This technical brief is based on the academic paper "Promoting Distance Learning in Metal Casting by Implementing Four Simulation Activities" by Dr. Sam Ramrattan and Dr. Matthew Cavalli P.E., Western Michigan University, published in the Proceedings of the 2024 ASEE North Central Section Conference. It is summarized and analyzed for HPDC professionals by the experts at CASTMAN.

Keywords

- Primary Keyword: Metal Casting Simulation

- Secondary Keywords: Solidification Simulation, Casting Simulation Analysis, Casting Defect Analysis, Hot-Spot Detection, Gating Design Simulation, Alloy Flowability, Investment Casting

Executive Summary

- The Challenge: The metal casting industry requires continuous learning, but traditional hands-on training can be costly, time-consuming, and was severely restricted during the recent pandemic.

- The Method: Researchers developed a distance-learning curriculum for engineering students using casting simulation software to model and solve real-world casting problems, from shrinkage and hot spots to flowability and final yield.

- The Key Breakthrough: The study demonstrated that simulation is a highly effective tool for teaching complex casting principles. It allows for the safe, rapid, and detailed visualization of in-mold events like solidification and filling, which are impossible to see in a traditional foundry setting.

- The Bottom Line: Simulation provides a powerful, predictive, and practical way to analyze and optimize casting processes, reducing defects and improving quality before the first piece of metal is poured.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, metal casting education has relied on a hands-on approach. While invaluable, this method faces modern challenges: the need for safer training environments, the high cost of materials and lab time, and the demand for a digitally fluent workforce ready for Industry 4.0. The COVID-19 pandemic accelerated the need for a new approach, forcing academia and industry to find ways to transfer critical technical knowledge remotely. This research tackles that problem head-on, exploring how simulation technology can bridge the gap, moving complex process training from the foundry floor to the desktop without losing educational fidelity.

The Approach: Unpacking the Methodology

To test the effectiveness of simulation-based learning, the researchers replaced a conventional, hands-on metal casting course with one based entirely on simulation activities. The study utilized a modern casting simulation software tool that enables a straightforward, five-step process: Import Model, Select Part, Import/Create Components, Setup the Process, and Run Simulation.

Eighteen sophomore and junior-level engineering students participated in four key activities over a semester:

- Determine Shrinkage in a Casting: Analyzing how gating design impacts shrinkage porosity in an aluminum casting.

- Study Hot Spots and Surface Area-to-Volume Effects: Identifying potential defect areas (hot spots) in various casting geometries.

- Flowability and Feeding Test for Cast Alloys: Simulating how pouring temperature affects the fluidity and filling of an aluminum alloy in a spiral mold.

- Perform Investment Casting: A final project where students designed and simulated a complex investment casting, aiming to optimize the design for maximum yield.

The Breakthrough: Key Findings & Data

The study confirmed that simulation provides deep, actionable insights into the casting process.

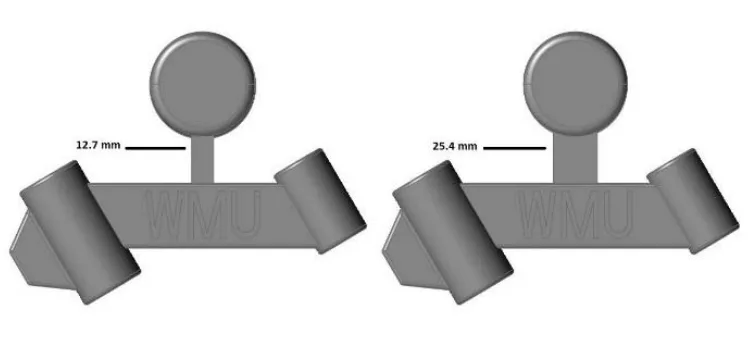

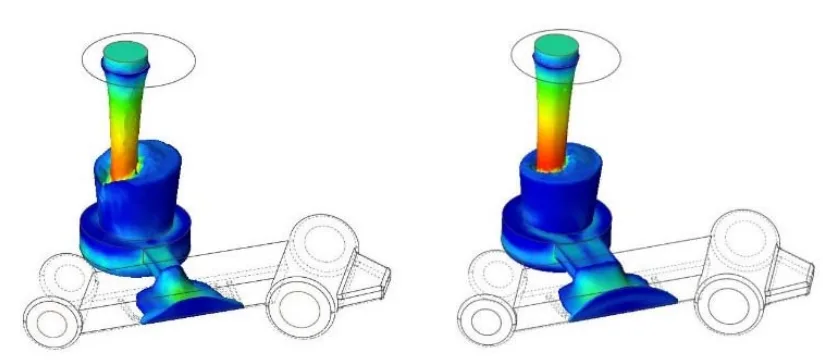

- Finding 1: Visualizing Shrinkage: By simulating a casting with two different gate sizes (12.7 mm vs. 25.4 mm), students could visually identify the resulting shrinkage porosity. The simulation results, shown in Figure 2, clearly predicted where defects would form based on gating design.

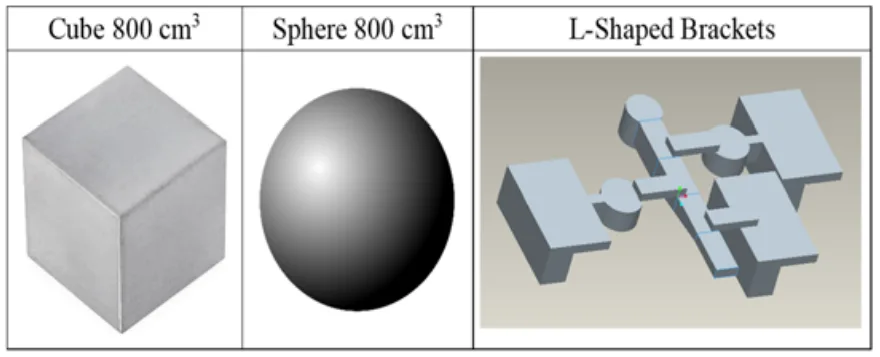

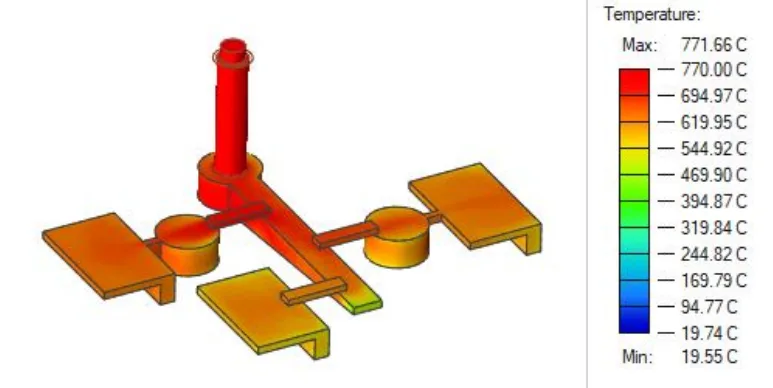

- Finding 2: Predicting Hot Spots: The research used various shapes, including cubes, spheres, and L-shaped brackets, to teach the critical concept of hot spots—areas that cool slower and are prone to defects. Figure 5 shows a thermal simulation of an L-shaped bracket, allowing students to see the precise temperature distribution during filling.

- Finding 3: Optimizing for Flowability: Students simulated a fluidity spiral test at three different temperatures (600°C, 675°C, and 720°C). The results in Figure 7 provided a clear visual representation of how superheat directly impacts the length of metal flow, a critical factor in preventing cold shuts and ensuring complete mold filling.

- Finding 4: Designing for Manufacturability (DFM): In a final project, students designed their own investment casting and used simulation to analyze and optimize it for an 80% or higher yield. Figure 9 shows the analysis of total shrinkage volume, a key metric for ensuring a sound final part.

Practical Implications for HPDC Products

While this study was conducted in an academic setting, its findings have direct and significant implications for commercial HPDC operations. The principles and tools highlighted in the paper are precisely what leading manufacturers use to enhance quality and efficiency.

- For Process Engineers: The findings on alloy flowability (Activity 3) and shrinkage (Activity 1) reinforce that simulation is a powerful tool for process optimization. This research suggests that by simulating parameters like pouring temperature and gate size, you can predict and mitigate defects like cold shuts and porosity, saving time and material on physical trials.

- For Quality Control: The correlation shown between casting geometry and hot spots (Figure 5) provides a clear method for predictive quality control. By analyzing a new die design with simulation software, your team can identify and address potential defect zones before the tool is even cut.

- For Die Design: This study's capstone project on investment casting (Activity 4) is a direct parallel to using simulation for Design for Manufacturability (DFM) in HPDC. It proves that optimizing gating, risering, and part orientation in a virtual environment is the most effective way to maximize yield and minimize scrap, as detailed in the paper's conclusion.

Paper Details

Promoting Distance Learning in Metal Casting by Implementing Four Simulation Activities

1. Overview:

- Title: Promoting Distance Learning in Metal Casting by Implementing Four Simulation Activities

- Author: Dr. Sam Ramrattan, Dr. Matthew Cavalli P.E.

- Year of publication: 2024

- Journal/academic society of publication: American Society for Engineering Education

- Keywords: distance learning, metal casting curriculum, solidification simulation; casting simulation analysis

2. Abstract:

The metal casting industry has less than thirty certified Foundry Educational Foundation (FEF) university/colleges in North America. For this reason, it is important to support and maintain quality educational programs. For the past thirty-five years, metal casting simulation tools have been affiliated with academia primarily in research and development. At the same time metal casting industry has adopted a digital approach to manufacturing where simulations play a major role. Educational institutes need to involve solidification and simulation technologies at the undergraduate level. Can solidification simulations be an effective tool to support student understanding of metal casting concepts in an introductory engineering course via distance learning? The authors investigated scaling up the use of a sequence of modules containing real-world simulation problems (hot-spot detection on castings, surface area-to-volume issues on castings, fluidity of various casting alloys, design optimization and yield calculations). The implementation of flow and solidification simulations activities were explored in an introduction to Metal Casting course when the COVID-19 pandemic prohibited the conventional, face-to-face, and hands-on learning activities of the engineering course. Participants were eighteen sophomore/junior level engineering students at Western Michigan University during the Summer Semester 2020. Casting flow and solidification predictive analysis were verified from actual casting trials where gating designs were experimentally evaluated preceding the course. The effectiveness studies were reported after comparing the evaluations of course assignment and examination scores prior and post the solidification simulation activities. At the end of the course evaluation, feedback from students was solicited regarding the distance learning solidification simulation experiences. The simulation activities were described, and output analysis was provided. The experience conveyed insights into the role of simulation as an efficient and effective teaching tool in distance education. Results supported an adoption and implementation of the simulation software tool when teaching introduction to Metal Casting on any platform.

3. Introduction:

An introduction to Metal Casting course has been taught the same way for many decades. The prerequisite of this course requires an understanding of material science - metallurgy, fluids, and thermodynamics.¹ In some cases, casting simulation software is presented or demonstrated but the technology is not central to the pedagogy in introduction to Metal Casting. The casting simulation technology is often reserved for more advanced courses involving solidification, risering and gating design.² In 2020, the COVID-19 outbreak presented society with unprecedented challenges and operational disruptions. The foundry industry must shift gears to help address shortages regarding a trained/educated workforce and improving metal casting education is an answer. This paper discusses how a simulation software can be made accommodating and beneficial in a distance learning environment to students equipped with a basic laptop computer. The philosophy of Industry 4.0/Foundry 4.0 is becoming more a reality. Thus, future engineers must be prepared in digital communication and smart data sharing technology.

4. Summary of the study:

Background of the research topic:

The study was initiated to address the challenges of teaching a hands-on subject like metal casting in a distance-learning environment, a need amplified by the COVID-19 pandemic. It aimed to leverage modern simulation technology to provide students with practical, virtual experiences.

Status of previous research:

Traditional metal casting courses rely on physical labs. While simulation software has existed since the 1980s, it was often reserved for advanced courses or research, not as a primary teaching tool in introductory courses.

Purpose of the study:

The purpose was to design and test a sequence of simulation activities for a distance-learning Metal Casting course and to compare student outcomes with those from the conventional, hands-on version of the course.

Core study:

The core of the study involved eighteen engineering students at Western Michigan University completing four distinct simulation-based activities. These activities were converted from traditional lab experiments to CAD models and simulation projects. The activities covered fundamental concepts: shrinkage, hot spots, alloy flowability, and investment casting design. Student performance and feedback were used to evaluate the effectiveness of this teaching method.

5. Research Methodology

Research Design:

The study was designed to replace traditional laboratory demonstrations and data gathering with casting simulations. A sequence of four simulation projects was administered, increasing in complexity, to build upon students' knowledge systematically. Students were evaluated via technical reports and electronic examinations after each activity.

Data Collection and Analysis Methods:

Data was collected from student technical reports, simulation project outputs, and examination scores. Additionally, student course ratings were gathered using WMU's online course rating system to gauge student interest, attitude, and motivation.

Research Topics and Scope:

The research focused on four main topics, each designed as a separate activity: (1) Shrinkage in a Casting, (2) Hot Spots and Effects of Surface Area-to-Volume, (3) Flowability and Feeding Test for Cast Alloys, and (4) Investment Casting design and optimization. The scope was limited to undergraduate engineering students in an 8-week summer semester.

6. Key Results:

The study found that the distance learning curriculum using simulation was effective. Students were able to use the simulation tool to conduct experiments, analyze data, and understand complex casting phenomena. Presenting real-world casting activities through interactive computer simulations provided students with an active learning experience, allowing them to see in-mold details that are hazardous and not readily observable in a conventional course. Student course ratings for the semester using this methodology (S20) were high, with an overall course rating of 5 out of 5.

Figure Name List:

- Figure 1. CAD image of Shrinkage model

- Figure 2. Simulation result of shrinkage porosity in 12.7 mm and 25.4 mm gate model

- Figure 3. Simulation result of filling variance in 12.7 mm and 25.4 mm gate model

- Figure 4. CAD image of Solidification model

- Figure 5. Filling temperature of L shaped bracket

- Figure 6. CAD image of Fluidity model

- Figure 7. Fluidity result of spiral at different temperature

- Figure 8. CAD design of investment casting model

- Figure 9. Simulation result of investment casting model.

- Figure 10. Casting produced by aluminum 356 at different temperatures using gravity casting

- Figure 11. Casting produced by gray iron lost foam (left) and aluminum investment

7. Conclusion:

The paper concluded that a casting curriculum that substitutes conventional academics with simulation-based learning can be highly beneficial. Casting simulation allows students to connect theory and practice, reinforcing learning outcomes for all activities. It provides learners with visual representations of dynamic theoretical entities (like flow, fill, and solidification) that are difficult to observe otherwise. The authors recommend that casting simulation be adopted to complement conventional hands-on casting courses and note it can be modified for industrial training programs.

8. References:

- EDMM 3520 Metal Casting on Western Michigan University eLearning, Summer 1 2020 wmich.edu/eLearning

- Metal casting Principles & Techniques, 1st Edition, Dec. 2013 American Foundry Society, ISBN: 978-0-87433-399-2.

- Altair Online Training Materials for Inspire Cast, https://2020.help.altair.com/2020.1.1/cast/en_us/topics/shared/get_started/training_support_c.htm

- Transport Phenomena in Metallurgy, Addison-Wesley series, by David R. Poirier, G. Geiger, 1st Edition 2016, ISBN 978-3-319-48090-9.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving understanding of the casting process?

A1: The study concluded that the use of casting simulation itself was the most critical factor. It provides "in-mold visualizations of what might be considered hazardous hot metal processing details, otherwise not readily observable within the conventional course," as detailed in the "Effectiveness of Casting Simulations" section.

Q2: How does this research compare to traditional methods for addressing casting education?

A2: The paper's Introduction and Results and Discussion sections note that while traditional methods rely on hands-on laboratory work, this research introduces a simulation-based approach that allows students to safely and repeatedly visualize and experiment with complex processes like solidification and fluid flow, which is impractical in a physical lab.

Q3: Is this finding applicable to all types of alloys, or a specific one?

A3: The research, as described in the Methodology section and various tables, was specifically conducted using Aluminum 356, AISI 1045 Steel, Gray Cast Iron 60, and Aluminium 319. The applicability to other alloys would require further investigation.

Q4: What specific measurement or simulation technique did the researchers use to arrive at this conclusion?

A4: The researchers utilized casting simulation software to analyze and visualize outcomes like shrinkage porosity, filling variance, temperature distribution, and fluid flow. The Acknowledgments section thanks Altair Engineering for software technology support.

Q5: According to the paper, what is the main limitation or area for future research?

A5: The authors state in the Limitations section that a key limitation was that the "Distance learning strategies were limited to one summer semester (8 weeks)." They also note that after the course, "students indicated an interest in hands-on laboratory experiences that supplements simulation technology," suggesting a blended approach for the future.

Q6: What is the direct, practical takeaway from this paper for a die casting facility?

A6: The core takeaway is that by using casting simulation, it is possible to train personnel and to analyze and optimize a casting process to reduce defects and improve yield before committing to expensive tooling and production runs. This conclusion is strongly supported by the overall results of the paper, "Promoting Distance Learning in Metal Casting by Implementing Four Simulation Activities".

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing process knowledge in HPDC. The findings offer a clear, data-driven path toward improving quality, reducing defects, and optimizing production by leveraging the predictive power of simulation. It demonstrates that the same tools used to train the next generation of engineers are indispensable for solving today's most complex manufacturing challenges.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "Dr. Sam Ramrattan" and "Dr. Matthew Cavalli P.E.". Based on "Promoting Distance Learning in Metal Casting by Implementing Four Simulation Activities".

- Source of the paper: Proceedings of the 2024 ASEE North Central Section Conference

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.