Boosting HPDC Performance: New Grain Refiner Increases Al-Si-Cu Alloy Strength by Over 12%

This technical summary is based on the academic paper "Effect of novel grain refiner and Ni alloying additions on microstructure and mechanical properties of Al-Si9.8-Cu3.4 HPDC castings – optimization using Multi Criteria Decision making approach" by K. Ch Apparao et al., published in Materials Science-Poland (2022).

Keywords

- Primary Keyword: HPDC Optimization

- Secondary Keywords: Al-Si-Cu alloy, grain refinement, Al-3.5FeNb-1.5C, Ni alloying, mechanical properties, ultimate tensile strength (UTS), hardness, Multi-Criteria Decision Making (MCDM), GRA, TOPSIS

Executive Summary

- The Challenge: Traditional grain refiners are often ineffective in high-silicon aluminum alloys used in HPDC due to a chemical "poisoning effect," limiting the mechanical performance of cast components.

- The Method: Researchers introduced a novel Niobium-based grain refiner (Al-3.5FeNb-1.5C) and Nickel (Ni) alloying additions to a commercial Al-Si9.8-Cu3.4 alloy under various HPDC process conditions.

- The Key Breakthrough: A specific combination of 0.1 wt.% of the novel grain refiner and 0.5 wt.% of Ni alloy addition dramatically improved the material's properties, increasing ultimate tensile strength (UTS) by 12.3% and microhardness by 20%.

- The Bottom Line: This study provides a validated, optimized formula and process window for significantly enhancing the strength and hardness of a common aluminum HPDC alloy, overcoming previous limitations.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive industry, the demand for lightweight, high-strength aluminum-silicon (Al-Si) cast components is relentless. The mechanical properties of these parts—tensile strength, hardness, and fatigue life—are critically dependent on their microstructure, specifically the size and distribution of the primary aluminum grains.

For decades, the industry has relied on master alloys like Al-Ti-B to refine these grains. However, a major challenge arises in Al-Si alloys where the silicon content exceeds 4 wt.%. The titanium (Ti) in the refiner reacts with silicon to form unwanted titanium silicides, consuming the active refining agent. This "poisoning effect" severely impairs the refiner's efficiency, leaving engineers with a coarser grain structure and suboptimal mechanical properties. This research directly confronts this long-standing industry problem by testing a novel refiner designed to resist silicon poisoning.

The Approach: Unpacking the Methodology

To find a solution, the researchers conducted a systematic investigation using a robust experimental design. Their approach provides high confidence in the results.

Method 1: Advanced Material Formulation

- Base Alloy: The study used a commercial Al-Si9.8-Cu3.4 alloy, a familiar material in automotive applications.

- Novel Grain Refiner: A new master alloy, Al-3.5FeNb-1.5C, was fabricated and added in varying amounts (0, 0.1, and 1.0 wt.%). Unlike titanium, niobium (Nb) forms more stable compounds that are not compromised by high silicon content.

- Alloying Element: An Al-6Ni master alloy was also added (0, 0.5, and 5.0 wt.%) to further enhance mechanical properties.

Method 2: Process Parameter Optimization

- HPDC Process Variables: Three critical HPDC process parameters were systematically varied:

- Molten metal temperature (720, 750, 780 °C)

- Die temperature (230, 260, 290 °C)

- Injection pressure (12, 18, 24 MPa)

- Experimental Design: The experiments were structured using a Taguchi L27 orthogonal array, an efficient method for studying multiple variables simultaneously. The results were then analyzed using Multi-Criteria Decision-Making (MCDM) techniques—Grey Relational Analysis (GRA) and TOPSIS—to identify the single best combination of material and process parameters.

The Breakthrough: Key Findings & Data

The study yielded clear, quantifiable results demonstrating the effectiveness of the new approach.

Finding 1: Optimal Grain Refinement Achieved at a Low Addition Level

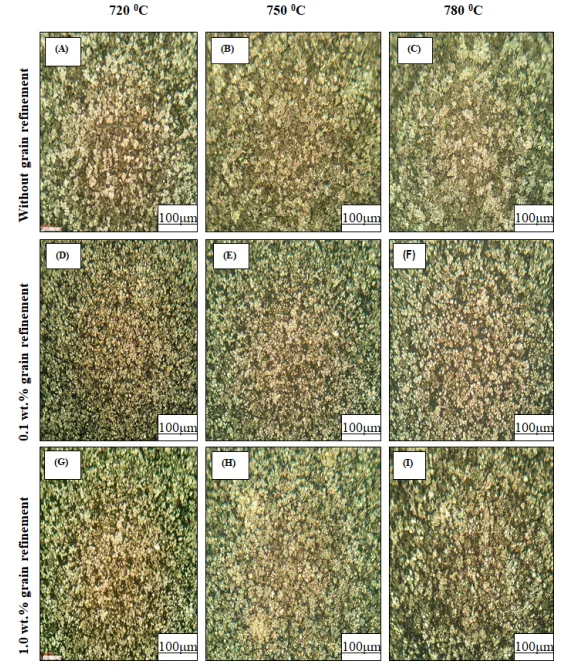

The novel Al-3.5FeNb-1.5C refiner proved highly effective, but the key was moderation. As shown in the microstructural analysis (Figure 3), the average grain size of the base alloy was reduced from over 60 µm to just 22.9 µm with the addition of only 0.1 wt.% of the refiner. This created a fine, uniform, equiaxed grain structure, which is ideal for superior mechanical properties. Conversely, adding a higher amount (1.0 wt.%) was counterproductive, leading to the formation of coarse β-Al5FeSi platelets that degraded the structure.

Finding 2: A 12.3% Increase in Tensile Strength

The optimized combination of additives and process parameters resulted in a significant boost in mechanical performance. The experimental run (R5) with 0.1 wt.% Al-3.5FeNb-1.5C and 0.5 wt.% Al-6Ni achieved the best results:

- Ultimate Tensile Strength (UTS): Increased by 12.3%, from 218.39 MPa in the unrefined alloy to 249.09 MPa.

- Brinell Hardness: Increased by 7.0%.

- Microhardness: Increased by 20%.

These improvements are directly linked to the successful grain refinement and the strengthening effect of the Ni additions.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the grain refiner addition to 0.1 wt.% of Al-3.5FeNb-1.5C and Ni to 0.5 wt.% can substantially improve mechanical properties. The optimal process parameters were identified as a 720°C molten metal temperature, a 230°C die temperature, and a 24 MPa injection pressure.

- For Quality Control Teams: The data in Figure 3 and Figure 8 of the paper illustrates the direct link between microstructure (fine equiaxed grains vs. coarse grains with β-Al5FeSi platelets) and mechanical performance. This could inform new microstructural inspection criteria for critical components.

- For Design Engineers: The findings on how excessive iron content (from the 1.0 wt.% refiner addition) leads to β-Al5FeSi platelets and potential shrinkage porosity are a valuable consideration for Design for Manufacturability (DFM) in complex castings.

Paper Details

Effect of novel grain refiner and Ni alloying additions on microstructure and mechanical properties of Al-Si9.8-Cu3.4 HPDC castings – optimization using Multi Criteria Decision making approach

1. Overview:

- Title: Effect of novel grain refiner and Ni alloying additions on microstructure and mechanical properties of Al-Si9.8-Cu3.4 HPDC castings – optimization using Multi Criteria Decision making approach

- Author: K. Ch Apparao, Praveen Kumar Bannaravuri, Kumar Swamy Pulisheru, E. D. Francis, Kalakanda Alfred Sunny, Gadudasu Babu Rao, P Freedon Daniel, Anil Kumar Birru

- Year of publication: 2022

- Journal/academic society of publication: Materials Science-Poland

- Keywords: die casting, Al-Si alloy, Al-3.5FeNb-1.5C grain refiner, Al-6Ni master alloy, GRA, TOPSIS, ultimate tensile strength and hardness

2. Abstract:

Studies dealing with process improvement of aluminum alloys and their grain structure refinement are the current area of interest in casting companies and foundries, the aim being to enhance the properties of the base metal. In this study, the microstructural and mechanical properties of commercial Al-Si9.8-Cu3.4 alloy die castings influenced by different additions of Al-3.5FeNb-1.5C master alloy (viz. 0 wt.%, 0.1 wt.%, and 1.0 wt.%) as a new grain refiner and Al-6Ni master alloy (viz. 0 wt.%, 0.5 wt.%, and 5.0 wt.%) as an alloying element have been investigated. A multi-criteria decision-making approach for the improvement of the die casting process was performed using grey relational analysis (GRA) and TOPSIS analytical techniques. It was observed that the primary aluminum α-grains were significantly refined, particularly at the lower addition level 0.1 wt.% of Al-3.5FeNb-1.5C, and conversely, poor grain refining efficiency was observed at a higher addition level 1.0 wt.% of Al-3.5FeNb-1.5C. Due to the refinement by Al-3.5FeNb-1.5C grain refiner and the effect of Ni alloying element additions, the ultimate tensile strength (UTS) and hardness (Brinell and micro) of the Al-Si9.8-Cu3.4 alloy are improved, particularly at 0.1 wt.% of Al-3.5FeNb-1.5C and 0.5 wt.% of Al-6Ni master alloys. Quantitatively, UTS, Brinell hardness, and microhardness values have been increased by 12.3%, 7.0%, and 20%, respectively.

3. Introduction:

Aluminum-silicon cast alloys are a primary material choice for the automotive industry due to their high strength-to-weight ratio. The mechanical properties of these alloys, such as tensile strength and hardness, are strongly dependent on their dendritic structure and the size of primary Al α-grains. Grain refinement is a highly effective process for achieving a homogeneous distribution of small, equiaxed grains, which enhances mechanical properties. Traditionally, Al-Ti-B based master alloys are used for this purpose. However, in Al-Si alloys with Si content exceeding 4 wt.%, these refiners lose their efficiency due to the formation of titanium silicides, a phenomenon known as the "poisoning effect." This study investigates a novel Ferroniobium (FeNb) and Carbon (C) based Al-3.5FeNb-1.5C master alloy as a grain refiner to overcome this limitation, along with the addition of an Al-Ni master alloy to further enhance mechanical properties in Al-Si9.8-Cu3.4 high pressure die castings (HPDC).

4. Summary of the study:

Background of the research topic:

The research addresses the need to improve the mechanical properties of aluminum-silicon alloys used in the automotive industry. The performance of these alloys is intrinsically linked to their microstructure, which can be improved through grain refinement.

Status of previous research:

Previous research has established that conventional Al-Ti-B grain refiners are subject to a "poisoning effect" in high-silicon aluminum alloys, reducing their effectiveness. Recent studies have indicated that Niobium (Nb)-based refiners, which form more stable borides and silicides, are a promising alternative to overcome this issue.

Purpose of the study:

The primary purpose was to investigate the effects of a novel Al-3.5FeNb-1.5C grain refiner and Ni alloying additions on the microstructure and mechanical properties of a commercial Al-Si9.8-Cu3.4 alloy. A secondary purpose was to use multi-criteria decision-making (MCDM) methods, specifically Grey Relational Analysis (GRA) and TOPSIS, to optimize the HPDC process parameters for achieving the best combination of tensile strength and hardness.

Core study:

The core of the study involved a designed experiment using a Taguchi L27 orthogonal array. Five factors were varied across three levels: molten metal temperature, wt.% of Al-3.5FeNb-1.5C refiner, wt.% of Al-6Ni alloy, die temperature, and injection pressure. The resulting cast samples were subjected to microstructural characterization (optical microscopy, SEM, XRD) and mechanical testing (UTS, Brinell hardness, microhardness). The experimental data was then analyzed using GRA and TOPSIS to determine the optimal set of parameters.

5. Research Methodology

Research Design:

The study employed a Taguchi L27 orthogonal array experimental design to systematically investigate the influence of five factors at three levels each. This design allows for an efficient analysis of the main effects of each parameter on the output responses. The optimization of the multi-response problem (UTS, hardness) was conducted using GRA and TOPSIS methodologies.

Data Collection and Analysis Methods:

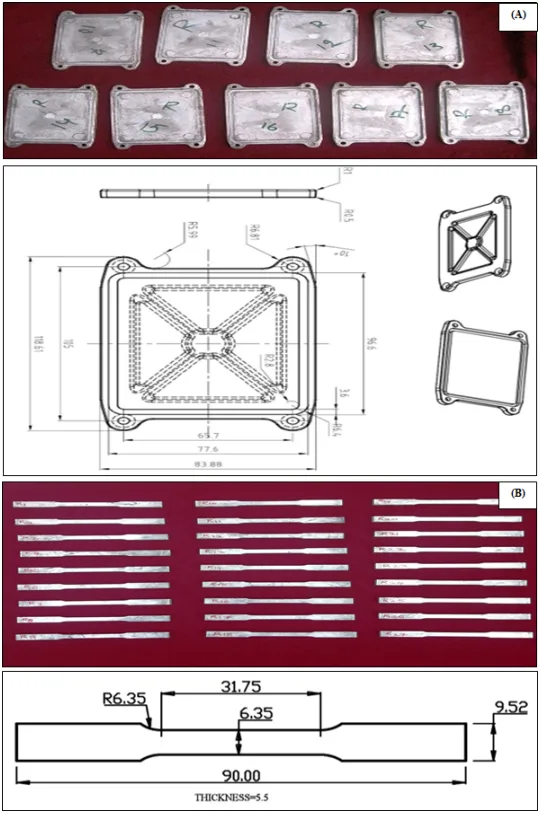

The Al-3.5FeNb-1.5C master alloy was prepared in-house using an inoculation technique. A commercial Al-Si9.8-Cu3.4 ingot was used as the base material. Test castings were produced using an HPDC machine according to the L27 experimental plan.

- Microstructural Analysis: Samples were prepared using standard metallographic techniques and examined with optical microscopy, Scanning Electron Microscopy (SEM) with Energy Dispersive X-ray Spectroscopy (EDS), and X-ray Diffraction (XRD) to identify phases and grain structure.

- Mechanical Testing: Ultimate tensile strength was measured according to ASTM: B557M-15 standard. Brinell hardness and Vickers microhardness were measured using a hardness tester.

- Data Analysis: The collected data for UTS, Brinell hardness, and microhardness were analyzed using GRA and TOPSIS to calculate relational grades and closeness coefficients, respectively, which were then used to rank the experimental runs and identify the optimal parameter settings.

Research Topics and Scope:

The research scope was confined to the commercial Al-Si9.8-Cu3.4 alloy. The investigation focused on the efficacy of the novel Al-3.5FeNb-1.5C grain refiner and Al-6Ni alloying element in combination with three key HPDC process parameters (molten metal temperature, die temperature, injection pressure). The output characteristics studied were limited to ultimate tensile strength, Brinell hardness, and microhardness.

6. Key Results:

Key Results:

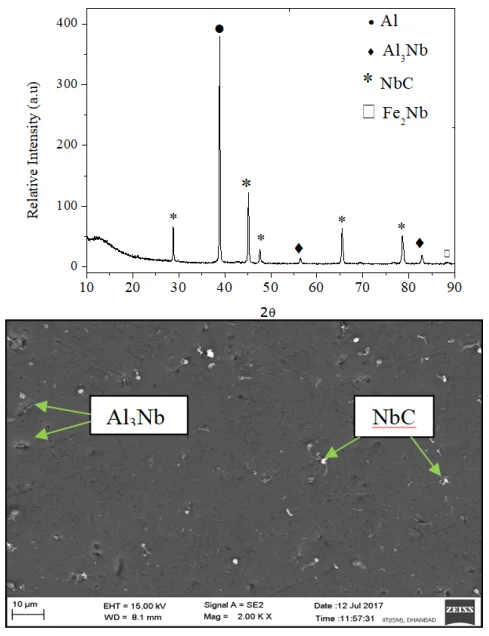

- The Al-3.5FeNb-1.5C master alloy was found to primarily contain α-Al, Al3Nb, and NbC phases, which serve as effective nucleation sites for grain refinement.

- Appreciable grain refinement of the Al-Si9.8-Cu3.4 alloy was observed at a low addition level of 0.1 wt.% of the Al-3.5FeNb-1.5C refiner, with the average grain size decreasing to 22.9 ± 3 µm.

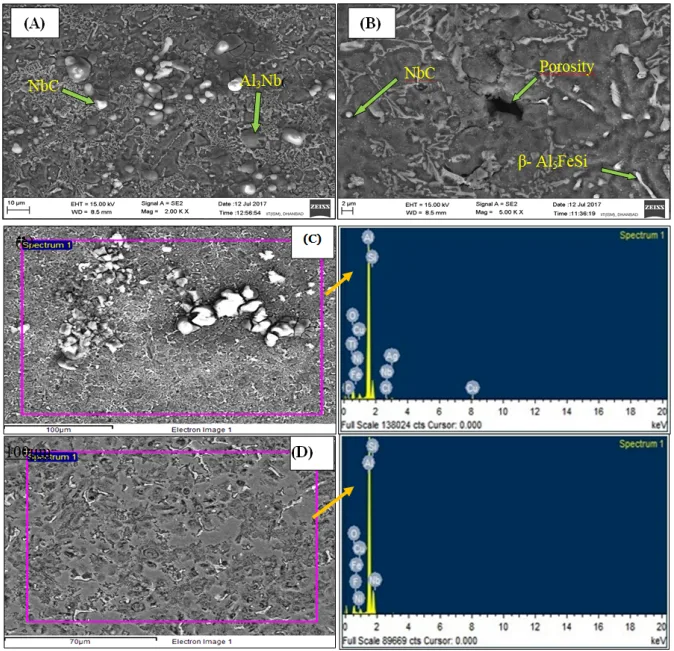

- A higher addition level of 1.0 wt.% of the refiner led to poor refining efficiency, attributed to the formation of β-Al5FeSi platelets which promote a coarse grain structure.

- The addition of the grain refiner and Ni alloying element significantly improved mechanical properties. The optimal combination was found to be 0.1 wt.% of Al-3.5FeNb-1.5C and 0.5 wt.% of Al-6Ni.

- At these optimal addition levels, UTS increased by 12.3%, Brinell hardness by 7.0%, and microhardness by 20% compared to the unrefined base alloy.

- Both GRA and TOPSIS optimization methods identified an identical set of optimal parameters: A1-B2-C2-D1-E3, corresponding to a molten metal temperature of 720°C, 0.1 wt.% refiner, 0.5 wt.% Ni, a die temperature of 230°C, and an injection pressure of 24 MPa.

Figure Name List:

- Fig. 1. Sample specimen of HPDC casting (A) Final castings with their dimensions (B) Tensile specimens with their dimensions used for the experimentations. HPDC, High pressure die casting

- Fig. 2. (A) XRD results of the Al-3.5FeNb-1.5C master alloy; (B) SEM microstructure of dispersed intermetallic particles extracted from Al-3.5FeNb-1.5C master alloy. XRD, X-ray diffraction

- Fig. 3. Optical microscopic images of experimental castings at 720°C, 750°C, and 780°C: (A-C) without grain refiner, (D−F) 0.1 wt% of Al-3.5FeNb-1.5C, (G-I) 1.0 wt% of Al-3.5FeNb-1.5C

- Fig. 4. (A) Tensile strength values (B) Brinell hardness and microhardness values obtained from experimental runs. (C) and (D) show the optical microscope images of (C) R5 and (D) R25 experimental castings, which have the highest and lowest mechanical properties, respectively. (E) and (F) show the SEM and EDS images of R5, respectively

- Fig. 5. Effect of process parameters on GRG. GRA, grey relational analysis

- Fig. 6. Effect of process parameters on CC. CC, closeness coefficient

- Fig. 7. GRG and CC value of each experimental run. CC, closeness coefficient; GRG, Grey relational grade

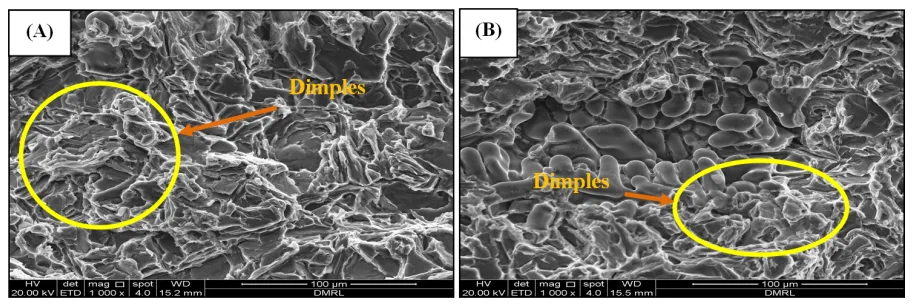

- Fig.8. SEM images of Al-Si9.8-Cu3.4 alloy: Experimental runs of (A) R5 at 0.1 wt.% of Al3.5FeNb-1.5C and 0.5 wt.% of Al-6Ni with base alloy and (B) R25 at 1.0 wt.% of Al3.5FeNb-1.5C with base alloy; EDX pattern of (C) Experimental run R5 and (D) Experimental run R25

- Fig. 9. SEM images of fracture pattern of experimental runs of (A) R5 at 0.1 wt.% of Al3.5FeNb-1.5C and 0.5 wt.% of Al-6Ni with base alloy and (B) R25 at 1.0 wt.% of Al3.5FeNb-1.5C with base alloy

7. Conclusion:

The study presents three main conclusions based on the experimental investigations:

1. Appreciable grain refinement of Al-Si9.8-Cu3.4 alloy was observed at a lower addition level of 0.1 wt.% of Al-3.5FeNb-1.5C. Conversely, poor grain refining efficiency was observed at a higher addition level of 1.0 wt.%, which resulted in the agglomeration of NbC and the formation of β-Al5FeSi platelets.

2. The developed Al–3.5FeNb-1.5C grain refiner demonstrated significant performance due to the inauguration of stable niobium silicides, effectively countering the "poisoning effect." Consequently, the mechanical properties (UTS, Brinell hardness, microhardness) of the alloy were significantly improved by 12.3%, 7.0%, and 20%, respectively, with the addition of 0.1 wt.% Al-3.5FeNb-1.5C and Al-6Ni alloy.

3. Both TOPSIS and GRA identified an identical set of optimal parameters (A1-B2-C2-D1-E3) for achieving better mechanical properties and microstructure. The confirmation test revealed a substantial increase in the closeness coefficient (CC) value by 0.647 and the grey grade value by 0.540, validating the optimization results.

8. References:

- [1] Camicia G, Timelli G. Grain refinement of gravity die cast secondary AlSi7Cu3Mg alloys for automotive cylinder heads. Trans Nonferrous Met Soc China. 2016;26(5):1211-21.

- [2] Biswas P, Prasadu KD, Manas Kuma M. Effect of Bi addition on microstructure and mechanical properties of hypereutectic Al-17.6Si alloy. Mater Res Express. 2019;6(11):1-26. https://doi.org/10.1088/2053-1591/ab4d34.

- [3] Cai Q, Mendis Ch. L, Chang TH, Fan Z. Microstructure and mechanical properties of new diecast quaternary Al-Cu-Si-Mg alloys. Mater Sci Eng A. 2021;800.140357.https://doi.org/10.1016/j.msea.2020.140357.

- [4] Lu L, Dahle AK. Effects of combined additions of Sr and AlTiB grain refiners in hypoeutectic Al-Si foundry alloys. Mater Sci Eng A. 2006;435(436):288-96.

- [5] Kori SA, Auradi V, Murty BS. Poisoning and fading mechanism of grain refinement in Al-7Si alloy. Mater Forum. 2005;29:387-93.

- [6] Murty BS, Kori SA, Chakraborty M. Grain refinement of aluminum and its alloys by heterogeneous nucleation and alloying. Int Mater Rev. 2002;47(1):3–29.

- [7] Liu F, Zhao H, Yang R, Sun F. Microstructure and mechanical properties of high vacuum die-cast AlSiMgMn alloys at as-cast and T6-treated conditions. Materials (Basel). 2019;12(13):2065.https://doi.org/10.3390/ma12132065.

- [8] Chen Z, Wang T, Gao L, Fu H, Li T. Grain refinement and tensile properties improvement of aluminum foundry alloys by inoculation with Al-B master alloy. Mater Sci Eng A. 2012;553:32-6.

- [9] Sigsworth GK. The grain refining of aluminum and phase relationships in the Al-Ti-B system. Metall Mater Trans A. 1984;15:277-82.

- [10] Guzowski MM, Sigworth GK, Sentner DA. The role of boron in the grain refinement of aluminum with titanium. Metall Mater Trans A. 1987;18:603-19.

- [11] Auradi V, Kori SA. Reaction time for the manufacturing of Al-Ti-B (Ti:B = 5:1, 1:3) master alloys and their grain refining efficiency on Al–7Si alloys. Trans Indian Inst Met. 2012;65:637-45.

- [12] Han YF, Li K, Wang J, Shu D, Sun BD. Microstructure and grain refining performance of Al-5Ti-1B master alloy prepared under high-intensity ultrasound. Mater Sci Eng A. 2006;430:326-31.

- [13] Li H, Lin B, Xu R, Liu K, Xiao H, Zhao Y. Enhanced mechanical properties of Al-Si-Cu-Mn-Fe alloys at elevated temperatures through grain refinement and dispersoid strengthening. Mater Sci Technol. 2020;36(3):307–19. https://doi.org/10.1080/02670836.2019.1705039.

- [14] Birol Y. Production of Al-Ti-B grain refining master alloys from B2O3 and K2TiF6. J Alloys Compd. 2007;443:94-8.

- [15] Qiu D, Taylor JA, Zhang MX. A mechanism for the poisoning effect of silicon on the grain refinement of Al-Si alloys. Acta Mater. 2007;55:1447-56.

- [16] Birol Y. AlB3 master alloy to grain refine AlSi10Mg and AlSi12Cu aluminium foundry alloys. J Alloys Compd. 2012;513:150-3.

- [17] Zhu M, Jian ZY, Yang GC. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater Des. 2012;36(1):243-9.

- [18] Sritharan T, Li H. Influence of titanium to boron ratio on the ability to grain refine aluminium-silicon alloys. J Mater Process Technol. 1997;63:585-9.

- [19] Murty BS, Kori SA, Chakraborty M. Influence of silicon and magnesium on grain refinement in aluminium alloys. Mater Sci Technol. 1999;15:986–92.

- [20] Murty BS, Kori SA, Chakraborty M. Development of an efficient grain refiner for Al-7Si alloy and its modification with strontium. Mater Sci Eng A. 2000;283:94-104.

- [21] Nowak M, Bolzoni L, Hari Babu N. Grain refinement of Al-Si alloys by Nb-B inoculation. Part I: Concept development and effect on binary alloys. Mater Des. 2015;66:366-75.

- [22] Apparao K. Ch, Birru AK. Grain refining potency of Al-3.5FeNb-1.5C master alloy on pure Al and Al-Si9.8-Cu3.4 alloy. China Foundry J. 2018;15(4):314–9.

- [23] Mostafa A, Mohammad HS, Parviz A, Abolfazl K. Hybrid multi-objective optimization of microstructural and mechanical properties of B4C/A356 composites fabricated by FSP using TOPSIS and modified NSGA-II. Trans Nonferrous Met Soc China. 2017;27:2317-33.

- [24] Srinivasan L, Khan Md C, Deepan BKT, Sathiya P, Biju S. Application of GRA and TOPSIS optimization techniques in GTA welding of 15CDV6 aerospace material. Trans Indian Inst Met. 2017;71:373-282.

- [25] Sudhagar S, Sakthivel M, Mathew PJ, Daniel A. A multi criteria decision making approach for process improvement in friction stir welding of aluminium alloy. Measurement. 2017;108:1-8.

- [26] Apparao K. Ch, Birru AK. QFD-Taguchi based hybrid approach in die casting process optimization. Trans Nonferrous Met Soc China. 2017;27:2345-2356.

- [27] Apparao K. Ch, Birru AK, Kumar BP. Porosity formation studies in high pressure die castings of Al-9Si-3Cu alloy based on Taguchi method. Int J Struct Integr. 2021;13(1):78-91.

- [28] Deng J. Introduction to grey system. J Grey Syst. 1989;1:1-24.

- [29] Ghetiya ND, Patel KM, Kavar AJ. Multi-objective optimization of FSW process parameters of aluminium alloy using taguchi-based grey relational analysis. Trans Indian Inst Met. 2016;69:917-23.

- [30] Zedan Y, Samuel FH. Effects of Fe intermetallics on the machinability of heat-treated Al-(7-11)% Si alloys. J Mater Process Technol. 2010;210:245-57.

- [31] Samuel AM, Doty HW, Valtierra S, Samuel FH. Beta Al5FeSi phase platelets-porosity formation relationship in A319.2 type alloys. Int J Met. 2017;12(1):55–70.

Expert Q&A: Your Top Questions Answered

Q1: Why was the Al-3.5FeNb-1.5C master alloy chosen over the traditional Al-Ti-B refiners?

A1: The Al-3.5FeNb-1.5C master alloy was chosen specifically to combat the "poisoning effect" that plagues Al-Ti-B refiners in high-silicon alloys like the Al-Si9.8-Cu3.4 used in this study. The niobium (Nb) and carbon (C) in the novel refiner form Al3Nb and NbC particles, which are more stable in the presence of silicon than the titanium-based particles. These particles act as potent heterogeneous nucleation sites for aluminum grains without being consumed by side reactions with silicon, ensuring effective grain refinement.

Q2: What was the single most optimal combination of additives and process parameters found in the study?

A2: The study used both GRA and TOPSIS analysis, and both methods converged on the same optimal settings. This combination, designated A1-B2-C2-D1-E3, consists of: a molten metal temperature of 720°C (A1), 0.1 wt.% of Al-3.5FeNb-1.5C refiner (B2), 0.5 wt.% of Al-6Ni alloy (C2), a die temperature of 230°C (D1), and an injection pressure of 24 MPa (E3). This specific recipe yielded the best overall mechanical properties.

Q3: The paper states that adding 1.0 wt.% of the refiner was detrimental. Why did a higher amount of refiner lead to worse results?

A3: While a small amount of the refiner was highly beneficial, adding 1.0 wt.% introduced an excessive amount of iron (from the ferroniobium raw material) into the melt. This led to the formation of large, needle-like β-Al5FeSi platelets. As stated by the authors, these platelets can hinder the flow of liquid metal during solidification, leading to the formation of shrinkage cavities and a coarser, less desirable grain structure, which ultimately degrades mechanical properties.

Q4: What specific intermetallic particles were identified as being responsible for the successful grain refinement?

A4: The XRD and SEM analysis (Figure 2) of the Al-3.5FeNb-1.5C master alloy confirmed the presence of Al3Nb (niobium aluminide) and NbC (niobium carbide) particles. The paper concludes that these two types of intermetallic particles, which are uniformly dispersed in the melt, act as the primary potential nucleation sites that promote the formation of fine, equiaxed α-aluminum grains during solidification.

Q5: How significant were the improvements, and were the optimization models (GRA/TOPSIS) validated?

A5: The improvements were quantitatively significant: UTS increased by 12.3%, Brinell hardness by 7.0%, and microhardness by 20%. The optimization models were validated through a confirmation test. The results showed that the experimental grey relational grade (0.979) and closeness coefficient (0.972) were very close to the predicted values, confirming the validity and reliability of the MCDM approach for this HPDC optimization problem.

Conclusion: Paving the Way for Higher Quality and Productivity

This research successfully addresses a critical limitation in the high pressure die casting of Al-Si alloys. By demonstrating the effectiveness of a novel Nb-based grain refiner, it provides a clear pathway to overcoming the silicon poisoning effect that hampers traditional methods. The study delivers a validated formula for HPDC Optimization, showing that a precise, low-level addition of Al-3.5FeNb-1.5C combined with Ni alloying can yield significant, double-digit percentage increases in strength and hardness. This provides engineers with a powerful tool to produce stronger, more reliable, and potentially lighter-weight components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Effect of novel grain refiner and Ni alloying additions on microstructure and mechanical properties of Al-Si9.8-Cu3.4 HPDC castings – optimization using Multi Criteria Decision making approach" by "K. Ch Apparao et al.".

Source: https://doi.org/10.2478/msp-2022-0005

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.