AlSi7Mg0.3 alloy was modified with a constant 0.2% Zr and varying levels of Ti (0.1, 0.2, and 0.3 wt.%). The modified alloys were cast into both shell and metal molds. These samples were then subjected to a T6 heat treatment (solution annealing at 540°C for 12 hours, water quench, and artificial aging at 150°C for 3 hours). The resulting materials were characterized through chemical analysis, Brinell hardness testing, tensile testing, and optical metallography to evaluate changes in their mechanical properties and microstructure.

5. Research Methodology

Research Design:

The study employed a comparative experimental design to assess the impact of three main variables: 1) alloying additions (Zr and Ti content), 2) casting mold type (shell vs. metal), and 3) heat treatment (as-cast vs. T6 condition).

Data Collection and Analysis Methods:

- Material Preparation: An AlSi7Mg0.3 alloy was used as the base. Three experimental melts were created with a constant 0.2% Zr and additions of 0.1, 0.2, and 0.3 wt.% Ti. Samples were cast into a shell mold and a metal mold.

- Chemical Analysis: The final chemical composition of the castings was verified using a spectrometer.

- Mechanical Testing: Hardness was measured using the Brinell method (HBW 5/250/10). Tensile properties (ultimate tensile strength and elongation) were determined using a universal testing machine on samples with a circular diameter of 8 mm.

- Microstructural Analysis: Standard optical metallography was performed on etched samples to observe the microstructure, particularly the morphology and distribution of Zr-based phases.

Research Topics and Scope:

The research scope was limited to the AlSi7Mg0.3 alloy with specific additions of Zr and Ti. The investigation focused on the effects of T6 heat treatment and the difference in solidification conditions between shell and metal molds. The primary outcomes measured were hardness, tensile strength, ductility, and microstructural changes.

6. Key Results:

Key Results:

- T6 heat treatment significantly increased the hardness of all samples compared to the as-cast condition. The increase was up to 30% for samples cast in the shell mold.

- The highest tensile strength achieved was 280 MPa for a metal mold sample (with 0.4% Ti) and 258 MPa for a shell mold sample (with 0.3% Ti), both slightly below their respective standard values of 290 MPa and 260 MPa.

- Ductility improved with heat treatment, with the metal mold samples showing a greater increase (up to 4% elongation).

- The addition of Zr resulted in the formation of large, needle-like phases in the as-cast microstructure, identified as probable Al3Zr or AlSiZr intermetallics.

- The casting mold type had a profound effect on the microstructure after heat treatment. In shell mold castings, the Zr phases remained as sharp needles. In metal mold castings, the faster cooling rate caused the large needles to decompose into smaller, more stable clusters with rounded ends.

Figure Name List:

- Fig. 1. Ultimate tensile strength, Mm NHT – metal mold non heat treatment, S NHT – Shell non heat treatment, Mm HT - metal mold heat treatment, S HT - Shell heat treatment

- Fig. 2. The ductility of examined samples

- Fig. 3. Microstructure of AlSi7Mg0.3 with 0.2% Zr before HT, etchant 0.5% HF

- Fig. 4. Microstructure of AlSi7Mg0.3 with 0.2% Zr, with HT cast into shell mold, etchant 0.5% HF.

- Fig. 5. Microstructure of AlSi7Mg0.3 whith 0.2% Zr, with HT cast into metal mold, etchant 0.5% HF.

7. Conclusion:

Samples cast into the shell mold with the addition of Ti by 0.1 wt.% to an AlSi7Mg0.3 alloy with a constant Zr content of about 0.20 wt.% have a higher hardness than samples cast into the metal mold. After heat treatment, the increase in hardness was 30%. The tensile strength test was done according to standard AC121 for both sample types. Ductility increased by 1% in shell and 4% in metal molds. In the structure, the zirconium phases were much more clear in shell form. The casting from the metal mold presents a larger number of small Zr phases. Corresponding results indicate the possibility of developing a more sophisticated alloy that would be able to better withstand changes during working condition, especially in internal combustion engines.

8. References:

- [1] Bolibruchová, D., Tillová, E. (2005). Al-Si foundry alloys. Žilina.

- [2] Michna, Š., Lukáč, I. (2005). et al. Encyclopedia of aluminum.

- [3] Bechný, L. (1990). Foundry metallurgy and technology. ALFA Bratislava.

- [4] Bolibruchová, D., Kuriš, M. & Matejka, M. (2019). Effect of Zr on selected properties and porosity of AlSi9Cu1Mg alloy for the purpose of production of high-precision castings. Manufacturing Technology. 19(4), 1213-2489.

- [5] Bolibruchova, D., Macko, J. & Bruna, M. (2014). Elimination of negative effect of Fe in secondary alloys AlSi6Cu4 (EN AC 45 000, A 319) by nickel. Archives of Metallurgy and Materials, 59, 717-721

- [6] Mahmudi, R., Sepehrband, P. & Ghasemi, H.M. (2006). Improved properties of A319 aluminum casting alloy modified with Zr. Materials Letters. 2606-2610. DOI 10.1016/j.matlet. 2006.01.046

- [7] Peng, G., Chen, K., Fang, H. & Chen, S. (2012). A study of nanoscale Al3(Zr, Yb) dispersoids structure and thermal stability in Al-Zr-Yb alloy. Materials Science and Engineering. Volume 535, 311-315.

- [8] Sha, G. & Cerezo, A. (2004). Early-stage precipitation in Al-Zn-Mg-Cu alloy (7050). Acta Materialia. 52(15), 4503-4516.

- [9] Lü, X., Guo, E., Rometsch, P. & Wang, L. (2012). Effect of one-step and two-step homogenization treatments on distribution of Al3Zr dispersoids in commercial AA7150 aluminium alloy. Transactions of Nonferrous Metals Society of China. 22, 2645-2651. Science Direct.

- [10] STN EN 1706. AC-42100. Aluminium alloy for general purpose castings.

- [11] Liu, S., Zhang, X.M. & Chen, M.A. & You, J. H. (2008). Influence of aging on quench sensitivity effect of 7055 aluminium alloy. Materials Characterization, 59(1), 53-60.

- [12] Pourkia, N., Emamy, M., Farhangi, H. & Seyed, E. (2010). The effect of Ti and Zr elements and cooling rate on the microstructure and tensile properties of a new developed super high-strength aluminium alloy. Materials Science and Engineering A. 527, 5318-5325.

- [13] Tillova, E., Chalupova, M. (2009). Structural analysis of Al-Si alloys. Žilina: EDIS ŽU UNIZA.

Expert Q&A: Your Top Questions Answered

Q1: Why was the specific T6 heat treatment (540°C for 12h, then 150°C for 3h) chosen for this study?

A1: The paper states this T6 mode is specifically used for castings from which good castability, corrosion resistance, pressure tightness, and weldability are required. These properties are critical for high-integrity components used in demanding applications such as nuclear power plants, aircraft pumps, and engine cylinder blocks, making this heat treatment protocol highly relevant for industrial practice.

Q2: What was the primary difference observed between casting in a shell mold versus a metal mold?

A2: The main difference was the heat transfer coefficient, which led to different cooling rates. The paper explains that the metal mold provides sharper heat dissipation, resulting in the formation of finer grains. This had a critical effect on the Zirconium phases after heat treatment; in the metal mold, they decomposed into desirable smaller, rounded clusters, while in the slower-cooling shell mold, they remained as large, sharp needles.

Q3: What was the intended role of adding Titanium (Ti) alongside Zirconium (Zr)?

A3: According to the paper, "The Ti inoculant was added due to the greater number of Zr grains. With Ti we wanted to influence the size of Zr grains and thus their number." This indicates that Titanium was used as an inoculant with the specific goal of refining the size and increasing the number of Zirconium-based grains, thereby promoting a finer and more homogenous microstructure.

Q4: Did the experimental alloys achieve the standard prescribed tensile strength for this material?

A4: No, they did not fully meet the standard. The paper states, "None of the samples reached the reference, conventional maximum tension." The highest value achieved for the shell mold was 258 MPa (standard is 260 MPa), and the highest for the metal mold was 280 MPa (standard is 290 MPa). While very close, this suggests further optimization of the process or composition may be needed.

Q5: What specific form did the Zirconium phases take in the microstructure, and how did they change?

A5: In the as-cast condition, the Zr phases were observed as large, non-regularly distributed needles with sharp edges, which the authors suggest are likely intermetallic phases of the Al3Zr or AlSiZr type. The key transformation occurred after heat treatment in the metal mold samples, where these large needles decomposed into smaller, more stable, and morphologically favorable plate-like or rounded phases.

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively demonstrates that the mechanical properties of AlSi7Mg0.3 can be significantly enhanced through a multi-faceted approach. The core problem—the need for stronger, more reliable lightweight alloys—was addressed by combining strategic alloying with Zr and Ti and a carefully controlled AlSi7Mg0.3 Heat Treatment protocol. The key breakthrough is the clear evidence that the casting method is not just a forming process but a critical tool for microstructural engineering. The faster cooling of a metal mold refines the Zirconium phases into a more beneficial morphology, a crucial insight for producing high-performance castings. These findings pave the way for developing more sophisticated alloys capable of withstanding demanding operating conditions in modern engines and structural components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Heat Treatment of AlSi7Mg0.3 Aluminium Alloys with Increased Zirconium and Titanium Content" by "E. Kantoríková, M. Kuriš, R. Pastirčák".

Source: https://doi.org/10.24425/afe.2021.136103

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.