This article introduces the paper "About the impact on gravity cast salt cores in high pressure die casting and rheocasting".

1. Overview:

- Title: About the impact on gravity cast salt cores in high pressure die casting and rheocasting

- Authors: Andreas Schilling, Daniel Schmidt, Jakob Glück, Niklas Schwenke, Husam Sharabi, Martin Fehlbier

- Year: 2022

- Journal/Conference: Simulation Modelling Practice and Theory

- Keywords:

- Cast salt cores

- Lost core

- Core damage

- Rheocasting

- Flow-3D

- Simulation

- Core testing

- High pressure die casting

2. Research Background:

- Social/Academic Context:

- High pressure die casting (HPDC) accounts for 60% of aluminum castings and over half of non-ferrous castings in Germany.

- Increasing casting complexity with internal geometries, especially in e-mobility, demands new technologies beyond complex molds with sliders.

- Lost salt core technology offers an alternative to slide systems for creating internal geometries.

- Salt cores are advantageous due to water solubility, simplifying removal after casting.

- Limitations of Existing Research:

- Core viability is a decisive issue for process-safe use of salt cores.

- Core loading in die casting is mainly attributed to the flow velocity of the impinging melt.

- High mechanical demands are placed on cores due to high pressures and flow speeds in HPDC.

- Research Need:

- Explore alternative casting methods like rheocasting to lower melt temperature and potentially reduce core loading.

- Investigate the application of rheocasting technology to salt cores to improve component quality and core durability.

3. Research Objectives and Research Questions:

- Research Objective:

- To investigate whether rheocasting technology can be applied to salt cores.

- To assess if rheocasting can simultaneously improve component quality when using salt cores.

- Core Research Question:

- What is the impact of rheocasting on the durability of gravity cast salt cores in high pressure die casting compared to conventional high pressure die casting?

- Research Hypothesis:

- Salt cores used in rheocasting will experience reduced loads.

- Salt cores in rheocasting will exhibit increased core viability compared to conventional HPDC. (This is implied by the expected lower core loading in rheocasting).

4. Research Methodology:

- Research Design:

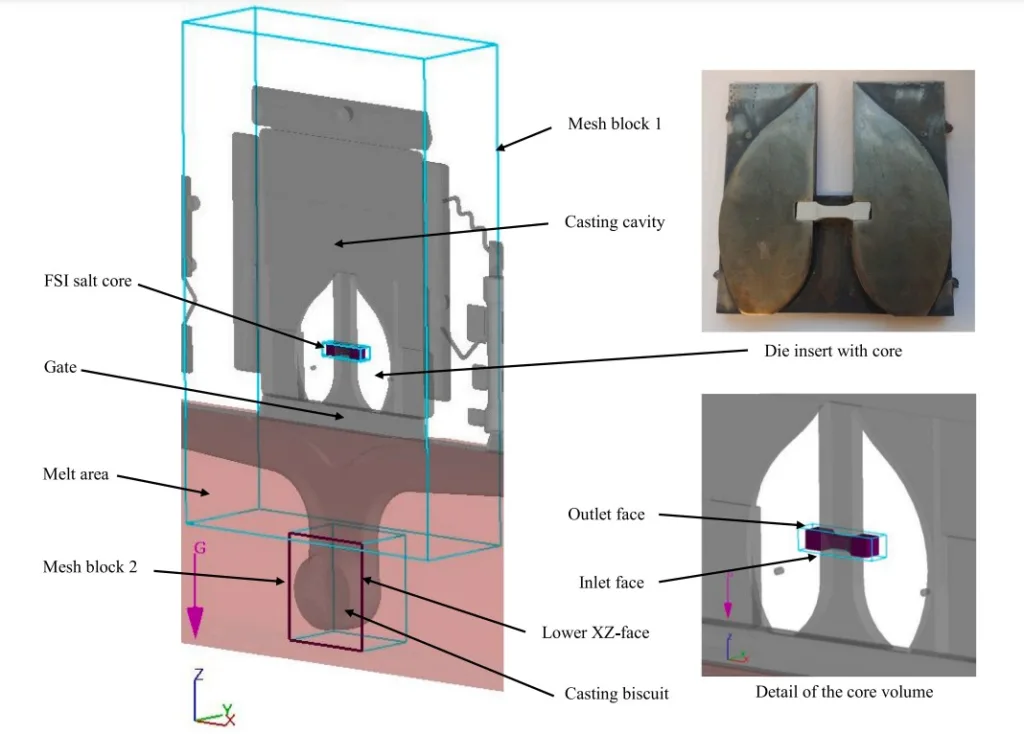

- Simulation study using Flow-3D fluid-structure-interaction (FSI) simulations.

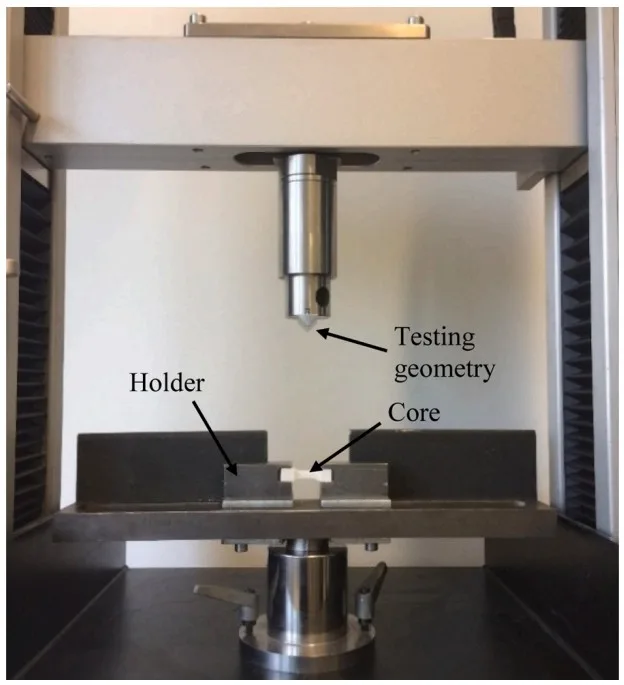

- Experimental validation through three-point bending tests on salt cores.

- Comparison of simulation results with experimental data.

- Data Collection Method:

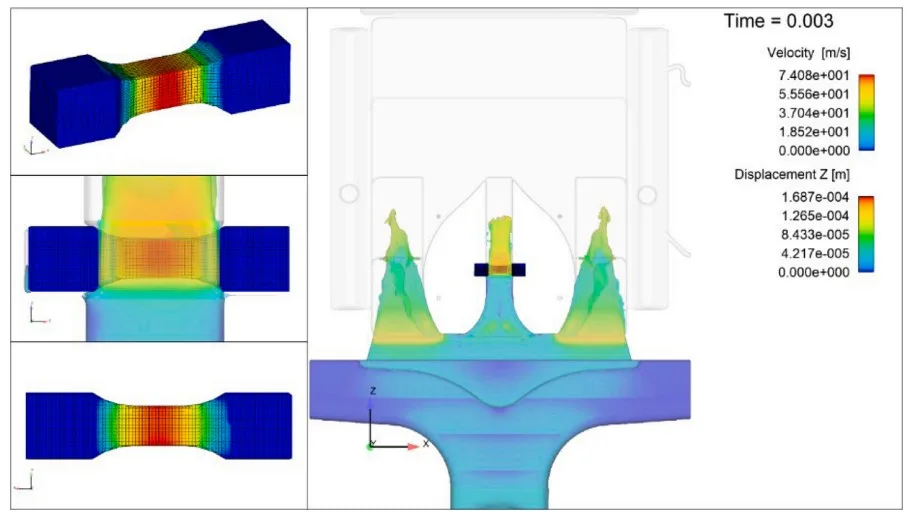

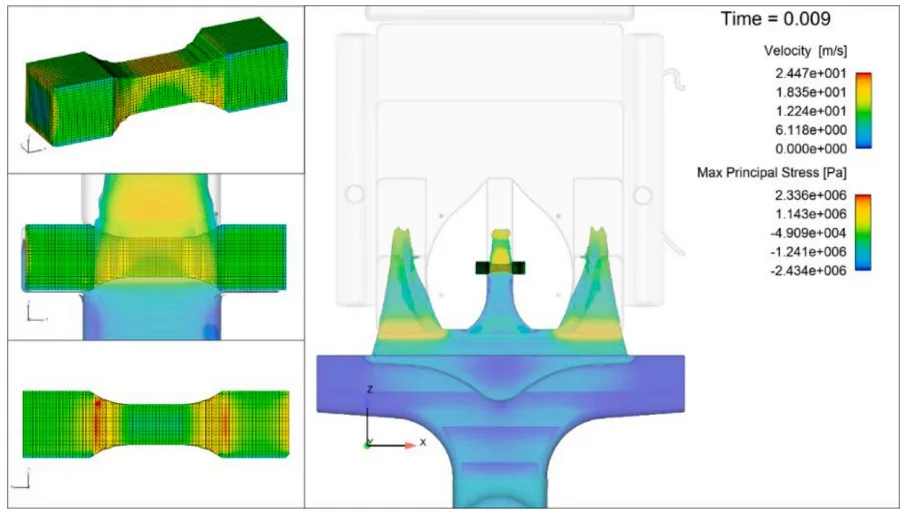

- Simulation: Numerical data on core loading, stress distribution, and energy transfer during mold filling in both conventional HPDC and rheocasting simulations.

- Experiment: Physical measurements of breaking strength and deformation of salt cores in three-point bending tests at 20 °C and 180 °C under different loading conditions (prism line load and area load).

- Analysis Method:

- FSI Simulation: Flow-3D Cast Version 5.0.1 was used to model mold filling and forces acting on the salt core. Rankine maximum-normal stress theory was used to predict core damage. Energy analysis was conducted to compare energy transfer to the core in different casting conditions.

- Three-point Bending Test: Modified three-point bending test was used to determine the failure-critical material data of salt cores. Tests were conducted at different temperatures and loading types to characterize core strength and deformation.

- Research Subject and Scope:

- Salt Core Geometry: A simple geometry with a total length of 60 mm, square cross-section (10 mm side length), and a middle part with a 6 mm side length and 20 mm length was used.

- Casting Processes: Conventional high pressure die casting and rheocasting were simulated and compared.

- Material: A356 (AlSi7Mg0,3) alloy and a salt mixture of 50 wt-% sodium chloride and 50 wt-% sodium carbonate for the core.

- Simulation Parameters: Piston speed of 6 m/s for conventional HPDC and 2 m/s for rheocasting. Melt temperature of 630 °C for conventional HPDC and 600 °C for rheocasting.

5. Major Research Findings:

- Core Research Findings:

- Rheocasting significantly reduces the load on salt cores compared to conventional HPDC.

- The highest core load occurs at the first impact of the melt.

- Core loads remain approximately constant during further mold filling after the initial impact.

- Salt cores in rheocasting show reduced stress levels, well below the failure limit observed in bending tests.

- Statistical/Qualitative Analysis Results:

- Bending Tests:

- Higher core temperature leads to a decreasing breaking load with triangular fin.

- Compression increases slightly at higher temperatures.

- Full load tests show higher breaking load and breaking elongation with higher variance.

- Fine-grained microstructure of the edge zone (0.8 - 1.0 mm thick) is decisive for bending strength.

- Breaking strength and compression data are presented in Fig. 5 for Prism 20°C, Prism 180°C, and Full face 20°C loading conditions.

- Simulation:

- Mesh dependency study showed that 0.5 mm mesh size for the salt core is a reasonable compromise between accuracy and computation time.

- Maximum normal stress in conventional HPDC (6 m/s piston speed) reaches up to 13 MPa immediately after melt impact (Fig. 10).

- Maximum normal stress in rheocasting (2 m/s piston speed) is significantly lower, around 2.3 MPa (Fig. 12).

- Calculated displacement in melt flow direction is 0.17 mm, comparable to bending test results.

- Energy analysis indicates lower energy transfer to the salt core in rheocasting.

- Bending Tests:

- Data Interpretation:

- Simulation results are consistent with the experimental bending test data, suggesting the simulation model is reasonably accurate.

- The significantly lower core loads in rheocasting, as indicated by simulations, suggest improved core viability compared to conventional HPDC.

- The initial melt impact is the most critical phase for core loading.

- Figure Name List:

- Fig. 1. Salt core geometry and casting die.

- Fig. 2. Modified three-point bending test.

- Fig. 3. Simulation model for the fluid structure interaction (FSI) calculation.

- Fig. 4. Detail of the core balance volume.

- Fig. 5. Breaking strength and compression resulting from three-point bending tests.

- Fig. 6. Sectional view of the salt core (6 x 6 mm) at 40x magnification.

- Fig. 7. Mesh dependency of the stresses in the salt core after the impact of the melt.

- Fig. 8. Balance volume of the salt core for energy consideration (purple).

- Fig. 9. Simulated impact of the melt on the salt core.

- Fig. 10. Stress condition on salt core surface immediately after the first impact of the melt.

- Fig. 11. Deformation of the salt core after first impact of the melt.

- Fig. 12. Stress condition on salt core surface immediately after the first impact of the semi solid melt.

6. Conclusion and Discussion:

- Summary of Major Findings:

- Simulation results indicate that rheocasting significantly reduces the load on salt cores during die casting compared to conventional HPDC.

- The load from the impacting melt is directly related to piston speed and melt flow rate, with higher speeds leading to higher loads.

- In conventional HPDC (6 m/s piston speed), the tension on the salt core can reach around 13 MPa, exceeding the tensile strength of the salt core (11 MPa), suggesting potential core failure.

- In rheocasting (2 m/s piston speed), the maximum stress is significantly reduced to approximately 2.3 MPa, well below the tensile strength.

- Academic Significance:

- This study demonstrates the potential of rheocasting as a viable alternative to conventional HPDC for applications using lost salt core technology.

- The research provides valuable insights into the core loading mechanisms in both HPDC and rheocasting processes.

- The use of FSI simulation combined with experimental validation offers a robust methodology for analyzing and optimizing salt core die casting processes.

- Practical Implications:

- Rheocasting offers a promising approach to enhance the process safety and reliability of salt core die casting by reducing core damage.

- Lower core loads in rheocasting can potentially enable the production of more complex and delicate internal geometries using salt cores.

- The findings suggest that adjusting casting parameters, particularly piston speed and melt temperature in rheocasting, can significantly improve core viability.

- Limitations of the Research:

- The simulation model simplifies the casting process and assumes isothermal flow and homogeneous salt core material properties.

- The deformation speed in the three-point bending test (5 mm/min) is significantly slower than the deformation rate in the casting process (deformation occurs within about 0.001 s), which might affect the direct comparability of failure limits.

- Experimental verification of the simulation results in real casting trials is still needed.

7. Future Follow-up Research:

- Future Research Directions:

- Experimental validation of the simulation results through real die casting and rheocasting trials in a casting laboratory.

- Investigation of the influence of various rheocasting parameters on core loading and component quality.

- Exploration of different salt core materials and compositions to further enhance core strength and viability in rheocasting.

- Evaluation of the impact of rheocasting and salt core technology on the microstructure and overall quality of cast components.

- Areas that need further exploration:

- Detailed analysis of the solid phase formation and its influence on core loading in rheocasting.

- Optimization of salt core design and casting process parameters for rheocasting applications.

- Investigation of the long-term durability and performance of components produced using rheocasting and salt core technology.

8. References:

- [1] B. Nogowizin, Theorie Und Praxis des Druckgusses, Fachverlag Schiele&Schön, Berlin, 2011.

- [2] Jelínek, P.; Adámková, E.: Lost Cores for High-Pressure Die Casting, Archives of Foundry Engineering, 14(2) 101-104, 2014, doi:10.2478/afe-2014-0045.

- [3] B. Fuchs, Salzkerntechnologie Für Hohlgussbauteile im Druckguss, Cuvillier Verlag, PhD, Erlangen, Nürnberg, 2014.

- [4] D. Pierri, C. Beck, Lost Core-Technologie - offen für alle, Chancen und Grundlagen des Verfahrens, In: Giesserei, Jg 103 (2016), 10/2016, DVS Media GmbH, Düsseldorf.

- [5] J. Yaokawa, D. Miura, K. Anzai, Strength of Salt Core Composed of Alkali Carbonate and Alkali Chloride Mixtures Made by Casting Technique, Mater. Trans. 48 (5) (2007) 1034-1041.

- [6] Schilling, A. et al.: Approach on simulation of solidification and shrinkage of gravity cast salt cores, Simulation Modelling Practice and Theory, 107, 102231, 2021, ISSN 1569-190X, doi:10.1016/j.simpat.2020.102231.

- [7] Kohlstädt, S.; Vynnycky, M.; Goeke, S.: On the CFD Modelling of Slamming of the Metal Melt in High-Pressure Die Casting Involving Lost Cores, Metals 2021, 11 (1), 78, doi:10.3390/met11010078.

- [8] Uggowitzer, P.J.; Gullo, G.; Wahlen, A.: Metallkundliche Aspekte bei der semi-solid Formgebung von Leichtmetallen, In: Vom Werkstoff zum Bauteil, ed. H. Kaufmann und P.J. Uggowitzer, LKR-Verlag Ranshofen, 95-107, 2000.

- [9] P. Das, Rheological Characterization of Semi-Solid A356 Aluminium Alloy, In: Solid State Phenomena, Vols. 192-193, Trans Tech Publications, Switzerland, 2013, pp. 329-334.

- [10] Fickel, P.: Hohl- und Verbundguss von Druckgussbauteilen – Numerische Auslegungsmethoden und experimentelle Verifikation, PhD, Stuttgart, 2017.

- [11] R.K. Freier, Aqueous Solutions, Data Inorg. Org. Compd. 2 (1978). Supplements, Gruyter, Berlin.

9. Copyright and Source Material:

This summary is based on the paper "About the impact on gravity cast salt cores in high pressure die casting and rheocasting" by Andreas Schilling.

Paper Source: https://doi.org/10.1016/j.simpat.2022.102585

This summary is for informational purposes only and should not be used for commercial purposes without permission from the author.

Copyright © 2025 CASTMAN. All rights reserved.