Unlocking Peak Performance: How Casting Method Dictates Al-Si-Mg-Fe Alloy Wear Resistance

This technical summary is based on the academic paper "EVALUATION OF DRY SLIDING WEAR CHARACTERISTICS AND CONSEQUENCES OF CAST Al-Si-Mg-Fe ALLOYS" by A.Chennakesava Reddy and S. Madhava Reddy, published in The Icfai University Journal of Mechanical Engineering (2010).

Keywords

- Primary Keyword: Al-Si-Mg-Fe Alloy Wear

- Secondary Keywords: dry sliding wear, casting methods, HPDC performance, tribological properties, wear resistance, aluminum alloy durability

Executive Summary

- The Challenge: Aluminum alloys are increasingly used in high-friction applications like engine blocks and brake rotors, but their wear characteristics under different manufacturing conditions are not fully optimized.

- The Method: The study systematically investigated the dry sliding wear behavior of an Al-Si-Mg-Fe alloy produced by three different casting methods: sand casting, investment casting, and die casting.

- The Key Breakthrough: Die-cast specimens demonstrated significantly superior mechanical properties and wear resistance compared to sand and investment cast specimens due to a finer, more uniform microstructure.

- The Bottom Line: The choice of casting process, specifically the solidification rate, is a critical factor that directly controls the durability and service life of Al-Si-Mg-Fe alloy components in tribological applications.

The Challenge: Why This Research Matters for HPDC Professionals

As industries from aerospace to automotive push for lighter, more efficient components, the use of cast aluminum alloys has surged. Parts like engine blocks, cylinder liners, pistons, and brake rotors demand exceptional friction and wear performance. However, the tribological behavior of these alloys is not inherent; it is heavily dependent on the material's final morphology—the composition, size, shape, and distribution of its micro-constituents. This research was driven by the need to understand precisely how different casting processes (sand, investment, and die casting) influence these microstructures and, consequently, the alloy's ability to withstand dry sliding wear, a common failure mode in many industrial applications.

The Approach: Unpacking the Methodology

The researchers conducted a controlled study to isolate the effects of the casting process on the wear characteristics of a specific Al-Si-Mg-Fe alloy.

Method 1: Material Preparation and Casting

An Al-Si-Mg-Fe alloy (7.83%Si-0.7%Mg-0.3%Fe) was melted in an oil-fired furnace. The melt was treated with a flux (coveral-11) to prevent drossing, degasified, modified with strontium (to refine silicon particles), and grain-refined with an Al-Ti master alloy. This prepared melt was then gravity poured into three different preheated molds: a sand mold, an investment shell, and a metal die, representing the three distinct casting methods being evaluated.

Method 2: Tribological Testing

Wear behavior was evaluated using a pin-on-disc friction and wear monitor, adhering to the ASTM G99 standard. Test pins (6mm diameter, 20mm length) were prepared from the alloys cast by each method. These pins were run against a hardened ground steel (En32) disc. The key variables studied were:

- Contact Time: The duration of the wear test.

- Sliding Speed: The relative velocity between the pin and the disc.

- Normal Pressure: The load applied to the pin.

During the tests, weight loss, pin temperature, and friction force were meticulously measured.

The Breakthrough: Key Findings & Data

The study revealed a clear hierarchy in performance, with the die-casting method producing a demonstrably superior alloy.

Finding 1: Die Casting Delivers Superior Mechanical Properties and Microstructure

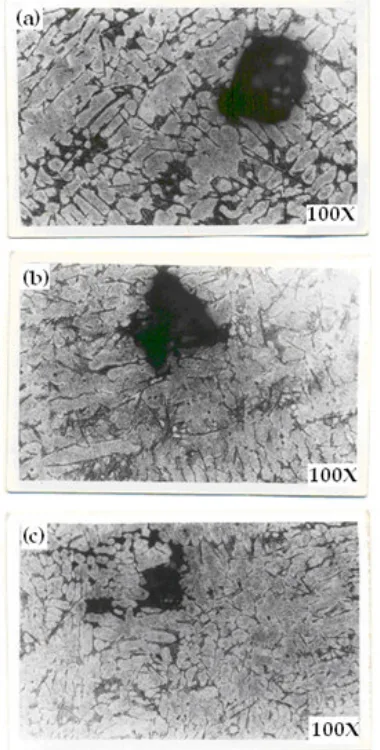

The choice of casting method had a profound impact on the alloy's fundamental properties. The die-cast alloy exhibited the highest tensile strength (234.11 N/mm²) and hardness (87 BHN), outperforming both investment cast (213.64 N/mm², 75 BHN) and sand cast (199.52 N/mm², 71 BHN) samples. As shown in Table 1, this represents a 17% increase in strength and a 22% increase in hardness over the sand-cast alloy. This improvement is directly attributed to the microstructure. Figure 1 shows that the rapid solidification in die casting produced fine, equiaxed α-Al dendrites, while the slower cooling in sand casting resulted in large, elongated dendrites and coarse intermetallic compounds, which are detrimental to mechanical performance.

Finding 2: Wear Resistance is Directly Linked to Casting Method

The mechanical superiority of the die-cast alloy translated directly into better wear resistance. Under identical test conditions (0.75 MPa pressure, 2 m/sec speed), the die-cast specimens consistently showed the lowest wear loss. As illustrated in Figure 4, after 30 minutes of testing, the wear loss for the die-cast sample was approximately 45 mg, whereas the sand-cast sample lost over 52 mg. The study concludes that wear loss increases with higher normal pressure and longer contact time but decreases at higher sliding speeds. Across all conditions, the die-cast alloy maintained its performance advantage, confirming that its fine-grain structure is more resilient to abrasive and adhesive wear mechanisms.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that maximizing the solidification rate is key to enhancing the wear properties of Al-Si-Mg-Fe alloys. Adjusting mold temperature, cooling channel design, and cycle times in die casting may contribute to further refining the grain structure and improving component durability.

- For Quality Control Teams: The data in Table 1 and Figure 1 of the paper illustrates the direct link between microstructure, hardness, and wear performance. This could inform new quality inspection criteria where microstructural analysis and hardness testing are used as predictive indicators of a component's service life in high-wear applications.

- For Design Engineers: The findings indicate that the manufacturing process is not just a fabrication step but a critical design parameter. When designing components for tribological applications, specifying a rapid-solidification casting process like HPDC is a valuable consideration in the early design phase to ensure the final part meets durability requirements.

Paper Details

EVALUATION OF DRY SLIDING WEAR CHARACTERISTICS AND CONSEQUENCES OF CAST Al-Si-Mg-Fe ALLOYS

1. Overview:

- Title: EVALUATION OF DRY SLIDING WEAR CHARACTERISTICS AND CONSEQUENCES OF CAST Al-Si-Mg-Fe ALLOYS

- Author: A.Chennakesava Reddy and S. Madhava Reddy

- Year of publication: 2010

- Journal/academic society of publication: The Icfai University Journal of Mechanical Engineering, Vol. III, No. 1

- Keywords: dry sliding wear, contact time, sliding speed, normal pressure

2. Abstract:

In the present study, dry sliding wear characteristics of Al-Si-Mg-Fe alloy have been investigated. The influence of variables viz: contact time, sliding speed, and normal pressure on wear behaviour were studied. The results conclude that the wear loss increases with increase in contact time and normal pressure and decreases with sliding speed. The wear mechanisms include abrasive, adhesive, slip, melt-wear and oxidative phenomena. The consequences of wear were work hardening, and diffusion of microstrucutral constituents.

3. Introduction:

The use of cast Al-alloys as tribological components has been expanding in aeronautical, automobile, and general industries. Applications requiring enhanced friction and wear performance include brake rotors, engine blocks, cylinder liners, connecting rods, and pistons. The tribological behavior of these alloys depends on material morphology (composition, microstructure) and service conditions (load, contact time, sliding speed). Modifiers such as strontium are used to refine the eutectic Si structure in Al-Si alloys. This present work focuses on the evaluation of wear characteristics and consequences of cast Al-Si-Mg-Fe alloys.

4. Summary of the study:

Background of the research topic:

Cast aluminum alloys are increasingly utilized for tribological components in various industries due to their favorable properties. However, their wear characteristics are highly dependent on both material morphology and service conditions.

Status of previous research:

Numerous studies have been reported on the wear behavior of Al-Si alloys. It is known that modifiers like strontium or sodium can be used to refine the eutectic silicon structure from angular platelets to fine fibers, thereby improving mechanical properties.

Purpose of the study:

The purpose of the present work is to evaluate the dry sliding wear characteristics and consequences of cast Al-Si-Mg-Fe alloys, specifically investigating the influence of contact time, sliding speed, and normal pressure.

Core study:

The study investigated an Al-Si-Mg-Fe alloy prepared by three different casting methods: sand casting, investment casting, and die casting. A pin-on-disc wear monitor was used to evaluate the wear behavior under varying conditions of contact time, sliding speed, and normal pressure. The mechanical properties, metallurgical morphology, and post-wear characteristics (hardness, microstructure, surface elements) of the specimens were analyzed to understand the relationship between the casting process, microstructure, and wear performance.

5. Research Methodology

Research Design:

The research employed a comparative experimental design. An Al-Si-Mg-Fe alloy was prepared and cast using three distinct methods (sand, investment, die) to produce test specimens with different microstructures. The wear characteristics of these specimens were then evaluated under systematically varied tribological conditions.

Data Collection and Analysis Methods:

Data was collected using a pin-on-disc friction and wear monitor (ASTM G99). Measurements included:

1. Weight loss, using an electronic balance with 0.1 mg accuracy.

2. Pin temperature, using a thermocouple.

3. Friction force, using a data acquisition system.

Post-test analysis included evaluation of mechanical properties (tensile strength, elongation, hardness), microstructural analysis using optical microscopy, and elemental analysis of worn surfaces using EDX. Each experiment was repeated twice, and average values were used for analysis.

Research Topics and Scope:

The scope of the research was to study the effects of casting procedure, contact time, sliding speed, and normal pressure on the dry sliding wear characteristics of an Al-Si-Mg-Fe alloy. The study also examined the consequences of wear, such as work hardening and changes in microstructure. The alloy composition was fixed at 7.83%Si-0.7%Mg-0.3%Fe-0.03%Cu-0.015%Mn-0.083%Zn-0.006%Pb-0.01%Sr-0.004Ti-0.0005%Ni-remainderAl.

6. Key Results:

Key Results:

- Mechanical Properties: Die-cast alloys exhibited superior mechanical properties (Tensile strength: 234.11 N/mm², Hardness: 87 BHN) compared to investment cast (213.64 N/mm², 75 BHN) and sand cast (199.52 N/mm², 71 BHN) alloys. This is attributed to the fine-grain structure resulting from rapid solidification.

- Effect of Contact Time and Normal Pressure on Wear: Wear loss increased with an increase in both contact time and normal pressure for all specimens. Die-cast specimens consistently showed the lowest wear loss under all conditions.

- Effect of Sliding Speed on Wear: Wear loss decreased with an increase in sliding speed for all specimens. At slow speeds, the wear mechanism is primarily abrasive, while at higher speeds, slip phenomena dominate, leading to lower wear.

- Frictional Force: Frictional force initially increased with contact time (up to 30 min) and then decreased. It decreased with increasing sliding speed and increased exponentially with increasing normal pressure. Die-cast specimens exhibited higher frictional forces.

- Temperature Rise: Temperature increased with contact time and normal pressure but was negligibly affected by sliding speed.

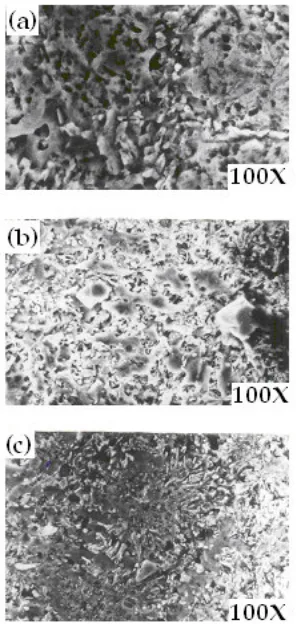

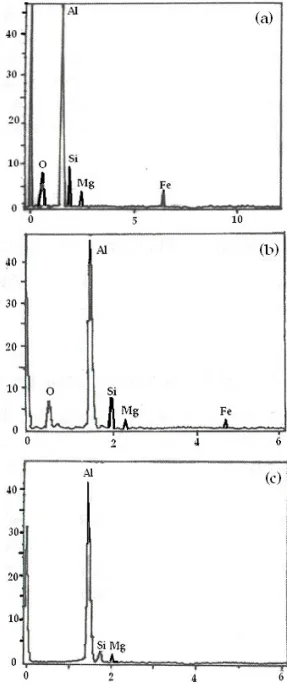

- Consequences of Wear: After the wear test, all specimens showed an increase in hardness, indicating work hardening. The microstructures of worn specimens became finer, and EDX analysis confirmed the presence of oxides (Fe₂O₃, Al₂O₃, MgO), indicating an oxidative wear mechanism.

Figure Name List:

- Figure 1: Microstructures of Al-Si-Mg-Fe alloys produced by (a) sand cast (b) investment cast, and (c) die cast processes

- Figure 2: Influence of contact time on wear.

- Figure 3: Influence of sliding speed on wear.

- Figure 4: Influence of normal pressure on wear.

- Figure 5: Influence of contact time on frictional force.

- Figure 6: Influence of sliding speed on frictional force.

- Figure 7: Influence of normal pressure on frictional force.

- Figure 8: Influence of contact time on temperature rise.

- Figure 9: Influence of sliding speed on frictional force.

- Figure 10: Influence of normal pressure on temperature rise.

- Figure 11: Hardness values of worn specimens

- Figure 12: Microstructures of Al-Si-Mg-Fe alloy worn specimens (a) sand cast, (b) investment cast, and (c) die cast.

- Figure 13: EDX analysis of Al-Si-Mg-Fe alloy worn surfaces (a) sand cast, (b) investment cast, and (c) die cast.

7. Conclusion:

- The wear resistance increases with the addition of grain refiner (Al-Ti master alloy) and the modification by strontium.

- The wear loss increases with increase in normal pressure at constant contact time and at constant sliding speed.

- The wear loss increases with increasing contact time at constant normal pressure and at constant sliding speed.

- The wear loss decreases with increasing sliding speed at constant normal pressure and at constant contact time.

- Al-Si-Mg-Fe alloy exhibits abrasive, adhesive, slip, melt-wear and oxidative mechanisms.

- The consequences of wear work hardening and diffusion microstrucutral constituents of Al-Si-Mg-Fe alloy.

8. References:

- Odani, Y. (1994), “Aluminium Alloys", Metal Powder Report, 49, 36-40.

- Noguchi, M. & Fukizawa, K. (1993), “Aluminium composite cylinder liners", Advances in Materials and Processes, 143(6), 19-21.

- Sarkar, A D. (1976), “Wear of metals", Pregaman Press, England, 1976.

- Kori. S A, Murty. B S, and Chakraborty. M. (2000), “Development of an efficient grain refiner for Al-7Si alloy and its modification with strontium", Materials science and engineering, 25, 94-104.

Expert Q&A: Your Top Questions Answered

Q1: Why was this specific Al-Si-Mg-Fe alloy composition chosen for the study?

A1: The paper focuses on a common type of cast aluminum alloy used in automotive and industrial applications where wear resistance is important. The composition (7.83%Si-0.7%Mg-0.3%Fe) is representative of alloys used for components like engine blocks and pistons. The inclusion of Si provides castability and wear resistance, Mg allows for strengthening through heat treatment, and Fe is a common impurity that forms intermetallic compounds affecting properties.

Q2: The paper states that die-cast specimens have a finer grain structure. What is the specific mechanism behind this?

A2: The paper attributes the fine grain structure in die-cast alloys to the fast solidification process. The metal die has a much higher thermal conductivity than a sand mold or an investment shell, leading to rapid heat removal from the molten alloy. This high cooling rate promotes a high nucleation rate of crystals and restricts their growth time, resulting in a large number of small, fine grains rather than a few large, coarse grains.

Q3: Why does wear loss decrease as sliding speed increases? This seems counterintuitive.

A3: According to the paper, the wear mechanism changes with speed. At slow speeds, abrasive wear is dominant, where hard particles plow through the surface, causing significant material removal. As the sliding speed increases, a "slip phenomena" begins to dominate. This can involve the formation of a mechanically mixed layer or a thin, partially molten layer at the interface, which can act as a lubricant, reducing direct metal-to-metal contact and lowering the overall wear rate.

Q4: The study mentions work hardening as a consequence of wear. How significant was this effect?

A4: The effect was quite significant. As shown in Figure 11, the hardness of the specimens increased substantially after the wear test. For example, the die-cast specimen's hardness increased from 87 BHN to approximately 98 BHN, a jump of over 12%. This increase is attributed to the plastic deformation of the surface layers during sliding, which introduces dislocations and strains the crystal lattice, making the material harder and more resistant to further deformation.

Q5: What are the primary wear mechanisms identified for this alloy under the tested conditions?

A5: The paper identifies a combination of wear mechanisms. The results suggest the presence of abrasive and adhesive wear, which are common in dry sliding. Additionally, the paper mentions slip, melt-wear (especially at higher pressures and temperatures on localized surfaces), and oxidative phenomena. The EDX analysis in Figure 13 confirmed the presence of oxygen on the worn surfaces, indicating that oxides of aluminum, iron, and magnesium formed during the process, which is characteristic of oxidative wear.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides clear, data-driven evidence that the manufacturing process is a decisive factor in determining the service life of high-performance aluminum components. The study confirms that for Al-Si-Mg-Fe alloy wear resistance, rapid solidification casting methods like die casting are vastly superior to slower methods like sand casting. By producing a fine-grained, homogenous microstructure, die casting yields components with inherently higher strength, hardness, and durability.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "EVALUATION OF DRY SLIDING WEAR CHARACTERISTICS AND CONSEQUENCES OF CAST Al-Si-Mg-Fe ALLOYS" by "A.Chennakesava Reddy and S. Madhava Reddy".

Source: The Icfai University Journal of Mechanical Engineering, Vol. III, No. 1, 2010.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.