Boost Al-12Si Casting Strength: The Untapped Potential of Vortex Runner Design

This technical summary is based on the academic paper "EFFECT OF VORTEX RUNNER GATING SYSTEM ON THE MECHANICAL STRENGTH OF Al-12Si ALLOY CASTINGS" by R. Ahmad and M.Y. Hashim, published in ARCHIVES OF METALLURGY AND MATERIALS (2011).

Keywords

- Primary Keyword: Vortex Runner Gating System

- Secondary Keywords: Al-12Si Alloy, Mechanical Strength, Gating System Design, Sand Casting, Weibull Analysis, Casting Defects

Executive Summary

- The Challenge: Inconsistent mechanical strength in Al-12Si castings is often caused by defects like porosity and oxide films originating from suboptimal gating system design.

- The Method: The study experimentally compared the mechanical strength of Al-12Si castings produced using a vortex runner gating system with three different runner diameters (15 mm, 20 mm, and 25 mm).

- The Key Breakthrough: A larger vortex runner diameter directly and significantly improves both the average bending strength and the consistency of the mechanical properties of the final casting.

- The Bottom Line: Optimizing the runner diameter within the gating system is a critical, high-impact lever for enhancing the reliability and performance of Al-12Si alloy components.

The Challenge: Why This Research Matters for HPDC Professionals

Every casting professional knows that the gating system is the heart of a quality component. Its design dictates how molten metal flows, fills the mold, and solidifies. An improper design leads to turbulence, which in turn causes critical defects like air entrapment, oxide film formation, and mold erosion. These defects act as stress concentrators, compromising the mechanical integrity and predictability of the final product.

While extensive research has focused on optimizing general gating designs, the specific influence of the runner's diameter has remained a gray area. For engineers working with highly fluid alloys like Al-12Si, which are essential for complex, thin-walled components, this knowledge gap represents a significant barrier to achieving maximum part strength and process reliability. This study directly addresses that gap, providing clear, data-driven evidence on how a single design parameter—the vortex runner diameter—can be tuned to produce superior castings.

The Approach: Unpacking the Methodology

The researchers conducted a rigorous experimental study to isolate and measure the effect of the runner diameter on mechanical strength.

Method 1: Controlled Geometry and Material

A vortex flow runner system was designed to produce Al-12Si (LM6) alloy plate castings. Three distinct runner diameters were tested: 15 mm, 20 mm, and 25 mm. All other gating system dimensions (sprue, ingate, etc.) and the cast plate geometry were held constant to ensure the runner diameter was the only variable. Al-12Si was chosen for its excellent fluidity and common use in intricate sand and die castings.

Method 2: Mechanical Strength Testing

After casting, the plates were machined to prepare standardized specimens for mechanical testing. A 3-Point Bending Test was performed on an AG-I SHIMADZU Universal Testing Machine, following the ASTM E290-97a standard. This test was chosen specifically to evaluate the material's strength, given the brittle characteristics resulting from its silicon morphology.

Method 3: Statistical Reliability Analysis

To go beyond simple averages, the researchers employed Weibull distribution analysis. This powerful statistical tool evaluates the variability of material strength, providing a "Weibull modulus" (m) that quantifies the consistency of the results. A higher modulus indicates a more reliable and predictable material performance, which is critical for high-performance applications.

The Breakthrough: Key Findings & Data

The experimental results demonstrate a clear and direct relationship between the vortex runner diameter and the mechanical performance of the Al-12Si castings.

Finding 1: Larger Runner Diameter Directly Increases Bending Strength

The study found that as the runner diameter increased, the average bending strength of the cast plates improved significantly. This trend was consistent across both horizontally and vertically sampled specimens.

- Horizontal Samples: The average bending strength increased from 141.366 MPa with a 15 mm runner to 170.244 MPa with a 25 mm runner—a 20.4% improvement.

- Vertical Samples: The average bending strength increased from 129.791 MPa with a 15 mm runner to 158.003 MPa with a 25 mm runner—a 21.7% improvement.

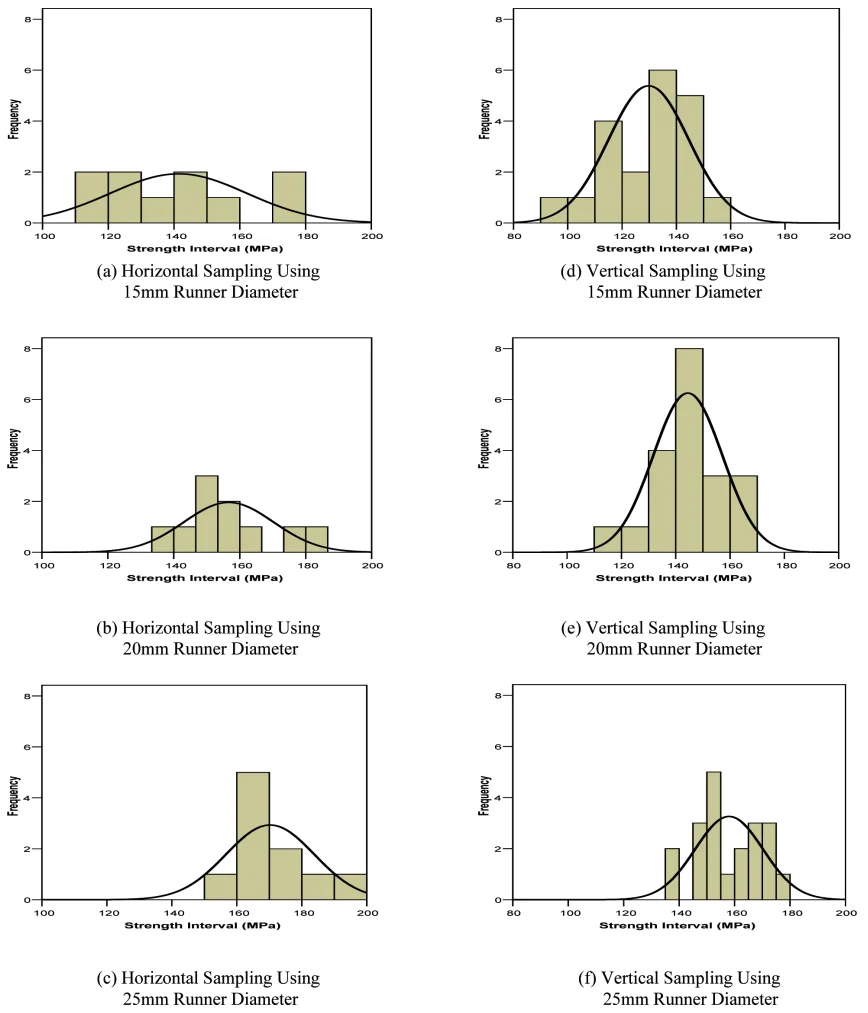

These results are visualized in the frequency histograms in Figure 3 of the paper.

Finding 2: Larger Runners Produce More Consistent and Reliable Castings

The Weibull analysis revealed that a larger runner diameter not only increases strength but also reduces the variability of that strength from one part to the next. A higher Weibull modulus (m) signifies greater reliability.

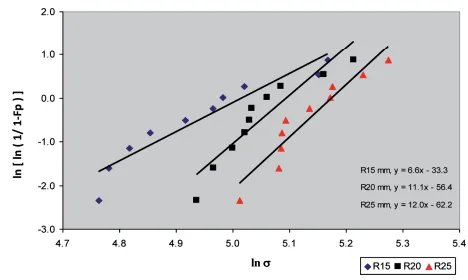

- Horizontal Samples: The Weibull modulus (m) increased from 6.6 for the 15 mm runner to 12.0 for the 25 mm runner.

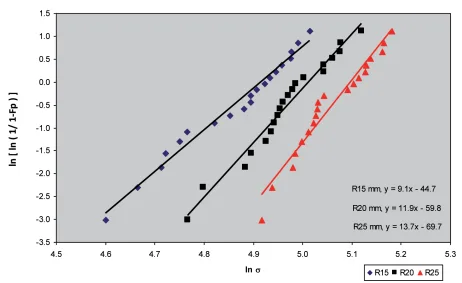

- Vertical Samples: The Weibull modulus (m) increased from 9.1 for the 15 mm runner to 13.7 for the 25 mm runner.

As shown in the Weibull plots (Figures 4 and 5), the steeper slope for the 25 mm runner data indicates a tighter distribution of strength values, meaning a more predictable and reliable manufacturing process.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the runner diameter is a powerful tool for improving mechanical strength. For components failing to meet strength specifications, increasing the runner diameter may be a more effective solution than altering melt temperature or other parameters.

- For Quality Control Teams: The data in the Weibull plots (Figures 4 and 5) of the paper illustrates the effect of runner design on process consistency. This could inform new quality inspection criteria, where a lower-than-expected Weibull modulus might signal an issue in the gating system or casting process, even if average strength seems acceptable.

- For Design Engineers: The findings indicate that the runner diameter should be considered a critical design feature, not just a means of metal transport. Specifying an optimized runner diameter in the early design phase can proactively eliminate defects and ensure the final part meets its required mechanical performance.

Paper Details

EFFECT OF VORTEX RUNNER GATING SYSTEM ON THE MECHANICAL STRENGTH OF Al-12Si ALLOY CASTINGS

1. Overview:

- Title: EFFECT OF VORTEX RUNNER GATING SYSTEM ON THE MECHANICAL STRENGTH OF Al-12Si ALLOY CASTINGS

- Author: R. AHMAD, M.Y. HASHIM

- Year of publication: 2011

- Journal/academic society of publication: ARCHIVES OF METALLURGY AND MATERIALS, Volume 56, Issue 4

- Keywords: gating system, sand casting, mechanical strength, weibull analysis

2. Abstract:

Gating system design is an essential element in casting process which affects significantly the molten metal flow behavior, heat transfer and solidification of the melt. Optimum gating design will lead to a good quality of casting product. One of the major components in gating system is runner. This study was conducted to determine the effect of vortex runner diameter gating system on the mechanical strength of Al-12Si alloy casting. Simulation was conducted to study the behavior of the fluid flow and the results obtained showed close agreement with the results obtained from the experiment. Experimental results showed that the casting product with bigger vortex runner diameter gating system led to the improvement of average bending strength.

3. Introduction:

The gating system is an important feature of the mould cavity, composed of a pouring basin, sprue, runner, gate, and riser. Its function is to allow molten metal to fill the casting cavity completely. A uniform flow is required to prevent air entrapment, metal oxidation, and mould erosion. Mould filling plays a significant role in the quality of the final product, and much research has focused on the effect of gating design on the flow pattern of the melt. While optimization of gating systems has been studied, there is little available information on the specific effect of runner diameter on the mechanical strength of the casting component.

4. Summary of the study:

Background of the research topic:

The design of the gating system is a fundamental element in the casting process, significantly influencing molten metal flow, heat transfer, and solidification. An optimal gating design is critical for producing high-quality cast products. The runner is a major component of this system.

Status of previous research:

Previous research has established that an optimum gating system can reduce melt flow turbulence and minimize defects such as air entrapment, sand inclusion, oxide films, and dross. Studies have explored various runner designs (vortex, rectangular, triangular) and their effects on controlling chaotic flow and reducing casting defects. However, a specific investigation into the relationship between the runner diameter and the resulting mechanical strength of Al-Si alloys has been limited.

Purpose of the study:

The purpose of this study was to determine the effect of the vortex runner diameter on the mechanical strength of Al-12Si alloy castings.

Core study:

The study involved an experimental investigation where Al-12Si alloy plates were produced using a sand casting process with a vortex runner gating system. Three different runner diameters (15 mm, 20 mm, and 25 mm) were used. The mechanical strength of the resulting castings was evaluated using three-point bending tests. The variability of the strength was analyzed using the Weibull distribution method. The experimental results were also compared with fluid flow simulations.

5. Research Methodology

Research Design:

The study employed an experimental design to investigate the causal relationship between one independent variable (vortex runner diameter) and one dependent variable (mechanical strength). Three levels of the independent variable were tested: 15 mm, 20 mm, and 25 mm.

Data Collection and Analysis Methods:

- Fabrication: Plate castings were produced using a vortex flow runner system. The 3D model was converted to STL format and fabricated using a Z406 3D Printer.

- Material: The material used was Al-12Si (Aluminium LM6) alloy.

- Data Collection: Mechanical strength was measured via a 3 Point Bending Test using an AG-I SHIMADZU Universal Testing Machine, in accordance with ASTM E290-97a. Specimens were sampled both horizontally and vertically from the cast plates.

- Data Analysis: The collected strength data was analyzed to determine average bending strength values. A two-parameter Weibull distribution analysis was conducted to assess the variability of the strength and calculate the Weibull modulus (m).

Research Topics and Scope:

The research was focused on Al-12Si alloy cast using a sand mould. The scope was limited to a vortex-type runner system and investigated the effect of runner diameter on the flexural (bending) strength of the final casting.

6. Key Results:

Key Results:

- The average bending strength of the Al-12Si castings increased as the runner diameter increased. For horizontal sampling, the strength increased from 141.366 MPa (15 mm runner) to 170.244 MPa (25 mm runner). For vertical sampling, it increased from 129.791 MPa (15 mm runner) to 158.003 MPa (25 mm runner).

- The Weibull modulus (m), a measure of strength consistency, also increased with a larger runner diameter. For horizontal samples, m increased from 6.6 to 12.0. For vertical samples, m increased from 9.1 to 13.7. This indicates that larger runners produce castings with less variability in their mechanical properties.

Figure Name List:

- Fig. 1. Geometry of gating system and cast part

- Fig. 2. Cutting Methods of Casting Samples for 3 Points Bending Test

- Fig. 3. Frequency Histogram Plots of Bending Strength for Horizontal and Vertical Sampling Method

- Fig. 4. Weibull Plots of All Casting Specimens for Horizontal Sampling

- Fig. 5. Weibull Plots of All Casting Specimens for Vertical Sampling

7. Conclusion:

The study was conducted to determine the effect of vortex runner gating system diameter on the mechanical strength of Al-12Si alloy castings. The results showed that the size of the vortex runner gating system had a significant effect on the flexural strength of the Al-12Si alloy castings. The increase in mechanical strength of the Al-12Si alloy castings was directly proportional with an increment of runner diameter size.

8. References:

- [1] D.R. Askeland, P.P. Phule, The Science and Engineering of Materials. 4th ed. Brooks/Cole-Thomson Learning, USA, 357-374 (2003).

- [2] E. Attar, P. Homayonifar, R. Babaei, K. Asgari, P. Davami, Modeling of air pressure effects in casting molds. Journal of Modeling and Simulation in Materials Science and Engineering 13, 903-917 (2005).

- [3] R. Babaei, J. Abdollahi, P. Homayonifar, N. Varahram, P. Davami, Improved advection algorithm of computational modeling of free surface flow using structured grids. Computer Methods in Applied Mechanics and Engineering 195, 775-795 (2006).

- [4] M. Barkhudarov, R. Williams, Simulation of surface turbulence in fluid phenomena during mold filling. AFS 99th Casting Congress. Kansas City. Beeley, P. 2001. Foundry Technology, 2nd ed. Oxford: Butterworth-Heinemann, 5-10 (1995).

- [5] J. Campbell, Casting. 2nd ed. Elsevier Butterworth-Heinemann, Oxford, 13-37, 117-127 (2003).

- [6] X. Dai, X. Yang, J. Campbell, J. Wood, Effect of runner system design on the mechanical strength of Al-7Si-Mg alloy castings. Journal of Materials Science and Engineering A 354, 315-325 (2003).

- [7] C.P. Esparza, M.P. Guerrero, M.A. R-z T-lio, M.C. L-do, Optimal design of gating systems by gradient search methods. computational Materials Science 36, 457-467 (2005).

- [8] R.A. Higgins, Engineering Metallurgy – Part 1 : Applied Physical Metallurgy. 6th ed. Edward Arnold, London, 413-415 (1993).

- [9] B.H. Hu, K.K. Tong, X.P. Niu, I. Pinwill, Design and optimization of runner and gating systems for the die casting of thin-walled magnesium telecommunication parts through numerical simulation. Journal of Materials Processing Technology 105, 128-133 (2000).

- [10] I.H. Katzarov, Finite element modeling of the porosity formation in casting. International Journal of Heat and Mass Transfer 46, 1545-1552 (2003).

- [11] P.D. Lee, A. Chirazi, D. See, Modeling microporosity in aluminum-silicon alloys: a review. Journal of Light Metals 1, 15-30 (2001).

- [12] M. Masoumi, H. Hu, J. Hedjazi, M.A. Boutorabi, Effect of Gating Design on Mold Filling. American Foundry Society Transactions 113, 185-196 (2005).

- [13] X. Yang, X. Huang, X. Dai, J. Campbell, J. Tatler, Numerical Modeling of the Entrainment of Oxide Film Defects in Filling of Aluminum Alloy Castings. International Journal of Cast Metals Research 17(6), 321-331 (2004).

Expert Q&A: Your Top Questions Answered

Q1: Why was the Al-12Si alloy specifically chosen for this study?

A1: The paper states that Al-12Si (LM6) alloy was selected for its widespread use in general-purpose sand and die casting. Its key properties include a low melting temperature, excellent fluidity, and good castability characteristics. This high fluidity makes it ideal for casting thin, intricate sections, which are often sensitive to flow-related defects, making it a perfect candidate material for this research.

Q2: What is the specific advantage of a "vortex runner" compared to other runner designs?

A2: While this paper focuses on the diameter of the vortex runner, it references a study by Dai et al. (2003) which found that the use of a vortex runner "could effectively control the chaotic behaviour of liquid metal flow in the runner, assist in the reduction of ingate velocity, and the consequent reduction of casting defects." This suggests the vortex design itself promotes a more stable, less turbulent flow, which is foundational to producing a defect-free casting.

Q3: Why was a 3-point bending test used instead of a more common tensile test?

A3: The authors selected the 3-point bending test "due to brittle characteristic of casting specimens resulting from the silicon morphology which developed during eutectic solidification." Brittle materials often fail with little to no plastic deformation, making them difficult to grip and test in tension. A bending test is a standard and more reliable method for determining the flexural strength of such materials.

Q4: What does the increase in the Weibull modulus (m) from 6.6 to 12.0 practically mean for a production environment?

A4: The Weibull modulus (m) is a measure of the distribution, or scatter, of strength data. A low value like 6.6 indicates a wide variation in strength from part to part, meaning the process is less predictable. A higher value like 12.0 signifies a much tighter distribution and greater consistency. For a manufacturer, this means a more reliable process, fewer field failures, and the ability to design components with a smaller safety factor, potentially saving weight and material.

Q5: The study mentions an "edge effect" in vertical samples. What causes this and what is its significance?

A5: The paper attributes the "edge effect"—where the outer surfaces of the plate casting have higher mechanical strength—to a "higher cooling speed on the casting surface." This faster cooling leads to a finer microstructure, which in turn increases mechanical strength. This is significant because it highlights that even within a single casting, local solidification conditions can create variations in material properties, and the gating system influences this thermal profile.

Q6: How does a larger runner diameter mechanistically lead to higher strength?

A6: The paper demonstrates a strong correlation but does not explicitly detail the underlying fluid dynamics. However, based on the introduction, the improvement is likely due to a more stable and less turbulent filling process. A larger runner can reduce the velocity of the molten metal for a given fill rate, minimizing the chances of mould erosion, air entrapment, and the folding-in of surface oxide films—all of which create the defects that ultimately reduce the mechanical strength of the final part.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides clear, actionable evidence that addresses a fundamental challenge in aluminum casting: achieving consistent mechanical strength. By demonstrating that a larger runner diameter in a Vortex Runner Gating System not only boosts average strength but also significantly improves process reliability, the study offers engineers a direct path to reducing defects and enhancing component performance. This simple design adjustment can lead to higher-quality parts, reduced scrap rates, and more predictable manufacturing outcomes.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "EFFECT OF VORTEX RUNNER GATING SYSTEM ON THE MECHANICAL STRENGTH OF Al-12Si ALLOY CASTINGS" by "R. AHMAD and M.Y. HASHIM".

Source: https://doi.org/10.2478/v10172-011-0109-6

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.