Xiaolong Gong, Wenming Jiang , Fuchu Liu, Zhiyuan Yang, Feng Guan, and Zitian Fan

State Key Laboratory of Materials Processing and Die and Mould Technology, Huazhong University of Science and

Technology, Wuhan 430074, China

Copyright 2020 American Foundry Society

https://doi.org/10.1007/s40962-020-00480-9

Abstract

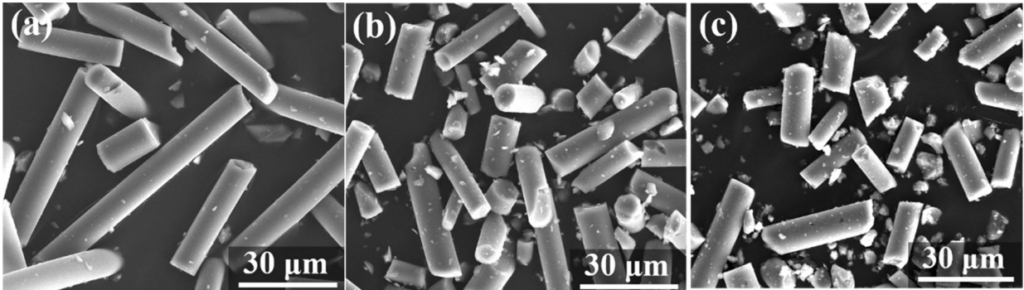

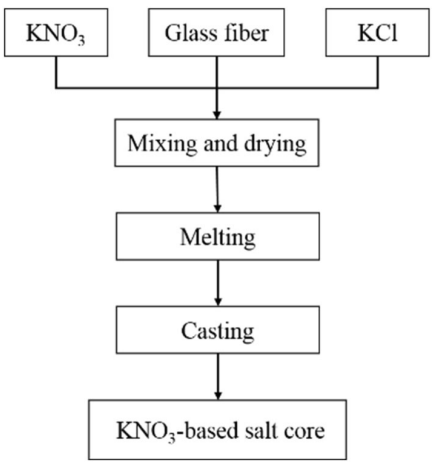

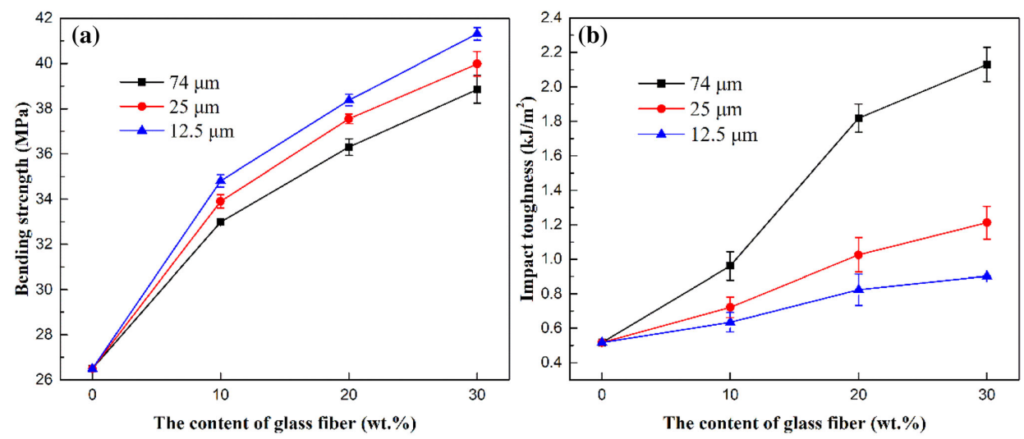

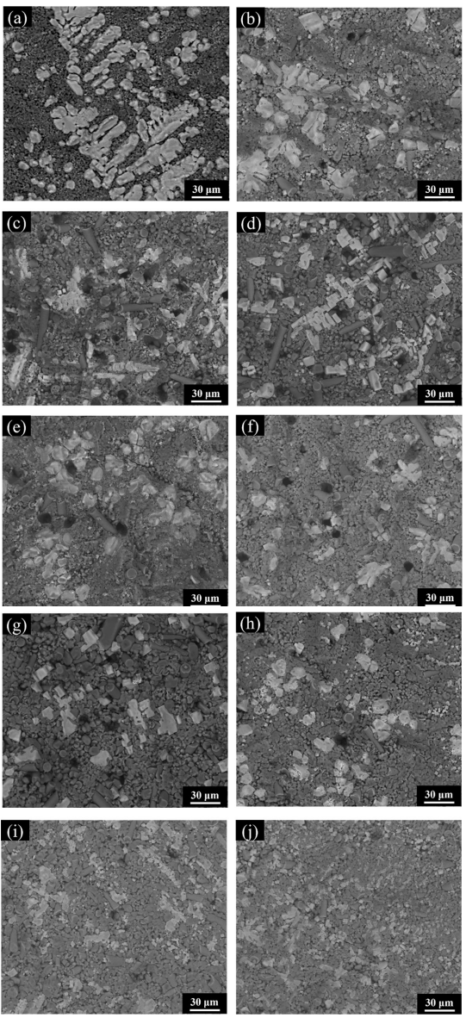

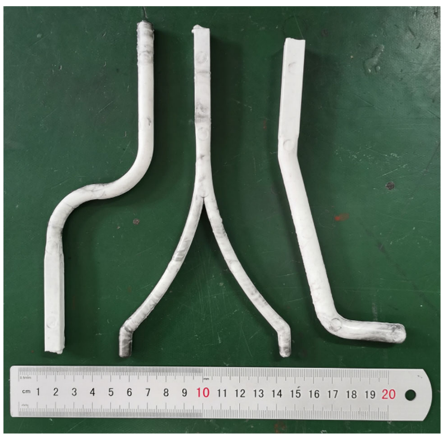

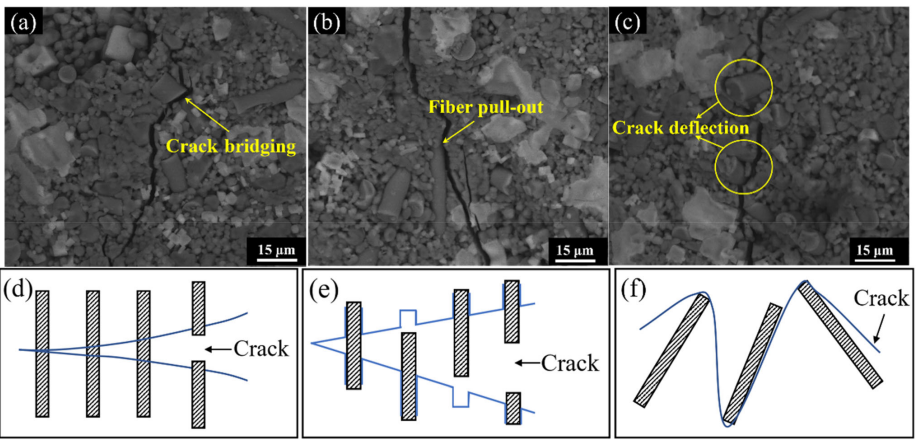

The water-soluble salt core with higher bending strength and toughness is necessary to withstand the high pressure needed to manufacture some complex parts by high pressure die casting (HPDC). In this paper, the effects of glass fiber size and content on microstructures and properties of KNO3-based (KNO3-30 mol%KCl) water-soluble salt core were systematically studied. The results showed that increasing the glass fiber content greatly improved the bending strength and impact toughness of the KNO3-based salt core, decreased the water solubility rate and increased the humidity resistance. In addition, increasing the glass fiber size sharply enhanced the impact toughness of the KNO3-based salt core, while decreasing the bending strength, water solubility rate and humidity resistance. The maximum bending strength and impact toughness of the reinforced KNO3-based salt core with the glass fiber were, respectively, 41.32 ± 0.38 MPa and 2.146 ± 0.108 kJ/m2, which were 55.9% and 315.1% higher than those of the unreinforced KNO3-based salt core, respectively. The microstructures show that the glass fibers were evenly distributed in the KNO3-based salt core, which significantly refined the KCl primary phases, especially for the 12.5-μm glass fiber. Meanwhile, many fiber pull-out holes were observed in the KNO3-based salt cores with 75-μm and 25-μm glass fiber. The grain refinement, fiber pull-out and crack deflection were the main mechanism for improving the strength and toughness of the KNO3-based salt core.

Keywords

salt core, potassium nitrate, glass fiber,

water-soluble, high pressure die casting (HPDC),

bending strength, impact toughness, microstructure

characteristics

(c) sample 3 (size = 12.5 lm)

toughness

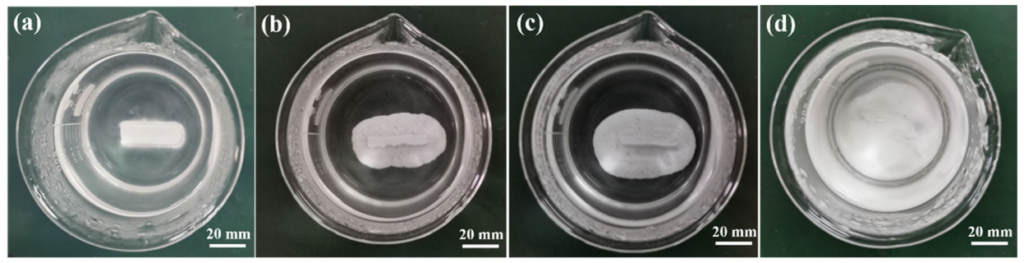

lm) in 80 C water: (a) 0 min; (b) 6 min; (c) 12 min; (d) 18 min

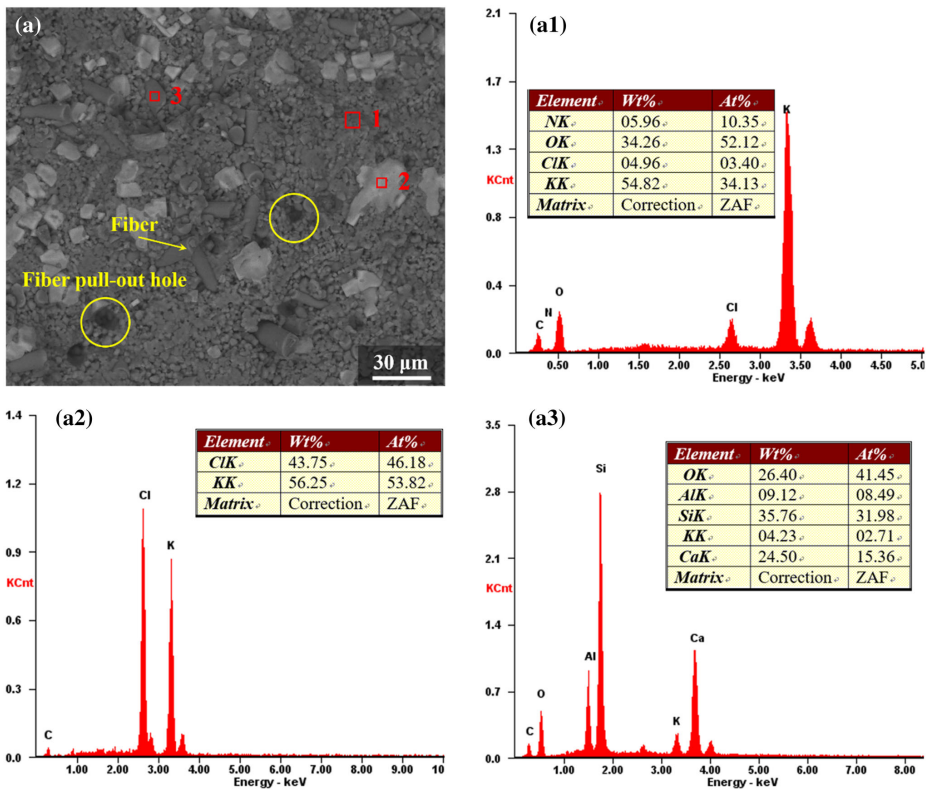

(size = 25 lm): (a) Backscattered SEM image and (a1–a3) EDS results labeled in (a)

with 25 lm size

(a) 30 wt.% glass fiber; (b) and (c) 20 wt.% glass fiber; (d) the scheme diagram of crack bridging; (e) the

scheme diagram of fiber pull-out; and (f) the scheme diagram of crack deflection

References

- Z. Xiao, L.T. Harper, A.R. Kennedy, N.A. Warrior, A water-soluble core material for manufacturing hollow composite sections. Compos. Struct. 182, 380–390 (2017)Article Google Scholar

- R. Huang, B. Zhang, Study on the composition and properties of salt cores for zinc alloy die casting. Inter Metalcast 11, 440–447 (2017). https://doi.org/10.1007/s40962-016-0086-7Article Google Scholar

- J. Yaokawa, D. Miura, K. Anzai, Y. Yamada, H. Yoshii, Strength of salt core composed of alkali carbonate and alkali chloride mixtures made by casting technique. Mater. Trans. 48, 1034–1041 (2007)CAS Article Google Scholar

- Y. Yamada, J. Yaokawa, H. Yoshii, K. Anzai, Developments and application of expendable salt core materials for high-pressure die casting to apply closed-deck type cylinder block, in JSAE-Report (Society of Automotive Engineers of Japan), pp. 1–5 (2007)

- R.J. Donahue, M.T. Degler, Congruent melting salt alloys for use as salt cores in high pressure die casting: U.S. Patent 9878367 (2018)

- K. Oikawa, K. Sakakibara, Y. Yamada, High-Temperature Mechanical Properties of NaCl–Na2CO3 Salt-Mixture Removable Cores for Aluminum Die-Casting. Mater. Trans. 60, 19–24 (2019)CAS Article Google Scholar

- S. Tu, F. Liu, G. Li, W. Jiang, X. Liu, Fabrication and characterization of high-strength water-soluble composite salt core for zinc alloy die castings. Int J Adv Manuf Tech 95, 505–512 (2018)Article Google Scholar

- D. Cica, D. Kramar, Intelligent process modeling and optimization of porosity formation in high-pressure die casting. Int. Metalcast. 12, 814–824 (2018). https://doi.org/10.1007/s40962-018-0213-8CAS Article Google Scholar

- B. Fuchs, H. Eibisch, C. Körner, Core viability simulation for salt core technology in high-pressure die casting. Int. Metalcast. 7, 39–45 (2013). https://doi.org/10.1007/BF03355557CAS Article Google Scholar

- X.X. Dong, H.L. Yang, X.Z. Zhu, High strength and ductility aluminium alloy processed by high pressure die casting. J. Alloy. Compd. 773, 86–96 (2019)CAS Article Google Scholar

- D.E. Grebe, M.P. Potratz, Disintegrative core for use in die casting of metallic components: U.S. Patent 7013948 (2006)

- Z. Long, Effect of kaolin on tensile strength and humidity resistance of a water-soluble potassium carbonate sand core. China Foundry 13, 15–21 (2016)Article Google Scholar

- Y. Youji, Method of manufacturing expendable salt core for casting. U.S. Patent 8574476B (2013)

- Y.J. Hori, N. Miura, Y Kurokawa, Water-soluble casting mold and method for manufacturing the same: U.S. Patent 20040238157A1 (2004)

- K. Hirokawa, Disintegrative core for high pressure casting, method for manufacturing the same, and method for extracting the same: U.S. Patent 6755238 (2004)

- A. Elsayed, C. Ravindran, B.S. Murty, Effect of aluminum-titanium-boron based grain refiners on AZ91E magnesium alloy grain size and microstructure. Inter Metalcast 5, 29–41 (2011)CAS Article Google Scholar

- M. Uludağ, R. Çetin, D. Dispinar, M. Tiryakioğlu, Effect of degassing and grain refinement on hot tearing tendency in Al8Si3Cu alloy. Inter Metalcast 12, 589–595 (2018). https://doi.org/10.1007/s40962-017-0197-9CAS Article Google Scholar

- P. Jelínek, F. Mikšovský, J. Beňo, E. Adámková, Development of foundry cores based on inorganic salts. Mater. Tech. 6, 689–693 (2013)Google Scholar

- Z.L. Lu, Y.X. Fan, K. Miao, H. Jing, D.C. Li, Effects of adding aluminum oxide or zirconium oxide fibers on ceramic molds for casting hollow turbine blades. Int. J. Adv. Manuf. Technol. 72, 873–880 (2014)Article Google Scholar

- X.W. Yin, Fibre-reinforced multifunctional SiC matrix composite materials. Int. Mater. Rev. 62, 117–172 (2017)CAS Article Google Scholar

- K. Lü, X. Liu, Z. Duan, Effect of firing temperature and time on hybrid fiber-reinforced shell for investment casting. Inter Metalcast 13, 666–673 (2019). https://doi.org/10.1007/s40962-018-0280-xCAS Article Google Scholar

- T.Q. Gao, Fabrication and characterization of three dimensional woven carbon fiber/silica ceramic matrix composites. Compos Part B-Eng 77, 122–128 (2015)CAS Article Google Scholar

- L. Wan, P.C. Xu, J.R. Luo, Properties and forming characters of water soluble salt-core reinforced by ceramic whiskers. Foundry 57, 234–238 (2008). (in Chinese)Google Scholar

- W.M. Jiang, Z.T. Fan, D.F. Liao, Investigation of microstructures and mechanical properties of A356 aluminum alloy produced by expendable pattern shell casting process with vacuum and low pressure. Mater. Des. 32, 926–934 (2011)CAS Article Google Scholar

- J.A. Dean, J. Dean, Analytical chemistry handbook (McGraw-Hill, New York, 1995)Google Scholar

- http://www.crct.polymtl.ca/fact/phase_diagram.php?file=KCl-KNO3.jpg&dir=FTsalt

- W. Yuan, S.K. Panigrahi, J. Su, R.S. Mishra, Influence of grain size and texture on Hall–Petch relationship for a magnesium alloy. Scripta Mater. 65, 994–997 (2011)CAS Article Google Scholar

- B. Yu, C. Geng, M. Zhou, Impact toughness of polypropylene/glass fiber composites: interplay between intrinsic toughening and extrinsic toughening. Compos Part B-Eng 92, 413–419 (2016)CAS Article Google Scholar

- J.J. Sha, J. Li, S.H. Wang, Toughening effect of short carbon fibers in the ZrB2-ZrSi2 ceramic composites. Mater Design 75, 160–165 (2015)CAS Article Google Scholar

- J. Njuguna, Z. Mouti, K. Westwood, Toughening mechanisms for glass fiber-reinforced polyamide composites, in Toughening Mechanisms in Composite Materials. Woodhead Publishing, pp. 211–232 (2015)

- S. Tang, L. Yang, G. Li, Effect of the addition of silica sol on layered extrusion forming of Al2O3-based cores. Adv. Appl. Ceram. 118, 1–8 (2018)Google Scholar