Optimizing LPDC Quality: How ProCAST Simulation Validates a New Standard for Test Bar Dies

This technical summary is based on the academic paper "Design and Verification of a New Test Bar Die for LPDC Process Based on Numerical Simulation" by Yang Zhao, Bingrong Zhang, and Xinping Hu, published in the International Journal of Mechanical Engineering and Robotics Research (2020).

Keywords

- Primary Keyword: LPDC Process Simulation

- Secondary Keywords: ProCAST, LPDC test bar, aluminum alloy casting, casting defect analysis, die design verification

Executive Summary

- The Challenge: The Low-Pressure Die Casting (LPDC) industry lacks a uniform standard for manufacturing tensile test bars, forcing reliance on less representative gravity casting methods.

- The Method: A new, specialized test bar die for the LPDC process was designed and its performance was simulated using ProCAST finite element software.

- The Key Breakthrough: The simulation results accurately predicted the melt filling process, temperature fields, and solidification behavior, verifying the rationality of the new mold design and identifying optimal process parameters.

- The Bottom Line: This research validates a new, standardized die and methodology for producing LPDC test bars, enabling more accurate and reliable assessment of mechanical properties for LPDC castings.

The Challenge: Why This Research Matters for HPDC Professionals

The Low-Pressure Die Casting (LPDC) process is renowned for producing aluminum alloy castings with superior mechanical properties, high efficiency, and excellent metal utilization compared to gravity casting. However, a significant gap exists in the industry: there is no uniform standard for the test bars used to determine the performance of these LPDC castings.

Often, engineers must resort to using test bars produced by gravity casting methods. This is problematic because the mechanical properties of separately cast bars from LPDC are generally better than those produced by gravity. This discrepancy means that quality assessments may not accurately reflect the true potential of the final LPDC component, creating uncertainty in performance validation and process optimization. This research directly addresses the need for a standardized, reliable method to produce test bars that are truly representative of the LPDC process itself.

The Approach: Unpacking the Methodology

To create a new standard, the researchers designed and verified a new test bar die specifically for the LPDC process. The methodology combined physical design with advanced numerical simulation.

Method 1: Mold Design and Material Selection

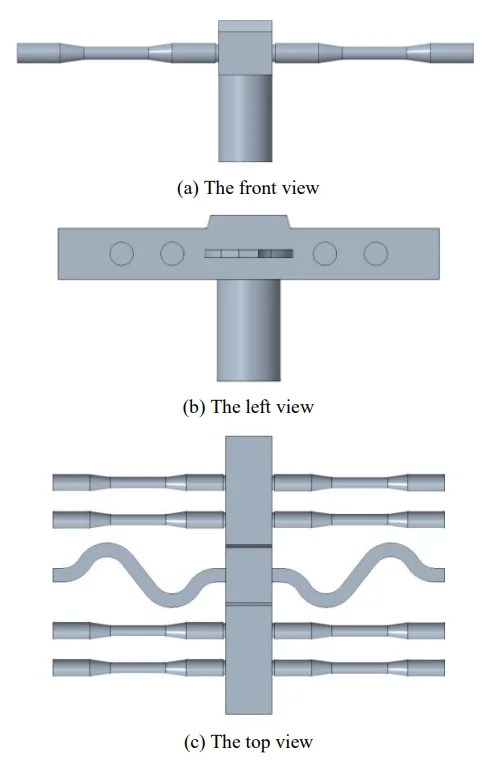

The tensile test bar casting was designed using Cero 4.0 software, featuring a new structure with eight dumbbell-shaped tensile test bars and two S-shaped fluidity test bars. The die itself was designed using H13 mold steel. The target casting material was the commercial Japanese aluminum alloy AC4B, which is compositionally similar to the Chinese national standard YL112 (YLAlSi9Cu3).

Method 2: Numerical Simulation with ProCAST

The core of the verification was conducted using ProCAST, a specialized finite element software for casting analysis.

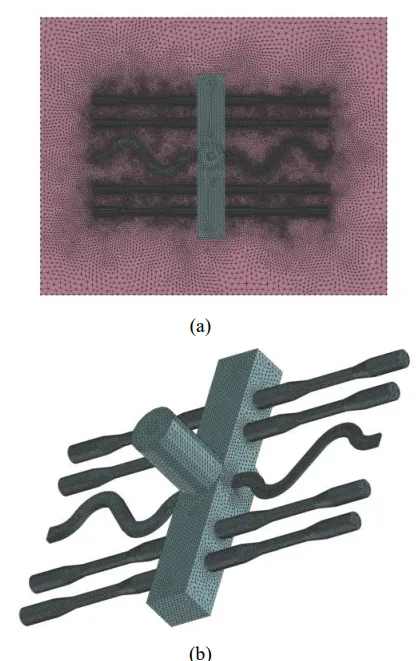

- Meshing: The die and casting models were meshed in the Visual-Mesh module, with a finer mesh in critical areas to ensure higher accuracy.

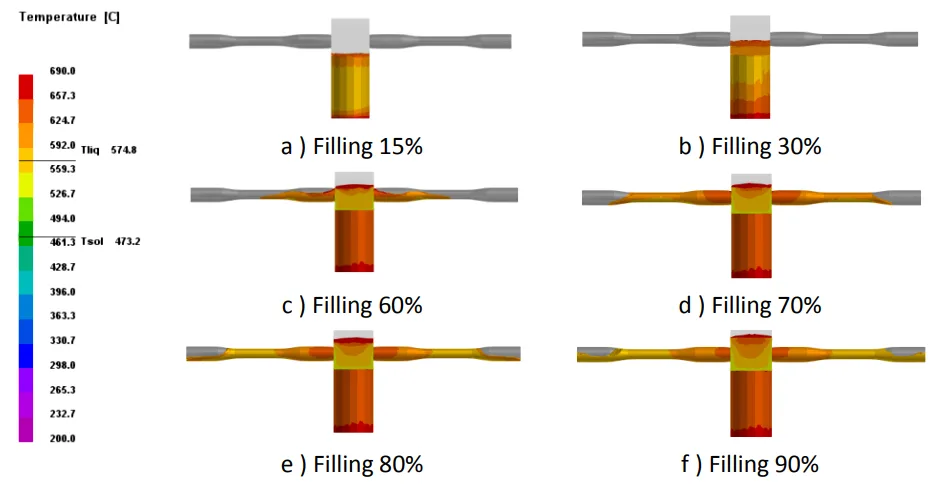

- Parameter Setting: Key process parameters affecting LPDC quality—pouring temperature, die temperature, and filling time—were analyzed. Based on orthogonal experiments, the optimal parameters were determined to be a pouring temperature of 690 °C and a die temperature of 300 °C.

- Analysis: The simulation analyzed the melt filling process, temperature field changes, and solidification process to predict casting defects and verify the mold's design.

The Breakthrough: Key Findings & Data

The numerical simulation provided critical insights that validated the new die design and process parameters.

Finding 1: Stable and Defect-Free Mold Filling

The simulation of the casting filling process demonstrated a highly stable and controlled melt flow. As shown in Figure 3, which visualizes the aluminum liquid temperature at various filling stages (15%, 30%, 60%, 70%, 80%, and 90%), the process was smooth. The analysis confirmed there was "no tumbling, impacting or spattering in the aluminum filling," which are common causes of defects like oxide inclusions and gas porosity. This stability is crucial for producing high-integrity test bars.

Finding 2: Predictable Solidification and Microstructure Formation

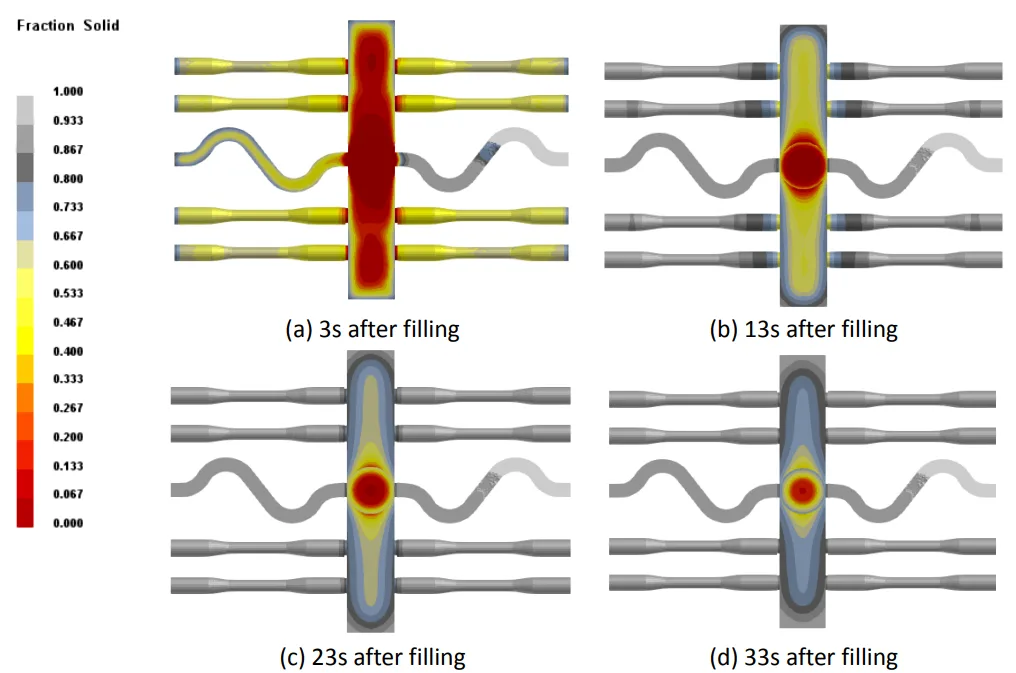

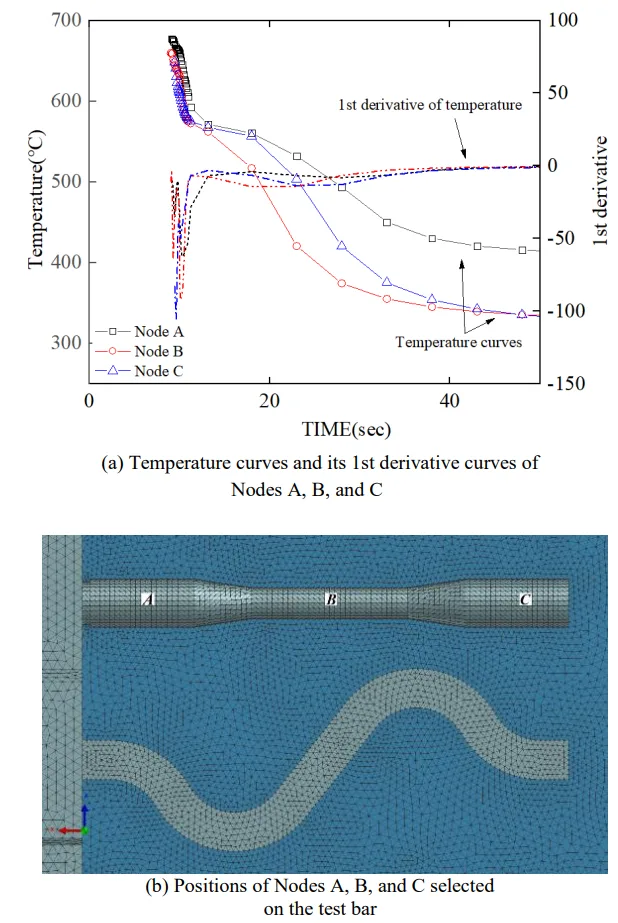

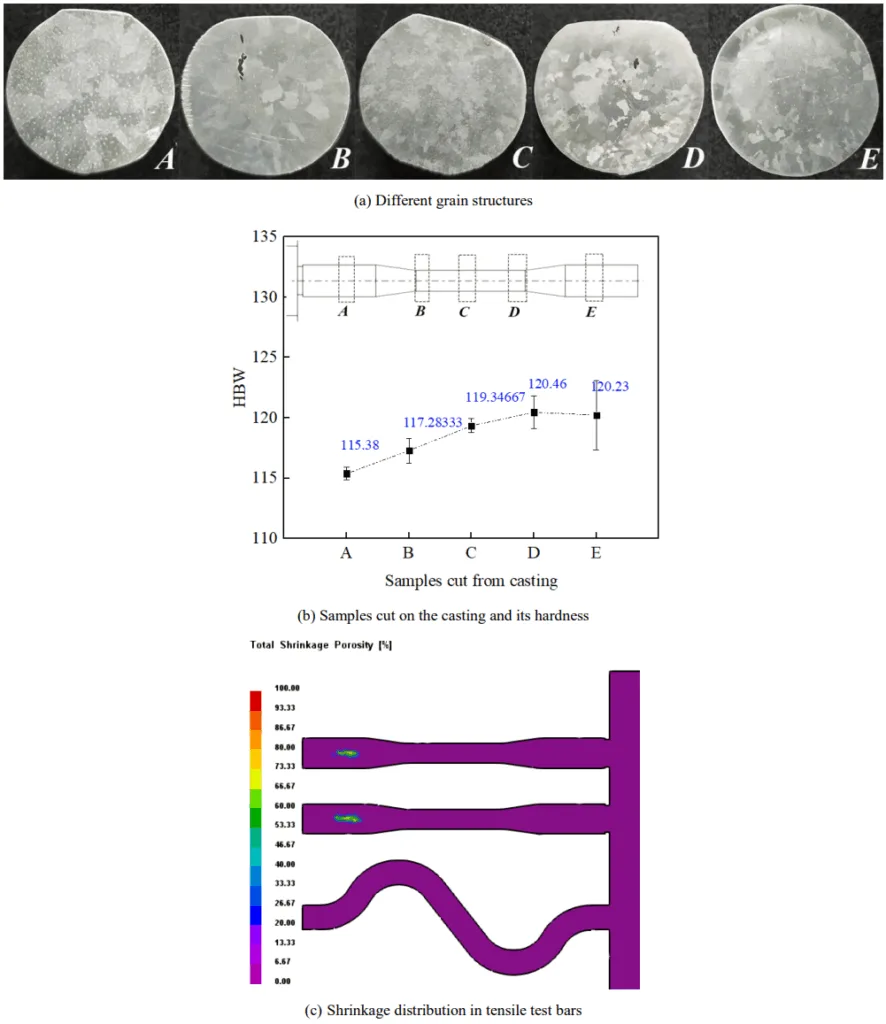

The simulation accurately modeled the solidification process, confirming that the design promotes sound castings. Figure 4 shows the solidification progress at 3s, 13s, 23s, and 33s after filling. The results indicated "no casting lap or short run during the solidification process." Furthermore, analysis of the final casting (Figure 7) revealed a direct correlation between the distance from the gate and the final material properties.

- Grain Structure & Hardness: As shown in Figure 7(a) and 7(b), the crystal grains become progressively finer and the Brinell hardness (HBW) increases with distance from the gate (from 115.38 HBW at point A to 120.46 HBW at point D).

- Shrinkage Porosity: The simulation predicted slight shrinkage at the furthest point (E), as seen in Figure 7(c). This was confirmed by a slight drop in hardness at sample E, validating the simulation's ability to predict feeding-related defects.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting pouring temperature to 690 °C and mold temperature to 300 °C can achieve a stable, defect-free filling process for similar Al-Si alloys in LPDC. This provides a validated starting point for process optimization.

- For Quality Control Teams: The data in Figure 7 of the paper illustrates the direct effect of solidification sequence on hardness. This relationship could inform new quality inspection criteria, where hardness measurements at specific locations can be used to verify casting integrity and consistency.

- For Design Engineers: The findings indicate that the runner and gate design directly influences the solidification pattern, grain structure, and final mechanical properties. The successful design of this test bar die serves as a valuable reference for designing gating systems that promote directional solidification and minimize defects in production components.

Paper Details

Design and Verification of a New Test Bar Die for LPDC Process Based on Numerical Simulation

1. Overview:

- Title: Design and Verification of a New Test Bar Die for LPDC Process Based on Numerical Simulation

- Author: Yang Zhao, Bingrong Zhang *, Xinping Hu

- Year of publication: 2020

- Journal/academic society of publication: International Journal of Mechanical Engineering and Robotics Research Vol. 9, No. 9, September 2020

- Keywords: ProCAST, LPDC, test bar, fluidity

2. Abstract:

In order to unify the standard for the manufacture of tensile test bars for LPDC process, a new die for LPDC process was designed. Based on the simulation results of the casting processes of the test bar die, the location and types of casting defects were analyzed, being helpful to select more suitable casting process parameters for the test bar. In this paper, the LPDC process was applied with suitable parameters based on the simulation results. The rationality of the mold design was verified. Finally, based on the simulation results, the melt filling process inside the test bar mold and the temperature field change at different points were analyzed, and the rationality of the mold design was verified.

3. Introduction:

The aluminum alloy castings produced by the Low-Pressure Die Casting (LPDC) process offer good comprehensive mechanical properties, high production efficiency, and high metal utilization, which is unmatched by gravity casting. However, a uniform standard for the test bar casting method used to determine the performance of LPDC castings is lacking, and it is often replaced by gravity casting methods. Studies have shown that the mechanical properties of separately cast bars by LPDC are better than those produced by gravity. The increasing application of Computer-Aided Engineering (CAE), particularly specialized software like ProCAST, aids in designing casting processes and reducing reliance on empirical worker experience. This paper details the design of a new test bar casting die for the LPDC process, using ProCAST simulation to verify the design's accuracy and to propose a new standardized detection process for LPDC casting performance.

4. Summary of the study:

Background of the research topic:

The study is set against the backdrop of the advanced LPDC process for aluminum alloys, which offers significant advantages over traditional gravity casting. The primary issue identified is the absence of a standardized method for producing test bars to evaluate the mechanical properties of LPDC castings, leading to inconsistent and potentially inaccurate quality assessments.

Status of previous research:

Previous research by Junming Cheng et al. confirmed the difference in tensile values between test bars made via LPDC and gravity casting, with LPDC yielding superior properties. Work by Xinping Hu et al. demonstrated the utility of CAE in simulating and analyzing the casting of Al-Si alloys. The integration of ProCAST software with Visual-Environment (VE) has made it a powerful tool for analyzing casting, welding, and heat treatment processes.

Purpose of the study:

The main purpose was to design a new test bar die specifically for the LPDC process to unify the manufacturing standard. The study aimed to use numerical simulation to verify the rationality of the mold design, analyze the casting process, identify optimal parameters, and confirm that this new method could serve as a reliable detection process for the performance of LPDC castings.

Core study:

The core of the study involved the complete cycle of design, simulation, and verification. A new test bar die, incorporating both tensile and fluidity test bars, was designed. This design was then modeled and simulated using ProCAST software under optimized LPDC process parameters. The simulation results, including the melt filling process, solidification, and temperature field changes, were analyzed in detail. Finally, the simulation was validated through production verification, which involved measuring the properties of actual castings produced using the new die and comparing them with simulation predictions and industry standards.

5. Research Methodology

Research Design:

The research followed a design-and-verify methodology. A new test bar die was designed using Cero 4.0 software. The verification was primarily conducted through numerical simulation using the ProCAST module within the Visual-Environment (VE) software suite. The simulation results were then compared with physical casting trials to confirm their accuracy.

Data Collection and Analysis Methods:

- Design: The die was designed to produce eight dumbbell-shaped tensile test bars and two S-shaped fluidity test bars. The material for the die was H13 mold steel.

- Simulation: The casting process for AC4B aluminum alloy was simulated. The model was meshed using Visual-Mesh. Orthogonal experiments were used to determine optimal process parameters (pouring temperature of 690 °C, mold temperature of 300 °C). The simulation analyzed melt filling, solidification (fraction solid), and temperature changes at specific nodes.

- Verification: Physical castings were produced. The length of the S-shaped fluidity bars was measured at different temperatures. Tensile test bars were sectioned, polished, and etched to observe grain structures. Brinell hardness was measured at different points along the bars.

Research Topics and Scope:

The research was focused on the design and verification of a new test bar die for the LPDC process. The scope included the 3D design of the die, finite element modeling and simulation of the casting process, analysis of simulation results (filling, solidification, temperature fields), and physical verification of the casting's fluidity, microstructure, and hardness.

6. Key Results:

Key Results:

- The simulation of the filling process showed a stable melt flow without tumbling, impacting, or spattering, indicating a low probability of related defects.

- The solidification simulation confirmed that the casting would solidify without defects such as laps or short runs, with the process completing around 33 seconds after filling.

- Temperature analysis at different nodes (A, B, C) on the test bar showed a consistent cooling rate without large fluctuations, indicating a stable solidification process.

- Physical verification showed that the grain size of the cast samples decreased with increasing distance from the gate, while the overall hardness increased, correlating with the simulated solidification pattern.

- The simulation accurately predicted a weak feeding effect at the furthest sample position (E), which was confirmed by a slight drop in hardness compared to the preceding sample (D).

- The new die and LPDC process parameters produced test bars with hardness values higher than the industry standard, verifying the rationality of the design.

Figure Name List:

- Figure 1. Shape of tensile specimen

- Figure 2. Finite element models

- Figure 3. Aluminum liquid temperature in casting filling

- Figure 4. Solidification process of the casting

- Figure 5. Temperature changes at different locations during test bar cooling

- Figure 6. Length of S-shaped test bars

- Figure 7. Macroscopic structures and hardness of test bar

7. Conclusion:

A new LPDC test bar metal die was successfully designed, and its pouring process was simulated using the ProCAST module. The simulation identified optimal process parameters and estimated the possibility of defect formation. The study demonstrated that the new die can be used to determine the fluidity of aluminum liquid under the LPDC process. Finally, anatomical and grain observation of the test bar castings revealed that the hardness was higher than the industry standard, which verified the rationality of the die design. The mold is reasonable and provides guiding significance for determining the parameters of the actual LPDC process.

8. References:

- [1] T. Liang, Y. Qu, X. Liu, F. Wang, and M. Zhang, "Simulation of filling and solidification processes of rump pan by ProCAST," Advanced Materials Research, vol. 2605, no. 785, 2013.

- [2] S. Lu, F. Xiao, S. Zhang, Y. Mao, and B, Liao, "Simulation study on the centrifugal casting wet-type cylinder liner based on ProCAST," Applied Thermal Engineering, vol. 73, pp, 512-521. 2014.

- [3] J. Wang, P. Fu, H.Liu, D. Li, and Y. Li, "Shrinkage porosity criteria and optimized design of a 100-ton 30Cr2Ni4MoV forging ingot," Mater. Des, vol. 35 pp. 446-456. 2012.

- [4] J. Cheng, Q. Lu, L. Li, H. Li, "A study on the mold of low- pressure casting of aluminum alloy test bar," Special Casting, vol. 3, pp. 67-69, 2014.

- [5] H. Lu, R. Chen, Y. Zhao, L. Wu, Z. Li, and H. Yang, "Numerical simulation and process optimization of aluminum alloy connecting rod based on ProCAST," Advanced Materials Research, vol. 712, 2013.

- [6] X. Hu, L. Xie, J. Zhang, "Self-tempering effect of near eutectic Al-Si casting with different wall thickness solidified and cooled in permanent die," Trans. Nonferrous Met. Soc. China, vol. 21, pp. 2576-2583, 2011.

- [7] S. Lu, F. Xiao, S. Zhang, Y. Mao, and B. Liao, "Simulation study on the centrifugal casting wet-type cylinderliner based on ProCAST," Applied Thermal Engineering, vol. 73, pp. 512-521, 2014.

- [8] H. Liu, F. Feng, C. Yan, and X. Zheng, "Computer simulation of the filling process of air intake hood based on ProCAST," Advanced Materials Research, vol. 1684, no. 487, 2012.

- [9] K. S. Keerthiprasan, M. E. Murali, P. G. Mukunda, S. Ajumdar, "Numerical simulation and cold modeling experiments on centrifugal casting, Metall," Mater. Trans, vol. 42, pp. 144-155, 2011.

- [10] N. Hua, L. Tian, Z. Cao, Z. Yu, F. Cai, "Centroid, area and volume of revolution of a plane figure," Stud. Coll. Math, vol. 16, pp. 50-52, 2013.

- [11] N. Song, Y. Luan, Y. Bai, Z. Xu, X. Kang, D. Li, "Numerical simulation of solidification of work roll in centrifugal casting process," J. Mater. Process. Technol, vol. 28, pp. 147-154, 2014

Expert Q&A: Your Top Questions Answered

Q1: Why was the AC4B aluminum alloy specifically chosen for this simulation and testing?

A1: The paper states that the commercial Japanese brand aluminum alloy AC4B was selected because its composition is close to the YL112 (YLAlSi9Cu3) in the Chinese national standard GB/T1173-1995. This similarity makes the results relevant to a widely used standard. Additionally, its known liquidus (574.8 °C) and solidus (473.2 °C) temperatures, calculated by the VE software, allowed for precise and accurate parameter setting within the ProCAST simulation.

Q2: What was the significance of finding the optimal process parameters of 690 °C pouring temperature and 300 °C mold temperature?

A2: These parameters were identified through orthogonal testing as the optimal combination for achieving a stable and defect-free casting process with this specific die and alloy. The simulation results shown in Figures 3 and 4 are based on these parameters. This provides a validated baseline for engineers, significantly reducing the trial-and-error often required in process setup and ensuring the production of high-quality, representative test bars.

Q3: How does the S-shaped test bar contribute to the verification process?

A3: The two S-shaped test bars, with different thicknesses (3 mm and 6 mm), were designed specifically to test the fluidity of the aluminum melt under LPDC conditions. As shown in Figure 6, the length of the filled portion of these bars was measured at different pouring temperatures. This provides a direct, quantitative measure of how well the melt flows into thin sections, which is a critical factor in producing complex castings.

Q4: The paper mentions that the hardness of sample E was lower than sample D. Why is this finding important?

A4: This finding is crucial because it demonstrates the predictive power of the simulation. The simulation (Figure 7c) predicted weak feeding and slight shrinkage porosity at position E, the furthest point from the gate. The measured hardness data (Figure 7b) confirmed this prediction, as the hardness at E was lower than at D, which is characteristic of areas with minor porosity. This correlation builds confidence that the simulation can be trusted to identify potential defect locations in actual production components.

Q5: What makes this new die design superior to simply using a gravity casting mold for LPDC test bars?

A5: The paper explicitly states that when gravity casting was attempted with this mold, "the test bar forming was difficult, and the performance was worse than that of the test bar formed by the LPDC process." This confirms that a die designed for the pressurized, controlled filling of LPDC is fundamentally different from one designed for gravity pouring. This new die is optimized for the LPDC process, ensuring the resulting test bars accurately reflect the superior mechanical properties achievable with LPDC.

Conclusion: Paving the Way for Higher Quality and Productivity

The lack of a standardized test bar for the LPDC process has long been an obstacle to accurate quality assessment. This research closes that gap by presenting a new, validated test bar die design. Through rigorous LPDC Process Simulation using ProCAST, the study confirms that this new die, combined with optimized parameters, produces sound, reliable test bars whose properties correlate directly with predictable solidification patterns. This provides the industry with a powerful tool for accurately gauging the performance of LPDC castings.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Design and Verification of a New Test Bar Die for LPDC Process Based on Numerical Simulation" by "Yang Zhao, Bingrong Zhang, and Xinping Hu".

Source: https://doi.org/10.18178/ijmerr.9.9.1240-1245

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.