- 98 Accesses

- Explore all metrics

Abstract

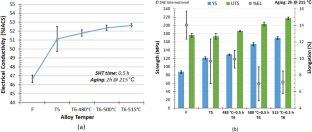

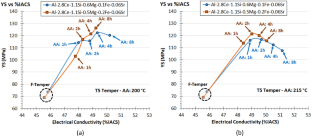

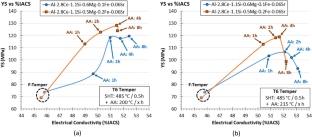

Lightweighting of electric vehicles is an important consideration to improve range and potentially reduce the vehicle price by downsizing expensive battery and motor components. Aluminum alloys have a combination of light weight, high electrical conductivity and strength that are required in e-motor applications to achieve high power output and efficiency. In this research, Al–Ce based high pressure die casting alloys were investigated in different heat treatment tempers to maximize mechanical properties while maintaining a high electrical conductivity. Testing of tensile properties and electrical conductivity were performed in the as-cast and heat-treated conditions, while microstructural characterization and solidification analysis were performed using scanning electron microscopy and the universal metallurgical simulator and analyzer, respectively. The results suggest that the Al–Ce–Si–Mg alloy had yield strength (YS) exceeding 110 MPa and electrical conductivity of at least 49 pct IACS (28.5 MS/m) in the T5 and T6 conditions, with elevated Fe levels causing a slight reduction in YS and conductivity. This combination of properties makes this alloy a promising alternative to the near pure Al or Cu-based alloys that are currently used in electric induction motors.

DOI https://doi.org/10.1007/s11661-024-07591-6

- Fig. 1

View in article

View in article - Fig. 2

View in article

View in article - Fig. 3

View in article

View in article - Fig. 4

View in article

View in article - Fig. 5

View in article

View in article - Fig. 6

View in article

View in article - Fig. 7

View in article

View in article - Fig. 8

View in article

View in article - Fig. 9

View in article

View in article - Fig. 10

View in article

View in article - Fig. 11

View in article

View in article - Fig. 12

View in article

View in article - Fig. 13

View in article

View in article - Fig. 14

View in article

View in article - Fig. 15

View in article

View in article

References

- “Electrification Trends Worldwide,” European Automobile Manufacturers’ Association (ACEA), 2022.

- L. Kirkpatrick: Aluminum Electrical Conductor Handbook, 3rd ed., The Aluminum Association, Washington, 1989, pp. 16.1–6.5.

- S. Palanivel, C. Kuehmann, J.R. Stucki, E. Filip, and P. Edwards: International Patent WO 2020/028730 A1, 1 August 2019.

- “Shape Casting Alloys Data Sheet—Alcan Rotor Alloys,” Rio Tinto Alcan, Montreal, 2004.

- “Primary Aluminum Casting Alloys,” Aluminum Reinfelden GmbH, Reinfelden, Germany, 2015.

- “NADCA Product Specification Standards for Die Casting,” 9th ed., North American Die Casting Association, Arlington Heights, 2015, pp. 3.6–3.7.

- “Aluminum Alloy – 6005A – T6 Extrusion,” Wilsons Ltd., Sawtry, 2018.

- “Alloy 6101 - North American Alloy Data Sheets,” Hydro Extrusion North America, Rosemont, 2019.

- G. Byczynski, A. Elsayed, and A. Lombardi: European Patent 19182661, 26 June 2019.

- Z.C. Sims, D. Weiss, S.K. McCall, M.A. McGuire, R.T. Ott, T. Geer, O. Rios, and P.A.E. Turchi: JOM, 2016, vol. 68, pp. 1940–47.Article CAS Google Scholar

- H.C. Liao, Y. Liu, C.L. Lu, and Q.G. Wang: Int. J. Cast Met. Res., 2015, vol. 28, pp. 213–20.Article CAS Google Scholar

- W. Yuan, Z. Liang, C. Zhang, and L. Wei: Mater. Des., 2012, vol. 34, pp. 788–92.Article CAS Google Scholar

- J.R. Davis: ASM Specialty Handbook: Aluminum and Aluminum Alloys, ASM International, Materials Park, 1993.

- X. Gao, Y. Zhao, X. Kai, W. Qian, L. Jin, C. Guan, and P. Sheng: J. Rare Earths, 2022, vol. 40, pp. 153–60.Article Google Scholar

- M.G. Mahmoud, A.O. Mosleh, M.S. Mohamed, M.H. El-Moayed, W. Khalifa, A.V. Pozdniakov, and S. Salem: J. Alloys Compd., 2023, vol. 948, 169805.Article CAS Google Scholar

- E. Aghaie, J. Stroh, D. Sediako, A. Rashidi, and A.S. Milani: Mater. Sci. Eng. A, 2020, vol. 793, 139899.Article CAS Google Scholar

- J. Shin, S. Ko, and K. Kim: J. Alloys Compd., 2015, vol. 644, pp. 673–86.Article CAS Google Scholar

- M. Mujahid and N.N. Engel: Scripta Metall., 1979, vol. 13, pp. 887–93.Article CAS Google Scholar

- W. Yuna, Z. Jianfeng, L. Hengcheng, W. Yongjun, and W. Yuping: J. Mater. Eng. Perform., 2016, vol. 25, pp. 2720–26.Article Google Scholar

- X. Xu, Z. Yang, Y. Ye, G. Wang, and X. He: Mater. Charact., 2016, vol. 119, pp. 114–19.Article CAS Google Scholar

- Q. Zhao, Z. Qian, X. Cui, Y. Wu, and X. Liu: J. Alloys Compd., 2016, vol. 666, pp. 50–57.Article CAS Google Scholar

- Q.G. Wang and C.J. Davidson: J. Mater. Sci., 2001, vol. 36, pp. 739–50.Article CAS Google Scholar

- A. Lombardi, G. Byczynski, B.G. Vidanalage, A. Fatima, and N.C. Kar: SAE Int. J. Adv. Curr. Pract. Mobility, 2023, vol. 5, pp. 2365–72.Article Google Scholar

- S. Shankar and D. Apelian: Int. J. Cast Met. Res., 2002, vol. 15, pp. 103–16.Article CAS Google Scholar

- R.J. Donahue, T.M. Cleary, and K.R. Anderson: European Patent 1683881A1, 2 August 2005.

- R.N. Lumley, R.G. Odonnell, D.R. Gunasegaram, and M. Givord: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 2564–74.Article CAS Google Scholar

- M.B. Djurdjevic, W.T. Kierkus, G.E. Byczynski, T.J. Stockwell, and J.H. Sokolowski: AFS Trans., 1999, vol. 14, pp. 173–79.Google Scholar

- M. Hosseinifar and D.V. Malakhov: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 825–33.Article Google Scholar

- M. Hosseinifar and D.V. Malakhov: J. Mater. Sci., 2008, vol. 43, pp. 7157–64.Article CAS Google Scholar

- X. Song, H. Yan, and X. Zhang: J. Rare Earths, 2017, vol. 35, pp. 412–18.Article CAS Google Scholar

- A. Mamala and W. Sciezor: Arch. Metall. Mater., 2014, vol. 59, pp. 413–17.Article CAS Google Scholar

- R.N. Lumley, I.J. Polmear, H. Groot, and J. Ferrier: Scripta Mater., 2008, vol. 58, pp. 1006–09.Article CAS Google Scholar

- B. Smyrak, B. Jurkiewicz, M. Zasadzinska, M. Gnielczyk, and P. Jalowy: Metals, 2020, vol. 10, pp. 1027–36.Article CAS Google Scholar

- A. Polat, M. Avsar, and F. Ozturk: Mater. Technol., 2015, vol. 49, pp. 487–93.Google Scholar

- S. Pogatscher, H. Antrekowitsch, H. Leitner, T. Ebner, and P.J. Uggowitzer: Acta Mater., 2011, vol. 59, pp. 3352–63.Article CAS Google Scholar