This introductory paper is the research content of the paper "Fields of Action in Mega-Casting for the Industrialization of Automotive Car Bodies" published by 27. - 29. SEP 2022 | BAD NAUHEIM, GERMANY, Car Body Parts - from development to production.

1. Overview:

- Title: Fields of Action in Mega-Casting for the Industrialization of Automotive Car Bodies

- Author: Falko Fiedler, Georg Bergweiler et al.

- Publication Year: 2022

- Publishing Journal/Academic Society: Presentation, Car Body Parts - from development to production

- Keywords: Mega-Casting, Gigacasting, Automotive Production, Body in White, Aluminum Die Casting, High Pressure Die Casting

2. Abstracts / Introduction

The automotive industry is undergoing a transformational process, driven by factors such as technology, changing customer behavior, and tightened regulations. Mega-casting, a high-pressure die casting process, has emerged, and has the potential for changing automotive body production. The paper is to offer opportunity and risk of mega-casting.

3. Research Background:

Background of the Research Topic:

The conventional automotive body-in-white (BIW) production involves press shops and body shops, which have high investment and tooling costs, and limited product flexibility.

Status of Existing Research:

There is No literature on Mega-Casting could be identified.

Current applications of aluminum high-pressure die casting (HPDC) in the automotive industry include structural components like shock towers and longitudinal beams, primarily in mid-class to upper-class, sports, and luxury cars, as well as SUVs. The cycle of cold-chamber die casting is described, including die locking forces up to 4 kt and cycle times between 30 and 180 seconds. [12]

Necessity of the Research:

Mega-Casting is gaining attention in the automotive industry. There is a need to understand the implications of Mega-Casting for the entire product-production system in the automotive industry.

4. Research Purpose and Research Questions:

Research Purpose:

To analyze the fields of action related to Mega-Casting in the context of automotive car body industrialization.

Key Research:

- What does Mega-Casting stands for and what can the automotive production learn from such a “Techy” (Big-Tech-Company)?

- What opportunities and challenges have Mega-Casting for the entire product-production system in the automotive industry?

5. Research Methodology

Research Design:

A multi-method approach was employed, combining:

- Systematic Internet Research (SIR)

- Systematic Literature Research (SLR)

- Systematic Patent Research (SPR)

- Grounded Theory-based Expert Interviews

Data Collection Method:

- SIR: Google Web and image searches, relevant business accounts on LinkedIn, forums, newsletters, and company websites.

- SLR: Databases such as STARLITE-Method [23], ScienceDirect, SpringerLink, RWTH University library, and Web of Science were searched using derived search strings and Boolean operations.

- SPR: FAMPAT and Espacenet databases were searched using IPC/CPC codes, keywords, and back-/forward analysis.

- Expert Interviews: Semi-structured interviews (1.5-2 hours) were conducted with 63 experts from 33 companies/institutions along the TIER pyramid. Consent for recording was obtained [25].

Analysis Method:

- SIR/SLR/SPR: Content analysis, segmentation, and summarization in a databank.

- Expert Interviews: Evaluation according to headings and codes, conceptualization and theory generation, development of the production concept, and analysis/evaluation. Transcription, anonymization, and classification of text passages were performed.[26]

Research Subjects and Scope:

The research focused on Mega-Casting within the automotive industry, encompassing organizational, product, production, and supplier perspectives.

6. Main Research Results:

Key Research Results:

- Organization: Three Tesla patents were identified, relating to a multi-directional unibody casting machine [17], die-cast aluminum alloys for structural components [27], and integrated energy-absorbing castings [29]. Expert interviews revealed that perception of Mega-Casting has increased since 2020, with OEMs and TIER-1 suppliers deeply involved.

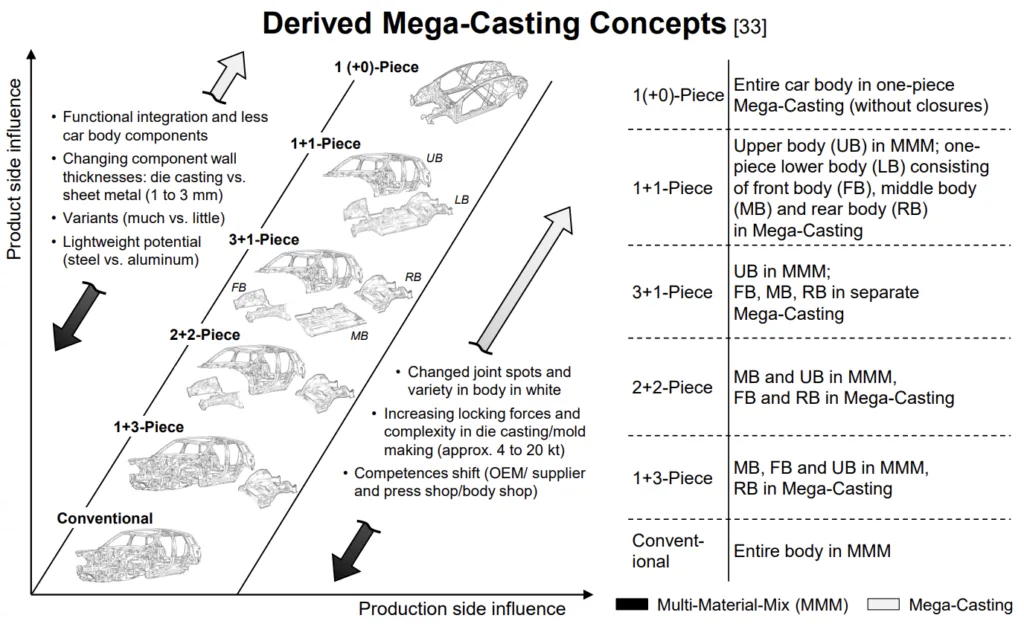

- Product: Mega-casting's strengths in reducing component and joint counts. Derived Mega-casting Concepts include 1(+0)-piece, 1+1-piece, 3+1-piece, 2+2-piece, and 1+3-piece, comparing them. [33]

- Production: Experts estimate the Technology Readiness Level (TRL) of Mega-Casting to be around 8, nearing 9, for the 3+1 and 1-piece concepts.

- Supplier:

Many Tier-1 companies involed in Mega-Casting, and the others threatened the loss of it's business. [34]

Declining demend for smaller casted parts, So significant development is needed. [34]

Raw material suppliers have a increasing demand for aluminium.

Analysis of presented data:

- SWOT analsysis.

- Porter Five Forces Analysis.

Figure Name List:

- [Fig.1] Cycle of cold-chamber die casting [12]

- [Fig.2] Multi-Directional Unibody Casting Machine For A Vehicle Frame And Associated Methods [17]

- [Fig.3] Die Cast Aluminum Alloys for Structural Components [27]

- [Fig.4] Integrated Energy Absorbing Castings [29]

- [Fig.5] Derived Mega-Casting Concepts [33]

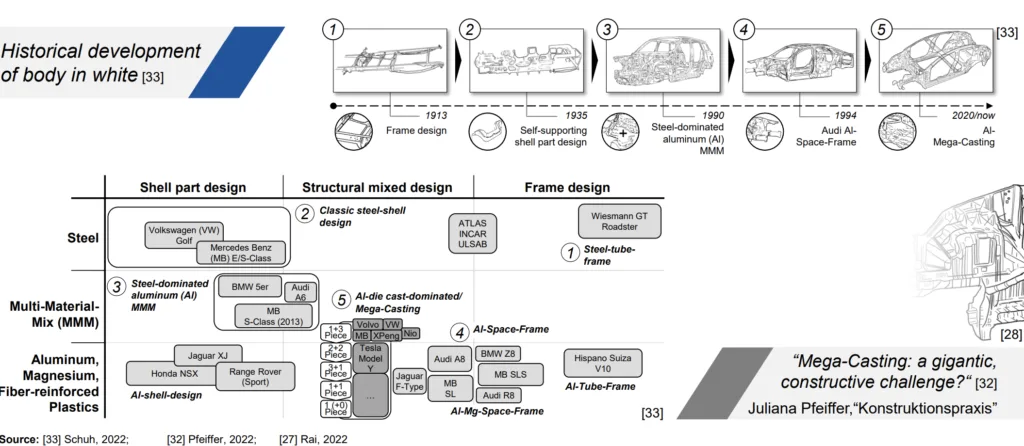

- [Fig.6] Historical development of body in white [33]

7. Conclusion:

Summary of Key Findings:

- Mega-Casting is emerging as a potential solution for current body-in-white challenges.

- There is limited existing literature on Mega-Casting.

- The industry's perception and engagement with Mega-Casting are increasing.

Academic Significance of the Study:

This study provides one of the first comprehensive analyses of Mega-Casting in the automotive context, filling a gap in the existing literature.

Practical Implications:

The findings highlight the potential for Mega-Casting to revolutionize automotive body production, leading to reduced complexity, increased efficiency, and new lightweighting opportunities. It may, however, also disrupt existing supplier relationships and require significant process adaptations.

Limitations of the Study and Areas for Future Research:

- The study is limited by the lack of publicly available data on Mega-Casting.

- Future research should include a quantitative online survey, a potential analysis using FESG-factors, and an industry consortia study with a representative benchmark car body.

8. References:

- [01] Bolduc, Douglas A.. 2022. “Volvo Plans Switch to Tesla Technique to Improve Next-Generation EVs.” URL: https://www.autonews.com/manufacturing/volvo-plans-switch-tesla-technique-improve-next-generation-evs. Accessed September 28, 2022.

- [02] Idra Group. 2022. URL: https://www.linkedin.com/posts/idragroup_munrolive-gigapress-engineering-activity-6947849688138055680-_si5/. Accessed September 28, 2022.

- [03] Strama-MPS Maschinenbau. 2022. URL: https://www.strama-mps.de/loesungen/karosserierohbauanlagen/schluesselfertige-anlagen. Accessed September 28, 2022.

- [04] Hora, Nataliya. 2022. URL: https://stock.adobe.com/de/contributor/200376593/nataliya-hora?asset id=398683236. Accessed September 28, 2022.

- [05] Focus. 2022. "Ich will auf dem Mars sterben - aber nicht bei der Landung': Die besten Zitate von Elon Musk" URL: https://www.focus.de/auto/elektroauto/tesla-wird-15-ich-will-auf-dem-mars-sterben-aber-nicht-bei-der-landung-die-besten-zitate-von-elon-musk id 9206821.html. Accessed September 28, 2022.

- [06] Weinberger, Andrea. 2021. “Warum Wir Alle Umdenken Müssen, Um Mobilität Neu Zu Erfinden.” URL: https://www.ey.com/de_de/decarbonization/warum-wir-alle-umdenken-mussen-um-mobilitat-neu-zu-denken. Accessed September 28, 2022.

- [07] Gall, Constantin. 2021. “Wie Unternehmen Sich Auf Die Mobilität Der Zukunft Vorbereiten Können." URL: https://www.ey.com/de_de/automotive-transportation/zukunftstrends-der-automobilindustrie-im-ueberblick. Accessed September 28, 2022.

- [08] Bork, Henrik. 2021. “Teslas Konstruktionsmethode Verbreitet Sich in China.” URL: https://www.konstruktionspraxis.vogel.de/teslas-konstruktionsmethode-verbreitet-sich-in-china-a-1081294/?cflt=rel. Accessed September 28, 2022.

- [09] Birket Arndt, Stefan Haage and Markus Straub. 2013. “Umformtechnische Herstellung Komplexer Karosserieteile“. Heidelberg: Springer Vieweg Berlin: p. 43.

- [10] Kropik, Markus. 2021. “Produktionsleitsysteme für die Automobilindustrie“. Heidelberg: Springer Vieweg Berlin: p. 17-20.

- [11] Schuler Group. 2022. URL: https://www.schulergroup.com/technologien/produkte/highlight zulieferpresswerk tower automotive/hydraulische_pressenlinie/index.html. Accessed September 28, 2022.

- [12] Friedrich, Horst E.. 2017. “Leichtbau in Der Fahrzeugtechnik“: Heidelberg: Springer Vieweg Berlin: p. 504.

- [13] Bühler. 2019. “Die Zukunft von Strukturbauteilen für Druckgusslösungen“: p. 1.

- [14] VDI. 2020. "Gießen Von Fahrwerks- Und Karosseriekomponenten". VDI-Berichte 2367: p. 103.

- [15] Karberg & Hennemann. 2022. URL: https://www.cjc.de/fluid-pflege-praxis/hfc-fluid-pflegen-druckgiessmaschinen/. Accessed September 28, 2022.

- [16] Musk, Elon. 2020. URL: https://twitter.com/elonmusk/status/1293923058109960192?s=20&t=UgjB95xj5y7zpkpH50EEBw. Accessed September 28, 2022.

- [17] Kallas, Matthew Kenneth. 2018. „Multi-Directional Unibody Casting Machine for a Vehicle Frame and Associa- Ted Methods“. US2019/0217380A1, filed January 18, 2018, and issued July 18, 2019.

- [18] Fuchslocher, Götz. 2022. "Gigacasting Ist Geeignet, Den Karosseriebau Neu Zu Denken.” URL: https://www.automobil-produktion.de/produktion/gigacasting-ist-geeignet-den-karosseriebau-neu-zu-denken-501.html. Accessed September 28, 2022.

- [19] Tech Space. 2021. Video: “GAME over! Tesla's SECRET WEAPON the Gigapress.". URL: https://www.youtube.com/watch?v=rsBbt3TxKGg. Accessed September 28, 2022.

- [20] Loveday, Steven. 2022. “VW's Project Trinity to Use Giga-Casting & Automation to Compete with Tesla: Both VW and Ford Have Said Publicly They're Learning from Tesla and Musk, and VW's Future Plans Substantiate Those Claims.” URL: https://insideevs.com/news/577128/volkwagen-compete-tesla-gigapress-robots/. Accessed September 28, 2022.

- [21] Stegmaier, Gerd. 2022. “Alu-Guss Statt Nur Schwedenstahl." URL: https://www.auto-motor-und-sport.de/tech-zukunft/volvo-mega-casting-alu-elektroauto-produktion-nachhaltigkeit-neue-e-auto-plattformen/. Accessed September 28, 2022.

- [22] Guba, Beate. 2008. "Systematische Literatursuche”. Wiener medizinische Wochenschrift, Nr. 1-2, 158., S. 62-69.

- [23] Booth, Andrew. 2006. “Brimful of STARLITE: Toward standards for reporting literature searches". Journal of the Medical Library Association JMLA, Nr. 4, 94., 421-9, e205.

- [24] Moher, David, Alessandro Liberati, Jennifer Tetzlaff and Douglas G. Altman. 2009. “Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement“. Journal of clinical epidemiology, Nr. 10, 62., S. 1006-1012.

- [25] Lamnek, Siegfried and Claudia Krell. 2016. “Qualitative Sozialforschung“. 6. completely revised edition. Weinheim: Beltz.

- [26] Bogner, Alexander, Beate Littig and Wolfgang Menz. 2005. "Das Experteninterview - Theorie, Methode, Anwendung". 2. completely revised edition. Wiesbaden: VS Verlag für Sozialwissenschaften.

- [27] Rai, Adip, Sachin S. Sawant, Petter Winberg, Malcolm Burgess, Tom Spencer, Pall Kornmayer, Grant Pattinson, Paul Edwards, Carlo D.Rinaldi, Alexandre Reikher, Charlie Kuehmann and Daniel Moll. 2020. "Integrated Energy Absorbing Castings", filed January 07 August, 2020, and issued February 10, 2021.

- [28] Boos, Wolfgang. 2021. "Die Produktionswende - Turning Data into Sustainability". Werkzeugmaschinenlabor WZL der RWTH Aachen University. 05/2021.

- [29] Stucki, Jason, Grant Pattinson, Quinlin Hamill, Avinash Prabhu, Sivanesh Palanivel and Omar Lopez-Garrity. 2020. "Die Cast Aluminum Alloys for Structural Components", filed January 22, 2020, and issued July 29, 2021.

- [30] Expert interviews of WZL RWTH Aachen University, utilization of anonymized content of 33 mainly industry expert interviews, 2021/22.

- [31] Pool/Getty Images Europe. 2022. URL: https://www.bloomberg.com/news/articles/2022-09-22/elon-musk-may-regret-putting-tesla-s-first-european-plant-in-Germany. Accessed September 28, 2022.

- [32] Pfeiffer Juliane. 2022. URL: https://www.konstruktionspraxis.vogel.de/mega-casting-eine-gigantische-konstruktive-herausforderung-a-1115965/. Accessed September 28, 2022.

- [33] Schuh, Günther, Georg Bergweiler, Leonhard Dworog and Falko Fiedler. 2022. "Chancen und Risiken von Mega-Casting in der Fahrzeugproduktion - Die Karosserie aus dem Aluminium-Druckguss / Opportunities and Risks of Mega-Casting in Automotive Production – The Aluminum Die-Casted Body in White”. DOI 10.37544/1436–4980–2022–09–52. 9. Wt Werkstattstechnik Online, 112, 580-585.

- [34] Burggräf, Peter, Georg Bergweiler and Falko Fiedler. 2022. "Einfluss von Mega-Casting auf die Automobilzulieferer”. Maschinenbau 5. Springer Professional. 26-29.

9. Copyright:

- This material is "Falko Fiedler"'s paper: Based on "Fields of Action in Mega-Casting for the Industrialization of Automotive Car Bodies".

- Paper Source: DOI: 10.13140/RG.2.2.13349.17125

This material was created to introduce the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.