Maximizing Recycled A356 Aluminum: A Data-Driven Guide to Balancing Cost and Performance

This technical summary is based on the academic paper "Effect of Chip Amount on Microstructural and Mechanical Properties of A356 Aluminum Casting Alloy" by A.Y. Kaya et al., published in ARCHIVES of FOUNDRY ENGINEERING (2021).

Keywords

- Primary Keyword: Recycled A356 Aluminum

- Secondary Keywords: A356 mechanical properties, aluminum casting, chip melting, gravity casting, aluminum recycling, microstructure

Executive Summary

- The Challenge: Increasing the use of recycled aluminum is critical for cost and energy savings, but impurities can compromise the mechanical properties essential for high-performance components.

- The Method: A356 aluminum alloy was gravity cast with five different ratios of primary to recycled ingot (from 100% primary to 100% recycled), T6 heat-treated, and then subjected to microstructural and mechanical testing.

- The Key Breakthrough: Adding 30% recycled ingot to the primary A356 melt resulted in a slight increase in both yield strength and ultimate tensile strength compared to using 100% primary ingot.

- The Bottom Line: For gravity-cast A356 components, a 30% recycled content represents an optimal "sweet spot" that enhances mechanical properties, while exceeding this threshold leads to a significant and progressive decline in performance, especially in elongation.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive and aerospace industries, the demand for lightweight, high-strength aluminum components is relentless. A356 is a workhorse alloy, but producing it from primary sources is incredibly energy-intensive—requiring about ten times more energy than producing it from recycled materials. The use of recycled aluminum, such as machining chips, offers massive energy savings and a significant reduction in greenhouse gas emissions.

However, a major barrier limits its widespread adoption: quality. Recycled aluminum often contains higher levels of impurities, such as iron (Fe) and oxides, which can introduce defects, form brittle intermetallic phases, and ultimately degrade the mechanical properties of the final casting. This research directly addresses this critical industry challenge: determining the maximum amount of recycled material that can be used without compromising—or even while improving—the performance of A356 castings.

The Approach: Unpacking the Methodology

The researchers conducted a systematic study to isolate the effect of recycled content on A356 alloy properties. The methodology provides a clear and reliable framework for the results.

Method 1: Material Preparation and Casting

- Materials: The study used primary A356 (AlSi7Mg0.3) ingots and recycled ingots produced by melting cleaned machining chips from aluminum wheels.

- Sample Compositions: Five distinct batches were prepared, each weighing 8 kg:

1. 100% Primary Ingot

2. 70% Primary + 30% Recycled Ingot

3. 50% Primary + 50% Recycled Ingot

4. 30% Primary + 70% Recycled Ingot

5. 100% Recycled Ingot

- Casting Process: The materials were melted at 750±5°C and cast into a permanent metallic mold using the gravity casting method. No degassing or grain refinement was applied in order to isolate the effect of the raw material composition.

Method 2: Heat Treatment and Mechanical Testing

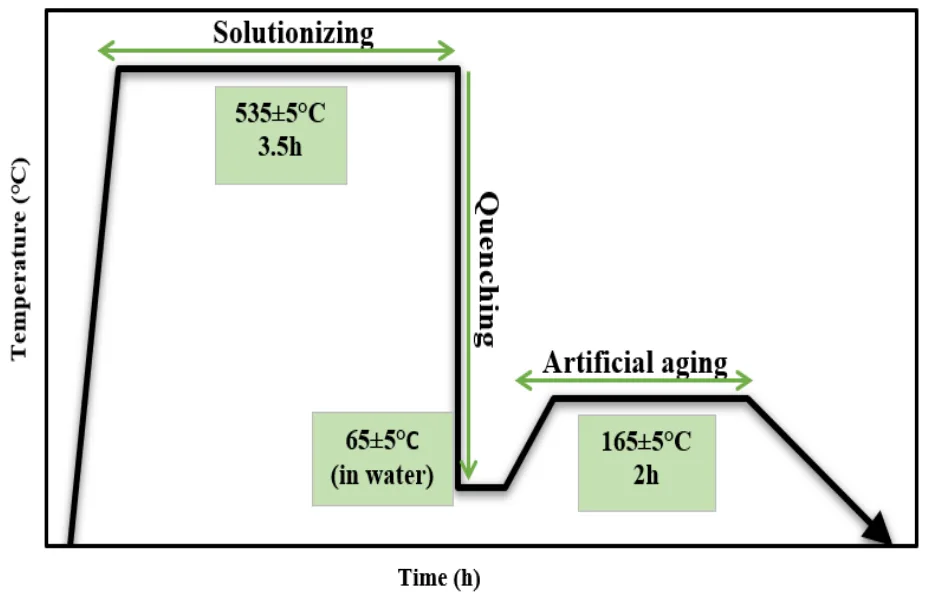

- T6 Heat Treatment: All cast samples underwent a T6 heat treatment to simulate industrial production conditions. This involved:

- Solutionizing: 535±5°C for 3.5 hours

- Quenching: In water at 65±5°C

- Artificial Aging: 165±5°C for 2 hours

- Testing: Tensile test specimens were machined from the castings and tested according to DIN 50125 standards to determine yield strength (YS), ultimate tensile strength (UTS), and elongation. Microstructural analysis was performed using optical microscopy.

The Breakthrough: Key Findings & Data

The results reveal a non-linear relationship between the amount of recycled content and mechanical performance, highlighting both an opportunity and a critical threshold.

Finding 1: The "Sweet Spot" at 30% Recycled Content

Contrary to the common assumption that any recycled content degrades properties, this study found a performance peak at a 30% recycled ingot ratio.

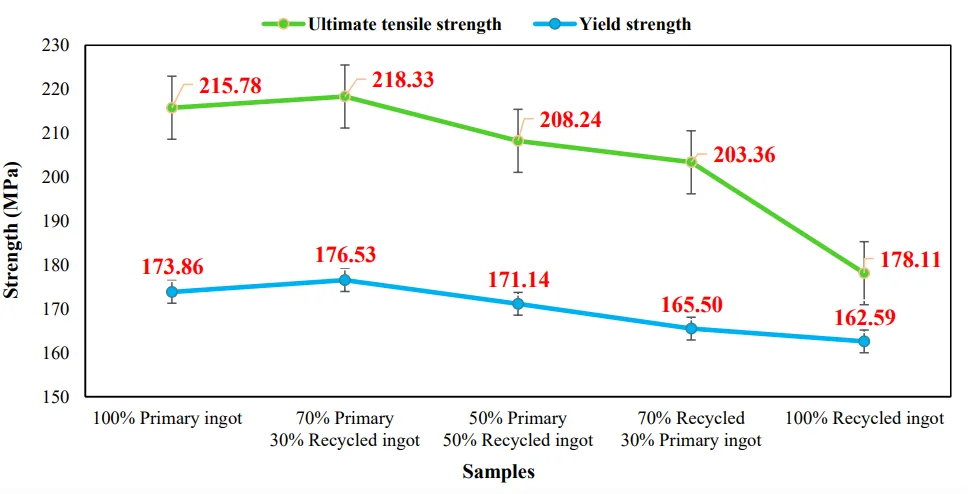

- As shown in Figure 7, the sample with 70% primary and 30% recycled ingot exhibited the highest mechanical strength. Its ultimate tensile strength (UTS) was 218.33 MPa, a 1.2% increase over the 215.78 MPa of the 100% primary ingot sample. Similarly, its yield strength (YS) was 176.53 MPa, a 1.5% increase over the 173.86 MPa of the baseline sample.

Finding 2: The Performance Cliff Beyond 30%

While a 30% blend was beneficial, increasing the recycled content further led to a consistent and significant decline in all measured mechanical properties.

- The 100% recycled ingot sample showed a dramatic drop in performance. As seen in Figure 7, its UTS plummeted to 178.11 MPa (an 18.4% decrease from the 30% peak), and its YS fell to 162.59 MPa.

- Ductility was most severely affected. Figure 8 shows that elongation dropped from 2.42% for the 100% primary sample to just 0.84% for the 100% recycled sample—a 65% reduction.

- Microstructural analysis (Figure 5) supports these findings, showing an increase in dark-colored inclusions (suspected oxides) and a higher eutectic silicon phase ratio in samples with more recycled content. The Fe content also increased from 0.100% in primary ingots to 0.123% in recycled ingots (Table 2), contributing to the formation of detrimental intermetallic phases.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that a blend of up to 30% recycled ingot can be a safe and even beneficial target for charge material formulation in gravity casting. This allows for significant cost savings without compromising component strength.

- For Quality Control Teams: The data in Table 2 and Figure 5 illustrates the effect of increasing Fe content and oxide inclusions on mechanical properties. Monitoring Fe levels in recycled scrap and assessing melt cleanliness are critical for ensuring consistent quality when using higher percentages of recycled material.

- For Design Engineers: The findings indicate that for applications requiring high ductility and fracture toughness, the use of high-percentage recycled A356 should be approached with caution. The sharp drop in elongation shown in Figure 8 is a critical design consideration.

Paper Details

Effect of Chip Amount on Microstructural and Mechanical Properties of A356 Aluminum Casting Alloy

1. Overview:

- Title: Effect of Chip Amount on Microstructural and Mechanical Properties of A356 Aluminum Casting Alloy

- Author: A.Y. Kaya, O. Özaydın, T. Yağcı, A. Korkmaz, E. Armakan, O. Çulha

- Year of publication: 2021

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 21, Issue 3/2021

- Keywords: A356, Gravity casting, Chip melting, Mechanical properties, Recycling

2. Abstract:

Aluminum casting alloys are widely used in especially automotive, aerospace, and other industrial applications due to providing desired mechanical characteristics and their high specific strength properties. Along with the increase of application areas, the importance of recycling in aluminum alloys is also increasing. The amount of energy required for producing primary ingots is about ten times the amount of energy required for the production of recycled ingots. The large energy savings achieved by using the recycled ingots results in a significant reduction in the amount of greenhouse gas released to nature compared to primary ingot production. Production can be made by adding a certain amount of recycled ingot to the primary ingot so that the desired mechanical properties remain within the boundary conditions. In this study, by using the A356 alloy and chips with five different quantities (100% primary ingots, 30% recycled ingots + 70% primary ingots, 50% recycled ingots + 50% primary ingots, 70% recycled ingots + 30% primary ingots, 100% recycled ingots), the effect on mechanical properties has been examined and the maximum amount of chips that can be used in production has been determined. T6 heat treatment was applied to the samples obtained by the gravity casting method and the mechanical properties were compared depending on the amount of chips. Besides, microstructural examinations were carried out with optical microscopy techniques. As a result, it has been observed that while producing from primary ingots, adding 30% recycled ingot to the alloy composition improves the mechanical properties of the alloy such as yield strength and tensile strength to a certain extent. However, generally a downward pattern was observed with increasing recycled ingot amount.

3. Introduction:

The introduction highlights the increasing energy requirements and environmental problems driving the need for recycling. In the automotive industry, the demand for fuel-efficient, lighter vehicles has led to the prevalent use of aluminum alloys due to their lightness, specific strength, and corrosion resistance. However, primary aluminum production is highly energy-intensive. Recycling aluminum saves significant energy (up to 14000 kWh per ton) and reduces greenhouse gas emissions. The primary challenge with recycled aluminum is the increase in impurities (e.g., Fe, Si, oxides) and defects (e.g., porosity), which can negatively impact mechanical properties and limit the use of recycled materials. The study aims to investigate these effects specifically for A356 alloy.

4. Summary of the study:

Background of the research topic:

The study is grounded in the industrial need to balance the economic and environmental benefits of aluminum recycling with the stringent mechanical property requirements for cast components, particularly in the automotive sector.

Status of previous research:

Previous literature has established that impurities in recycled aluminum, especially iron, form detrimental intermetallic compounds. It is also known that oxides and porosity negatively affect melt quality and mechanical performance. Studies have also investigated the effects of T6 heat treatment on A356 alloys. However, a systematic quantification of how varying percentages of recycled machining chips affect the final T6-treated properties of A356 was needed.

Purpose of the study:

The purpose was to examine the effect of different quantities of recycled A356 chips on the microstructural and mechanical properties of the alloy. The study aimed to determine the maximum amount of chips that can be used in production while maintaining desired properties, thereby providing a practical guideline for foundries.

Core study:

The core of the study involved creating five different melts of A356 alloy with recycled ingot content ranging from 0% to 100%. These melts were gravity cast, subjected to a standard T6 heat treatment, and then evaluated for their chemical composition, microstructure (α-Al and eutectic Si phase ratios), yield strength, ultimate tensile strength, and elongation.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. Five groups of samples were created, with the independent variable being the weight percentage of recycled ingot (0%, 30%, 50%, 70%, 100%). The dependent variables were the resulting mechanical properties (YS, UTS, elongation) and microstructural features.

Data Collection and Analysis Methods:

- Chemical Analysis: An optical emission spectrometer (OES) was used to determine the chemical composition of the ingots and cast samples.

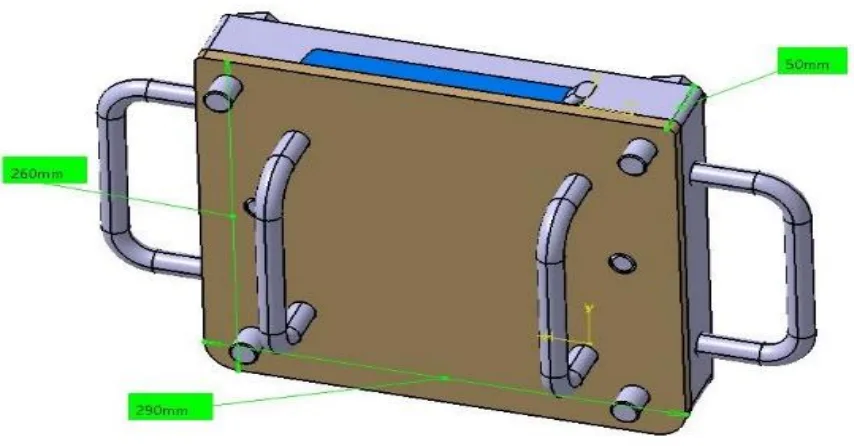

- Casting: A permanent metallic mold (290mm x 260mm x 50mm) was used for gravity casting.

- Heat Treatment: A controlled T6 heat treatment (solutionizing at 535±5°C for 3.5h, water quenching, aging at 165±5°C for 2h) was applied to all samples.

- Mechanical Testing: Tensile tests were performed using a Zwick Z100 test machine according to PN-EN ISO 6892-1: 2020-05. At least three tests were conducted for each sample condition.

- Microstructural Analysis: Samples were examined using a Nikon optical microscope with Clemex image analysis software to analyze phases and defects at magnifications of 50x, 100x, and 200x.

Research Topics and Scope:

The research was scoped to the A356 aluminum alloy and the gravity casting process. It specifically focused on the impact of recycled content derived from machining chips. Melt treatments such as degassing and grain refinement were intentionally excluded to isolate the variable of interest.

6. Key Results:

Key Results:

- Adding 30% recycled ingot to a 70% primary ingot charge resulted in a 1.5% increase in yield strength and a 1.2% increase in ultimate tensile strength compared to a 100% primary ingot charge.

- Increasing the recycled ingot amount beyond 30% led to a progressive decrease in both yield and tensile strength. The 100% recycled ingot sample showed an 18.4% decrease in UTS compared to the peak strength observed in the 30% recycled sample.

- Elongation decreased steadily with increasing recycled content, with a sharp drop observed in the 100% recycled ingot sample, which had an elongation of only 0.84%.

- Microstructural analysis showed that the eutectic-Si phase ratio increased with the amount of recycled ingot, from 10.86% in the 100% primary sample to 17.95% in the 100% recycled sample.

- The presence of dark-colored inclusions, presumed to be oxides, was observed to increase in the microstructure as the amount of recycled ingot increased.

- The iron (Fe) content was higher in the recycled ingot (0.123%) compared to the primary ingot (0.100%), and this content increased in the samples with higher recycled material ratios.

Figure Name List:

- Fig. 1. Recycled ingots

- Fig. 2. T6 Heat treatment

- Fig. 3. Test sheet borders of permanent mold product

- Fig. 4. Permanent Mold (290mm x 260mm x 50mm)

- Fig. 5. Optical microscope images of the samples at different magnifications

- Fig. 6. Phase analysis images and results of the samples

- Fig. 7. Yield strength and ultimate tensile strength values of the samples

- Fig. 8. Elongation values of the samples (%)

7. Conclusion:

The study concluded that the amount of recycled ingot significantly affects the properties of A356 alloy. While adding 30% recycled ingot can slightly improve yield and tensile strength, higher amounts cause adverse effects. The increase in Fe content and oxides in recycled ingots is identified as the primary cause for the degradation in mechanical properties, particularly the sharp decrease in elongation. The eutectic-Si phase ratio was also observed to increase with higher recycled content. The results suggest that while recycling is beneficial, the proportion of recycled material must be carefully controlled to meet performance specifications.

8. References:

- [1] Miller, W.S., Zhuang, L., Bottema, J., Wittebrood, A.J., Smet, P. De., Haszler, A. & Vieregge, A. (2000). Recent development in aluminium alloys for the automotive industry. Materials Science and Engineering: A. 280, 37-49. doi.org/10.1016/S0921-5093(99)00653-X

- [2] Cagan, S.C., Venkatesh, B. & Buldum, B.B. (2020). Investigation of surface roughness and chip morphology of aluminum alloy in dry and minimum quantity lubrication machining. Materials Today: Proceedings. 27, 1122-1126. doi.org/10.1016/j.matpr.2020.01.547

- [3] Naumova, E.A., Belov, N.A. & Bazlova, T.A. (2015). Effect of heat treatment on structure and strengthening of cast eutectic aluminum alloy Al9Zn4Ca3Mg. Metal Science and Heat Treatment. 57, 5-6. doi.org/10.1007/s11041-015-9874-6

- [4] Krolo, J., Gudić, S., Vrsalović, L., Branimir, L., Zvonimir, D. (2020). Fatigue and corrosion behavior of solid-state recycled aluminum alloy EN AW 6082. Journal of Materials Engineering and Performance. 29(7), 4310-4321. doi.org/10.1007/s11665-020-04975-8

- [5] TMMOB Metalurji Mühendisleri Odası, Alüminyum Komisyonu, Alüminyum Raporu.

- [6] Dhindaw, B.K., Aditya, G.S.L. & Mandal, A. (2020). Recycling and downstream processing of aluminium alloys for automotive applications. In Saleem Hashmi and Imtiaz Ahmed Choudhury (Eds.), Encyclopedia of Renewable and Sustainable Materials. 3 (pp.154-161). Elsevier Inc.

- [7] Grjotheim, K., Krohn, C., Malinovsky, M., Matiasovsky, K., Thonstad, J. (1982). Aluminium electrolysis: Fundamentals of the Hall-Heroult Process. 2nd Edition. University of California.

- [8] Peng, T., Ou, X., Yan, X. & Wang, G. (2019). Life-cycle analysis of energy consumption and GHG emissions of aluminium production in China. Energy Procedia. 158, 3937-3943. doi.org/10.1016/j.egypro.2019.01.849

- [9] Prasada Rao, A. K. (2011). An approach for predicting the composition of a recycled Al-Alloy. Transactions of the Indian Institute of Metals. 64, 615-617. doi.org/10.1007/s12666-011-0084-7

- [10] Capuzzi, S. & Timelli, G. (2018). Preparation and melting of scrap in aluminum recycling: A Review. Metals. 8(4), 249. doi.org/10.3390/met8040249

- [11] Khalid, S.N.A.B. (2013). Mechanical strength of as-compacted aluminium alloy waste chips. Malaysia: MSc Thesis, Universiti Tun Hussein Onn Malaysia.

- [12] Bjurenstedt, A. (2017). On the influence of imperfections on microstructure and properties of recycled Al-Si casting alloys. Sweden: PhD. Thesis, Jönköping University Jönköping.

- [13] Bogdanoff, T., Seifeddine, S. & Dahle, A. K. (2016). The effect of Si content on microstructure and mechanical properties of Al-Si alloy. La Metallurgia Italiana. 108(6), 65-69.

- [14] Wang, Y., Liao, H., Wu, Y. & Yang, J. (2014). Effect of Si content on microstructure and mechanical properties of Al-Si-Mg alloys. Materials & Design. 53, 634-638.

- [15] Ozaydin, O. & Kaya, A. (2019). Influence of different Si levels on mechanical properties of aluminium casting alloys. European Journal of Engineering And Natural Sciences. 3(2), 165-172.

- [16] Zhang, X., Ahmmed, K., Wang, M. & Hu, H. (2012). Influence of aging temperatures and times on mechanical properties of vacuum high pressure die cast aluminum alloy A356. Advanced Materials Research. 445, 277-282. doi.org/10.4028/www.scientific.net/AMR.445.277

- [17] Ozaydin, O., Dokumaci, E., Armakan, E., Kaya, A. (2019). The effects of artificial ageing conditions on a356 aluminum cast alloys. In ECHT 2019 - European Conference on Heat Treatment. Bardolino, Italy.

- [18] Peng, J., Tang, X., He, J. & Xu, D. (2011). Effect of heat treatment on microstructure and tensile properties of A356 alloys. Trans. Nonferous Met. Soc. Chinea. 21, 1950-1956. DOI: 10.1016/S1003-6326(11)60955-2

- [19] Wang, L., Makhlouf, M. & Apelian, D. (2013). Aluminium die casting alloys: alloy composition, microstructure, and properties-performance relationships. International Materials Reviews. 40(6), 221-238. doi.org/10.1179/imr.1995.40.6.221

- [20] Yuksel, C.K., Tamer, O., Erzi, E., Aybarc, U., Cubuklusu, E., Topcuoglu, O., Cigdem, M. & Dispinar, D. (2016). Quality evaluation of remelted A356 scraps. Archives of Foundry Engineering. 16(3), 151-156. DOI: 10.1515/afe-2016-0069

- [21] Hu, M., Ji, Z., Chen, X. & Zhang, Z. (2007). Effect of chip size on mechanical property and microstructure of AZ91D magnesium alloy prepared by solid state recycling. Materials Characterization. 59(4), 385-389. doi.org/10.1016/j.matchar.2007.02.002

- [22] Testing Of Metallic Materials – Tensile Test Pieces, Prüfung Metallischer Werkstoffe - Zugproben Deutsche Norm DIN 50125, 2016.

- [23] Metallic Materials - Tensile Testing - Part 1:Method Of Test at Room Temperature, PN-EN ISO 6892-1: 2020-05

- [24] Taylor J.A. (2012). Iron-containing intermetallic phases in Al-Si based casting alloys. Procedia Materials Science. 1, 19-33. doi.org/10.1016/j.mspro.2012.06.004

- [25] Eisaabadi, G.B., Davami, P., Kim, S.K., Varahram, N., Yoon, Y.O. & Yeom, G.Y. (2012). Effect of oxide films, inclusions and Fe on reproducibility of tensile properties in cast Al-Si-Mg alloys: Statistical and image analysis. Materials Science and Engineering: A. 558, 134-143. doi.org/10.1016/j.msea.2012.07.101

- [26] Schlesinger, M.E. (2013). Aluminum Recycling. CRC Press. 2nd Edition. CRC Press

- [27] Dispinar, D., Akhtar, S., Nordmark, A., Sabatino, M. Di. & Arnberg, L. (2010). Degassing, hydrogen and porosity phenomena in A356. Materials Science and Engineering: A. 527(17), 3719-3725. doi.org/10.1016/j.msea.2010.01.088

- [28] Akhtar, S., Dispinar, D., Arnberg, L. & Sabatino, M.Di. (2009). Effect of hydrogen content melt cleanliness and solidification conditions on tensile properties of A356 alloy. International Journal of Cast Metals Research. 22(4), 22-25. doi.org/10.1179/136404609X367245

- [29] Bösch, D., Pogatscher, S., Hummel, M., Fragner, W., Uggowitzer, P.J., Göken, M. & Höppel, H.W. (2015). Secondary Al-Si-Mg high-pressure die casting alloys with enhanced ductility. Metallurgical and Materials Transactions A. 46(3), 1035-1045.

- [30] Taylor, J.A. (2004). The effect of iron in Al-Si casting alloys. In 35th Australian Foundry Institute National Conference, 31 Oct - 3 Nov 2004 (148-157). Australia: Australian Foundry Institute (AFI).

- [31] Campbell, J. (1993). Castings, 2nd Edition. Elsevier.

Expert Q&A: Your Top Questions Answered

Q1: Why were melt treatments like degassing and grain refinement not used in this study?

A1: The paper states that these processes were intentionally omitted to create a baseline and isolate the direct effect of the recycled chip content on the final properties. By not performing any melt treatment, the researchers could ensure that any observed changes in microstructure and mechanical performance were attributable solely to the raw material composition. Future work is planned to incorporate these processes to better simulate real-world production.

Q2: What is the primary cause identified for the sharp decline in mechanical properties at higher recycled content levels?

A2: The paper attributes the decline to two main factors. First is the increased iron (Fe) content in the recycled ingots, which promotes the formation of brittle, iron-containing intermetallic compounds that negatively affect strength and ductility. Second is the higher concentration of impurities like oxides in the recycled material, which act as defects and crack initiation sites, as observed in the microstructures of the high-recycled-content samples.

Q3: The study showed a surprising increase in strength at 30% recycled content. Does the paper explain why this happens?

A3: The paper observes and reports the "sudden rise" in both yield strength and ultimate tensile strength in the sample with 30% recycled ingot but does not offer a specific hypothesis for this improvement. It focuses on the overall downward trend that becomes dominant as the recycled content increases further. This slight improvement could be due to minor compositional fluctuations or complex phase interactions, but the main takeaway remains that a threshold exists beyond which properties degrade significantly.

Q4: How did the microstructure specifically change as more recycled material was added?

A4: The microstructural analysis in Figures 5 and 6 showed two key changes. The phase ratio of eutectic silicon increased from 10.86% in the 100% primary sample to 17.95% in the 100% recycled sample. Additionally, the prevalence of dark-colored regions, identified as inclusions and suspected to be oxides, increased noticeably in the samples with higher recycled content.

Q5: What were the exact parameters for the T6 heat treatment applied to the samples?

A5: The T6 heat treatment, detailed in Figure 2, consisted of three steps. First, a solutionizing treatment was performed at 535±5°C for 3.5 hours. This was followed by quenching the samples in water held at a temperature of 65±5°C. Finally, the samples underwent artificial aging at 165±5°C for 2 hours.

Q6: Did the amount of other key alloying elements, like Si and Mg, change significantly between the samples?

A6: According to the OES results in Table 2, the Si and Mg contents showed only slight fluctuations. For example, Si ranged from 7.14% to 7.34%, and Mg ranged from 0.26% to 0.28%. The paper concludes that these minor variations are acceptable and not responsible for the major changes observed in mechanical properties, pointing instead to Fe and oxides as the primary drivers.

Q7: How does this study's use of gravity casting relate to other processes like high-pressure die casting (HPDC)?

A7: While this study used gravity casting, the fundamental findings regarding the impact of impurities like Fe and oxides are highly relevant to HPDC. In fact, the negative effects of these impurities can be even more pronounced in HPDC due to the rapid solidification and turbulent mold filling, which can entrap oxides and lead to different intermetallic morphologies. This research provides a valuable baseline for understanding raw material quality, which is a critical input for any casting process.

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively demystifies the use of Recycled A356 Aluminum, transforming it from a simple cost-cutting measure into a strategic process variable. The key breakthrough is clear: a carefully controlled blend of up to 30% recycled ingot not only matches but can slightly exceed the mechanical strength of 100% primary material. However, it also establishes a critical warning that exceeding this threshold, particularly without advanced melt treatment, can lead to a sharp decline in performance, especially ductility. This data provides engineers with a tangible framework for optimizing material costs while confidently meeting quality specifications.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Effect of Chip Amount on Microstructural and Mechanical Properties of A356 Aluminum Casting Alloy" by "A.Y. Kaya et al.".

Source: https://doi.org/10.24425/afe.2021.136108

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.