Unlocking Peak Performance in Cast Aluminum: How Friction Stir Processing Tool Design Eliminates Defects and Boosts Ductility

This technical summary is based on the academic paper "Friction stir processing in multiple passes of cast aluminum alloy EN AW 5083 (AlMg4.5Mn0.7)" by L.-N. Boțilǎ, R. Cojocaru, V. Verbiţchi, C. Ciucă, published in WELDING & MATERIAL TESTING (year XXVIII, no. 3/2019).

Keywords

- Primary Keyword: Friction Stir Processing Aluminum

- Secondary Keywords: cast aluminum alloy, EN AW 5083, multiple passes, mechanical properties, microstructure refinement, casting defects, surface processing

Executive Summary

- The Challenge: Cast aluminum alloys like EN AW 5083 suffer from coarse microstructures and inherent defects that limit their mechanical performance in demanding applications.

- The Method: Researchers applied multi-pass Friction Stir Processing (FSP) to the surface of cast EN AW 5083 using three distinct tool pin geometries to refine the material structure.

- The Key Breakthrough: A conical pin tool with four flat bevels successfully produced a fully consolidated, defect-free processed zone, whereas other tool designs created surface-level "tunnel" defects.

- The Bottom Line: Selecting the optimal FSP tool geometry is the most critical factor for eliminating surface defects, refining the microstructure, and significantly improving the ductility of cast aluminum components.

The Challenge: Why This Research Matters for HPDC Professionals

Cast aluminum alloy EN AW 5083 is widely used in shipbuilding, pressure vessels, and automotive components due to its excellent corrosion resistance and casting properties. However, its "as-delivered" state presents a significant challenge for engineers: a coarse grain structure and the potential for casting defects. These issues can compromise mechanical integrity and limit the material's use in high-performance applications.

Traditional surface modification techniques like arc deposition or thermal spraying can improve properties but are often pollutant and environmentally unfriendly. This research explores Friction Stir Processing (FSP)—a clean, solid-state mechanical process—as a solution to refine the microstructure, eliminate defects, and enhance the mechanical characteristics of this crucial cast alloy, paving the way for its use in more demanding roles.

The Approach: Unpacking the Methodology

The study was conducted on 8 mm thick plates of cast aluminum alloy EN AW 5083. The researchers used a multi-pass FSP strategy to process a wide surface area, with each of the five passes overlapping the previous one. While the core process parameters were held constant (1450 rpm rotational speed, 100 mm/min processing speed), the critical variable was the geometry of the FSP tool.

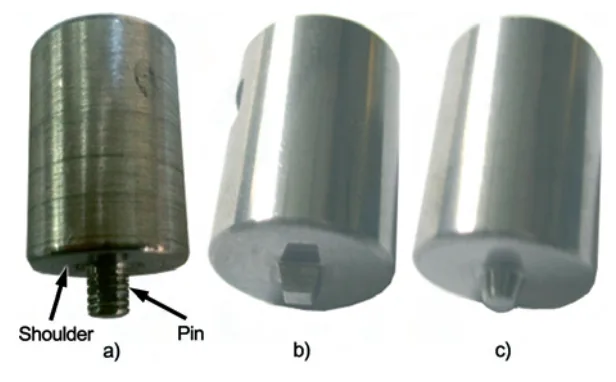

Method 1: Threaded Cylindrical Pin Tool

- Material: X38CrMoV5 steel

- Dimensions: 22.0 mm shoulder diameter, 5.5 mm pin length (M6 thread)

- Key Feature: A standard threaded pin designed for robust material stirring.

Method 2: Conical Pin Tool with Four Flat Bevels

- Material: P20S tungsten sintered carbide

- Dimensions: 20.0 mm shoulder diameter, 5.0 mm pin length

- Key Feature: A tapered pin with flat faces, designed to combine frictional heating with a cutting action.

Method 3: Smooth Conical Pin Tool

- Material: P20S tungsten sintered carbide

- Dimensions: 20.0 mm shoulder diameter, 4.6 mm pin length

- Key Feature: A simple tapered pin relying purely on frictional forces for material plasticization.

The Breakthrough: Key Findings & Data

The choice of tool geometry had a dramatic and decisive impact on the quality and properties of the processed material.

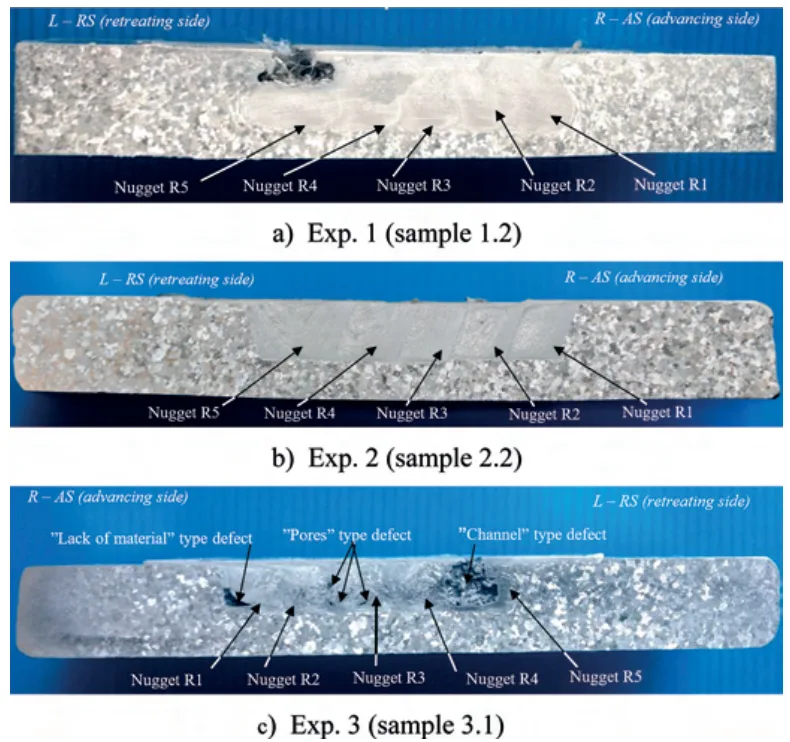

Finding 1: Conical Pin with Bevels Eliminates Surface Defects

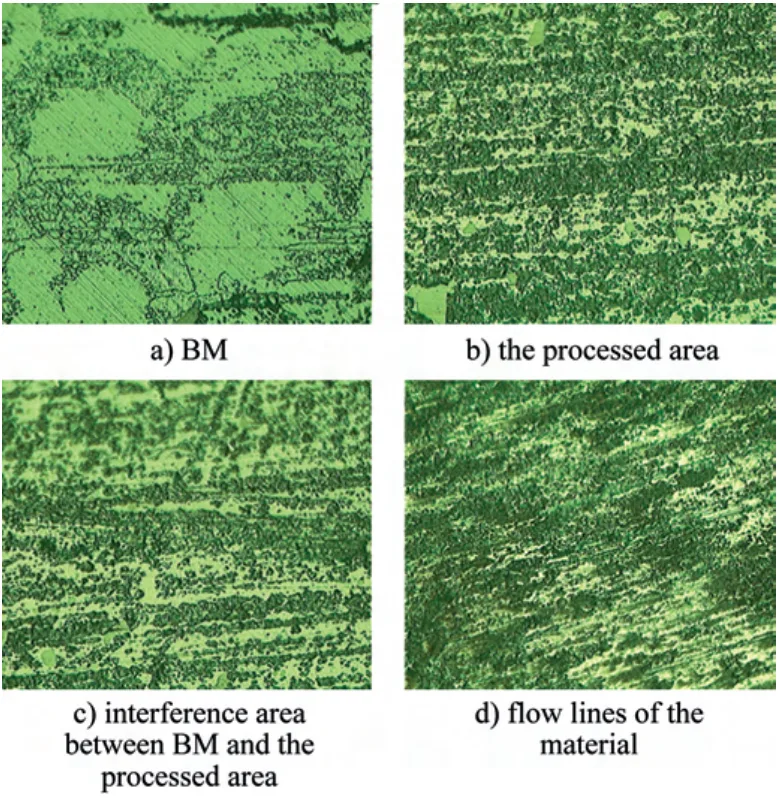

The most significant finding was the difference in surface integrity. The threaded cylindrical pin (Exp. 1) and the smooth conical pin (Exp. 3) both created a "tunnel" type defect along the final processed pass. As shown in Figure 5c, this appears as a visible channel or groove on the surface. In stark contrast, the conical pin with four flat bevels (Exp. 2) produced a perfectly consolidated, defect-free surface across all five passes. Figure 5b clearly shows a uniform, high-quality processed area, demonstrating this tool's superior material flow characteristics.

Finding 2: Superior Hardness and Ductility Achieved

The FSP treatment successfully refined the coarse cast structure into a fine-grained, homogeneous microstructure in all experiments. However, the defect-free process yielded superior mechanical properties.

- Hardness: The average hardness in the area processed with the conical pin with four bevels (Exp. 2) was ~94 HV1, a significant increase over the base material's ~81 HV1. The other two tools produced hardness values closer to the base material.

- Ductility: The bending test results were particularly revealing. As shown in Figure 8b, the base material (specimen B.5 BM) fractured at a small bending angle of 46°. The material processed with the superior tool (specimen B.5.2. Long.) sustained a much larger bending angle of 74° before fracture, demonstrating a dramatic improvement in ductility and toughness.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that when implementing multi-pass FSP on cast aluminum, a tool with features that enhance material flow, such as a conical pin with flat bevels, is critical to preventing end-of-pass defects.

- For Quality Control Teams: The data in the paper illustrates the effect of tool geometry on final material properties. The hardness value of ~94 HV1 and a bending angle of 74° can serve as new quality inspection criteria for FSP-treated EN AW 5083 components.

- For Design Engineers: The findings indicate that FSP can be used as a localized strengthening and toughening process. This allows for the use of a base cast component while selectively enhancing properties in critical areas, potentially reducing weight and manufacturing complexity.

Paper Details

Friction stir processing in multiple passes of cast aluminum alloy EN AW 5083 (AlMg4.5Mn0.7)

1. Overview:

- Title: Friction stir processing in multiple passes of cast aluminum alloy EN AW 5083 (AlMg4.5Mn0.7)

- Author: L.-N. Boțilǎ, R. Cojocaru, V. Verbiţchi, C. Ciucă

- Year of publication: 2019

- Journal/academic society of publication: WELDING & MATERIAL TESTING (year XXVIII, no. 3/2019)

- Keywords: Friction stir processing, multiple passes, cast aluminum alloy, EN AW 5083 (AlMg4.5Mn0.7), experiments.

2. Abstract:

This paper presents experimental results from the application of Friction Stir Processing (FSP) in multiple passes to a cast aluminum alloy EN AW 5083 (AlMg4.5Mn0.7). The study investigates the influence of different FSP tool pin geometries—specifically a threaded cylindrical pin, a conical pin with four flat bevels, and a smooth conical pin—on the surface quality, microstructure, and mechanical properties of the processed material. The experiments were conducted using five overlapping passes with constant rotational and processing speeds. The results demonstrate that the tool geometry is a critical parameter. The conical pin with four flat bevels produced a defect-free, well-consolidated processed area with enhanced hardness and ductility. In contrast, the other two tool designs resulted in the formation of a "tunnel" defect on the final processed pass. The study concludes that FSP, with an optimized tool design, is an effective method for refining the microstructure and improving the mechanical properties of cast aluminum alloys.

3. Introduction:

Friction Stir Processing (FSP) is an emerging surface engineering technique capable of producing significant local modifications in the mechanical characteristics of materials, particularly cast alloys. Unlike conventional methods such as electric arc deposition or thermal spraying, FSP is a purely mechanical, environmentally friendly process that operates below the material's melting point. Cast aluminum alloys, like EN AW 5083, are widely used for their corrosion resistance and casting properties but are often characterized by a coarse microstructure and potential casting defects. This research program was developed to apply the FSP process to cast aluminum alloy EN AW 5083 to refine its microstructure, eliminate defects, and improve its overall properties.

4. Summary of the study:

Background of the research topic:

The base material, cast aluminum alloy EN AW 5083, is used in various industrial applications but possesses a coarse microstructure and is susceptible to casting defects. FSP offers a potential solution for refining this structure and enhancing its mechanical characteristics.

Status of previous research:

Prior experimental research has demonstrated that FSP can induce spectacular local modifications of mechanical characteristics in cast alloys, including aluminum. It is recognized as a non-pollutant alternative to other surface treatment processes.

Purpose of the study:

The purpose of this study was to experimentally investigate the effects of applying multi-pass FSP to cast aluminum alloy EN AW 5083, with a specific focus on how different processing tool geometries influence the outcome.

Core study:

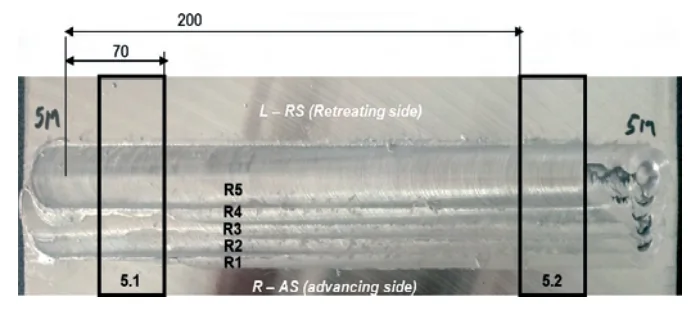

The core of the study involved conducting three distinct FSP experiments on 8 mm thick plates of cast EN AW 5083. Each experiment consisted of five overlapping passes with a pitch of 5 mm. The rotational speed (1450 rpm) and processing speed (100 mm/min) were kept constant. The independent variable was the FSP tool: 1) a threaded cylindrical pin, 2) a conical pin with four flat bevels, and 3) a smooth conical pin. The processed materials were then subjected to visual inspection, macroscopic and microscopic analysis, hardness measurements, and mechanical (tensile and bending) tests to evaluate the effects of the processing.

5. Research Methodology

Research Design:

The research employed a comparative experimental design to assess the impact of three different FSP tool pin geometries on the surface and mechanical properties of a cast aluminum alloy.

Data Collection and Analysis Methods:

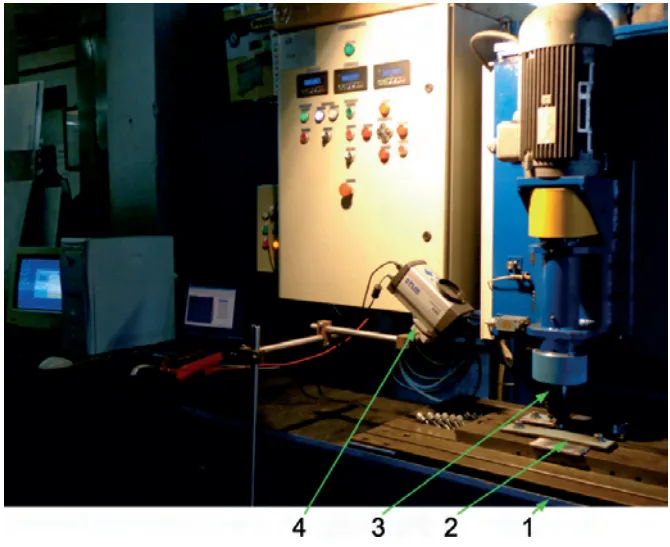

Data was collected through multiple methods. An FSP process monitoring system with infrared thermography was used to record temperature evolution during processing. Post-processing analysis included visual inspection, macroscopic analysis of cross-sections, and microscopic analysis to examine the grain structure. Mechanical properties were characterized using HV1 hardness measurements, tensile tests on small-scale specimens, and bending tests.

Research Topics and Scope:

The research was focused on the friction stir processing of 8 mm thick cast aluminum alloy EN AW 5083. The scope was limited to a single set of processing parameters (rotational speed and travel speed) and a multi-pass (five rows) strategy. The primary investigation centered on the comparative performance of a threaded cylindrical steel pin, a conical tungsten carbide pin with four flat bevels, and a smooth conical tungsten carbide pin.

6. Key Results:

Key Results:

- Surface defects in the form of a "channel" or "tunnel" were formed on the last processed row in experiments using the threaded cylindrical pin and the smooth conical pin.

- The experiment using the conical pin tool with four flat bevels produced a defect-free, compact, and uniform processed area.

- Macroscopic analysis showed that for all tool types, the overlapping passes resulted in a well-consolidated nugget for the first four rows (R1-R4), with defects from one pass being resolved by the subsequent pass.

- Microstructural analysis revealed a significant refinement of the coarse grains of the cast base material into a much more homogeneous microstructure of fine grains in all FSP experiments.

- The highest average hardness in the processed area (~94 HV1) was achieved in the experiment with the conical pin with four flat bevels, compared to the base material hardness of ~81 HV1.

- The mechanical strength (Rm ≈ 255 N/mm²) of the processed material was close to that of the base material.

- The bending angle at breakage improved significantly from 46° for the base material to 74° for the material processed with the conical pin with four bevels, indicating enhanced ductility.

Figure Name List:

- Figure 1. FSW experimental technique from ISIM Timisoara

- Figure 2. Processing tools used in the experimental program: a) Threaded cylindrical pin tool; b) Conical pin tool with 4 flat bevels; c) Smooth conical pin

- Figure 3. Temperature evolution during FSP processing

- Figure 4. Appearance on the surface of the processed FSP material

- Figure 5. Macroscopic appearance of the samples

- Figure 6. Microstructural analysis for the base material and processed material

- Figure 7. Sketch of small dimensional specimen for tensile test

- Figure 8. Appearance of specimens taken from the processed material and BM (Exp.1, 2) tested at: a) tensile tests (T); b) bending tests (B)

7. Conclusion:

The study on multi-pass FSP of cast EN AW 5083 alloy highlights several key phenomena. The use of a threaded cylindrical pin and a smooth conical pin resulted in the formation of a "tunnel" type defect on the final pass. However, a conical pin tool with four flat bevels successfully produced a high-quality, compact, and defect-free processed area. This indicates that tool geometry is a critical factor. The overlapping pass strategy was shown to be effective in "repairing" defects that may have occurred during individual passes. In all cases, FSP induced a "burst" of the coarse cast grains, resulting in a much more homogeneous and fine-grained microstructure. The lowest process temperatures were recorded with the four-bevel conical pin, suggesting its geometry combines friction with a cutting phenomenon.

8. References:

- [1]. Mishra, R.S., Mahoney, M.W.:,, Friction Stir Welding and Processing“, ASM International, The Materials Information Society, Ohio, USA, 2007;

- [2]. Xu XY: Progress of Friction Stir Surface Modification Technology, Rare Metals and Engineering, Volume 38, pag. 213-216, suppl.1, Apr. 2009;

- [3]. Sorensen C.D, Nelson TW, Packer SM, Allen C.: Friction stir processing of D2 tool steel for enhanced blade performance, Friction Stir Welding and Processing IV, TMS 2007, 409-418;

- [4]. Fuller C., Mahoney M.: The Effect of Friction Stir processing on 5083-H321/5356 Al Arc Welds: Microstructural and Mechanical Analysis;

- [5]. Murray W. Mahoney: Friction Stir Welding and Processing - Proceedings of the 7th International Conference on Trends in Welding Research, pag. 233-240. April 2005;

- [6]. Vilaça, P., Santos, J. P., Góis, A., Quintino, L.: Joining Aluminium Alloys Dissimilar in Thickness by Friction Stir Welding and Fusion Processes", Welding in the World, Vol. 49, No. 3/4, 56-62, 2005;

- [7]. Mahoney, M. W., Mishra, R. S., Nelson, T., Flintoff, J, Islamgaliev, R., Hovansky, Y.Y.: „Proc. of Friction Stir Welding and Processing”, Indianapolis, USA, 4-8 Nov. 2001;

- [8]. Kopyściański, M., Węglowski, M.St. et al: "Electron microscopy investigation of a cast AlSi9Mg aluminum alloy subjected to friction stir processing with overlapping passes", International Journal of Materials Research, 106 (2015), pp. 813-817;

- [9]. Verbiţchi, V., Cojocaru, R. a.o.: “Weld surfacing of industrial valves. Equipment and technology experiments“. Journal Armatura, January 2003, CRIA, Romanian Committee for the Valve Industry, „Valahia” University of Târgovişte, Romania;

- [10]. Boțilă, L.N., R. Cojocaru. R.: “Reconditioning of the used components from transportation devices using mechanized MIG/MAG welding procedure", published in Annals of Faculty of Engineering from Hunedoara, Tom II, Fascicle 3/2004, pp. 171-178, ISSN 1584-2673, B+ category, BDI indexed;

- [11]. Murariu, A.C., Perianu, A.: Influence of HVOF deposition thickness on adhesion strength of WC-CrC-Ni coatings, The 4th IIW South-East European Welding Congress, SEEIIW 2018, October 10-13, Belgrade, Serbia;

- [12]. Bîrdeanu, V. a.o.: Investigations of corrosion behavior on combined fast laser texturing and HVOF TiO2 powder deposition surface engineering treatment, The 9th International Conference "Innovative technologies for joining advanced materials", TIMA 18, 1 2 November 2018, Timişoara, Romania.

Expert Q&A: Your Top Questions Answered

Q1: Why were multiple overlapping passes used instead of a single, wider pass?

A1: The paper employed a multiple-pass strategy to process a larger surface area than a single tool could cover. More importantly, this approach revealed a key phenomenon: the FSP action of a subsequent pass can "repair" or resolve defects that may have formed in the previous pass by mixing and re-consolidating the material at the overlap zone. This is crucial for achieving a uniformly processed, defect-free surface over large areas.

Q2: What is the significance of the temperature differences observed between the three experiments?

A2: The conical pin tool with four flat bevels (Exp. 2) recorded the lowest average process temperature (~324°C) compared to the threaded pin (~463°C) and smooth conical pin (~399°C). The authors suggest this is because its geometry induces not only friction but also a cutting phenomenon. This more efficient material plasticization mechanism likely contributed to better material flow and the prevention of defects, even at a lower heat input.

Q3: The paper states that the ultimate tensile strength didn't change much. Why is the improved bending performance still considered a major breakthrough?

A3: While the ultimate strength remained similar, the base material was brittle, as shown by its low bending angle of 46°. For many structural components, ductility and toughness (the ability to deform without fracturing) are more critical than raw strength. The increase in the bending angle to 74° represents a significant enhancement in the material's ability to withstand deformation, making the processed component more reliable and damage-tolerant.

Q4: Why did the threaded cylindrical and smooth conical pins create a "tunnel" defect specifically on the last pass?

A4: The paper notes this type of defect has been observed in FSW of magnesium-containing alloys. The defect did not appear on the first four passes because the subsequent overlapping pass effectively filled and forged it shut. The defect only became visible on the final, fifth pass because there was no subsequent pass to repair the inadequate material flow left behind by those specific tool geometries.

Q5: Could this process be applied to other cast aluminum alloys used in HPDC?

A5: While this study focused specifically on EN AW 5083, the underlying principles are highly relevant to other cast aluminum alloys. The research demonstrates that FSP can effectively refine coarse cast microstructures and that tool design is paramount. Similar benefits in terms of defect elimination and ductility improvement could likely be achieved in other cast alloys, though process parameters and tool geometry would need to be optimized for each specific alloy.

Conclusion: Paving the Way for Higher Quality and Productivity

This research clearly demonstrates that Friction Stir Processing Aluminum is a powerful tool for overcoming the inherent limitations of cast alloys. The core challenge of coarse microstructures and defects can be effectively addressed, but the key to success lies in the meticulous selection of the FSP tool. The breakthrough finding—that a conical pin with four flat bevels produces a defect-free surface with superior hardness and ductility—provides a clear roadmap for process engineers. This moves FSP from a theoretical possibility to a practical, high-value surface engineering solution.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Friction stir processing in multiple passes of cast aluminum alloy EN AW 5083 (AlMg4.5Mn0.7)" by "L.-N. Boțilǎ, R. Cojocaru, V. Verbiţchi, C. Ciucă".

Source: The paper was published in WELDING & MATERIAL TESTING, year XXVIII, no. 3/2019.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.