How Vacuum Casting Intensifies HPDC Cavitation and What to Do About It

This technical summary is based on the academic paper "Effect of Cavitation Phenomenon on the Quality of High-Pressure Aluminium Alloy Castings" by Marcin Brzeziński and Jakub Wiśniowski, published in the Journal of Casting & Materials Engineering (2023). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: HPDC Cavitation

- Secondary Keywords: Mould Erosion, High-Pressure Die Casting, Casting Defects, Vacuum Casting, Aluminium Alloys, Flow Simulation

Executive Summary

- The Challenge: High-pressure die casting (HPDC) moulds are experiencing premature erosion and failure, particularly after implementing vacuum systems, leading to costly regeneration at only 30% of their expected service life.

- The Method: Researchers investigated changes in the surface of a pressure mould by comparing photographs of castings at the start of its life (300 injections) and at 30% life (29,100 injections), correlating these physical changes with simulation results from a Flow3D "cavitation potential" module.

- The Key Breakthrough: The use of vacuum in the die cavity, while effective for removing air and gases, significantly increases the tendency for cavitation to occur by creating a larger pressure differential, which accelerates mould erosion.

- The Bottom Line: Proactively simulating for HPDC Cavitation potential is critical, especially for complex castings with sharp edges, to mitigate premature mould wear when using modern vacuum-assisted die casting technology.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of high-volume manufacturing, particularly for the automotive industry, HPDC is the leading technology due to its efficiency, dimensional accuracy, and superior surface finish. To meet ever-increasing quality demands, foundries are adopting advanced techniques like vacuum systems to minimize air occlusion and porosity. However, this progress is not without its challenges.

A critical and costly problem has emerged: premature mould erosion. A tool expected to withstand several hundred thousand cycles can fail at a fraction of its declared service life, forcing expensive and time-consuming regeneration. This study addresses a case where a mould required costly intervention at just 30% of its lifespan after a vacuum system was applied. The research was necessary to uncover the root cause of this highly unfavorable and difficult-to-predict phenomenon, which was suspected to be HPDC Cavitation.

The Approach: Unpacking the Methodology

The study aimed to determine if the cavitation phenomenon was the cause of premature mould failure. The methodology combined physical inspection with advanced simulation.

- Physical Analysis: Researchers visually documented the mould's condition at two key stages: after 300 injections (representing the beginning of its life) and after 29,100 injections (representing 30% of its life). Photographs of the castings and thermal images of the mould were used to identify and track the degradation of specific surface areas.

- Process Conditions: The casting process under analysis utilized a vacuum generator to reduce the gas/air pressure within the mould cavity, a common practice to improve casting quality.

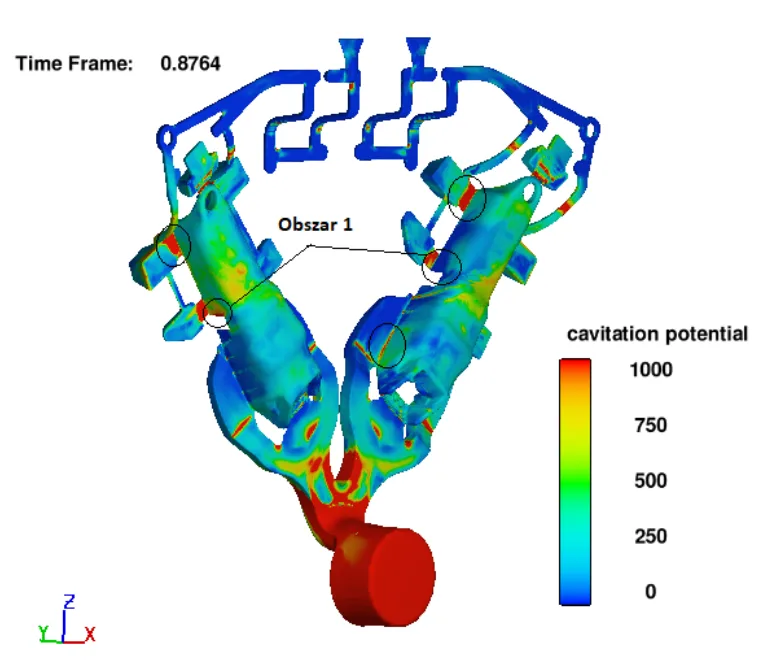

- Simulation: The team used the Flow3D-cast software, specifically its "cavitation potential" module. This simulation tool does not pinpoint the exact location of bubble implosion (the damage event) but rather identifies areas where conditions—such as a significant local pressure drop below the metal's evaporation pressure—are favorable for the nucleation (formation) of cavitation bubbles. This predictive approach is key to understanding and preventing the issue before it causes physical damage.

The Breakthrough: Key Findings & Data

The research delivered clear evidence linking process parameters and casting geometry to the observed mould erosion, confirming cavitation as the primary cause.

Finding 1: Visual Confirmation of Progressive Mould Degradation

Direct comparison of the mould's condition over time revealed a clear and significant increase in degradation. As shown in Figure 4, the mould surface after 29,100 injections (b) exhibits severe erosion compared to its state after only 300 injections (a). The damage is concentrated in specific locations: at the overflow slots, in the shadow of the feed gate, and on sharp edges perpendicular to each other. This pattern indicates that the damage is not random wear but is caused by a specific fluid dynamics phenomenon.

Finding 2: Vacuum Systems Directly Increase Cavitation Tendency

The study concluded that the use of a vacuum is a direct contributing factor to increased HPDC Cavitation. The initiation of cavitation requires a boiling process driven by a pressure differential. While high metal velocities in HPDC can create low-pressure zones even at atmospheric pressure, reducing the overall cavity pressure with a vacuum (e.g., to 200 mbar) significantly amplifies this effect. This lower baseline pressure makes it much easier for localized pressure to drop below the liquid metal's vapor pressure, creating ideal conditions for cavitation bubbles to form and subsequently collapse, eroding the mould surface.

Finding 3: Complex Geometries Are High-Risk Zones

The areas most prone to cavitation are those with sudden, rapid changes in flow direction and velocity. Figure 5 highlights how castings that are more structurally complex—featuring sharp edges and perpendicular planes—are more susceptible. The simulation result in Figure 3 ("Obszar 1") identifies a high cavitation potential in an area where the metal flow is forced to change direction abruptly. This confirms that geometric design is a critical factor in mitigating cavitation risk.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that while vacuum is a necessary tool for high-quality casting, its level must be carefully managed. The data implies a trade-off between gas porosity reduction and mould life. Adjusting vacuum pressure based on simulation results for HPDC Cavitation potential may be necessary to find an optimal balance.

- For Quality Control Teams: The data in Figure 4 provides a clear visual baseline for identifying early-stage cavitation erosion. This can inform new mould inspection criteria, allowing for proactive maintenance before catastrophic failure occurs.

- For Design Engineers: The findings indicate that design features like sharp edges, perpendicular planes, and areas causing abrupt changes in flow direction directly influence cavitation formation. Using simulation tools like the "cavitation potential" module during the early design phase is a valuable strategy to design more robust and durable moulds.

Paper Details

Effect of Cavitation Phenomenon on the Quality of High-Pressure Aluminium Alloy Castings

1. Overview:

- Title: Effect of Cavitation Phenomenon on the Quality of High-Pressure Aluminium Alloy Castings

- Author: Marcin Brzeziński, Jakub Wiśniowski

- Year of publication: 2023

- Journal/academic society of publication: Journal of Casting & Materials Engineering Vol. 7 No. 3 (2023) 27-30

- Keywords: foundry, aluminium alloys, cavitation, casting defects, simulation

2. Abstract:

This article presents an analysis of the effect of cavitation on the erosion of pressure moulds intended for the HPDC casting mould manufacturing process. Changes in the surface area of the eroded areas were investigated via photographs of castings at the beginning of the mould life as well as at 30%. The individual process variables were described and their influence verified via the cavitation potential module of the Flow3D simulation programme. The results are presented graphically with a description of the relationships and observations. The summary provides an explanation of the results and the dependencies that occurred.

3. Introduction:

High-pressure casting, due to its production characteristics (high process efficiency) and advantages such as dimensional accuracy and stability, and very good surface finish, is the leading technology for casting [1, 2]. This contributes to the choice of high-pressure casting as the main casting method in the context of high-volume production. As interest in this method of casting production is increasing, so to is the complexity of projects implemented via die casting. As the main customer for die casting is the automotive industry, manufacturers are faced with the need to select increasingly demanding technology to meet market expectations. While using advanced technologies, at the same time as increasing process requirements, undesirable effects can occur, the phenomenon of which itself is not obvious and the reasons for its appearance are ambiguous [3-5]. One of the basic conditions for obtaining die castings with the required quality parameters is to minimise air occlusion and to fully control the filling phase of the mould cavity with the liquid casting alloy. Minimising the contact between liquid aluminium and air is a guarantee of high strength properties and low porosity [6, 7]. These measures are implemented in several stages. One example is Parashot technology. It is based on the time-varying speed of the piston in the first filling phase, consisting of a smooth initial movement and constant acceleration. This results in a continuous increase in metal velocity, creating an accelerating wave of aluminium [8]. Due to the varying cross-sections in the gate system, the velocity increases until close to the gate gap, where the start of phase II, the filling of the mould cavity, takes place [9, 10]. In this way, the aluminium moves in a laminar fashion and the continuity of the velocity increase results in an inability to switch to turbulent flow and increase air contact. Another translation of eliminating air contact with the liquid metal is the use of reduced pressure in the cavity [11]. This allows the better evacuation of air and gases through the vacuum created in the die cavity before and during injection of the liquid metal. As a result, foundries are increasingly retrofitting their machines with vacuum systems [8, 12]. In addition to the many advantages, the problem of premature mould erosion occurred in the case studied after the application of vacuum. After analysis, the occurrence of a cavitation problem was demonstrated. This phenomenon, not only in die-casting but also in other industries where conditions are favourable to its occurrence, is the cause of the premature erosion of tools and deterioration of their working conditions [13]. Unlike the moulds used in traditional casting, which are based on classic moulding materials, the cost of a mould in a die-casting machine represents a large percentage of the total project. The mould must be able to withstand several hundred thousand castings in an unaltered state (within the appropriate tolerance range). Therefore, the phenomenon in question is a highly unfavourable, undesirable factor that is also very difficult to predict [14]. This paper presents an attempt to find the root cause of the problem of premature mould erosion, which resulted in a costly regeneration of the tool at 30% of its declared service life.

4. Summary of the study:

Background of the research topic:

High-pressure die casting (HPDC) is a dominant manufacturing technology, especially for the automotive industry, due to its efficiency and the high quality of the resulting products. To further improve quality by minimizing porosity, advanced techniques such as applying a vacuum to the mould cavity are increasingly used.

Status of previous research:

Previous research and industry practice have focused on the benefits of vacuum systems for reducing air and gas entrapment. However, an undesirable side effect—premature mould erosion—has been observed, with ambiguous causes. This erosion represents a significant, unpredictable cost and operational disruption.

Purpose of the study:

The study's purpose was to find the root cause of premature mould erosion in a specific HPDC process that utilized a vacuum system. The hypothesis was that the cavitation phenomenon was the primary cause of the damage, which led to a costly mould regeneration at only 30% of its intended service life.

Core study:

The core of the study involved a two-pronged approach: 1) physically documenting the progression of mould erosion by comparing the mould surface after 300 injections and 29,100 injections, and 2) using Flow3D simulation software with a "cavitation potential" module to analyze the fluid dynamics within the mould and identify areas susceptible to cavitation bubble formation. The study then correlated the simulated high-potential areas with the locations of actual physical damage.

5. Research Methodology

Research Design:

The research was designed as a case study to diagnose the cause of a specific mould failure. It combined empirical observation (photographic evidence of mould wear) with numerical simulation (Flow3D analysis) to establish a cause-and-effect relationship between the casting process parameters, mould geometry, and the observed erosion.

Data Collection and Analysis Methods:

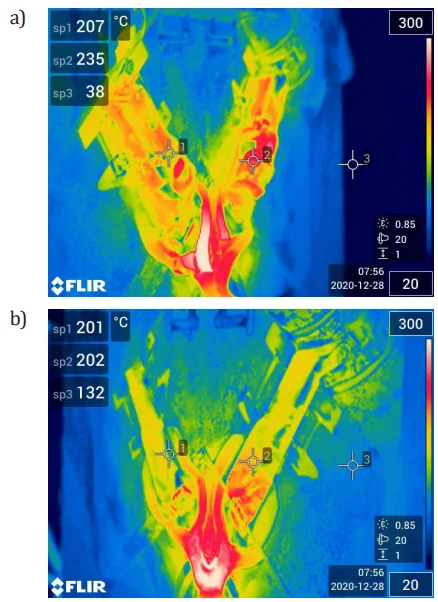

Data was collected through photographs of castings at different stages of the mould's life (300 and 29,100 injections) and thermal imaging of the mould. This visual data was analyzed to identify the location and severity of degradation. The simulation data was generated using the Flow3D-cast software's 'cavitation potential' model, which predicts areas where conditions are favorable for cavitation to begin. The analysis involved comparing the simulation's predictions with the actual observed damage.

Research Topics and Scope:

The research focused on the effect of the cavitation phenomenon on the erosion of an HPDC mould for aluminium alloy castings. The scope was limited to a single case study involving a specific casting system design. It specifically investigated the influence of process parameters, particularly the use of vacuum, on the tendency for cavitation to occur.

6. Key Results:

Key Results:

- There is a clear, visually documented increase in mould degradation between 300 and 29,100 injections, with erosion concentrated at overflow slots, in the shadow of the feed gate, and on sharp, perpendicular edges.

- The use of vacuum in the die casting process directly increases the tendency for cavitation. As cavity pressure decreases, the conditions required for cavitation (a significant pressure drop) are more easily met.

- Castings with more complex geometries, featuring rapid changes in flow direction and velocity (e.g., sharp edges, perpendicular planes), are significantly more prone to cavitation.

- The lack of symmetry in defect occurrence between the left-hand and right-hand cavities indicates that filling dynamics can differ even in a seemingly symmetrical design, leading to localized wear.

- Simulation using a 'cavitation potential' module can successfully identify high-risk areas for cavitation, providing a tool for proactive mould design and process optimization.

Figure Name List:

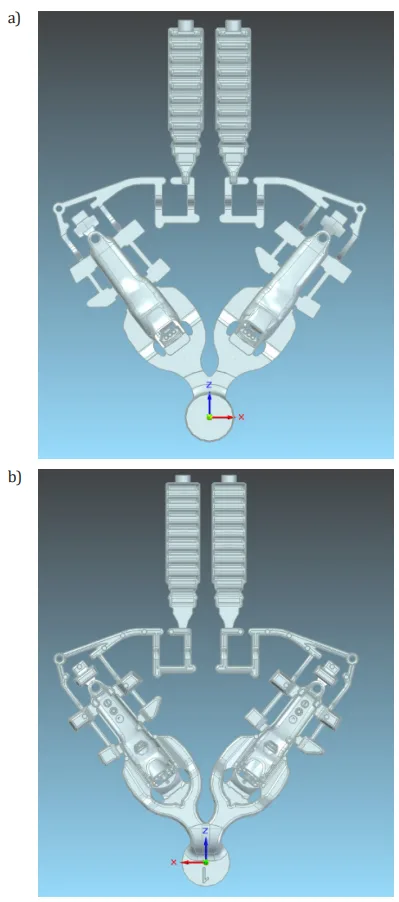

- Fig. 1. Photograph of the project under analysis. View: a) from the fixed half; b) from the mobile half

- Fig. 2. Thermal images of the mould used in the study: a) fixed half; b) mobile half

- Fig. 3. The result of an input simulation

- Fig. 4. Summary of visually inspected areas of the casting made at the beginning of the mould life and at 30% of the life: a) 300 injections; b) 29,100 injections

- Fig. 5. Areas of remaining castings visually inspected at beginning of mould life and 30% of mould life

7. Conclusion:

Problems of premature mould wear can be caused by the adverse effects of cavitation. Castings with more complex designs (with variable directions of metal flow, with sharp edges, kinks and shadows at the gaps) are subject to its adverse effects. The use of a vacuum has a direct effect on increasing the propensity for cavitation to occur and its presence is currently a necessary addition to die casting technology. Recommendations from the research presented in this article suggest that when implementing technologically challenging projects, an analysis of the potential for cavitation problems and their negative impact on the die casting mould should be carried out, for example using the 'cavitation potential' simulation module.

8. References:

- [1] Sobczak J., Balcer E. & Kryczek A. (2018). Odlewnictwo w kraju i na świecie - status quo i tendencje rozwojowe. Przegląd Odlewnictwa, 68(1-2), 8-14.

- [2] Census of World Casting Production. Global Casting Production Growth Stalls (2017). Modern Casting, 24-28.

- [3] Sawicki J., Górecki M., Kaczmarek Ł. & Świniarski J. (2013). Numerical analysis of stresses in mould in the process of pressure casting, Biuletyn WAT, 42(2), 33-41.

- [4] Zinc Die Casting Manufacturer & Supplier. Retrieved from: https://www.dycastspec.com/blog/common-defects-in-high-pressure-die-casting/ [accessed: 29.05.2023].

- [5] Aluminum Die Casting Defects: Causes & Solutions (2023). Retrieved from: https://castingod.com/aluminum-die-casting-defects-causes-solutions-2023/ [accessed: 29.05.2023].

- [6] Fiorese E., Bonollo F., Timelli G., Arnberg L. & Gariboldi E. (2015). New Classification of Defects and Imperfections for Aluminum Alloy Castings. International Journal of Metalcasting, 9(1), 55-66. Doi: https://doi.org/10.1007/BF03355602.

- [7] Dańko J. (2000). Maszyny i urządzenia do odlewania pod ciśnieniem. Uczelniane Wydawnictwa Naukowo-Dydaktyczne AGH, Kraków.

- [8] Kowalczyk W. & Dańko R. (2013). Nowe kierunki i rozwiązania w konstrukcji zimnokomorowych maszyn ciśnieniowych nowej generacji. Archives of Foundry Engineering, 13 (spec. iss. 3), 83-88.

- [9] Dańko R., Dańko J. & Stojek J. (2015). Experiments on the model testing of the 2nd phase of die casting process compared with the results of numerical simulation. Archives of Foundry Engineering, 15(4), 21-24. Doi: https://doi.org/10.1515/afe-2015-0072.

- [10] Koya E. & Nakagawa M. (2018). Influence of defects on HPDC strength and effectiveness of gas porosity by atomize flow. Congress Proceedings 73rd World Foundry Congress, Kraków.

- [11] Dong X., Zhu X. & Ji S. (2019). Effect of super vacuum assisted high pressure die casting on the repeatability of mechanical properties of Al-Si-Mg-Mn die-cast alloys. Journal of Materials Processing Technology, 266, 105-113. Doi: https://doi.org/10.1016/j.jmatprotec.2018.10.030.

- [12] Kowalczyk W. & Dańko R. (2017). Rola dokładności i powtarzalności ilościowej dozowania ciekłego stopu w zimnokomorowym procesie odlewania pod wysokim ciśnieniem. Przegląd Odlewnictwa, 67(1-2), 22-25.

- [13] Zyska A., Konopka Z., Łągiewka M. & Nadolski M. (2015). Porosity of castings produced by the vacuum assisted pressure die casting method, Archives of Foundry Engineering, 15(1), 125-130. Doi: https://doi.org/10.1515/afe-2015-0023.

- [14] Krella A.K. & Zakrzewska D.E. (2018). Cavitation erosion – phenomenon and test rigs. Advances in Materials Science, 18(2), 15-26. Doi: https://doi.org/10.1515/adms-2017-0028.

- [15] Grassivaro D. (2016). Application of cavitation models to study a real case of die erosion. Retrieved from: http://www.formstampi.it/media/EUC-2016_FORM-SRL.pdf [accessed: 29.05.2023].

Expert Q&A: Your Top Questions Answered

Q1: Why was the Flow3D 'cavitation potential' module used for the analysis instead of just observing the physical mould damage?

A1: The 'cavitation potential' module offers a predictive advantage. It identifies areas where cavitation bubbles are likely to form (nucleate) due to favorable pressure conditions, rather than just showing where the damage from their collapse (implosion) occurs. This allows engineers to proactively modify a mould design or process parameters to prevent the problem from starting, which is far more effective than reacting to damage after it has already happened.

Q2: The paper states that applying a vacuum increased the cavitation tendency. Does this mean vacuum-assisted HPDC is a flawed technology?

A2: Not at all. The paper acknowledges that vacuum systems are a necessary and beneficial addition to modern die casting for reducing gas porosity and improving part quality. The key takeaway is that there is a trade-off. While solving the problem of air entrapment, vacuum creates conditions that favor cavitation. The solution is not to abandon vacuum technology, but to manage its effects by using simulation to predict and design against cavitation, ensuring both high part quality and long mould life.

Q3: What specific geometric features were identified as being most at risk for cavitation-induced erosion?

A3: The paper clearly identifies several high-risk features based on both physical observation (Figure 4 and 5) and simulation. These include areas with sudden and rapid changes in metal flow, such as sharp edges, perpendicular planes, overflow slots, and areas "in the shadow" of the feed gate. These features force the liquid metal to change direction abruptly, causing the local pressure drops that lead to cavitation.

Q4: How severe was the mould degradation, and what was its practical impact?

A4: The degradation was severe enough to be considered a premature failure. The paper states that the problem resulted in the need for a "costly regeneration of the tool at 30% of its declared service life." This represents a significant financial loss and major operational disruption, highlighting the critical importance of predicting and preventing this type of wear.

Q5: The study mentions a "lack of symmetry" in the defects between the two casting cavities. Why is this significant?

A5: This is a crucial finding for anyone running multi-cavity tools. It demonstrates that even in a mould designed to be symmetrical, the actual filling dynamics of the liquid metal can be different for each cavity. This can lead to one cavity wearing out much faster than the other. It underscores the necessity of running detailed flow simulations for the entire casting branch, not just a single cavity, to identify these subtle but critical differences in flow behavior.

Q6: Can this cavitation phenomenon be completely eliminated?

A6: While complete elimination in all high-velocity scenarios might be difficult, its effects can be significantly mitigated. The paper suggests that through a combination of simulation, experienced mould design, and a continuous improvement process, it is possible to compensate for these unfavorable phenomena. The goal is to manage the process and design to reduce cavitation potential below a damaging threshold, allowing the mould to reach its full service life.

Conclusion: Paving the Way for Higher Quality and Productivity

The premature failure of expensive HPDC moulds due to erosion is a critical barrier to productivity and profitability. This research successfully identifies HPDC Cavitation—amplified by the use of modern vacuum systems—as the primary culprit. The key breakthrough is the confirmation that while vacuum is essential for part quality, it creates a process environment where complex geometries with sharp edges and abrupt flow changes are highly susceptible to cavitation damage. By leveraging simulation tools like the 'cavitation potential' module, engineers can now proactively design moulds and optimize processes to mitigate this risk, balancing the need for low porosity with the demand for long tool life.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Effect of Cavitation Phenomenon on the Quality of High-Pressure Aluminium Alloy Castings" by "Marcin Brzeziński, Jakub Wiśniowski".

- Source: https://doi.org/10.7494/jcme.2023.7.3.27

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.