Paper Title Optimizing EN AC 46000 Alloy Performance: The Real Impact of Copper Content in High Pressure Die Casting

This technical summary is based on the academic paper "Characterization of microstructural and mechanical properties of high-pressure die-cast en ac 46000 alloy" by M. Tocci, S. Ferri, L. Montesano, and A. Pola, published in La Metallurgia Italiana (2021). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: High Pressure Die Casting

- Secondary Keywords: EN AC 46000, Aluminum Alloy, Copper Content, Intermetallics, Mechanical Properties, Microstructure

Executive Summary

- The Challenge: To understand the conflicting effects of varying copper (Cu) content on the mechanical performance of the widely used EN AC 46000 aluminum alloy in an industrial High Pressure Die Casting (HPDC) environment.

- The Method: Real industrial castings were produced using a 2500-ton HPDC machine with EN AC 46000 alloy at two Cu levels (2 wt.% and 4 wt.%), and samples were analyzed from zones with different cooling rates.

- The Key Breakthrough: Increasing Cu content from 2% to 4% boosts yield strength but significantly reduces ductility and ultimate tensile strength, primarily by increasing the volume of brittle intermetallic particles.

- The Bottom Line: Higher copper content is not a simple upgrade; it creates a critical trade-off between yield strength and ductility, which is heavily influenced by the casting's cooling conditions and resulting porosity.

The Challenge: Why This Research Matters for HPDC Professionals

For professionals in the automotive industry and beyond, the Al-Si-Cu alloy EN AC 46000 is a cornerstone of High Pressure Die Casting. It offers high productivity, low cost, and the ability to form complex, thin-walled parts. However, its performance is not without challenges. The formation of porosity during rapid filling and the presence of Fe-containing intermetallic particles are critical aspects that dictate the final quality of the component.

While the role of iron (Fe) in reducing die soldering is well-documented, the precise effect of copper (Cu) has been less clear, with previous studies showing conflicting results. Most research has been conducted on primary alloys with low Fe or on lab-scale castings, which don't fully replicate the thermal and fluid dynamics of a real industrial process. This study closes that gap by investigating the influence of Cu content—varied within the alloy's standard limits—on large, industrially produced castings, providing results that are directly applicable to real-world manufacturing challenges.

The Approach: Unpacking the Methodology

To ensure industrial relevance, this study was conducted on actual castings produced using a 2500-ton HPDC machine. The core of the research involved a comparative analysis of the EN AC 46000 alloy with two different copper concentrations:

- Alloy 1 (Cu2): Contained approximately 2 wt.% Cu (the minimum allowed by the standard).

- Alloy 2 (Cu4): Contained approximately 4 wt.% Cu (the maximum allowed by the standard).

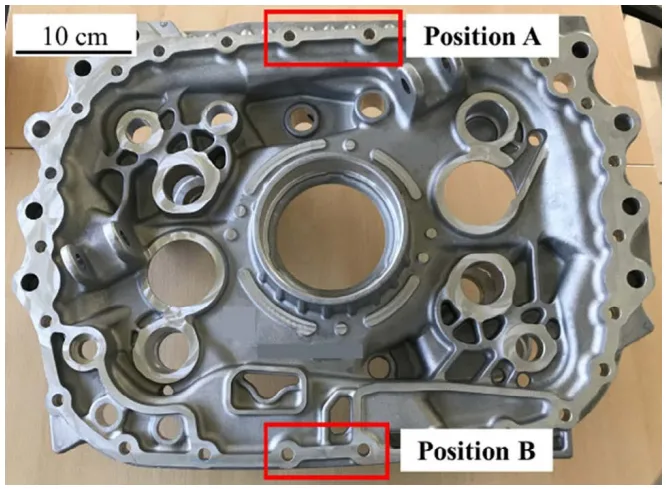

To understand the impact of solidification conditions, samples were extracted from two distinct areas of the same casting:

- Position A: Located near the gate, representing a warmer zone with a slower solidification rate.

- Position B: Located opposite the gate, representing a colder zone with a faster solidification rate.

A comprehensive suite of analyses was performed on samples from these locations:

- Microstructural Characterization: Secondary Dendrite Arm Spacing (SDAS) and porosity levels were measured using optical microscopy.

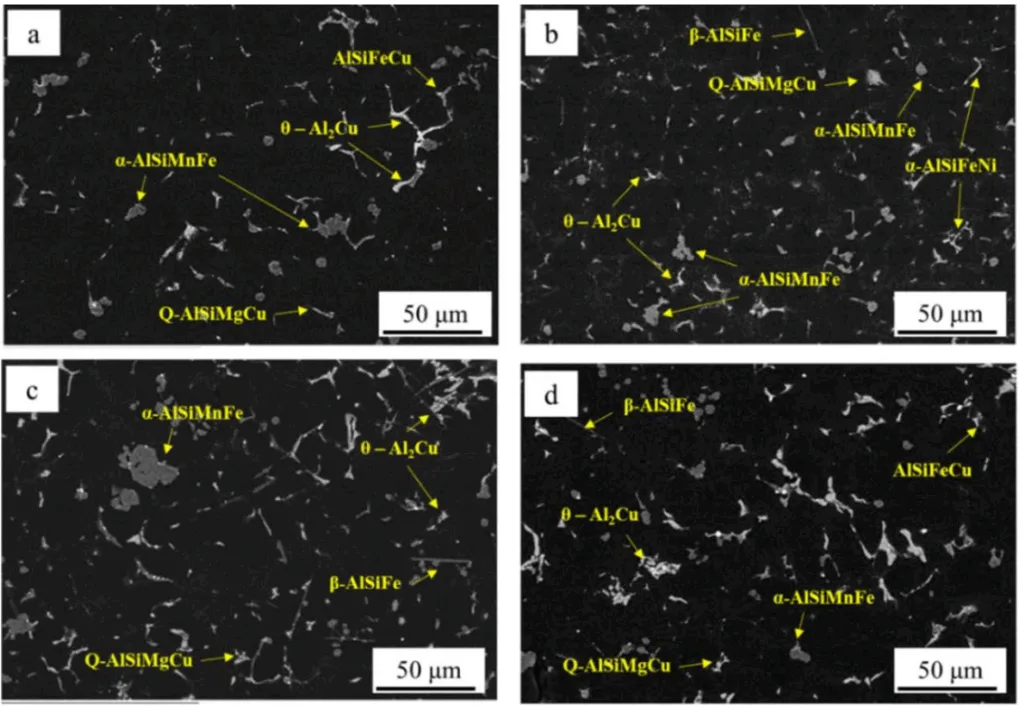

- Intermetallic Analysis: A Scanning Electron Microscope (SEM) with Energy Dispersive Spectroscopy (EDS) was used to identify and quantify the area fraction, number density, and size distribution of intermetallic particles.

- Mechanical Testing: Tensile tests were conducted to determine Ultimate Tensile Strength (UTS), Yield Strength (YS), and Elongation (El. %), providing a complete picture of the material's performance under load.

The Breakthrough: Key Findings & Data

The research delivered clear, data-driven insights into the trade-offs associated with adjusting copper content in EN AC 46000 alloy.

Finding 1: Higher Copper Content Doubles Intermetallic Volume and Reduces Ductility

The most significant microstructural change observed was the increase in intermetallic particles with higher copper content. In the slower-cooling zone (Position A), the area fraction of intermetallics more than doubled from 4.1% in the Cu2 alloy to 8.2% in the Cu4 alloy (Table 3). These brittle particles act as stress concentration points, leading to premature failure.

This directly impacted mechanical properties. As shown in Figure 4, the Cu4-A sample exhibited a significant drop in ductility (elongation) and a lower Ultimate Tensile Strength (UTS) compared to its Cu2-A counterpart. The Quality Index, which combines strength and ductility, fell from 321 for Cu2-A to just 260 for Cu4-A, quantifying the degradation in overall performance.

Finding 2: Higher Copper Boosts Yield Strength, But Porosity Becomes a Critical Failure Point

While higher copper content was detrimental to ductility, it provided a notable increase in Yield Strength (YS), as seen in Figure 4. The researchers attribute this to the post-casting water cooling process acting as an effective quench. The higher Cu concentration in the Cu4 alloy leads to more copper being retained in the solid solution, which hinders dislocation motion and strengthens the material against initial plastic deformation.

However, this benefit can be completely negated by casting defects. The Cu4-B sample (high copper, fast cooling) showed the highest porosity level at 1.25% (Table 2). This high porosity, caused by hindered liquid feeding during rapid solidification, drastically reduced the load-bearing area. As a result, the Cu4-B sample had the worst overall performance, with the lowest Quality Index of 208, demonstrating that in fast-cooling zones, the negative effect of porosity can overwhelm any potential benefits of the alloy chemistry.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting copper content is a critical trade-off. Increasing Cu to boost yield strength may not be effective if the process cannot control porosity, especially in thinner sections or areas far from the gate that cool rapidly. The data indicates that for parts with complex geometries and varying cooling rates, a lower Cu content (e.g., 2%) may provide more consistent and reliable overall mechanical properties.

- For Quality Control Teams: The data in Table 2 (Porosity) and Figure 4 (Tensile Properties) illustrates the critical effect of porosity on the performance of high-Cu alloys. This suggests that inspection criteria should be particularly stringent for porosity in components cast with ~4% Cu alloy, as these defects are shown to be a primary driver of mechanical failure, more so than in lower-Cu variants.

- For Design Engineers: The findings indicate that part geometry, which dictates cooling rates, interacts strongly with alloy composition. For EN AC 46000, specifying a high copper content for a design with slow-cooling, thick sections (like Position A) could lead to an excessive volume of brittle intermetallics. Conversely, specifying it for a design with fast-cooling, thin sections (like Position B) could increase susceptibility to porosity-related failures.

Paper Details

Characterization of microstructural and mechanical properties of high-pressure die-cast en ac 46000 alloy

1. Overview:

- Title: Characterization of microstructural and mechanical properties of high-pressure die-cast en ac 46000 alloy

- Author: M. Tocci, S. Ferri, L. Montesano, A. Pola

- Year of publication: 2021

- Journal/academic society of publication: La Metallurgia Italiana - International Journal of the Italian Association for Metallurgy

- Keywords: HIGH PRESSURE DIE CASTING, MICROSTRUCTURE, INTERMETALLICS, TENSILE PROPERTIES

2. Abstract:

The present research focuses on the characterization of microstructural and mechanical properties of real castings produced by HPDC using EN AC 46000 alloy. The Cu content of the alloy was varied inside the limits prescribed by the standard for EN AC 46000 alloy to investigate the influence of Cu on the material performance and to provide results useful for industrial applications. Castings with Cu content of 2 wt.% and 4 wt.% were industrially produced using a 2500-ton HPDC machine. Two areas of the casting with different cooling rates were selected to obtain samples for microstructural and mechanical characterization. In particular, area fraction, number density and equivalent diameter of intermetallic compounds were investigated, and the size distribution of these particles were statistically evaluated. Finally, hardness measurements and tensile tests were performed and the results were correlated to microstructural features and solidification conditions to deeply understand the alloy behavior.

3. Introduction:

Al-Si-Cu alloys are widely used for high-pressure die-casting (HPDC) processes. In particular, AlSi9Cu3 alloy (EN AC 46000) is frequently applied for the production of various components by HPDC, especially for the automotive industry. It offers advantages such as high productivity, low cost, and the ability to obtain complex shapes with good microstructural properties due to fast solidification. However, challenges include porosity formation and the presence of Fe-containing intermetallic particles. While Fe has beneficial effects like reducing die soldering, its impact is well-studied. In contrast, few studies have examined the effect of Cu on the properties of secondary die-casting alloys, with some conflicting findings. This study aims to clarify the role of Cu by studying its effect on industrial-scale castings to provide results directly applicable to industry.

4. Summary of the study:

Background of the research topic:

The EN AC 46000 (AlSi9Cu3) alloy is a key material in HPDC for the automotive sector. Its performance is dictated by its microstructure, which is influenced by both alloy composition and process conditions like cooling rate. Key microstructural features affecting performance are porosity and intermetallic compounds.

Status of previous research:

Previous research has thoroughly investigated the effects of Fe, Mn, and Cr on intermetallic formation. However, the effect of Cu in secondary die-casting alloys is less understood. Some studies noted that high Cu content increased porosity, while others found it enhanced tensile strength. These studies often varied multiple parameters at once or used lab-scale samples, making it difficult to isolate the true effect of Cu in an industrial setting.

Purpose of the study:

The purpose was to systematically investigate the influence of Cu content, varied within the standard range (2 wt.% to 4 wt.%), on the microstructural and mechanical properties of the commercial EN AC 46000 alloy. The study used real, large-scale industrial castings to ensure the findings are relevant and useful for industrial applications.

Core study:

The study compared two batches of EN AC 46000 alloy, one with ~2 wt.% Cu (Cu2) and another with ~4 wt.% Cu (Cu4). Samples were taken from two locations on the castings representing slow (Position A) and fast (Position B) cooling rates. The research quantified and correlated microstructural features (SDAS, porosity, intermetallic area fraction, and size) with mechanical properties (UTS, YS, Elongation) to understand the alloy's behavior under different compositional and solidification conditions.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. The primary independent variable was the copper content in the EN AC 46000 alloy (2% vs. 4%). The secondary variable was the cooling rate, represented by two different sampling locations (A and B) on an industrial casting. The dependent variables were the microstructural features and mechanical properties.

Data Collection and Analysis Methods:

- Material Production: Castings were produced on a 2500-ton HPDC machine.

- Chemical Analysis: Optical emission spectrometer was used to verify the composition of the final castings.

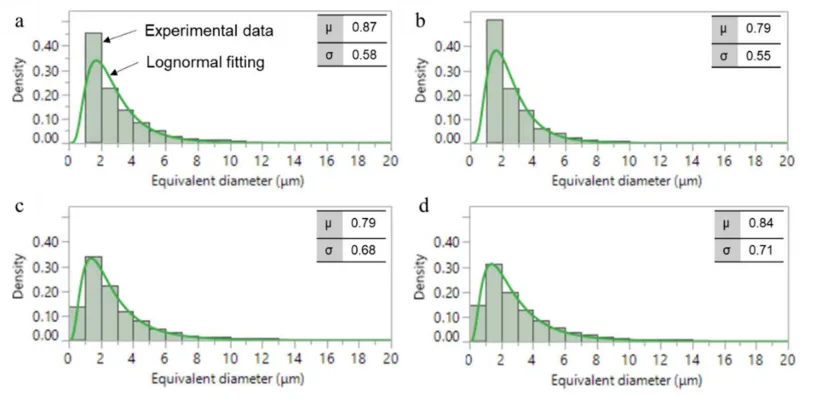

- Microstructural Analysis: Samples were mirror-polished and observed with an optical microscope to calculate SDAS and porosity. A Scanning Electron Microscope (SEM) with EDS was used to identify and analyze intermetallic compounds. Digital image analysis on 20 SEM images per condition was used to quantify intermetallic area fraction, density, and equivalent diameter.

- Mechanical Testing: Tensile specimens were machined according to UNI EN ISO 6892-1 standard. Tensile tests were performed at room temperature to obtain stress-strain curves, from which UTS, YS, and Elongation % were derived. The Quality Index was calculated from these results.

Research Topics and Scope:

The research focused exclusively on the as-cast properties of EN AC 46000 alloy produced by HPDC. It investigated the influence of Cu content within the standard specification and the effect of cooling rate as determined by location within a single, complex industrial casting. The study did not investigate the effects of heat treatment or other post-processing operations.

6. Key Results:

Key Results:

- Increasing Cu content from 2 wt.% to 4 wt.% significantly increases the total area fraction of intermetallic particles, especially in slower cooling zones (from 4.1% to 8.2% in Position A).

- The particle size distribution of intermetallics is similar for all conditions, with most particles having an equivalent diameter below 6 µm.

- The alloy with 4 wt.% Cu exhibits higher Yield Strength (YS) but lower Ultimate Tensile Strength (UTS) and significantly reduced elongation compared to the 2 wt.% Cu alloy.

- The fastest cooling zone (Position B) combined with high Cu content (Cu4-B) resulted in the highest porosity level (1.25%), leading to the poorest overall mechanical performance and the lowest Quality Index (208).

- The increase in YS for the high-Cu alloy is attributed to solid solution strengthening from Cu retained in the aluminum matrix after the post-casting water cooling.

Figure Name List:

- Fig.1 - Picture of the casting used for the present study with indication of the analyzed areas.

- Fig.2 -SEM images and intermetallics identification for a) Cu2-A, b) Cu2-B, c) Cu4-A and d) Cu4-B samples.

- Fig.3 - Experimental data and relative lognormal fitting for intermetallic particles in the studied samples as a function of equivalent diameter: a) Cu2-A, b) Cu2-B, c) Cu4-A and d) Cu4-B samples.

- Fig.4 - Tensile properties of studied samples.

7. Conclusion:

The study concluded that increasing the Cu content in EN AC 46000 alloy from 2 wt.% to 4 wt.% leads to a higher total area fraction of intermetallic particles. This results in lower tensile strength and ductility. The effect is particularly pronounced in areas with high porosity, which can be exacerbated by the combination of high Cu content and fast cooling rates. On the other hand, a higher Cu content was found to improve yield strength, likely due to a greater amount of Cu retained in solid solution after the post-casting quench. Therefore, selecting the optimal Cu content requires a careful balance based on the specific mechanical requirements and geometric complexity of the casting.

8. References:

- [1] J.A. Taylor, Iron-containing intermetallic phases in Al-Si based casting alloys, Proc. Mater. Sci. 1 (2012) 19-33.

- [2] Z.W. Chen, M.Z. Jahedi, Die erosion and its effect on soldering formation in high pressure die casting of aluminium alloys, Mater. Des. 20-6 (1999) 303-309.

- [3] H. Yang, S. Ji, Z. Fan, Effect of heat treatment and Fe content on the microstructure and mechanical properties of die-cast Al-Si-Cu alloys, Mater. Des. 85 (2015) 823-832.

- [4] A. Fabrizi, S. Ferraro, G. Timelli, The influence of Sr, Mg and Cu addition on the microstructural properties of a secondary AlSi9Cu3(Fe) die casting alloy, Mater. Char. 85 (2013) 13-25.

- [5] I. Outmani, L. Fouilland-Paille, J. Isselin, M. El Mansori, Effect of Si, Cu and processing parameters on Al-Si-Cu HPDC castings, J. Mater. Process. Technol. 249 (2017) 559-569.

- [6] Y. Zheng, W. Xiao, S. Ge, W. Zhao, S. Hanada, C. Ma, Effects of Cu content and Cu/Mg ratio on the microstructure and mechanical properties of Al-Si-Cu-Mg alloys, J. Alloys Compd. 649 (2015) 291-296.

- [7] S. Seifeddine, E. Sjölander, T. Bogdanoff, On the Role of Copper and Cooling Rates on the Microstructure, Defect Formations and Mechanical Properties of Al-Si-Mg Alloys, Materials Sciences and Applications 4 (2013) 171-178.

- [8] A.M.A. Mohamed, F.H. Samuel, S. Al Kahtani, Microstructure, tensile properties and fracture behavior of high temperature Al-Si-Mg-Cu cast alloys, Mat. Sci. Eng. A 577 (2013) 64-72.

- [9] S.G. Shabestari, H. Moemeni, Effect of copper and solidification conditions on the microstructure and mechanical properties of Al-Si-Mg alloys, J. Mater. Process. Technol. 153-154 (2004) 193-198.

- [10] R.N. Lumley, R.G. O'Donnell, D.R. Gunasegaram, T. Kittel-Sherri, M. Gershenzon, A.C. Yob, I.J. Polmear, The role of alloy composition in the heat treatment of aluminium high pressure die castings, Metall. Sci. Techn. 26 (2008) 2-11.

- [11] X.Y. Jiao, J. Wang, C.F. Liu, Z.P. Guo, G.D. Tong, S.L. Ma, Y. Bi, Y.F. Zhang, S.M. Xiong, Characterization of high-pressure die-cast hypereutectic Al-Si alloys based on microstructural distribution and fracture morphology, J. Mater. Sci. Technol. 35 (2019) 1099-1107.

- [12] S.G. Shabestari, The effect of iron and manganese on the formation of intermetallic compounds in aluminum-silicon alloys, Mat. Sci. Eng. A 383 (2004) 289-298.

- [13] S. Ferraro, G. Timelli, Influence of Sludge Particles on the Tensile Properties of Die-Cast Secondary Aluminum Alloys, Metall. Mater. Trans. B 46B (2015) 1022-1034.

- [14] M. Drouzy, S. Jacob, M. Richard, Interpretation of tensile results by means of Quality Index and probable yield strenth, International cast metals journal 5-2 (1980) 43-50.

- [15] S. Ferraro, A. Bjurenstedt, S. Seifeddine, On the Formation of Sludge Intermetallic Particles in Secondary Aluminum Alloys, Metall. Mater. Trans. A 46A (2015) 3713-3722.

- [16] M. Tiryakioğlu, Si particle size and aspect ratio distributions in an Al-7%Si-0.6%Mg alloy during solution treatment, Mat. Sci. Eng. A 473-1-2 (2008) 1-6.

- [17] S. Ferraro, A. Fabrizi, G. Timelli, Evolution of sludge particles in secondary die-cast aluminium alloys as function of Fe, Mn and Cr, Mater. Chem. Phys. 153 (2015) 168-179

Expert Q&A: Your Top Questions Answered

Q1: Why was it important to use a real, large industrial casting for this study instead of a simpler, lab-scale sample?

A1: The researchers explicitly state they used an actual casting of significant size "to make this study as close as possible to the industrial field." Lab-scale castings often have more uniform and predictable cooling conditions, which don't capture the complex thermal gradients and fluid flow turbulence seen in the production of real components. By analyzing different zones of an industrial part, the results provide a much more accurate and applicable understanding of how the alloy behaves in a true manufacturing environment.

Q2: The paper mentions that most intermetallic particles were below 6 µm in diameter. What is the significance of this finding?

A2: According to the paper, particles of this size typically correspond to proeutectic intermetallics, which form during the solidification of the casting itself. This is distinct from larger primary "sludge" particles, which can form in the holding furnace before casting. This finding is consistent with the calculated sludge factor (1.8-2) and the estimated sludge area fraction (~1%), suggesting that the vast majority of the intermetallics observed (which ranged from 4% to 8% area fraction) were formed in the die, not carried over from the furnace.

Q3: The 4% Cu alloy showed a higher Yield Strength (YS). What is the proposed mechanism for this increase?

A3: The paper explains that the castings are cooled in water after extraction from the die. This operation acts as an effective quenching process. For the Cu4 alloy, which has an excess of copper compared to the Cu2 alloy, this rapid cooling traps a higher amount of Cu in the solid solution of the aluminum matrix. This dissolved copper is effective in hindering dislocation motion during tensile testing, which manifests as an increase in the stress required to initiate plastic deformation, i.e., a higher yield strength.

Q4: Why did the Cu4-B sample (4% Cu, fast cooling) have the worst mechanical properties, even though it had a lower volume of intermetallics than the Cu4-A sample?

A4: The poor performance of the Cu4-B sample is directly linked to its high porosity level, which was measured at 1.25%—the highest of all samples. The paper suggests that in this colder, faster-solidifying zone, the formation of eutectic intermetallic phases hindered the feeding of liquid metal to compensate for shrinkage. This led to significant microporosity, which diminishes the effective load-bearing area of the material and acts as a potent crack initiator, overriding the influence of the intermetallic volume.

Q5: The study identifies two zones, A and B. What is the key difference between them and why does it matter?

A5: Position A is located near the gate and is described as the "warmer zone," meaning it solidifies more slowly. Position B is located opposite the gate and is the "coldest zone," solidifying much faster. This difference is critical because the cooling rate directly influences the microstructure. The slower cooling in Position A allowed more time for intermetallic particles to grow, resulting in a larger area fraction, while the faster cooling in Position B promoted the formation of porosity due to inadequate feeding.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear, industrially relevant framework for understanding the role of copper in EN AC 46000 alloy within High Pressure Die Casting. The key takeaway is that simply increasing copper content to the upper limit of the standard is not a universal solution for improving performance. It introduces a critical trade-off: the gain in yield strength comes at the cost of ductility and can significantly increase the risk of failure from both intermetallic embrittlement and porosity, depending on the part's geometry and cooling conditions.

For engineers aiming to optimize component integrity and manufacturing efficiency, this study underscores the need for a holistic approach. The choice of alloy chemistry must be made in concert with thoughtful part design and process control to manage cooling rates and minimize defects.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Characterization of microstructural and mechanical properties of high-pressure die-cast en ac 46000 alloy" by "M. Tocci, S. Ferri, L. Montesano, A. Pola".

- Source: La Metallurgia Italiana - November/December 2021, pagina 31-36.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.