Multi-material Automotive Bodies and Dissimilar Joining Technology to Realize Multi-material

This technical summary is based on the academic paper "Multi-material Automotive Bodies and Dissimilar Joining Technology to Realize Multi-material" by Dr. Junya NAITO and Dr. Reiichi SUZUKI, published in KOBELCO TECHNOLOGY REVIEW (2020).

Keywords

- Primary Keyword: Multi-material Joining

- Secondary Keywords: Dissimilar Metal Joining, Automotive Lightweighting, High-Strength Steel, Aluminum Alloy Joining, Weight Reduction, Body-in-White (BIW), Self-Pierce Riveting (SPR), Element Arc Spot Welding (EASW)

Executive Summary

- The Challenge: To significantly reduce vehicle weight to meet stringent fuel efficiency and emissions regulations, especially with the added mass of electrification, while maintaining safety and performance.

- The Method: Designing and simulating four multi-material Body-in-White (BIW) concepts for an E-segment SUV, progressively increasing the ratio of ultra-high-strength steel and aluminum alloys (including sheets, extrusions, and castings) against an all-steel baseline.

- The Key Breakthrough: A multi-material design strategy utilizing a high percentage of aluminum alloy (72.5%) can achieve a 33% (142.8 kg) weight reduction in the BIW while also reducing the total number of parts by 27%.

- The Bottom Line: Achieving next-generation automotive lightweighting goals is not just about material substitution; it requires a holistic approach that combines strategic material placement with advanced dissimilar joining technologies capable of reliably bonding materials like high-strength steel and aluminum.

The Challenge: Why This Research Matters for HPDC Professionals

The automotive industry is at a critical juncture. Global pressure to reduce CO2 emissions and improve fuel efficiency is relentless. The shift towards electric vehicles (EVs), while eliminating tailpipe emissions, introduces the significant weight of batteries and hydrogen tanks. This means the demand for vehicle lightweighting is more intense than ever, regardless of the powertrain.

For years, engineers have relied on high-strength steel to shed pounds, but there's a limit to what one material can achieve. The next frontier is the multi-material body, strategically combining the strength of steel with the low density of aluminum alloys. However, this creates a major manufacturing hurdle: you can't simply weld steel to aluminum. Traditional welding creates extremely brittle intermetallic compounds, leading to joint failure. This paper tackles the dual challenge of designing an optimal multi-material structure and developing the joining technology to make it a reality.

The Approach: Unpacking the Methodology

The researchers at Kobe Steel conducted a systematic study to quantify the benefits and trade-offs of a multi-material approach.

Method 1: Baseline Vehicle and Design Cases

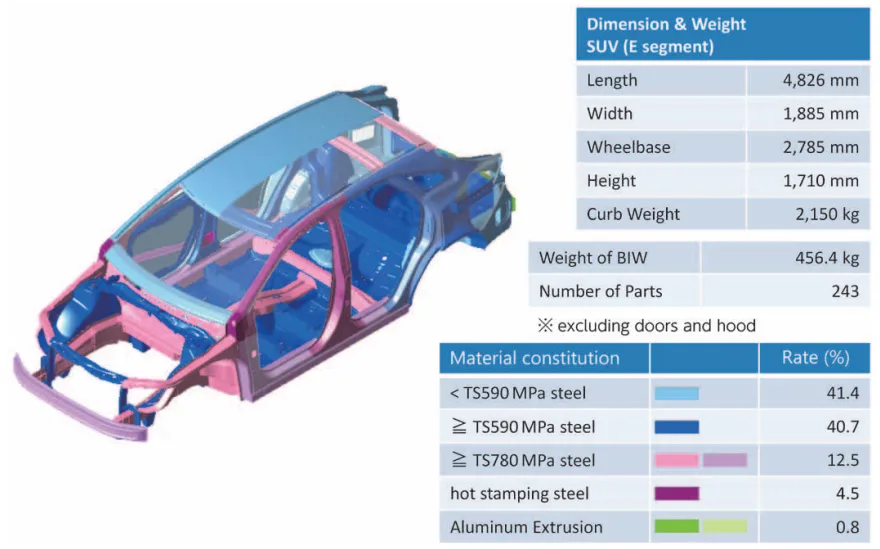

The study used a detailed model of an E-segment SUV as the baseline. This all-steel vehicle had a Body-in-White (BIW) weight of 456.4 kg and consisted of 243 parts. From this baseline, four new designs were developed:

* Case 1: Maximized the use of ultra-high tensile steel.

* Cases 2 & 3: A balanced combination of steel and aluminum alloys.

* Case 4: Proactive use of aluminum alloys, with high-strength steel applied only where severe collision requirements dictated. This case made extensive use of aluminum extrusions and die castings.

Method 2: Performance Validation

All designs were subjected to rigorous virtual testing to ensure they met critical performance requirements. This included:

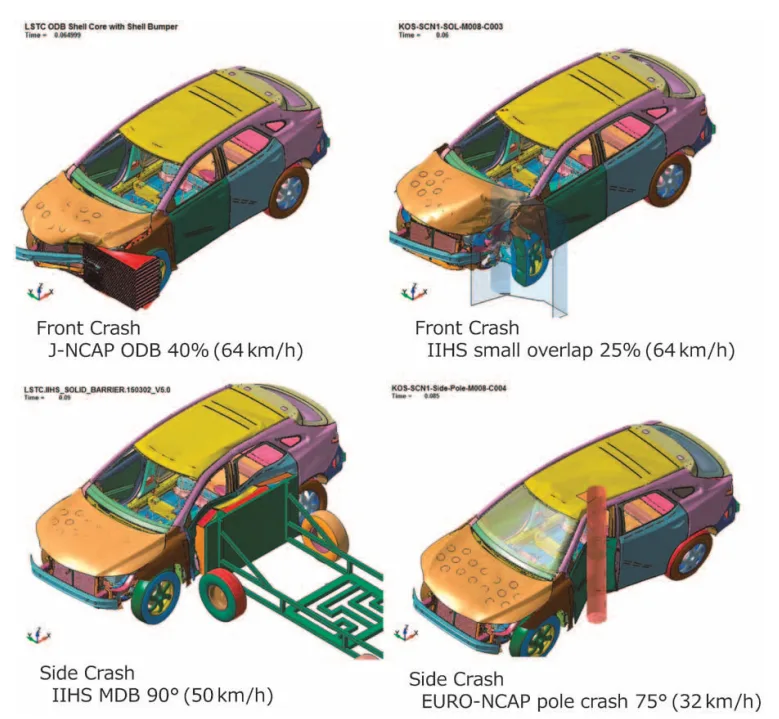

* Collision Analysis: Simulating key crash scenarios like the J-NCAP ODB, IIHS small overlap, and EURO-NCAP pole crash to ensure deformation was evaluated as "Good."

* Stiffness Analysis: Evaluating torsional and bending stiffness to ensure they met or exceeded 50 Hz and 40 Hz, respectively, to maintain vehicle handling and dynamics.

The Breakthrough: Key Findings & Data

The study delivered clear, quantifiable results on the potential of multi-material design and the importance of enabling technologies.

Finding 1: A 33% Weight Reduction is Achievable

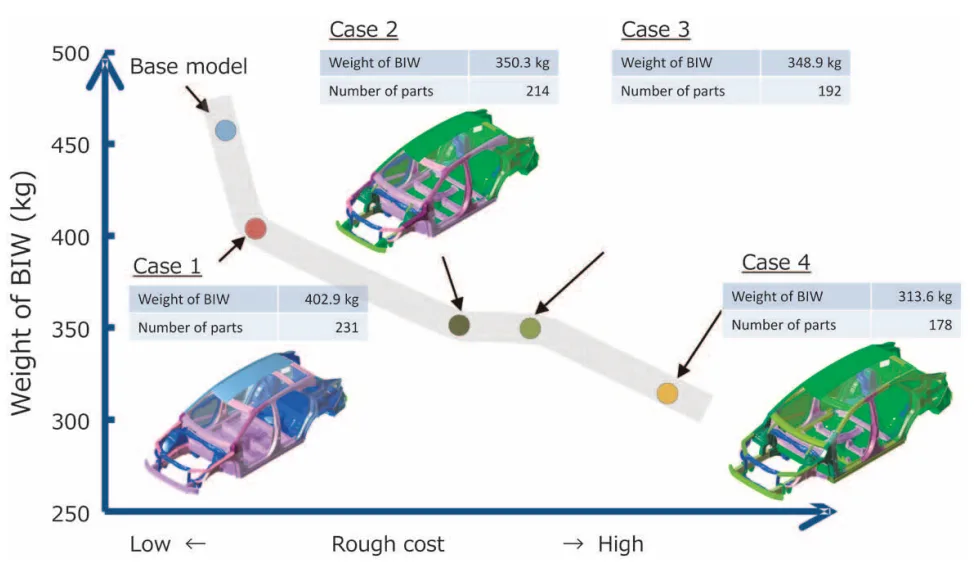

The progressive substitution of conventional steel with ultra-high-strength steel and aluminum alloys yielded significant weight savings. As shown in Figure 3, the results were dramatic:

* Case 1 (Max Steel Strength): Achieved a 12% weight reduction (402.9 kg BIW).

* Cases 2 & 3 (Steel/Aluminum Mix): Achieved a 22-24% weight reduction (down to 348.9 kg BIW).

* Case 4 (Max Aluminum Use): Achieved an impressive 33% weight reduction, bringing the BIW down to 313.6 kg. This represents a saving of 142.8 kg over the baseline.

Finding 2: Part Integration with Aluminum Castings Reduces Complexity and Cost

A critical finding, particularly for the HPDC industry, is the potential for part consolidation. By strategically using aluminum die castings and extrusions, Case 4 reduced the total number of BIW parts from 243 to 178. As noted in the paper, this integration helps offset the higher material cost of aluminum by reducing machining and joining process costs.

Finding 3: Novel "EASW" Joining Technology Outperforms Conventional Methods

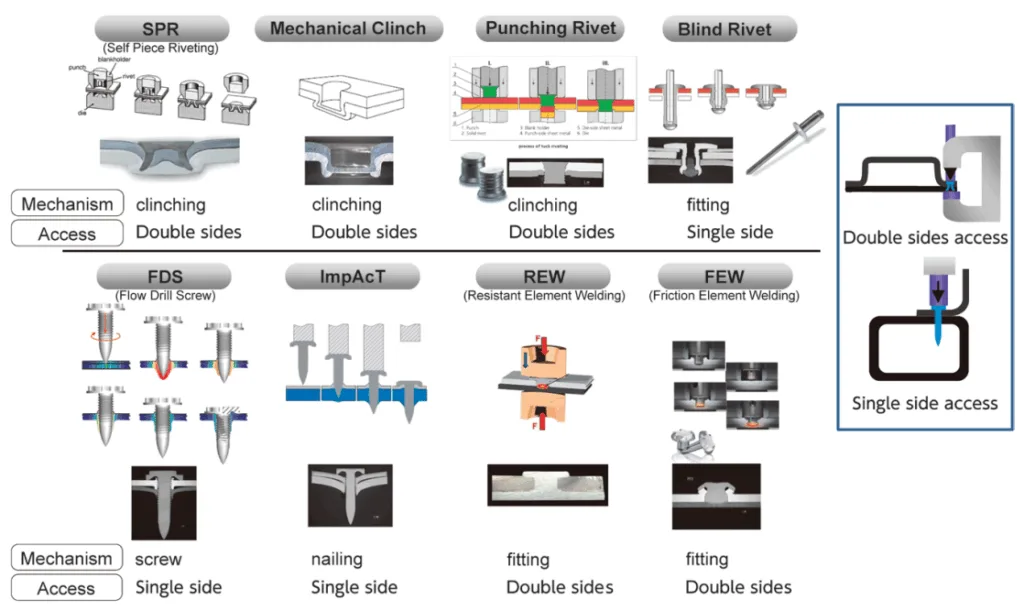

The paper introduces a unique dissimilar joining technology called "element arc spot welding" (EASW). This method avoids the pitfalls of traditional welding by inserting a hollow steel rivet into the aluminum sheet and then arc welding a steel wire inside the rivet to bond it to the underlying steel sheet. As shown in Figure 6, this method delivers significantly higher tensile shear strength (TSS) and cross-tension strength (CTS) compared to conventional mechanical methods like Self-Pierce Riveting (SPR), Flow Drill Screw (FDS), and others, especially when joining high-strength steels.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that as steel strength increases, conventional mechanical joining methods like riveting become more difficult. New technologies like EASW, which do not require plastic deformation of the high-strength steel, may be essential for future multi-material assembly lines.

- For Quality Control Teams: The data in Figure 6 illustrates the superior joint strength of EASW. This could inform new quality standards for critical dissimilar metal joints. Furthermore, the paper highlights the necessity of using adhesives in hybrid joining to prevent galvanic corrosion, a key quality consideration.

- For Design Engineers: The findings from Case 4 provide a clear blueprint for lightweighting. Integrating multiple stamped steel parts into single, complex aluminum die castings can drastically reduce weight and part count, simplifying assembly and potentially lowering overall costs.

Paper Details

Multi-material Automotive Bodies and Dissimilar Joining Technology to Realize Multi-material

1. Overview:

- Title: Multi-material Automotive Bodies and Dissimilar Joining Technology to Realize Multi-material

- Author: Dr. Junya NAITO, Dr. Reiichi SUZUKI

- Year of publication: 2020

- Journal/academic society of publication: KOBELCO TECHNOLOGY REVIEW NO. 38

- Keywords: Multi-material, Automotive Body, Dissimilar Joining, Weight Reduction, High-Strength Steel, Aluminum Alloy, EASW

2. Abstract:

This paper introduces multi-material car body designs that utilize ultra-high strength steel and aluminum alloy, achieving an estimated weight reduction of 12% to 33% compared to a conventional steel base body. The study presents the results of trial calculations for car body weights under different material composition ratios. It also provides an explanation of the dissimilar joining technologies necessary for realizing multi-material car bodies, including a discussion of existing methods and a novel dissimilar joining technology, "element arc spot welding" (EASW), uniquely developed by Kobe Steel.

3. Introduction:

Increasingly stringent global regulations on fuel efficiency and CO2 emissions, coupled with the trend toward vehicle electrification (HEV, PHEV, EV, FCV), have intensified the demand for automotive weight reduction. While high-strength steel sheets have been widely adopted, further weight savings necessitate multi-material structures combining steel with lighter materials like aluminum alloys. Realizing such structures requires not only advanced design and evaluation technologies but also robust, low-cost dissimilar metal joining technologies to connect materials that cannot be joined by conventional welding due to the formation of brittle intermetallic compounds. This paper focuses on multi-material bodies composed of high-strength steel and aluminum alloys, analyzing their weight reduction potential and the joining technologies required for their implementation.

4. Summary of the study:

Background of the research topic:

The automotive industry faces a continuous demand for weight reduction to improve fuel efficiency, performance, and safety, a need that persists even with the shift to electric powertrains which add heavy components like batteries. This has led to the increased use of aluminum alloys and high-strength steels in vehicle bodies.

Status of previous research:

While lightweighting projects in the EU and U.S. have estimated the weight reduction effects of multi-material bodies, there are few publicly available studies that detail the relationship between the specific ratio of applied materials (e.g., steel vs. aluminum) and the corresponding weight reduction effect for a given vehicle model.

Purpose of the study:

The study aims to:

1. Introduce examples of lightweight designs for a given vehicle body, showing the effects of changing the ratio of steel and aluminum alloy.

2. Estimate the potential for weight reduction and part number reduction in these multi-material designs.

3. Introduce existing and newly developed dissimilar metal joining technologies required to manufacture these bodies.

Core study:

An E-segment SUV with an all-steel body was used as a baseline. Four alternative designs were created with varying compositions of ultra-high tensile steel and aluminum alloys (sheet, extrusion, and cast). The weight of each design was calculated, and its performance was validated through collision and stiffness simulations. The study also details the challenges of dissimilar metal joining (brittle intermetallic formation, galvanic corrosion) and presents Kobe Steel's "element arc spot welding" (EASW) as a high-strength solution.

5. Research Methodology

Research Design:

The study employed a comparative design analysis. A baseline vehicle model (all-steel E-segment SUV) was established. Four alternative multi-material design cases were then developed under different material application policies to systematically evaluate the relationship between material composition, body weight, part count, and relative cost.

Data Collection and Analysis Methods:

- Baseline Model: An E-segment SUV BIW was modeled, with specifications, weight (456.4 kg), part count (243), and material constitution detailed.

- Simulation: Designs were evaluated using collision analysis (crash simulation) and dynamic stiffness analysis to ensure they met predefined performance requirements (e.g., "Good" deformation rating, torsional stiffness ≥ 50 Hz, bending stiffness ≥ 40 Hz).

- Weight & Cost Calculation: The BIW weight for each of the four cases was calculated. A "rough cost" was also estimated based on relative material costs and the cost reduction effects from reduced machining and joining associated with a lower part count.

- Joining Strength Comparison: The joint strength (Tensile Shear Strength and Cross Tension Strength) of the proposed EASW method was compared against conventional dissimilar joining methods (SPR, Punching Rivet, FDS, ImpAcT, FEW, REW).

Research Topics and Scope:

The research is scoped to the Body-in-White (BIW) of an E-segment SUV. The materials considered are various grades of steel (including hot stamping steel) and aluminum alloys (extrusion, sheet, and cast). The study investigates weight reduction, part count reduction, and the enabling technology of dissimilar metal joining.

6. Key Results:

Key Results:

- Case 1 (Full exploitation of ultra-high-tensile steel): Resulted in a 12% (53.5 kg) weight reduction.

- Cases 2 and 3 (Use of multi-materials): Resulted in a 22% to 24% (106.1 kg to 107.5 kg) weight reduction.

- Case 4 (Proactive use of aluminum alloy): Resulted in a 33% (142.8 kg) weight reduction.

- Part Count Reduction: The number of parts was reduced from 243 in the base model to 178 in Case 4, primarily through the integration of parts using aluminum die-casting and extrusion.

- Joining Technology Performance: The newly developed EASW technology demonstrated higher tensile shear strength (TSS) and cross tension strength (CTS) compared to all evaluated conventional dissimilar material joining methods.

Figure Name List:

- Fig. 1 Body-in-white, main specifications, and material constitution of base vehicle

- Fig. 2 Deformation of vehicle in typical cases of crash simulation

- Fig. 3 Results of light weight design

- Fig. 4 Practically applied methods of joining dissimilar metals for car body structure

- Fig. 5 Basic mechanism of EASW 7)

- Fig. 6 Joining strength of EASW

- Fig. 7 Prototype robot system for EASW (right) and appearance of joining (left)

7. Conclusion:

The trend toward multi-material automotive bodies is an inevitable measure to achieve necessary weight reduction for CO2 emission and collision safety regulations. The study demonstrates that significant weight reduction (up to 33%) is possible through the strategic application of aluminum alloys in conjunction with high-strength steel. However, this approach introduces challenges of increased cost and the need for robust dissimilar material joining. To make multi-material bodies practical, it is effective to suppress costs by reducing the number of parts via integration with aluminum die-casting or extrusion. Furthermore, the development of low-cost, high-strength dissimilar joining technologies like EASW is critical to the successful implementation of these advanced lightweight structures.

8. References:

- 1) M. Maeda et al. Knowledge creation and integration. April, 2017, pp.46-63.

- 2) H. Sakagami et al. Journal of the Society of Automotive Engineers of Japan. 2016, Vol.70, No.8, pp.42-44.

- 3) Jens Meschke. ALIVE Final publishable summary report. Nov. 2016.

- 4) Tim Skszek et al. Multi-Material Lightweight Vehicles. June 2015.

- 5) R. Suzuki. Welding technology. January 2017. pp.64-72.

- 6) R. Suzuki et al. International Institute of Welding. July 2018, Doc.XII-2390-18.

- 7) L. CHEN et al. R&D Kobe Steel Engineering Reports. 2018, Vol.67, No.1, pp.104-110.

Expert Q&A: Your Top Questions Answered

Q1: What is the primary reason traditional welding cannot be used to join steel and aluminum in car bodies?

A1: According to the paper, weld joining steel and aluminum is impossible due to the formation of "extremely brittle intermetallic compounds" at the interface. These compounds compromise the structural integrity of the joint, making it unsuitable for automotive applications that require high strength and durability. This is why mechanical or specialized hybrid joining methods are necessary.

Q2: How does the EASW (element arc spot welding) technology work, and why is it effective for high-strength steel?

A2: The EASW mechanism involves inserting a hollow steel element (a rivet) into a hole in the aluminum alloy sheet. This assembly is placed over a lower steel sheet. An arc welding process then melts a wire inside the hollow element, casting it and welding it firmly to the lower steel sheet. The aluminum sheet is effectively clamped between the flange of the steel element and the lower steel sheet. This method is highly effective because it requires no plastic deformation of the steel sheet, making it possible to join even ultra-high-strength and hot-stamped steels that are difficult to penetrate or form with conventional mechanical methods like SPR.

Q3: The study shows a significant cost increase accompanies the weight reduction. How does the paper suggest mitigating this cost?

A3: The paper anticipates that both material and processing costs will increase. It proposes two key strategies to suppress this cost increase. The first is to reduce the number of parts by integrating them using aluminum die-casting or extrusion, as demonstrated in Case 4 where the part count dropped by 27%. The second is to develop technology that minimizes the capital investment required for dissimilar material joining processes.

Q4: What role do adhesives play in joining dissimilar metals like steel and aluminum?

A4: Adhesives play a crucial dual role. The primary function is to prevent electrolytic (galvanic) corrosion, which occurs when two different metals are in contact in the presence of moisture. The adhesive acts as a sealant, keeping moisture away from the joint surface. Secondly, since the adhesive forms a surface joint, it also contributes to the joint's high shear strength, creating a "hybrid joining" method when combined with a mechanical fastener.

Q5: What specific performance targets did the redesigned vehicle bodies have to meet?

A5: The designs had to satisfy strict performance criteria to be considered viable. For collision safety, the amount of deformation at each part had to be evaluated as "Good" based on main collision criteria from simulations like J-NCAP and IIHS. For vehicle dynamics, the torsional stiffness and bending stiffness of the entire vehicle had to be 50 Hz and 40 Hz or higher, respectively.

Q6: Why was an E-segment SUV chosen as the base vehicle for this study?

A6: The paper specifies an E-segment SUV was used as the base. While it doesn't state the exact reason for the choice, this class of vehicle is typically large and heavy, making it an ideal candidate to demonstrate the significant impact of advanced lightweighting strategies. The benefits of reducing mass are more pronounced on heavier vehicles, and their larger structures offer more opportunities for part integration using castings and extrusions.

Conclusion: Paving the Way for Higher Quality and Productivity

This research from Kobe Steel provides a clear and compelling roadmap for the future of automotive manufacturing. The core takeaway is that achieving ambitious weight reduction targets of 30% or more is not a matter of simple material substitution but a sophisticated balancing act. A successful strategy requires intelligent multi-material design, leveraging the unique properties of high-strength steel and aluminum alloys where they are most effective. The key to unlocking this potential lies in advanced Multi-material Joining technologies and the strategic use of aluminum castings to integrate parts, reduce complexity, and control costs.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how our high-integrity aluminum components can be the cornerstone of your next-generation lightweighting strategy.

Copyright Information

This content is a summary and analysis based on the paper "Multi-material Automotive Bodies and Dissimilar Joining Technology to Realize Multi-material" by "Dr. Junya NAITO and Dr. Reiichi SUZUKI".

Source: KOBELCO TECHNOLOGY REVIEW NO. 38 MAR. 2020

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.