Unlocking Superior Wear Resistance in 7000-Series Aluminum: The Al-SiC Nanocomposite Breakthrough

This technical summary is based on the academic paper "Investigation of the Microstructure and Mechanical Properties of Cast Al-8Zn-3Mg-2.5Cu Nanocomposite Reinforced with SiC Nanoparticles after Age Hardening Heat-Treatment" by Mohammad Alipour, published in Journal of Metallurgical and Materials Engineering (2023).

Keywords

- Primary Keyword: Al-SiC Nanocomposite

- Secondary Keywords: 7000-Series Aluminum, Al-8Zn-3Mg-2.5Cu, SiC Nanoparticles, Ultrasonic Stir Casting, Age Hardening, Wear Resistance, Mechanical Properties

Executive Summary

- The Challenge: To enhance the hardness and wear resistance of high-strength cast Al-8Zn-3Mg-2.5Cu (AA 7000-series) alloys for demanding automotive and aerospace applications while maintaining cost-effectiveness.

- The Method: A novel synthesis approach combining powder metallurgy with ultrasonic-assisted stir casting to create an Al-8Zn-3Mg-2.5Cu matrix nanocomposite reinforced with varying percentages of Silicon Carbide (SiC) nanoparticles.

- The Key Breakthrough: The addition of 3 wt.% SiC nanoparticles, combined with T6 age hardening, optimally refines the grain structure and achieves a uniform particle distribution, resulting in a 67% increase in hardness and a significant reduction in wear rate.

- The Bottom Line: This research provides a validated manufacturing process for producing high-performance Al-SiC nanocomposites with superior mechanical properties, offering a lighter, stronger, and more durable alternative to traditional materials like brass, copper, and steel.

The Challenge: Why This Research Matters for HPDC Professionals

In the transportation sector, the drive for fuel efficiency and cost reduction is relentless. This places a premium on lightweight materials that don't compromise on strength or durability. While AA 7000-series aluminum alloys are primary candidates due to their high strength-to-weight ratio, their performance in as-cast conditions has received limited attention. Key challenges include achieving a fine, uniform microstructure and preventing defects like porosity or particle agglomeration, which can severely degrade mechanical properties. This research directly addresses the need to improve the hardness and wear resistance of these cast alloys, making them suitable for high-stress applications like bumper beams, chassis parts, and structural components where reliability is paramount.

The Approach: Unpacking the Methodology

The study employed a sophisticated, multi-stage process to ensure the successful integration of SiC nanoparticles into the aluminum alloy matrix. This methodology was designed to overcome common issues like poor particle wetting and clumping (agglomeration).

Method 1: Preform Preparation via Powder Metallurgy:

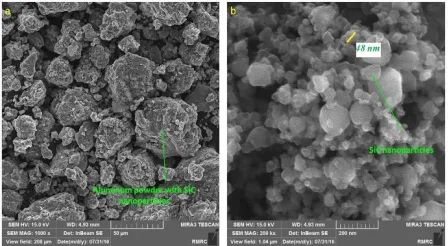

The process began not by adding SiC nanoparticles directly to the molten aluminum, but by first creating a composite powder. Aluminum powder (40 µm) and SiC nanoparticles (35-50 nm) were combined and subjected to high-energy mechanical milling for 2 hours. This crucial step coats the aluminum particles with SiC nanoparticles, ensuring excellent pre-dispersion and preventing clumping later in the process.

Method 2: Ultrasonic-Assisted Stir Casting:

Ingots of Al-8Zn-3Mg-2.5Cu alloy were melted in a graphite crucible at ~750°C. The melt was homogenized using a mechanical stirrer (500 rpm) while simultaneously being subjected to high-power ultrasonic waves (2000 W) for 60 seconds. This ultrasonic treatment generates intense acoustic streaming and cavitation, which breaks down any remaining particle clusters and ensures a uniform temperature throughout the melt. The pre-milled Al-SiCnp composite powder was then added to the vortex, and the mixture was poured into a permanent mold.

Method 3: Characterization and Testing:

Samples with 0, 1, 2, 3, and 5 wt.% SiC nanoparticles were produced. The microstructure was analyzed using SEM and EDX. Mechanical properties were evaluated through hardness testing (ASTM E10) and dry sliding wear tests (ASTM G99) using a pin-on-disc setup. A T6 age hardening heat treatment was also applied to a set of samples to evaluate its effect on performance.

The Breakthrough: Key Findings & Data

The combination of powder metallurgy pre-processing, ultrasonic casting, and T6 heat treatment yielded significant and quantifiable improvements in the material's properties.

Finding 1: Optimal Reinforcement Achieved at 3 wt.% SiC

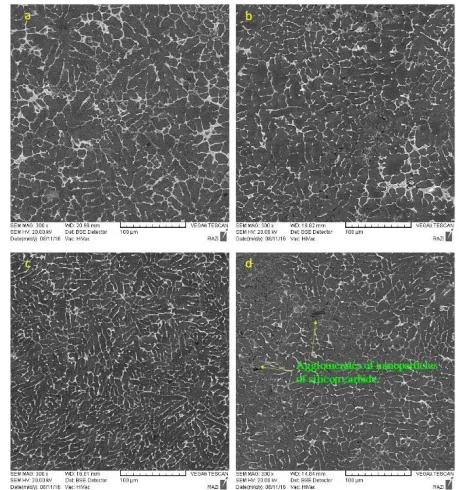

The study conclusively identified 3 wt.% as the optimal concentration of SiC nanoparticles. As shown in the microstructural images (Fig. 2), adding SiC refines the grain structure of the aluminum alloy. However, at 5 wt.% SiC, agglomeration of nanoparticles occurs at the grain boundaries, leading to embrittlement, porosity, and a decrease in mechanical properties. The 3 wt.% sample provided the best balance of reinforcement and structural integrity.

Finding 2: T6 Heat Treatment Dramatically Enhances Hardness and Wear Resistance

The T6 age hardening process was a critical factor in unlocking the material's full potential. The hardness of the 3 wt.% SiC nanocomposite after T6 treatment showed a 67% increase compared to the as-cast base alloy. This directly translated to superior wear performance. As shown in Figure 3, the weight loss due to wear was significantly lower for samples containing SiC, especially after T6 treatment. The wear rate for the T6-treated 3 wt.% SiC nanocomposite was 2.67 times lower than that of the as-cast base alloy under a 20 N load.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that incorporating ultrasonic treatment into stir casting processes can be highly effective for achieving uniform dispersion of nanoparticles. The two-step approach of using a pre-milled composite powder, rather than adding raw nanoparticles to the melt, may significantly reduce defects related to agglomeration.

- For Quality Control Teams: The data in Figure 2 and the associated discussion highlight the microstructural indicators of poor nanoparticle dispersion (agglomerates at grain boundaries). This can inform new microscopic inspection criteria to ensure the quality and performance of nanocomposite components.

- For Design Engineers: The findings demonstrate that a 3 wt.% SiC reinforcement can substantially increase the wear resistance and hardness of AA 7000-series alloys. This allows for the design of lighter components for high-wear applications without sacrificing durability, providing a valuable alternative to heavier materials.

Paper Details

Investigation of the Microstructure and Mechanical Properties of Cast Al-8Zn-3Mg-2.5Cu Nanocomposite Reinforced with SiC Nanoparticles after age Hardening Heat Treatment

1. Overview:

- Title: Investigation of the Microstructure and Mechanical Properties of Cast Al-8Zn-3Mg-2.5Cu Nanocomposite Reinforced with SiC Nanoparticles after age Hardening Heat Treatment

- Author: Mohammad Alipour

- Year of publication: 2023

- Journal/academic society of publication: Journal of Metallurgical and Materials Engineering

- Keywords: Casting nanocomposite, SiC nanoparticles, Stir casting, Ultrasonic treatment.

2. Abstract:

In this study, microstructure and wear properties of Al-8Zn-3Mg-2.5Cu nanocomposite reinforced with 1, 2, 3 and 5 wt.% SiC nanoparticles (SiCnp) produced by stir casting and ultrasonic treatment have been investigated. Ultrasound device equipped with a cooling system with 2000 W powers was used for mixing alloy and nanoparticles. Also scanning electron microscopy was used for microstructure studies. The microstructure of nanocomposite was investigated by scanning electron microscope. The microstructural studies of the nanocomposite revealed that SiCnp addition reduces the grain size, but adding higher SiCnp content (5 wt.%) does not change the grain size considerably. Further investigations on hardness revealed that the addition of SiCnp increases hardness and wear resistance. At higher SiCnp contents (5 wt.%), the presence of SiCnp agglomerate on grain boundaries was found that causes decrease the hardness and wear resistance. The optimum amount of nanoparticles before and after heat treatment is 3 wt.% SiCnp that nanocomposite exhibits best wear resistance.

3. Introduction:

The demand for weight reduction in the transportation industry to improve fuel efficiency has made aluminum and its alloys primary candidates for structural parts due to their low density, high strength, and ductility. The AA 7000 alloy series is particularly suited for high-strength applications. The properties of these alloys can be improved through new processing techniques, including the inclusion of nano-sized reinforcements. While much research has focused on mechanically deformed alloys, less attention has been given to the as-cast condition. This paper reports on the development of Al-8Zn-3Mg-2.5Cu matrix nanocomposites reinforced with SiC nanoparticles, synthesized by a combination of powder metallurgy and ultrasonic-assisted stir casting, to evaluate their hardness and wear resistance.

4. Summary of the study:

Background of the research topic:

Aluminum matrix composites (AMCs), particularly those from the 7000-series, are advanced materials used in various industries due to their low density, high specific strength, and good corrosion resistance. Reinforcing these alloys with nanoparticles like Silicon Carbide (SiC) has the potential to further enhance their mechanical properties, such as hardness and wear resistance.

Status of previous research:

Previous research has extensively studied high-strength aluminum alloys after mechanical deformation. However, the properties of these alloys in the as-cast and semi-solid states have received less attention. While various casting methods exist for producing composites, they can suffer from issues like porosity and non-uniform particle distribution. The use of ultrasonic waves to de-agglomerate nanoparticles and improve dispersion in molten metal is a promising area of investigation.

Purpose of the study:

The primary purpose of this study was to investigate the microstructure and mechanical properties of a cast Al-8Zn-3Mg-2.5Cu nanocomposite. The research aimed to determine the optimal percentage of SiC nanoparticle reinforcement (1, 2, 3, and 5 wt.%) and to evaluate the effect of a subsequent T6 age hardening heat treatment on the material's hardness and wear resistance.

Core study:

The core of the study involved synthesizing Al-8Zn-3Mg-2.5Cu/SiCnp nanocomposites using a novel method combining powder metallurgy (to pre-disperse SiCnp on Al powder) and ultrasonic-assisted stir casting. The microstructures of the resulting composites were analyzed, and their mechanical performance (hardness and wear) was tested both before and after T6 heat treatment to identify the optimal processing and composition parameters.

5. Research Methodology

Research Design:

The study was designed as an experimental investigation. The independent variables were the weight percentage of SiC nanoparticles (0, 1, 2, 3, and 5 wt.%) and the application of a T6 heat treatment. The dependent variables were the resulting microstructure (grain size, particle distribution), hardness, and wear rate.

Data Collection and Analysis Methods:

- Material Synthesis: Al-8Zn-3Mg-2.5Cu alloy was melted at 750°C. A composite powder of Al and SiCnp was prepared by 2 hours of high-energy milling. This powder was added to the melt, which was mixed with a mechanical stirrer (500 rpm) and subjected to ultrasonic waves (2000 W) before being cast.

- Microstructural Analysis: Samples were analyzed using optical microscopy and Scanning Electron Microscopy (SEM) equipped with Energy Dispersive X-ray analysis (EDX).

- Mechanical Testing: Hardness was measured according to ASTM E10 standard. Dry sliding wear tests were conducted according to ASTM G99 standard using a pin-on-disc apparatus at a constant load of 20 N.

Research Topics and Scope:

The research focused on an Al-8Zn-3Mg-2.5Cu matrix alloy. The scope was limited to reinforcement with SiC nanoparticles at concentrations up to 5 wt.%. The manufacturing process was a specific combination of powder metallurgy and ultrasonic stir casting. The investigation covered the material's microstructure, hardness, and wear properties in both as-cast and T6 heat-treated conditions.

6. Key Results:

Key Results:

- The combination of mechanical alloying and ultrasonic-assisted stir casting is an effective method for achieving a uniform distribution of SiC nanoparticles in the Al-8Zn-3Mg-2.5Cu matrix.

- The optimal amount of SiC nanoparticle reinforcement was found to be 3 wt.%.

- At SiC concentrations exceeding 3 wt.% (e.g., 5 wt.%), agglomeration of nanoparticles occurs at grain boundaries, leading to embrittlement, porosity, reduced interfacial bonding, and a subsequent decrease in mechanical properties.

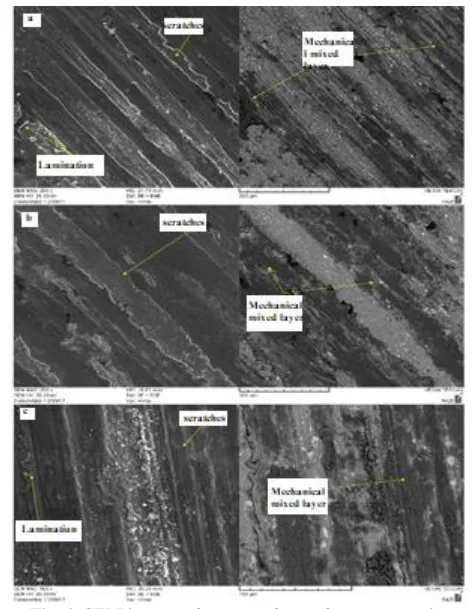

- SEM analysis of worn surfaces indicated that abrasive wear was the primary wear mechanism for these composites.

- The addition of SiC nanoparticles and the application of T6 heat treatment both contribute to a significant decrease in weight loss during wear tests compared to the unreinforced alloy.

Figure Name List:

- شکل ۱ شماتیک تاثیر کاویتاسیون و جریان گردابی ناشی از امواج مافوق صوت برای پخش یکنواخت نانوذرات در داخل مذاب [10].

- شکل ۲ آنالیز اندازه و تصویر TEM از نانوذرات SiC.

- شکل ۳ تصویر پودر کامپوزیتی Al-30SiCnp بعد از ۲ ساعت آسیاب کاری پرانرژی.

- شكل ٤ تصوير الف) قالب ریخته گری، ب) ابعاد نمونه تست کشش.

- شکل ٥ تصویر میکروسکوپ الکترونی روبشی ریزساختار و یوتکتیک مرزدانه ای آلیاژ پایه آلومینیوم Al-8Zn-3Mg-2.5Cu.

- شكل ٦ تصویر میکروسکوپ الکترونی روبشی ریزساختار، الف) آلیاژ پایه آلومینیوم Al-8Zn-3Mg-2.5Cu، ب) ٪۱، ج) ٪٣، و د) ٥ نانوذرات SiC.

- شکل ۷ آنالیز EDX و نحوه توزیع عناصر سطح نمونه نانوکامپوزیت با ٥ درصد نانوذرات تقویت کننده SiC.

- شکل ۸ میزان کاهش وزن نمونه های نانوکامپوزیت حاوی درصدهای مختلف نانوذرات کاربیدسیلیسیم قبل و بعد از اعمال عملیات T6 تحت نیروی ۲۰ نیوتن.

- شکل ۹ نرخ سایش آلیاژ پایه و نمونه های نانوکامپوزیت حاوی ۳ درصد وزنی کاربیدسیلیسیم قبل و بعد از عملیات T6.

- شکل ۱۰ تصاویر SEM از سطوح سایش نانوکامپوزیت تقویت شده با ۳ درصد وزنی نانوذرات کاربیدسیلیسیم تحت نیروی ۲۰ نیوتن. الف) قبل از عملیات حرارتی T6، ب و پ) بعد از عملیات حرارتی T6.

- شکل ۱۱ نتایج آزمون سختی سنجی برای نانوکامپوزیت تقویت شده با نانوذرات کاربیدسیلیسیم.

7. Conclusion:

The stir casting method combined with ultrasonic waves is highly effective for improving the mechanical properties of Al-8Zn-3Mg-2.5Cu aluminum alloy matrix composites reinforced with SiC nanoparticles, achieving uniform particle distribution. The optimum amount of nanoparticles is 3 wt.%. At higher concentrations, agglomeration at grain boundaries leads to a decrease in mechanical properties. The primary wear mechanism observed was abrasive wear.

8. References:

- [1] P. SenthilKumar, Padmalaya G, N. Elavarasan, B.S.Sreeja, "GO/ZnO nanocomposite - as transducer platform for electrochemical sensing towards environmental applications", Chemosphere, Vol. 313, pp 137345, 2023

- [2] Balakrishnan Somasekaran, Alwarsamy Thirunarayanaswamy, Ilamathi Palanivel " Synthesis of Graphene and fabrication of Aluminium-Grp nanocomposites: A review ", Materials Today: Proceedings, Vol. 50, pp 2436-2442, 2022.

- [3] Mamta Dahiya, Virat Khann, Suneev Anil Bansal " Aluminium-graphene metal matrix nanocomposites: Modelling, analysis, and simulation approach to estimate mechanical properties" Materials Today: Proceedings, 2022.

- [4] Reza Abedinzadeh, Ehsan Norouzi, Davood Toghraie " Study on machining characteristics of SiC-Al2O3 reinforced aluminum hybrid nanocomposite in conventional and laser-assisted turning ", Ceramics International, Vol. 48, pp 29205-29216, 2022.

- [5] Shijina S.Sainudeen, Antony Joseph, Mathew Joseph, V.Sajith, " Heat transfer phenomena of copper-graphene nanocomposite coated aluminium heat spreaders", Applied Thermal Engineering, Vol. 212, pp 118545, 2022.

- [6] Miracle, D., "Metal matrix composites-from science to technological significance", Composites Science and Technology, vol. 65, pp. 2526-2540, 2005.

- [7] Wenzhen, L., Shiying, L., Qiongyuan, Z., Xue, Z., "Ultrasonic-Assisted Fabrication of SiC Nanoparticles Reinforced Aluminum Matrix Composites", Materials Science Forum, Vol. 654-656, pp. 990-993, 2010.

- [8] Hihn, JY., Doche, ML., Mandroyan, A., Hallez, L. and Pollet, BG., "Respective Contribution of Cavitation and Convective Flow to Local Stirring in Sonoreactors", Ultrasonics Sonochemistry, Vol. 18, pp. 881-887, 2011.

- [9] Amirkhanlou, S., Ji, S., Zhang, Y., Watson, D., Fan, Z., "High modulus Alsingle bondSisingle bondMgsingle bondCu/Mg2Sisingle bondTiB2 hybrid nanocomposite: Microstructural characteristics and micromechanics-based

- [10]Yan, J., Xu, Z., Shi, L., Ma, X., Yang, S., "Ultrasonic assisted fabrication of particle reinforced bonds joining aluminum metal matrix composites" Mater & Design, Vol. 32, pp. 343-347, 2011.

- [11]Shabana, S., Sonawane, SH., Ranganathan, V., Pujjalwar, PH., Pinjari, DV., Bhanvase, BA., Gogate, PR., Ashokkumare, M., "Improved synthesis of aluminium nanoparticles using ultrasound assisted approach and subsequent dispersion studies in di-octyl adipate", Ultrasonics Sonochemistry, Vol. 36, pp. 59–69, 2017.

- [12]Mazahery, H. Abdizadeh, H.R. Baharvandi, "Development of high-performance A356/nano-Al2O3 composites", Materials Science & Engineering A, Vol. 518, pp. 61-64, 2009.

- [13]Y.L Shen, J.J Williams, G Piotrowski, N Chawla, Y.L Guo, "Correlation between tensile and indentation behavior of particle-reinforced metal matrix composites: an experimental and numerical study", Acta Materialia, Vol. 49, pp. 3219-3229, 2001.

- [14]R. Hamzaoui, O. Elkedim, E. Gaffet, "Milling conditions effect on structure and magnetic properties of mechanically alloyed Fe-10% Ni and Fe-20% Ni alloys", Materials Science and Engineering: A, Vol. 381, pp. 363-371, 2004.

- [15]K.S. Al-Rubaie, H.N. Yoshimura, J.D. Biasoli de Mello, "Two-body abrasive wear of Al-SiC composites", Wear, Vol. 233. pp. 444-454, 1999.

- [16]S. Mula, P. Padhi, S.C. Panigrahi, S.K. Pabi, S. Ghosh, "On structure and mechanical properties of ultrasonically cast Al-2% Al2O3 nanocomposite", Materials Research Bulletin, Vol. 44, pp. 1154-1160, 2009.

Expert Q&A: Your Top Questions Answered

Q1: Why was a combination of powder metallurgy and stir casting chosen instead of just adding SiC nanoparticles directly to the melt?

A1: Adding nanoparticles directly to molten metal often results in severe agglomeration (clumping) due to van der Waals forces and poor wetting by the liquid metal. By first using high-energy milling to create an Al-SiCnp composite powder, the nanoparticles are mechanically forced into a uniform distribution on the surface of the larger aluminum powder particles. This pre-dispersion step is critical for achieving a homogeneous final microstructure when the composite powder is introduced into the melt.

Q2: What is the specific role of the ultrasonic treatment in this process?

A2: The ultrasonic treatment serves two key functions. First, it generates intense acoustic streaming and cavitation within the molten metal. The collapse of cavitation bubbles creates localized micro-jets and shockwaves that effectively break apart any remaining clusters of nanoparticles, ensuring they are individually dispersed. Second, it helps homogenize the temperature of the entire melt, which is crucial for consistent solidification and microstructure formation.

Q3: The study identifies 3 wt.% SiC as optimal. What exactly happens at 5 wt.% that degrades the properties?

A3: At 5 wt.%, the volume of nanoparticles becomes too high for the casting process to disperse them effectively. As the aluminum alloy begins to solidify, the advancing solidification front pushes the excess, agglomerated nanoparticles. These clumps get trapped at the boundaries of the newly forming grains, creating weak points that act as stress concentrators. This leads to embrittlement, increased porosity, and poor interfacial bonding, which collectively reduce the material's overall hardness and wear resistance.

Q4: How does the T6 heat treatment contribute to the improved wear resistance?

A4: The T6 heat treatment (solutionizing, quenching, and artificial aging) causes the precipitation of fine, coherent strengthening phases within the aluminum matrix. These precipitates act as obstacles to dislocation movement, which significantly increases the hardness and strength of the alloy. A harder material is inherently more resistant to plastic deformation and abrasion from a counter-surface, which directly translates to a lower wear rate.

Q5: What is the primary wear mechanism identified, and what does that imply for potential applications?

A5: The study identified abrasive wear as the main wear mechanism. This is characterized by scratching and grooving of the surface by hard particles or asperities. The implication for applications is that this Al-SiC nanocomposite is particularly well-suited for components that experience sliding contact against hard surfaces, such as in bearings, pistons, or brake components, where resistance to scratching and material removal is critical for longevity.

Q6: Could this process be applied to other aluminum alloys or nanoparticle reinforcements?

A6: While the paper focuses specifically on Al-8Zn-3Mg-2.5Cu and SiC, the fundamental principles of the hybrid methodology are broadly applicable. The combination of pre-dispersion via powder metallurgy and final dispersion via ultrasonic casting could likely be adapted for other cast aluminum alloy systems (like the A356 series) and other ceramic nanoparticles (such as Al2O3 or TiB2). However, process parameters like milling time, ultrasonic power, and melt temperature would need to be optimized for each specific material combination.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of creating lightweight, high-performance cast components is a constant in modern manufacturing. This research demonstrates a powerful and effective pathway for enhancing 7000-series aluminum alloys through the creation of an Al-SiC Nanocomposite. By identifying an optimal 3 wt.% SiC reinforcement and leveraging a sophisticated ultrasonic-assisted casting process, this study provides a blueprint for achieving significant gains in hardness and wear resistance. The findings offer a clear advantage for R&D and operations teams looking to push the boundaries of material performance in demanding applications.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Investigation of the Microstructure and Mechanical Properties of Cast Al-8Zn-3Mg-2.5Cu Nanocomposite Reinforced with SiC Nanoparticles after Age Hardening Heat-Treatment" by "Mohammad Alipour".

Source: https://doi.org/10.22067/jmme.2022.79507.1084

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.