A Deep Dive into Aluminum Arc Welding: Boosting Quality and Productivity in Electric Vehicles

This technical summary is based on the academic paper "Aluminum Arc Welding Technology to Improve Quality and Productivity of Electric Vehicles" by Woohyeon Ju, Taewan Kim, and Yoochan Kim, published in the Journal of Welding and Joining (2022).

Keywords

- Primary Keyword: Aluminum Arc Welding

- Secondary Keywords: Electric Vehicle Manufacturing, EV Battery Casing, Aluminum Welding Defects, MIG Welding Aluminum, TIG Welding Aluminum, Lightweighting Technology

Executive Summary

- The Challenge: Welding aluminum for critical EV components like battery cases and chassis is notoriously difficult due to the material's inherent properties, which often lead to defects like porosity and cracking that compromise structural integrity.

- The Method: The paper provides a comprehensive review of aluminum's material characteristics, alloy classifications, and the specific challenges they pose for welding, while analyzing various arc welding technologies and process control strategies to overcome them.

- The Key Breakthrough: Modern digital control technologies in arc welding, such as Spatter Free Ignition (SFI) and Synchro Pulse, provide precise control over the arc and heat input, significantly mitigating common defects and enabling the production of high-quality, consistent aluminum welds.

- The Bottom Line: A systematic and technologically advanced approach to Aluminum Arc Welding—from material preparation and storage to the use of digitally controlled processes—is essential for manufacturing robust, lightweight, and safe electric vehicles.

The Challenge: Why This Research Matters for HPDC Professionals

The automotive industry's pivot to electric vehicles (EVs) brings a critical engineering challenge: offsetting the immense weight of batteries. Aluminum has become the material of choice for lightweighting chassis and battery platforms. However, its benefits are coupled with significant manufacturing hurdles.

Unlike steel, aluminum has a low melting point (660°C) but is covered by a stubborn, high-melting-point oxide layer (2050°C). This discrepancy, combined with high thermal conductivity and a high affinity for hydrogen absorption when molten, makes Aluminum Arc Welding a difficult process. Without precise control, welds are highly susceptible to defects like porosity (gas bubbles trapped in the weld) and hot cracking, which can severely compromise the quality, safety, and productivity of EV manufacturing. This research consolidates the knowledge needed to tackle these exact problems.

The Approach: Unpacking the Methodology

The paper systematically breaks down the complexities of Aluminum Arc Welding by reviewing the entire process, from material science fundamentals to advanced machine control.

Method 1: Foundational Material and Alloy Analysis

The authors begin by establishing the fundamental properties of aluminum, including its Face-Centered Cubic (FCC) crystal structure and the protective Al₂O₃ oxide layer. They detail the classification of aluminum alloys into wrought (e.g., 1000-7000 series) and cast types, explaining how principal alloying elements like Mg, Si, and Cu influence strength, corrosion resistance, and weldability. This provides the necessary context for understanding why different alloys behave differently under the welding arc.

Method 2: Rigorous Pre-Welding Preparation

The paper emphasizes that high-quality welds begin long before the arc is struck. The methodology reviewed includes strict protocols for preparation and handling. This involves removing contaminants from the oxide film and surface through cleaning and degreasing, as organic solvents can introduce hydrogen and oxygen, leading to pores. Additionally, proper storage and handling of both the base aluminum and the welding wire are critical to prevent moisture contamination and physical damage.

Method 3: Advanced Welding Process and Equipment Control

The core of the review focuses on the technology used to control the welding process. The authors analyze different types of welding machines, including Tungsten Inert Gas (TIG), Metal Inert Gas (MIG), and Pulse MIG. The study highlights the importance of each component in the welding system, from the wire feeder (recommending a push-pull system for soft aluminum wires) and 4-roll drive systems to the use of Teflon or graphite liners to minimize friction. The review culminates in an analysis of modern digital control strategies designed to ensure weld quality.

The Breakthrough: Key Findings & Data

The paper synthesizes existing knowledge to highlight critical techniques and technologies that directly address the primary challenges of welding aluminum.

Finding 1: The Critical Role of Hydrogen in Porosity Defects

The primary cause of porosity in aluminum welds is hydrogen. The paper highlights this with a crucial data visualization. As shown in Figure 2, the solubility of hydrogen in aluminum plummets dramatically as the metal transitions from a liquid to a solid state. Molten aluminum can hold a large amount of hydrogen, but as it cools and solidifies rapidly during welding, this hydrogen is forced out of solution and becomes trapped as gas pores. This finding underscores why meticulous cleaning to remove any hydrogen-containing contaminants (moisture, oils) and control of shielding gas purity are not just best practices, but essential requirements for defect-free welds.

Finding 2: Digital Process Control Enables Unprecedented Quality

Modern welding machines offer advanced digital controls that solve long-standing problems in Aluminum Arc Welding. The paper details two such technologies:

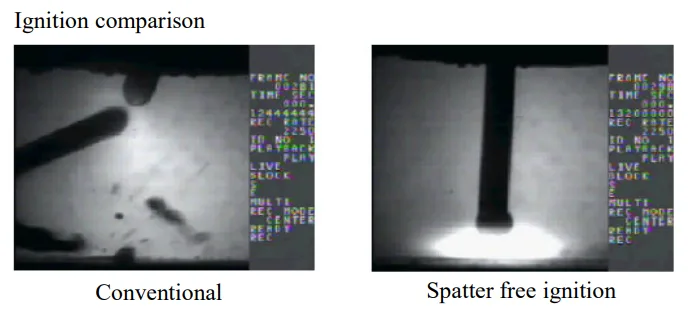

- Spatter Free Ignition (SFI): Conventional arc starting creates a short circuit that results in a current spike (up to 700A) and an explosive arc, generating significant spatter. As illustrated in Figure 6, SFI technology avoids this by reversing the wire at the moment of contact and initiating a soft arc without spatter. This not only produces a cleaner weld from the very start but also extends the life of the contact tip.

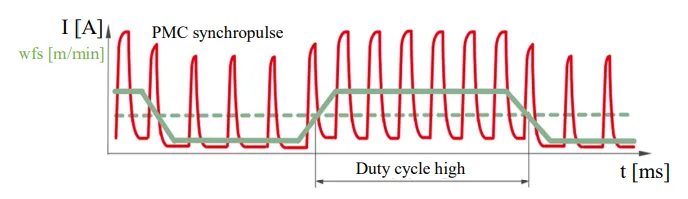

- Synchro Pulse: Controlling heat input is vital to minimize distortion and porosity. Figure 7 shows the waveform for Synchro Pulse, where the pulse current is synchronized with the wire feed rate. This allows for a high-current pulse for deposition followed by a low-current phase, effectively reducing the overall heat input into the component. This creates a distinct, high-quality bead appearance and reduces hydrogen generation.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that implementing Pulse MIG welding with Synchro Pulse control can significantly reduce heat-affected zones and distortion. The data in Table 7 on argon-helium shielding gas mixtures provides a clear guide for adjusting gas composition to control penetration and bead profile for specific applications.

- For Quality Control Teams: The paper's emphasis on fusion defects at the start and end of the weld (Figure 5) indicates that these areas require heightened inspection focus. Understanding that hydrogen porosity is the most common defect allows teams to trace its root cause back to material cleanliness, storage conditions, or gas quality.

- For Design Engineers: The findings indicate that joint design is a critical factor in performance. Figure 9 illustrates how a double butt joint offers superior fatigue performance compared to a partial penetration weld. This is a crucial consideration when designing structural components like battery enclosures and chassis frames that are subject to vibration and stress.

Paper Details

Aluminum Arc Welding Technology to Improve Quality and Productivity of Electric Vehicles

1. Overview:

- Title: Aluminum Arc Welding Technology to Improve Quality and Productivity of Electric Vehicles

- Author: Woohyeon Ju, Taewan Kim, and Yoochan Kim

- Year of publication: 2022

- Journal/academic society of publication: Journal of Welding and Joining, Vol.40 No.5

- Keywords: Aluminum welding, MIG, TIG, Quality

2. Abstract:

In the automobile industry, the use of aluminum bodies is increasing to reduce to the weight of automobile owing to the recent carbon-neutral policy. Because of a significant competition in the electric vehicle market, the technologies for batteries and motors must be secured. In particular, the main parts of the battery are made of copper and aluminum materials, and the battery platform is also made of aluminum materials to reduce the weight. Despite the high demand for aluminum materials, aluminum arc welding is known to be a difficult process owing to pores and cracks. Therefore, this thesis aims to investigate the characteristics of welding of aluminum materials in general and arc welding technology applied to electric vehicles.

3. Introduction:

In response to global warming and climate change, the supply of environmentally friendly cars, particularly electric vehicles (EVs), is rapidly increasing. With the European Parliament banning the sale of internal combustion engine cars after 2035, EV development has become a critical issue for the automobile industry. Unlike conventional vehicles, EVs are powered by motors and batteries. This shift requires new platforms for mounting these components. The main components of a battery are made from copper and aluminum, making welding technology for these materials essential. Furthermore, to compensate for the increased weight of batteries, vehicle weight reduction strategies are necessary. The chassis, which houses the battery and motor, requires a new lightweight platform design, for which aluminum is a representative material. This technical thesis aims to summarize general information about aluminum welding, from basic material properties to welding know-how, that can be applied to EV components.

4. Summary of the study:

Background of the research topic:

The transition to electric vehicles (EVs) is driven by carbon-neutral policies. This transition necessitates lightweighting strategies to compensate for heavy battery packs. Aluminum is a primary material for this purpose, used in battery platforms, chassis, and other components.

Status of previous research:

The paper establishes that while aluminum is in high demand for EV manufacturing, aluminum arc welding is widely recognized as a difficult process. The primary challenges identified in the field are the formation of defects such as pores and cracks, which can compromise the quality and integrity of the final product. This paper serves as a technical review to consolidate existing knowledge and present modern solutions.

Purpose of the study:

The objective of this thesis is to investigate the general characteristics of welding aluminum materials and to review the arc welding technologies that are specifically applied to the manufacturing of electric vehicles.

Core study:

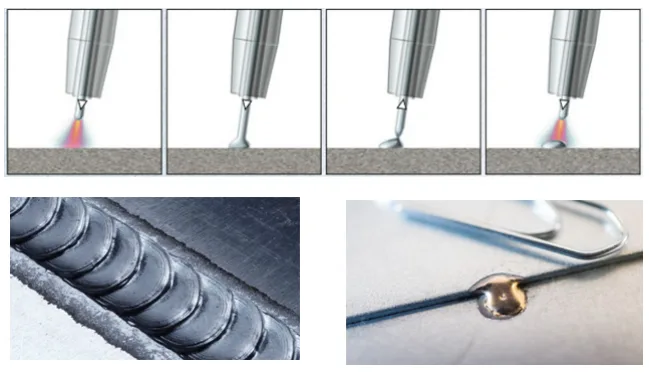

The study provides a comprehensive review of aluminum as a welding material, covering its fundamental characteristics, alloy classifications (wrought and cast), and the roles of various alloying elements. It then delves into the specific challenges of welding aluminum, such as managing the high-melting-point oxide film and high thermal conductivity. The paper details common welding defects, primarily porosity caused by hydrogen and high-temperature cracking. It examines the composition and management of aluminum arc welding machines (MIG/TIG), including torches, wire feeders, and liners. Finally, it explores various welding processes and quality assurance techniques, such as Spatter Free Ignition (SFI), Synchro Pulse, and Cycle Step, as well as methods for preventing welding distortion and minimizing defects through control of shielding gas and preheating.

5. Research Methodology

Research Design:

The study is structured as a technical review. It synthesizes and summarizes existing knowledge on aluminum materials, welding principles, and modern arc welding technologies.

Data Collection and Analysis Methods:

The research is based on a review of established material science principles, industry standards for aluminum alloys (e.g., Aluminum Association), and technical documentation for advanced welding processes. Data is presented through comparative tables (e.g., properties of Al vs. Fe, alloy classifications, shielding gas effects) and illustrative figures (e.g., hydrogen solubility graph, process waveforms).

Research Topics and Scope:

The scope of the paper covers the entire lifecycle of the aluminum arc welding process in the context of EVs. It begins with the material science of aluminum and its alloys, proceeds to preparation and handling, details the equipment and different arc welding processes (TIG, MIG, Pulse MIG), analyzes defect formation and prevention, and concludes with applications in EV chassis and battery systems.

6. Key Results:

Key Results:

- The significant difference in melting points between pure aluminum (660°C) and its surface oxide layer (Al₂O₃ at 2050°C) is a fundamental challenge that must be overcome for successful welding.

- Hydrogen is identified as the main cause of porosity. The drastic decrease in hydrogen solubility as aluminum solidifies is the primary mechanism for pore formation (Fig. 2).

- High-temperature cracking occurs in alloys due to tensile stress generated during solidification when low-melting-point liquid becomes isolated between dendrites. This can be prevented by controlling material composition and using low-heat welding processes.

- Advanced digital welding controls offer significant quality improvements. Spatter Free Ignition (SFI) provides a clean, spatter-free arc start by reversing the wire upon contact (Fig. 6). Synchro Pulse welding synchronizes current pulses with wire feed, enabling low heat input and reducing porosity and distortion (Fig. 7).

- The selection of shielding gas is critical. While 100% argon is stable, adding helium increases heat input and penetration. The characteristics of the weld are highly dependent on the argon-helium mixing ratio (Table 7).

- For structural applications, joint design is crucial. A double butt joint is presented as a superior alternative to a typical butt joint with partial penetration, offering better fatigue performance (Fig. 9).

Figure Name List:

- Fig. 1 Work sequence of aluminum welding

- Fig. 2 Hydrogen solubility in aluminum

- Fig. 3 Configuration of MIG torch

- Fig. 4 Configuration of wire drive roller

- Fig. 5 Current waveform at the start and end of welding

- Fig. 6 Comparison of conventional arc ignition and SFI

- Fig. 7 Waveform during synchropulse

- Fig. 8 Characteristic of cycle step

- Fig. 9 Aluminum butt joint specimen dimension. left side: butt joint, Right side: double butt joint

- Fig. 10 Battery system structure of electric vehicle (E-GMP, Hyundai-Kia Motor Company)

7. Conclusion:

The paper reviewed the fundamentals of arc welding technology for aluminum materials applicable to EVs. Aluminum is a valuable lightweight material, but special caution is required during arc welding due to its low melting point and fast heat transfer. Fortunately, welding quality can be ensured by using various arc welding control methods that have been developed. The effective application of these technological solutions to aluminum parts in EVs is expected.

8. References:

- Y. Kim and Y. D. Park, Joining Technologies and Solutions for Aluminum-based Battery Case Manufacturing, J. Weld. Join. 40(1) (2022) 54-73. https://doi.org/10.5781/JWJ.2022.40.1.7

- H. T. Kim and S. C. Kil, Trends of welding technologies (aluminum structure), J. Korean Weld. Join. Soc. 22(4) (2004) 29-34.

- D. H. Jung and J. P. Jung, Aluminum alloys and their joining methods, J. Microelectron. Packag. Soc. 25(2) (2018) 9-17. https://doi.org/10.6117/kmeps.2018.25.2.009

- S. K. Hong, Series I: Melting and castings of aluminum alloys, J. Korea Foundry Soc. 28(1) (2008) 5-14.

- S. Y. Baek, K. D. Park, W. I. Kim, and S. M. Cho, A study on tensile properties and HAZ softening depending on the amount of heat input in MIG welding of A16082-T6, J. Korean Weld. Join. Soc. 29(1) (2011) 59-64.

- M. J. Kang and C. H. Kim, A Review of joining processes for high strength 7xxx Series aluminum alloys, J. Weld. Join. 35(6) (2017) 79-88. https://doi.org/10.5781/JWJ.2017.35.6.12

- M. Felberbaum, Porosity in aluminum alloys : Visualization, characterization, and modeling, EPFL, Lausanne, Switzerland, (2010) 191. http://dx.doi.org/10.5075/epfl-thesis-4639

- Korean Welding and Joining Society, Welding and Joining Handbook, I: Steel and non-ferrous materials, Korean Welding and Joining Society, Daejeon, Korea (2008) 305-321.

- S. I. Seo, Welding technology for aluminum rolling stocks, J. Korean Weld. Join. Soc. 22(3) (2004) 32-38.

- K. H. Youn and Y. S. Han, Gas metal arc welding of aluminum alloys, J. Korean Weld. Join. Soc. 12(1) (1994) 16-27.

- C. J. Lee, Y. C. Kim, and J. D. Kim, Technology on arc welding machine of aluminum by digital control, J. Korean Weld. Join. Soc. 31(1) (2013) 26-62. https://doi.org/10.5781/KWJS.2013.31.1.26

- S. H. Park, H. K. Lee, J. Y. Kim, H. T. Chung, Y. W. Park, and C. Y. Kang, Effect of welding condition on microstructures of weld metal and mechanical properties in Plasma-MIG hybrid welding for Al 5083 alloy, J. Weld. Join. 33(1) (2015) 61-71. https://doi.org/10.5781/JWJ.2015.33.1.61

- Y. B. Choi, M. J. Kang, D. C. Kim, and I. S. Hwang, High current arc welding technology of aluminum alloy, J. Korean Weld. Join. Soc. 31(1) (2013) 21-25. https://doi.org/10.5781/KWJS.2013.31.1.21

- D. Steyer and B. S. Jun, Shielding gases for welding aluminum, J. Korean Weld. Join. Soc. 31(1) (2013) 38-42. https://doi.org/10.5781/KWJS.2013.31.1.38

- J. Chen, B. S. Amirkhiz, R. Zhang, and B. Rona, On the joint formation and interfacial microstructure of cold metal transfer cycle step braze welding of aluminum to steel butt joint, Met. Mater. Trans. A 51 (2020) 5198-5212. https://doi.org/10.1007/s11661-020-05917-8

- J. H. Cho, S. J. Baek, S. C. Shin, G. H.Lee, M. G. Kang, and Y. R. Jo, Effect of aluminum arc butt joint weld geometry on fatigue srength, J. Weld. Join. 39(1) (2021) 103-108. https://doi.org/10.5781/JWJ.2021.39.1.12

Expert Q&A: Your Top Questions Answered

Q1: Why is hydrogen such a significant problem in aluminum welding compared to steel?

A1: The paper highlights this in Figure 2, which shows the hydrogen solubility in aluminum. Molten aluminum can absorb a significant amount of hydrogen, but its solubility in solid aluminum is extremely low. During the rapid cooling of the welding process, this dissolved hydrogen has no time to escape and is forcefully expelled from the metal lattice, forming internal gas pockets, or porosity. This dramatic change in solubility is much more pronounced in aluminum than in steel, making it uniquely susceptible to this defect.

Q2: The paper mentions SFI (Spatter Free Ignition). How does this technology fundamentally differ from a conventional MIG arc start?

A2: A conventional MIG start involves the wire feeding forward until it touches the workpiece, creating a short circuit. The machine then applies a very high current to blast through the short, creating an explosive arc and significant spatter. According to the paper's description of SFI, the process is inverted: the moment the wire makes contact, a controlled welding current is applied while the wire is simultaneously reversed or pulled back. This action draws a stable arc without the violent short circuit, resulting in a clean, spatter-free ignition.

Q3: What is the primary trade-off when adding Helium to the Argon shielding gas, according to the paper?

A3: According to Table 7, adding helium to argon gas increases the heat input, leading to deeper and more rounded penetration and allowing for faster welding speeds. However, this comes with trade-offs. The cleaning effect on the oxide layer is lower than with pure argon, and a higher arc voltage is required for ignition. Furthermore, helium is more expensive than argon, so the cost of the shielding gas increases.

Q4: For heat-treatable aluminum alloys (e.g., 6000 series), what is a key concern mentioned regarding preheating?

A4: Section 5.4.3 of the paper advises that special attention must be paid to the effect of preheating temperature and time on the properties of the material. For heat-treatable alloys like cold wrought alloys and quench aging alloys (which includes many 6000 and 7000 series alloys), improper or excessive preheating can negatively alter the carefully engineered metallurgical properties (e.g., temper) in the heat-affected zone, potentially reducing the strength of the final assembly.

Q5: The paper proposes a double butt joint as an alternative. What is the main advantage of this design for EV applications?

A5: The main advantage, as described in Section 5.4.4, is improved fatigue performance. A typical butt joint may only achieve partial penetration, leaving a stress concentration point that is weak under cyclic loading. The double butt joint design, shown in Figure 9, facilitates a more complete weld through the joint thickness. For EV applications like chassis frames and battery enclosures that experience constant vibration and road stresses, this superior fatigue resistance is critical for long-term durability and safety.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing flawless welds in aluminum is a critical bottleneck in the quest for lighter, more efficient electric vehicles. As this paper comprehensively details, the root causes of common defects like porosity and cracking lie in the fundamental properties of the material itself. The key breakthrough is the application of modern digital controls and a systematic approach to the entire Aluminum Arc Welding process. By leveraging technologies like Spatter Free Ignition and Synchro Pulse, manufacturers can gain precise control over heat input and arc stability, directly addressing these long-standing quality issues.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Aluminum Arc Welding Technology to Improve Quality and Productivity of Electric Vehicles" by "Woohyeon Ju, Taewan Kim, and Yoochan Kim".

Source: https://doi.org/10.5781/JWJ.2022.40.5.8

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.