Beyond Brittle Bonds: How a PVD Al-Si Coating Revolutionizes Steel-Aluminum Hybrid Casting

This technical summary is based on the academic paper "Evaluation of Coating Systems for Steel Aluminum Hybrid Casting" by Xiangfan Fang, published in Journal of Materials Science and Engineering A (2017). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Steel-Aluminum Hybrid Casting

- Secondary Keywords: High Pressure Die Casting, PVD Coating, Intermetallic Compounds, Ductile Joints, Aluminum-Steel Joining, Automotive Body Structure

Executive Summary

- The Challenge: Creating strong, ductile joints between steel and aluminum in hybrid casting is notoriously difficult due to the formation of brittle Al-Fe intermetallic compounds (IMPs).

- The Method: Researchers developed a new PVD Al-Si coating for steel inserts and evaluated its performance in a high pressure die casting process against conventional electro-galvanized (EG) Zn and industrial hot-dipped Al-Si coatings.

- The Key Breakthrough: The new PVD Al-Si coating, when combined with specific process parameters, created a stable material-based joint that exhibited a ductile fracture behavior, a first for this type of application.

- The Bottom Line: This research proves that a carefully designed PVD Al-Si coating system can overcome the challenge of brittle IMPs, enabling the production of reliable, ductile steel-aluminum components for dynamically loaded applications.

The Challenge: Why This Research Matters for HPDC Professionals

In the quest for lightweighting, particularly in the automotive industry, joining steel and aluminum is a critical goal. Hybrid casting, where molten aluminum is cast around steel inserts, is a promising technology. However, a major roadblock has always been the material connection. During the process, very brittle Al-Fe intermetallic compounds (IMPs) inevitably form at the interface.

Traditional joining methods in hybrid casting rely on form locking and force locking, which are often insufficient for the high static and dynamic loads experienced by vehicle components. This has prevented the widespread adoption of material-based connections in real-world production. The core challenge, therefore, is to develop a method that can control the formation of IMPs to create a joint that is not only strong but also ductile, preventing catastrophic, brittle failure. This research directly tackles that challenge by engineering a new surface coating for the steel insert.

The Approach: Unpacking the Methodology

The study evaluated three different coating systems on steel substrates to be joined with an AlSi9MgMn aluminum alloy via high pressure die casting.

- Materials:

- Steels: A low carbon deep drawing steel (DC04) for the new coating, a complex phase steel (CPW 800) with an EG Zn coating, and a boron steel (MBW 1500) with an industrial hot-dipped Al-Si coating.

- Aluminum Alloy: An AlSi9MgMn alloy containing 9.5-11.5 wt.% Si, suitable for pressure die casting.

- Coatings Investigated:

- Industrial EG Zn Coating: A 7 µm thick electro-galvanized zinc layer.

- Industrial Hot-Dipped Al-Si Coating: A ~30 µm thick layer with 6-8 wt.% Si.

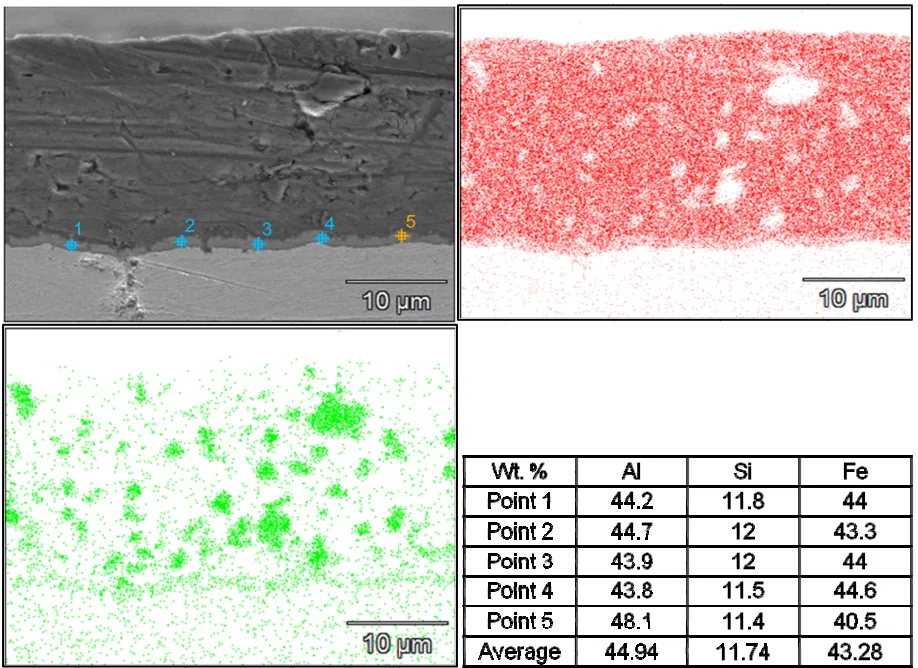

- New PVD Al-Si Coating: A novel ~20 µm thick coating applied via Physical Vapor Deposition (PVD) onto the DC04 steel. It was designed with two sub-layers: a thin (1-3 µm) steel-contacting layer and a thicker (15-17 µm) outer layer.

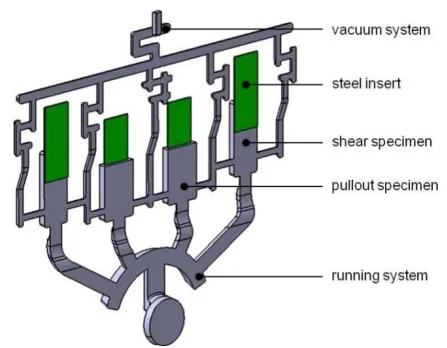

- Process: Shear tensile samples were produced using a high pressure die casting machine. Key process variables included the Al-melt temperature (685°C and 750°C), steel insert pre-heating temperature (Room Temperature to 300°C), and injection volume flow rate (3,000 to >7,000 mm³/s).

- Analysis: The resulting joints were evaluated using quasi-static shear tensile tests to measure strength and behavior. Fracture surfaces and cross-sections were analyzed using Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDX).

The Breakthrough: Key Findings & Data

The study yielded critical insights into how different coatings perform under hybrid casting conditions, with the new PVD coating demonstrating a significant advantage in joint behavior.

Finding 1: PVD Al-Si Coating Enables a Stable, Ductile Joint

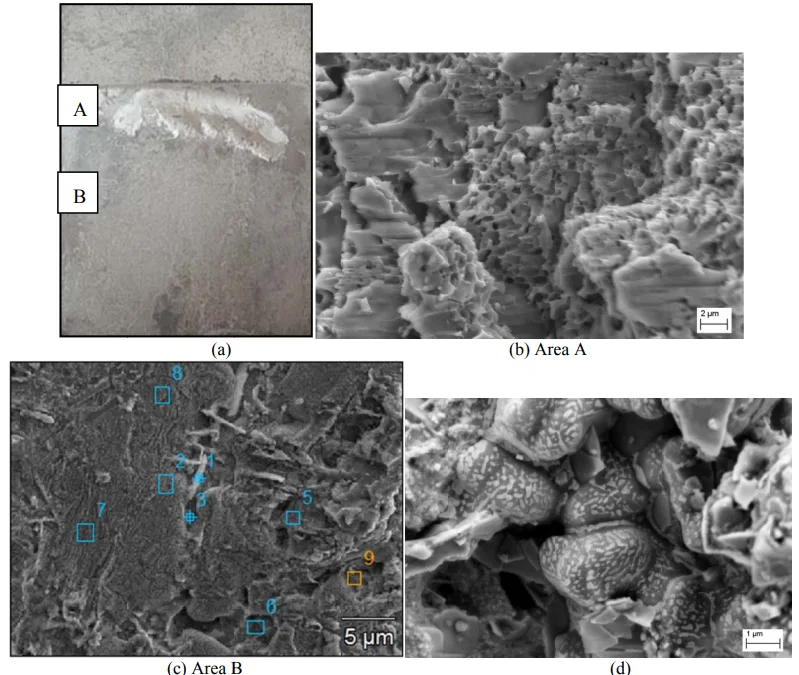

The most significant breakthrough was the performance of the new PVD Al-Si coating. While it produced a lower peak shear strength than the EG Zn coating, its failure mode was completely different. As shown in Figure 6b, the force-displacement curves for the PVD coating show a continuous deformation at a nearly constant force level after reaching the peak. This indicates a stable, ductile crack growth rather than a sudden, brittle failure. A very stable joint with a mean shear strength of 11.3 MPa was achieved with an Al-melt temperature of 685°C and a steel pre-heating temperature of 300°C (Table 3). The fracture surface was consistently ductile, exhibiting honeycomb-like structures across the entire area (Figure 10).

Finding 2: EG Zn Coating Provides High Strength but Brittle Failure

The EG Zn coated steel achieved the highest mean shear strength, reaching 18.32 MPa when the steel was pre-heated to 200°C and cast with 750°C Al-melt (Table 3). However, the force-displacement curves in Figure 6a show that after reaching the maximum force, the load drops immediately to zero. This signifies a brittle rupture. Fracture analysis revealed that the joint was a mix of a small ductile area (Area A in Figure 7a) where the fracture occurred in the Al-cast alloy, and a large brittle area (Area B) where failure occurred at the interface. The joining mechanism was found to be a combination of a material-based connection (an Al-Fe-Zn-Si mixture) and microscopic form locking.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for achieving a ductile joint with a PVD Al-Si coating, restricting the diffusion process is key. This can be achieved by using a lower Al-melt temperature (around 685°C) and a high injection volume flow rate (>7,000 mm³/s). Pre-heating the steel insert to 220-300°C is also critical for joint formation.

- For Quality Control Teams: The data in Figure 6 of the paper illustrates the stark difference between a brittle (Fig. 6a) and ductile (Fig. 6b) failure mode. The shape of the force-displacement curve, not just the peak strength, could become a critical quality inspection criterion for dynamically loaded hybrid components.

- For Design Engineers: The findings indicate that a material-based joining approach using an engineered PVD Al-Si coating is viable. This opens up the possibility of designing hybrid components that rely on a ductile material bond, potentially reducing weight and complexity compared to designs that depend solely on mechanical form/force locking.

Paper Details

Evaluation of Coating Systems for Steel Aluminum Hybrid Casting

1. Overview:

- Title: Evaluation of Coating Systems for Steel Aluminum Hybrid Casting

- Author: Xiangfan Fang

- Year of publication: 2017

- Journal/academic society of publication: Journal of Materials Science and Engineering A

- Keywords: Hybrid casting, Fe-Al-intermetallic phase, interfacial diffusion reaction, coating systems, die casting process, material based joining, ductile fracture

2. Abstract:

Hybrid casting is a well known technology to join steel inserts and Aluminum. State of the art is to produce force and form locked connections, since the material based connection is very brittle. In the current work, a new metal coating concept has been developed based on the recent development of intermetallic alloys and surface coatings for Fe-Al-X-system. The new PVD coating consists of two sub-layers. The first layer is less than 3 µm in thickness and consists of Fe, Si as well as lower Al-content. A second layer consists of only Al and Si. For developed process parameters of die casting and Al-alloy, a reproducible material based connection with more than 10 MPa shear tensile stress and ductile behavior could be produced. Based on SEM (Scanning electron microscopy)study on coating layer morphology and composition as well as fracture surface, the mechanisms for the new material joining have been investigated. The specific chemical composition, the thickness of the new coating layer in combination with the casting conditions are found to be responsible for the ductile behavior of the joining between steel and Aluminum. For the first time, there is a chance to apply steel Aluminum hybrid hybrid casting technique on real products.

3. Introduction:

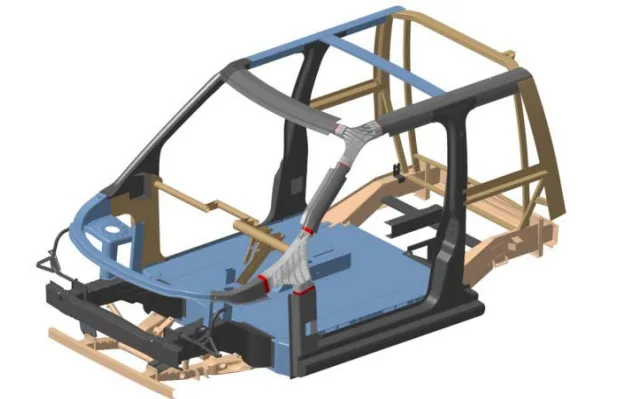

In the last few years, with the increasing requirement on light weight design and cost saving, considerable attention has been paid to multi-material design in automotive body and chassis structures. It means that the right material should be used for the right applications in order to achieve the best compromise between weight and cost in the final product. Beside of this, the modern vehicle BIW (body in white) is being built by using platform. In this case, several different types of BIWs must be built on the same assemble line. For example, all steel or steel intensive BIW are selected for the conventional vehicle because of the lower requirement on weight saving. On the other hand, due to the tremendous demands of weight reduction for the full electric vehicle, steel-Aluminum hybrid designs or Aluminum intensive designs can be selected to obtain more driving range and reduce the expanses of battery systems. In order to join the steel and the Aluminum parts, many different new joining technologies such as riveting and adhesive bonding have been developed, which requires expensive investments in assemble lines and thus hinders the use of multi-material systems. Therefore the author proposed a new method to be able to build both steel intensive design BIW and steel-aluminum mix-material design BIW with the same assemble line. For this kind of flexible BIW structure, a type of modular platform using hybrid casting gussets could be a good choice. In this hybrid casting method, the steel parts (red) are small inserts, as illustrated in Fig. 1, which are molded during the Al-casting (white) process. Here, the gussets for upper and lower A-pillar are designed in Aluminum-casting and the parts in between, i.e. A-pillar reinforcement can be made of both steel or Aluminum. It is easy to imagine that further gussets could be used in the other areas as well. For a steel intensive BIW, only the gussets are made of Aluminum and for the light weight full electric vehicles all the parts in between can be designed in Aluminum as well.

4. Summary of the study:

Background of the research topic:

The research addresses the need for effective methods to join steel and aluminum for lightweight multi-material designs in the automotive industry. Specifically, it focuses on hybrid casting, where steel inserts are joined with cast aluminum. The primary challenge is the formation of brittle intermetallic compounds (IMPs) at the steel-aluminum interface, which prevents the creation of strong, ductile, material-based joints.

Status of previous research:

Previous research on hybrid casting relied on form-locking or force-locking connections, which are not strong enough for high-load applications. Studies on welding and inter-diffusion showed that while elements like Si can reduce the thickness of the brittle η–Al5Fe2 layer, a truly ductile connection had not been realized. Existing investigations used uncoated steel or standard Zn-coated steel, but there was a lack of deep investigation into other coatings, like Al-Si, that could influence the phase-building kinematics of FeAl IMPs.

Purpose of the study:

The purpose was to develop and evaluate a new coating system for steel that would enable a ductile, material-based joint with aluminum during the hybrid casting process. The study aimed to investigate the formation of the joining layer, understand the joining mechanism, and identify the optimal process conditions to achieve a reproducible and reliable ductile connection.

Core study:

The core of the study involved comparing three coating systems: an industrial electro-galvanized (EG) Zn coating, an industrial hot-dipped Al-Si coating, and a newly developed PVD Al-Si coating. Steel samples with these coatings were placed in a die and an AlSi9MgMn alloy was cast around them using a high pressure die casting process. The mechanical behavior (shear strength, ductility) of the resulting joints was tested, and the fracture surfaces and interface microstructures were analyzed using SEM and EDX to understand the joining mechanisms.

5. Research Methodology

Research Design:

The research was designed as a comparative experimental study. Three different coating systems on steel were subjected to a high pressure die casting process with an aluminum alloy. The casting process parameters (Al-melt temperature, steel pre-heating temperature, volume flow rate) were varied to determine their influence on joint quality. The resulting samples were then mechanically tested and microstructurally analyzed to evaluate the performance of each coating system.

Data Collection and Analysis Methods:

Data was collected through shear tensile tests using a Zwick tensile test machine, which generated force-displacement curves. The mean shear strength was calculated from these tests. Fracture surfaces and cross-sections of the cast samples were analyzed using Scanning Electron Microscopy (SEM) for morphology and Energy-Dispersive X-ray Spectroscopy (EDX) for chemical composition analysis of the interface layers and fracture zones.

Research Topics and Scope:

The research scope included the development of a new PVD Al-Si coating, the characterization of this coating alongside two existing industrial coatings (EG Zn and hot-dipped Al-Si), and the investigation of their performance in a Steel-Aluminum Hybrid Casting process. The study focused on the mechanical properties (shear strength, failure mode) of the joints and the underlying microstructural and chemical mechanisms responsible for the joint formation and fracture behavior.

6. Key Results:

Key Results:

- The newly developed PVD Al-Si coating produced a stable joint with a ductile failure mode, achieving a mean shear strength of 11.3 MPa under optimized conditions (685°C Al-melt, 300°C pre-heat).

- The EG Zn coating achieved a higher mean shear strength (up to 18.32 MPa) but resulted in a brittle fracture.

- The industrial hot-dipped Al-Si coating failed to form any joint under the tested conditions.

- For the PVD Al-Si coating, lower Al-melt temperature (685°C vs 750°C) and pre-heating of the steel insert were critical for successful joint formation.

- The ductile joining mechanism for the PVD coating is attributed to the formation of a thin (1-3 µm) ductile Al57Fe27Si15 intermetallic layer at the steel interface, with the crack propagating through the weaker, Si-segregated second layer of the coating itself.

- The joining mechanism for the EG Zn coating is a combination of a material connection (Fe-Al-Zn-Si mixture) and microscopic form locking.

Figure Name List:

- Fig. 1 Hybrid gussets Al-Steel for a full electric urban utility vehicle (red parts: steel inserts, white parts: Al-casting nodes).

- Fig. 2 (a) Microstructure of an EG Zn coating; (b) An industrial hot dipped Al-Si coating.

- Fig. 3 Distribution of Al (red) and Si (green) in the coating layer PVD Al-Si on DC04 steel as well as the chemical composition of the first thin layer contacting steel substrate (on 5 points).

- Fig. 4 Sample shape for pure shear tension test.

- Fig. 5 Injection die for a high pressure die casting trial.

- Fig. 6 (a) Shear force and displacement curve of a Zn coated steel (with (red) and without pre heating (blue)) hybrid casted by a Al at 750 °C; (b) A PVD Al-Si coated steel with pre heating at 220 °C (blue) and 300 °C (red) when casted by a Al-melt at 685 °C.

- Fig. 7 (a) Shear tensile fracture surface of Zn coated steel sheet; (b) rough area A; (c) flat area B and EDX measuring area; (d) enlarged area in flat area B ("asian script" zone: light spots: high Zn content approximately 60-70 wt. %, Rest: Al; dark: lower content of Zn of approximately 50 wt. %, Rest Al.

- Fig. 8 (a) Cross section of Zn coated steel sheet after hybrid casting; (b) area with a kind of microscopic interlock of materials between Al and Steel surface (Steel: light, Al: dark)

- Fig. 9 (a) Cross section of Zn coated steel sheet after hybrid casting and the (b) chemical composition of the Al-Fe-Zn mixture in the first 3-4 µm from steel surface: Box 8 consisting of 47 wt.% Al, 6.6 wt.% Si, 22 wt.% Fe and 25 wt.% Zn.

- Fig. 10 (a) Schematic fracture surface of PVD AlSi coated steel sheet; (b) SEM area A; (c) SEM area B; (d) SEM area C.

- Fig. 11 (a) Surface of PVD Al-Si coated steel sheet after hybrid casting in Zone S of Fig. 10a. (b) Surface of PVD AlSi coated steel sheet after hybrid casting in Zone A of Fig. 10a. Box 1: Al: 99.1%, Si: 0.9%; Box2: Al: 99%, Si: 1%; Box 3: Al: 96.3%, Si: 3.7%.

- Fig.12 Cross section of a shear tensile sample hybrid casted using the PVD Al-Si coating.

- Fig. 13 Principle formation of a Al-Si coating and the crack forming mechanism.

7. Conclusion:

The study successfully developed a new PVD Al-Si coating that enables a ductile, material-based joint between steel and aluminum in a hybrid casting process. The key is a thin (1-3 µm) sub-layer that forms a ductile intermetallic phase (Al57Fe27Si15) with the steel. By restricting the diffusion process with a lower Al-melt temperature (<700°C) and a high volume flow rate (>7,000 mm³/s), this ductile layer is preserved. The resulting joint shows stable crack growth and a honeycomb-like ductile fracture surface, a significant improvement over the brittle failure of traditional Zn-coated steel joints. This breakthrough provides a viable path to applying Steel-Aluminum Hybrid Casting to highly dynamic loaded structures, such as automotive body components, for the first time. The mechanism for joining with Zn-coated steel was also clarified, involving both a material mixture and microscopic form locking.

8. References:

- [1] Lämmer, H. 1994. Verfahren zum Verbinden zweier Werkstücke aus Metall zu einem Verbundbauteil. German Patent, DE 44 14 095 A1.

- [2] Watkins, T., Erdman, D., Joshi, P., Ludtka, G., Murphy, B., Sabau, A., Yin, H., Zhang, W., Skszek, T., and Niu, Χ. 2013. "Residual Stress of Bimetallic Joints and Characterization." In Proceedings of the 2013 DOE Vehicle Technologies Annual Merit Review and Peer Evaluation Meeting.

- [3] Jochen, D., and Wibbeke, M. 2007. Method for manufacturing of a subframe. German Patent, DE 10 2008 020 467 A1.

- [4] Roeth, T., and Vomhof, R. 2006. Light-weight component. US Patent, US 7 152 896 B2.

- [5] Jacome, L., Weber, S., Leitner, E., Arenholz, E., Bruckner, J., Hackl, H., and Pyzalla, A. 2009. "Influence of Filler Composition on the Microstructure and Mechanical Properties of Steel-Aluminum Joints Produced by Metal Arc Joining." Advanced Engineering Materials 11 (5): 350-8.

- [6] Gatzen, M., Radel, T., Thomy, C., and Vollersten, F. 2014. "Wetting Behavior of Eutectic Al-Si Droplets on Zinc Coated Steel Substrates." Journal of Materials Processing Technology 214: 123-31.

- [7] Baker, I., and George, E. P. 1998. "The Mechanical Properties of FeAl." MRS Proceedings 552.

- [8] Alexander, D. J., Maziasz, P. J., and Wright, J. L. 1998. "Processing and Alloying Effects on Tensile and Impact Properties of FeAl Alloys." Material Science and Engineering A 258 (1-2): 276-84.

- [9] Salzar, M., Albiter, A., Rosas, G., and Perez, R. 2003. "Structural and Mechanical Properties of AlFe Intermetallic Alloy with Li, Ce and Ni Additions." Material Science and Engineering A 351: 154-9.

- [10] Springer, H., Kostka, A., Payton, E. J., Raabe, D., Kaysser-Pyzalla, A., and Eggeler, G. 2010. "On the Formation Growth of Intermetallic Phases during Interduffsion between Low-carbon Steel and Aluminium Alloys." Acta Materialia 59: 1586-660.

- [11] Oberschelp, C. 2012. "Hybride Leichtbaustruktur für den Karosseriebau." Ph.D. Thesis, RWTH Aachen.

- [12] Springer, H., Kostka, A., Santos, F. J., and Raabe, D. 2011. "Influence of Intermetallic Phases and Kirkendall-porosity on the Mechanical Properties of Joints between Steel and Aluminum Alloys." Materials Science and Engineering A 528: 4630-42.

- [13] Springer, H. 2013-2015. Personal Communications.

- [14] Shahverdi, H. R., Ghomashchi, M. R., Shabestari, S., and Hejazi, J. 2002. "Micostructural Analysis of Interfacial Reaction between Molten Aluminum and Solid Iron." Journal of Materials Processing Technology 124: 345-52.

- [15] Shih, T., and Tu, S. 2007. “Interaction of Steel with Pure Al, Al-7Si and A356 Alloys." Material Science and Engineering A 454-455: 349-56.

- [16] Hein, P., Kefferstein, R., and Dahan, Y. 2006. "New Development in Sheet Metal Forming Technology." In Proc. Int. Conf.

- [17] Suehiro, M., Kusumi, K., Miyakoshi, T., Maki, J., and Ohgami, M. 2003. "Nippon Steel Report No. 88."

- [18] Jenner, F., Walter, M. E., Lyenger, R., and Hughes, R. 2010. "Evolution of Phases, Microstructure, and Surface Roughness during Heat Treatment of Aluminized Low Carbon Steel." Metallurgical and Materials Transactions A 41A: 1554-63.

- [19] Richards, R. W., Jones, R. D., Clements, P. D., and Clarke, H. 1994. "Metallurgy of Continuous Hot Dip Aluminizing." International Materials Reviews 39 (5): 191-212.

- [20] Gundlach, J. 2015. Personal Communications.

Expert Q&A: Your Top Questions Answered

Q1: Why was a PVD method chosen to create the new Al-Si coating instead of a more common method like hot-dipping?

A1: The PVD (Physical Vapor Deposition) method was selected to create a coating structure that is different from the industrial hot-dipped Al-Si coating. The specific goal was to apply a ~20 µm Al-Si coating with a much thinner and more ductile first layer (1-3 µm) in direct contact with the steel. PVD allows for precise control over layer thickness and composition, enabling the creation of this novel two-layer structure designed to promote a ductile joint.

Q2: The EG Zn coating produced a higher peak shear strength. Why is the PVD Al-Si coating considered the superior result?

A2: While the EG Zn coating's peak strength was higher, its failure mode was brittle, as shown by the immediate drop to zero force in Figure 6a. For automotive components subjected to dynamic loads, a brittle failure is catastrophic and undesirable. The PVD Al-Si coating, despite a lower peak strength, exhibited a ductile failure, maintaining a nearly constant force during a continuous deformation (Figure 6b). This stable crack propagation is a far more reliable and safe behavior for structural parts.

Q3: What were the most critical process parameters for achieving a successful ductile joint with the PVD Al-Si coating?

A3: The study identified three critical parameters. First, the Al-melt temperature had to be relatively low, around 685°C; at 750°C, no joint could be formed. Second, pre-heating the steel sheet to 220-300°C was essential. Third, a high injection volume flow rate of more than 7,000 mm³/s was found to be highly important, as it reduces the reaction time between the steel and the molten aluminum, helping to preserve the thin ductile layer.

Q4: What is the proposed mechanism for the ductile joint formation with the PVD Al-Si coating?

A4: The mechanism, illustrated in Figure 13, is based on the coating's two-layer structure. During casting, the first thin layer (1-3 µm) interacts with the steel to form a ductile, Fe-rich intermetallic phase (identified as Al57Fe27Si15). This thin layer creates an effective material bond. The crack does not propagate at the steel interface but rather through the second, thicker layer of the Al-Si coating, which has locally lower strength due to Si segregation. This forces the failure to occur within the coating in a ductile manner.

Q5: Why did the industrial hot-dipped Al-Si coating fail to form a joint at all?

A5: The paper states that "for all casting conditions investigated in this work, no joint could be determined between Al and steel with an industrially hot dip coated Al-Si layer." While it doesn't provide a detailed explanation for this specific failure, it contrasts this result with the successful PVD coating. The difference likely lies in the initial state and structure of the coating layers and how they interact with the molten aluminum during the very short die filling time. The pre-existing thick and potentially brittle IMPs in the industrial coating may have prevented a proper bond from forming.

Conclusion: Paving the Way for Higher Quality and Productivity

The persistent challenge of joining steel and aluminum without creating a brittle, unreliable connection has long hindered progress in lightweighting. This research demonstrates a clear and viable solution. By engineering a novel PVD Al-Si coating and carefully controlling process parameters, it is now possible to achieve a reproducible, material-based joint that fails in a safe, ductile manner. This breakthrough in Steel-Aluminum Hybrid Casting opens the door for its use in highly loaded, safety-critical automotive structures.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Evaluation of Coating Systems for Steel Aluminum Hybrid Casting" by "Xiangfan Fang".

- Source: doi: 10.1016/j.msea.2017.03.001

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.