Unlocking Peak Performance in A356 Alloy: A Deep Dive into T6 Heat Treatment for Semi-Solid Die Casting

This technical summary is based on the academic paper "Effect of T6 Treatment on Microstructures and Mechanical Properties of Semi-Solid A356 Alloy" by Jun Zhou, Caihua Wang*, and Larry Wang, published in The 75th World Foundry Congress (2024).

![Fig. 1 SEED pulping process principle

[3]](https://castman.co.kr/wp-content/uploads/image-3689-1024x268.webp)

Keywords

- Primary Keyword: T6 Treatment A356 Alloy

- Secondary Keywords: Semi-Solid Die Casting, Rheological Forming, A356 Microstructure, Mechanical Properties, High Solid Fraction, SEED Process

Executive Summary

- The Challenge: To significantly enhance the mechanical strength of semi-solid die-cast A356 aluminum components to meet the demanding requirements of the automotive and aerospace industries.

- The Method: An A356 alloy, prepared using the SEED semi-solid pulping process, was subjected to a T6 heat treatment consisting of solutionizing at 540°C for 2 hours followed by artificial aging at 170°C for 4 hours.

- The Key Breakthrough: The T6 treatment dramatically increased the tensile strength by 47% (from 210 MPa to 310 MPa) and more than doubled the yield strength (from 115 MPa to 245 MPa).

- The Bottom Line: T6 heat treatment is a highly effective post-casting process for transforming semi-solid A356 alloy into a high-performance material, enabling the production of stronger, more reliable die-cast components.

The Challenge: Why This Research Matters for HPDC Professionals

A356 aluminum alloy is a cornerstone material in the automotive and aerospace sectors due to its excellent fluidity, lightweight nature, and good workability. For high-performance applications, however, as-cast components often fall short of the required mechanical strength and fatigue resistance. The industry constantly seeks reliable methods to elevate these properties without compromising the benefits of semi-solid metal forming, a process known for producing complex, near-net-shape parts with low porosity. This research directly addresses the critical need to bridge the gap between the as-cast state and the high-performance requirements of modern engineering components.

The Approach: Unpacking the Methodology

This study employed a systematic, industry-relevant methodology to evaluate the effects of T6 treatment on semi-solid A356 alloy.

Method 1: Slurry Preparation via SEED Process

The process began with a commercial A356 aluminum ingot, melted at 760°C and subjected to rotational degassing under argon protection to ensure melt quality. The qualified melt, held at 630°C, was then processed using the SEED (Swirled Enthalpy Equilibration Device) pulping process. As illustrated in Figure 1 of the paper, this technique involves swirling the melt to create a non-dendritic, globular microstructure ideal for semi-solid die casting.

Method 2: High Pressure Die Casting (HPDC)

The prepared semi-solid slurry was cast using a LEAP-840T die-casting machine. Key process parameters were precisely controlled: a slow injection speed of 0.5 m/s, a fast injection speed of 1.5 m/s, and a boost pressure of 100 MPa. This ensures the production of dense, uniform test samples.

Method 3: T6 Heat Treatment and Analysis

Half of the as-cast samples were subjected to a standard T6 heat treatment: a solution treatment at 540°C for 2 hours, followed by aging at 170°C for 4 hours. Both as-cast and T6-treated samples were then meticulously analyzed using optical microscopy (OM), scanning electron microscopy (SEM), and X-ray diffraction (XRD) to characterize microstructural changes, while tensile tests were conducted to measure ultimate tensile strength (UTS), yield strength (YS), and elongation (EL).

The Breakthrough: Key Findings & Data

The research revealed significant microstructural and mechanical transformations in the A356 alloy following the T6 treatment.

Finding 1: Microstructure Refinement and Phase Transformation

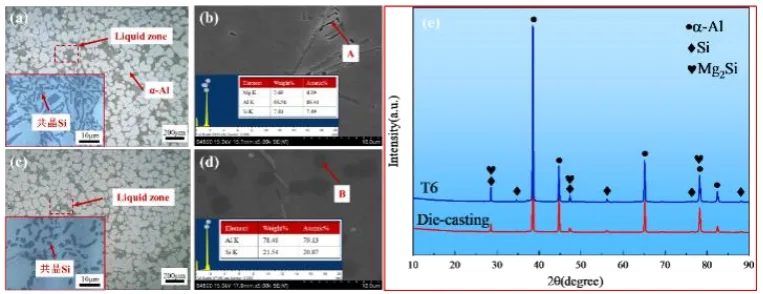

The T6 treatment induced critical changes in the alloy's microstructure. While the primary phases (α-Al, eutectic Si, Mg2Si) remained the same, their morphology and distribution were altered. As seen in the SEM images (Figure 2), the as-cast alloy's fishbone-like Mg2Si phase dissolved into the α-Al matrix during treatment. Concurrently, the brittle, lath-like eutectic Si network broke down and spheroidized into fine, short rod or near-spherical particles. Furthermore, the solid phase fraction increased from 66% in the as-cast state to 75% after T6 treatment, while the shape factor of the primary α-Al improved (decreased) from 0.7 to 0.6.

Finding 2: Dramatic Improvement in Mechanical Strength

The microstructural refinements translated directly into superior mechanical properties. As detailed in Table 2, the T6 treatment resulted in a remarkable increase in strength:

- Ultimate Tensile Strength (UTS): Increased from 210 MPa to 310 MPa.

- Yield Strength (YS): Increased from 115 MPa to 245 MPa.

- Elongation (EL): Showed a slight decrease from 14.4% to 12.1%, a common trade-off for such a significant gain in strength.

These results demonstrate that the performance of the T6-treated semi-solid A356 alloy is substantially higher than the lower limit specified by the Chinese national standard (GB/T40809-2021) for semi-solid castings.

Practical Implications for R&D and Operations

- For Process Engineers: This study confirms that implementing a T6 heat treatment cycle (540°C × 2h + 170°C × 4h) is a reliable strategy to significantly upgrade the mechanical performance of semi-solid A356 components, moving them into a higher value category.

- For Quality Control Teams: The data in Table 2 provides clear, quantitative benchmarks for post-treatment mechanical properties. These values (310 MPa UTS, 245 MPa YS) can be used to establish robust quality inspection criteria for high-strength structural parts.

- For Design Engineers: The substantial increase in yield strength to 245 MPa allows for the design of components with thinner walls and more complex geometries without sacrificing structural integrity. This enables weight reduction and improved performance, particularly in automotive and aerospace applications.

Paper Details

Effect of T6 Treatment on Microstructures and Mechanical Properties of Semi-Solid A356 Alloy

1. Overview:

- Title: Effect of T6 Treatment on Microstructures and Mechanical Properties of Semi-Solid A356 Alloy

- Author: Jun Zhou, Caihua Wang*, Larry Wang

- Year of publication: 2024

- Journal/academic society of publication: The 75th World Foundry Congress

- Keywords: A356 alloy; rheological forming; microstructure; mechanical properties; high solid faction.

2. Abstract:

In this work, the semi-solid A356 alloy was prepared by SEED semi-solid pulping process, and effect of T6 treatment on microstructures and mechanical properties were studied by optical microscopy (OM), scanning electron microscopy (SEM), X-ray diffraction (XRD) and other methods. The results indicated that the phase composition of A356 alloy remained unchanged after the T6 treatment, and included α-Al matrix, eutectic Si, and Mg2Si phases, while, the solid phase fraction (S) of the alloy increased from 66% to 75%, and the shape factor (F) decreased from 0.7 to 0.6, and the mechanical properties significantly improved. The tensile strength (UTS), yield strength (YS), and elongation (EL) of the T6-A356 alloy was 310MPa, 245MPa, and 12.1%, respectively.

3. Introduction:

A356 aluminum alloy is a hypoeutectic alloy with Si and Mg as the main alloying elements. It possesses good fluidity and a wide temperature range in the two-phase zone, making it suitable for semi-solid metal forming. Due to its lightweight nature, excellent mechanical strength, ductility, fatigue performance, compactness, and workability, A356 alloy is increasingly used in the automotive and aerospace industries. This study was conducted to prepare semi-solid A356 alloy via SEED semi-solid die-casting and to investigate the influence of T6 treatment on its microstructural evolution and mechanical property changes.

4. Summary of the study:

Background of the research topic:

A356 aluminum alloy is a widely used hypoeutectic casting alloy known for its favorable characteristics for semi-solid metal forming, including good fluidity and a wide solidification range. Its application in demanding sectors like automotive and aerospace is growing due to its excellent combination of properties.

Status of previous research:

The paper references existing literature on modifying aluminum alloys and the effects of heat treatment, indicating that enhancing the properties of A356 is an active area of research. Specifically, it cites work on the SEED technology and the effect of heat treatment on A356 alloys.

Purpose of the study:

The primary purpose was to prepare a semi-solid A356 alloy using the SEED process and to systematically study the effect of a subsequent T6 heat treatment on the alloy's microstructure and resulting mechanical properties.

Core study:

The study is an experimental comparison between as-cast and T6-treated semi-solid A356 alloy samples. It characterizes the changes in microstructure (phase morphology, solid fraction, shape factor) and quantifies the improvements in mechanical properties (tensile strength, yield strength, elongation).

5. Research Methodology

Research Design:

The research was designed as a comparative study. A batch of semi-solid A356 alloy samples was produced under identical die-casting conditions. A portion of these samples was retained in the as-cast state, while the other portion underwent a T6 heat treatment. Both groups were then characterized and tested to isolate the effects of the T6 treatment.

Data Collection and Analysis Methods:

- Material: Commercial A356 alloy ingot with chemical composition as detailed in Table 1.

- Processing: Slurry was prepared using the SEED semi-solid pulping process and cast with a LEAP-840T die-casting machine. T6 treatment was performed at 540 °C × 2h + 170 °C × 4h.

- Characterization: Microstructures were analyzed using Zeiss optical microscopy, S4800 field emission SEM, and Smart Lab 9kw XRD.

- Analysis: Metallographic analysis software was used to calculate the solid phase fraction (S) and shape factor (F) of the primary α-Al phase using formulas (1) and (2). Mechanical properties were determined via tensile testing.

Research Topics and Scope:

The scope of the research is focused on the A356 aluminum alloy prepared by the SEED semi-solid die-casting process. The study investigates the influence of a specific T6 heat treatment cycle on the final microstructure and room-temperature mechanical properties of this alloy.

6. Key Results:

Key Results:

- The phase composition of the A356 alloy (α-Al matrix, eutectic Si, and Mg2Si phases) did not change after T6 treatment.

- The solid phase fraction (S) of the primary α-Al increased from 66% (as-cast) to 75% (T6-treated).

- The shape factor (F) of the primary α-Al decreased from 0.7 (as-cast) to 0.6 (T6-treated), indicating a more spherical morphology.

- After T6 treatment, the fishbone Mg2Si phase dissolved into the matrix, and the lath-like eutectic Si transformed into short rod or near-spherical particles.

- Tensile strength (UTS) increased significantly from 210 MPa to 310 MPa.

- Yield strength (YS) increased significantly from 115 MPa to 245 MPa.

- Elongation (EL) decreased from 14.4% to 12.1%.

Figure Name List:

- Fig. 1 SEED pulping process principle [3]

- Fig.2 microstructure of A356 alloy: As-cast (a, b); T6 (c, d); XRD patterns (e)

7. Conclusion:

(1) Microstructures of both as-cast and T6-treated A356 alloys are composed of α-Al matrix, eutectic Si, and Mg2Si phases. The solid phase ratio and shape factor of α-Al is 66% and 75%, 0.7 and 0.6, respectively.

(2) T6-treated A356 alloy exhibits superior mechanical properties with Rm, Rp0.2, and A of 310MPa, 245MPa and 12.1%, which is overall higher than the lower limit values specified by the national standard for semi-solid rheological die castings.

8. References:

- [1] Colombo M, Gariboldi E and Morri A. Er addition to Al-Si-Mg based casting alloy[J]. Journal of Alloys and Compounds, 2017, 708: 1234-1244.

- [2] Mao F, Yan G, Xuan Zand et al. Effect of Eu addition on t he microstructures and mechanical properties of A356 alum inum alloys[J]. Journal of Alloys and Compounds, 2015, 65 0: 896-906.

- [3] Côté P, Larouche M E and Chen X G. New developments w ith the SEED technology[J]. Solid State Phenomena, 2013, 192: 373-378.

- [4] Liu Z, Mao W, Wang W and et al. Preparation of semi-soli d A380 aluminum alloy slurry by serpentine channel[J]. Tra nsactions of Nonferrous Metals Society of China, 2015, 25 (5): 1419-1426.

- [5] Peng J, Tang X, He J and et al. Effect of heat treatment on microstructure and tensile properties of A356 alloys[J]. Tra nsactions of Nonferrous Metals Society of China, 2011, 21 (9): 1950-1956.

Expert Q&A: Your Top Questions Answered

Q1: What is the primary mechanism behind the significant increase in strength after T6 treatment?

A1: The paper indicates two primary mechanisms. First, the solution treatment step causes the fishbone Mg2Si phase to dissolve, diffusing Mg and some Si atoms into the α-Al matrix, which creates a solid solution strengthening effect. Second, the subsequent aging step promotes the precipitation of fine, coherent strengthening phases (not explicitly detailed but implied by the T6 process), which effectively hinder dislocation movement, dramatically increasing both tensile and yield strength.

Q2: Why did the solid phase fraction increase from 66% to 75% after heat treatment?

A2: While the paper states this observation, the underlying mechanism is related to the solution heat treatment. At the high temperature of 540°C, some of the lower-melting-point eutectic phases can re-melt and subsequently re-solidify onto the existing primary α-Al grains during cooling. This process, known as coarsening or ripening, leads to an increase in the measured volume of the primary phase and a more consolidated microstructure.

Q3: The elongation decreased from 14.4% to 12.1%. Is this reduction a significant drawback?

A3: This decrease is a typical and expected trade-off when significantly increasing the strength of an alloy through heat treatment. The strengthening precipitates that block dislocation movement also reduce the material's ability to deform plastically. However, an elongation of 12.1% is still considered very high for a cast aluminum alloy with a tensile strength of 310 MPa, indicating excellent overall performance and toughness.

Q4: How does the change in eutectic Si morphology from lath-like to spherical impact the alloy's properties?

A4: The sharp, acicular, or lath-like eutectic Si in the as-cast state acts as a stress concentrator, providing easy pathways for cracks to initiate and propagate, which limits ductility and toughness. The T6 treatment breaks down this brittle network and transforms the Si into smaller, rounded particles. This spheroidization reduces stress concentrations, improving the material's ability to resist fracture and contributing to better overall mechanical performance, especially in terms of fatigue life and ductility.

Q5: The study used the SEED process. How does this initial slurry preparation method influence the final T6-treated properties?

A5: The SEED process is crucial because it creates a non-dendritic, globular primary α-Al microstructure from the start. This fine, uniform, and spherical starting structure is ideal for heat treatment. It allows for more efficient and uniform diffusion of alloying elements (like Mg) during solution treatment and results in a more homogeneous distribution of precipitates during aging, leading to consistent and optimized mechanical properties throughout the final component.

Conclusion: Paving the Way for Higher Quality and Productivity

This research clearly demonstrates the transformative power of T6 treatment on A356 alloy prepared by semi-solid casting. By refining the microstructure and optimizing phase distribution, the T6 process elevates the material's mechanical strength to levels required for high-stress structural components. For manufacturers, applying the principles of T6 Treatment A356 Alloy is not just a post-processing step; it is a strategic tool to unlock new applications, enable lightweighting initiatives, and deliver superior product quality and reliability.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Effect of T6 Treatment on Microstructures and Mechanical Properties of Semi-Solid A356 Alloy" by "Jun Zhou, Caihua Wang*, Larry Wang".

Source: The 75th World Foundry Congress, October 25-30, 2024, Deyang, Sichuan, China

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.