Optimizing HPDC: A Data-Driven Approach to Eliminating Porosity in Automotive Brackets

This technical summary is based on the academic paper "RESEARCHES CONCERNING CONSTRUCTIVE AND TECHNOLOGICAL IMPROVEMENTS OF AUTOMOTIVE GEARBOX SUSPENSION BRACKETS" by Ferencz PETI#¹ and Lucian GRAMA #2, published in The 6th edition of the Interdisciplinarity in Engineering International Conference “Petru Maior” University of Tîrgu Mureş, Romania (2012).

Keywords

- Primary Keyword: HPDC Porosity Reduction

- Secondary Keywords: gearbox suspension bracket, high pressure die casting, aluminium casting, shrinkage porosity, gas porosity, casting process optimization

Executive Summary

- The Challenge: Porosity defects in critical, high-stress automotive components like gearbox suspension brackets compromise their structural integrity and performance.

- The Method: The research integrated digital flow and solidification simulations with systematic physical experiments on a 700-ton HPDC machine to test various process parameters.

- The Key Breakthrough: A specific set of process parameters—changeover point at 320mm, second stage velocity of 3.24-3.26 m/s, and intensification pressure of 280 bar—was identified to consistently produce brackets with a minimal porosity level (Class 2, ASTM E 505).

- The Bottom Line: Optimizing key HPDC parameters based on a combination of simulation and empirical testing is a proven, effective method to minimize porosity and enhance the quality of complex aluminum brackets.

The Challenge: Why This Research Matters for HPDC Professionals

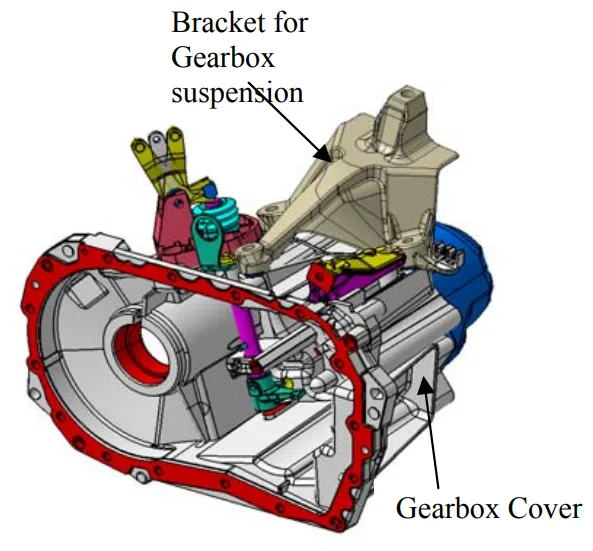

In the automotive industry, every component counts. The gearbox suspension bracket is a key structural part, responsible for supporting the substantial weight of the engine and gearbox while also resisting constant operational vibrations. These brackets are commonly manufactured using the high pressure die casting (HPDC) process due to its efficiency and precision.

However, the most common and persistent challenge in HPDC is porosity. Whether it's gas porosity from trapped air or shrinkage porosity from cooling, these internal defects can severely compromise the bracket's mechanical properties and lead to premature failure. This research was undertaken to find an ideal solution for minimizing these defects, thereby increasing the constructive role and reliability of these critical components.

The Approach: Unpacking the Methodology

The research employed a comprehensive, multi-stage methodology to move from theoretical prediction to validated production settings.

Method 1: Digital Experiments & Simulation

The process began in the digital realm. A 3D model of the Renault X95 gearbox suspension bracket was created. Using Flow 3D software, the team performed detailed flow and solidification simulations. This allowed them to predict the last areas of the part to fill—where air is most likely to be trapped—and the areas with the highest risk of shrinkage porosity. These simulations were crucial for optimizing the design of the runner system and overflows before any metal was cast.

Method 2: Physical Experiments on the Workbench

Based on the digital findings, a two-cavity mould was manufactured and mounted on an Idra 700 tF HPDC machine. Using an AlSi9Cu3(Fe) aluminum alloy, seven distinct categories of samples (labeled A through G) were produced. Each category was cast using a different set of process parameters, systematically modifying the three factors with the most significant influence on internal quality:

- Changeover point (the position where the plunger switches from slow to fast injection speed)

- Second phase velocity (the fast injection speed)

- Intensification pressure (the final pressure applied to compact the casting during solidification)

Method 3: Laboratory Analysis

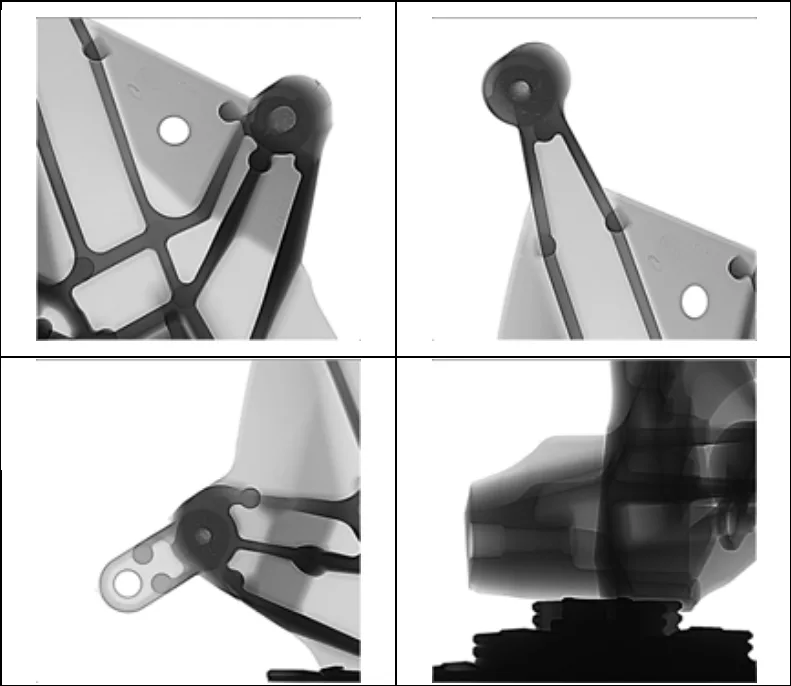

Each sample from every category was subjected to rigorous non-destructive testing. An RX machine (YXLON MU2000/160 kV) was used to perform an X-ray analysis of the brackets' internal structure. This allowed the researchers to visualize and quantify the presence, location, and severity of porosity. The findings were then classified according to the industry-standard ASTM E 505 reference radiographs for aluminum die castings.

The Breakthrough: Key Findings & Data

The study yielded clear, actionable results that bridge the gap between simulation and real-world production.

Finding 1: Simulation Accurately Predicts Real-World Defect Locations

The digital simulations proved to be highly effective. The areas identified as having the highest probability of gas porosity in the filling simulation (Figure 17) and shrinkage porosity in the solidification simulation (Figure 18) were precisely where defects were found during the RX analysis of the physical parts. This confirms that simulation is a powerful predictive tool for optimizing mould design and gating to mitigate defects before production begins.

Finding 2: A Definitive Process Window for Superior Quality

The experimental data identified a clear winner. As detailed in Table 5, the samples from Category B consistently achieved the best results, with a porosity level of Class 2 according to the ASTM E 505 standard. This meets the stringent material health requirements for this component. The optimal parameters used to produce these high-quality parts were:

- Changeover Point: 320 mm

- Second Stage Velocity (V2max): 3.22 - 3.30 m/s

- Intensification Pressure (P3max): ~280 bar (279.92 - 281.38 bar)

As shown in the graph in Figure 19, this combination of parameters delivered a demonstrably lower porosity level compared to other settings, such as the Class 4 porosity observed in Category D11 samples.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the changeover point, second stage velocity, and intensification pressure to the identified optimal window may contribute to a significant reduction in porosity defects for similar bracket geometries.

- For Quality Control Teams: The data in Figure 19 and Table 5 of the paper illustrates the direct effect of process parameters on the final porosity level. This could inform new, more targeted quality inspection criteria based on process data monitoring.

- For Design Engineers: The findings indicate that the fixing hole areas are inherently prone to porosity (as shown in Figures 17 and 18). This suggests that considering thermal management and overflow placement around such critical features is a valuable consideration in the early design phase.

Paper Details

RESEARCHES CONCERNING CONSTRUCTIVE AND TECHNOLOGICAL IMPROVEMENTS OF AUTOMOTIVE GEARBOX SUSPENSION BRACKETS

1. Overview:

- Title: RESEARCHES CONCERNING CONSTRUCTIVE AND TECHNOLOGICAL IMPROVEMENTS OF AUTOMOTIVE GEARBOX SUSPENSION BRACKETS

- Author: Ferencz PETI, Lucian GRAMA

- Year of publication: 2012

- Journal/academic society of publication: The 6th edition of the Interdisciplinarity in Engineering International Conference “Petru Maior” University of Tîrgu Mureş, Romania, 2012

- Keywords: High pressure die casting, bracket, mould, porosity, aluminium, automotive

2. Abstract:

The brackets, which are the objective of this research, belong to the gearbox suspension system of the car, being key component of the car. Due to the fact that the bracket supports the weight of the engine and gearbox it has a robust shape and a specific weight. The objective of this research is to find an ideal solution in combining of the manufacturing process elements which have major influence on the constructive and technological characteristics of the gearbox suspension brackets.

3. Introduction:

The introduction emphasizes the important role of manufacturing technology, specifically the high pressure die casting (HPDC) process, in the production of automotive brackets. It identifies porosity (gas, shrinkage, or leaker) as the most common defect in HPDC. The research is focused on finding an ideal solution to minimize these defects to enhance the constructive role of gearbox suspension brackets, which are key components for holding the gearbox and engine and resisting vibrations.

4. Summary of the study:

Background of the research topic:

The research addresses the manufacturing of automotive gearbox suspension brackets, which are critical structural components. The study focuses on the challenges posed by the HPDC process, primarily the formation of porosity defects that can compromise the part's integrity.

Status of previous research:

The paper does not provide a detailed review of previous literature but builds upon established principles of HPDC process optimization, utilizing modern tools such as digital simulation and systematic process parameter variation.

Purpose of the study:

The objective is to find an ideal combination of manufacturing process elements to optimize the technological and constructive characteristics of gearbox suspension brackets. The primary aim is to minimize porosity-type defects inherent in the HPDC process.

Core study:

The research follows a structured, multi-stage approach as outlined in Figure 2. This includes:

1. Digital Experiments: 3D design of the bracket and mould, followed by flow and solidification simulations to predict defect-prone areas.

2. Experiments on Workbenches: Manufacturing of physical samples using an HPDC machine with systematically varied process parameters (changeover point, second phase velocity, intensification pressure).

3. Experiments in Laboratory: Analysis of the manufactured samples using an RX machine to determine internal material health and porosity levels, with classification according to ASTM E 505.

5. Research Methodology

Research Design:

The research was designed as a comparative experimental study, correlating digital simulation results with physical outcomes. The methodology involved three main directions: digital experiments, workbench experiments, and laboratory experiments. This structure allowed for the validation of simulation predictions against empirical data.

Data Collection and Analysis Methods:

- Simulation: 3D models were created, and flow and solidification simulations were performed using Flow 3D software.

- Production: Samples were cast from AlSi9Cu3(Fe) alloy on an Idra 700 tF HPDC machine. Seven categories of samples (A-G) were produced by varying process parameters as detailed in Table 2.

- Analysis: The internal quality of the samples was inspected using an RX machine (YXLON MU2000/160 kV). Porosity levels were classified according to the ASTM E 505 standard. Process data was collected from the machine's Shot control function.

Research Topics and Scope:

The research is focused on a specific automotive part, the Renault X95 gearbox suspension bracket. The scope is limited to the improvement of its constructive and technological characteristics by minimizing porosity defects through the optimization of key HPDC process parameters.

6. Key Results:

Key Results:

- The filling and solidification simulations accurately predicted the locations with the highest risk of porosity, primarily in the fixing hole areas of the bracket.

- The results obtained on the workbenches during manufacturing proved that porosities were localized in the same areas predicted by the simulations.

- A specific set of process conditions was determined to produce samples that satisfy the material health requirements imposed by the customer.

- The best parts were from category B, achieving a porosity level of 2 according to the ASTM E 505 standard.

- The recommended parameters for the specific geometry of the gearbox suspension bracket are: changeover point of 320mm, second stage velocity (V2 max) of 3.24-3.26 m/s, and intensification pressure (P3) of 280 bar.

Figure Name List:

- Fig. 1 - Isometric view subassembly gearbox cover and bracket Renault X95

- Fig. 2 – Definition of the research steps

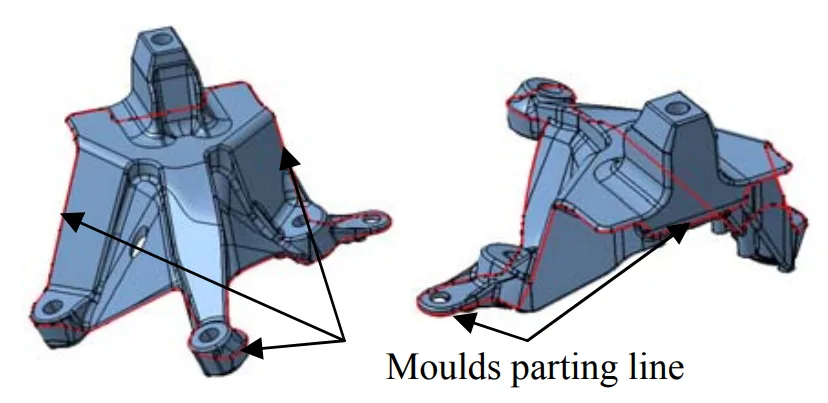

- Fig. 3 – Definition of parting lines

- Fig. 4 – Analyze of draft angles

- Fig. 5 – 3D design of the runner system

- Fig. 6 – Flow simulation with Flow 3D software

- Fig. 7 – Solidification simulation with Flow 3D software

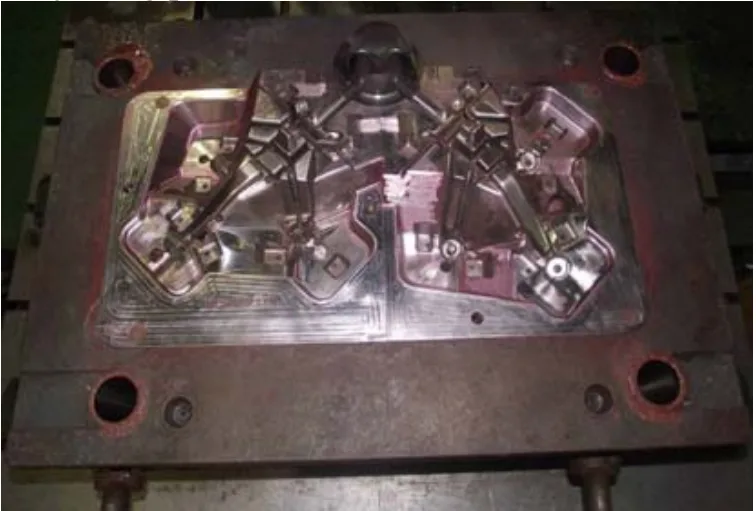

- Fig. 8 - 3D design of the cavities of the mould

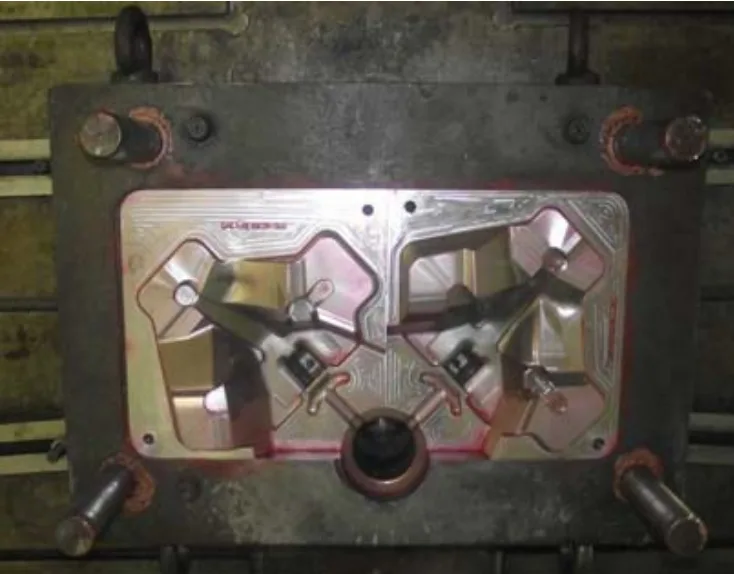

- Fig. 9 – Structural scheme of the mould

- Fig. 10 – Mobile side of the mould – 3D view

- Fig. 11 – Fix side of the mould – 3D view

- Fig. 12 – Mobile side of the mould – mounted on the adjusting press

- Fig. 13 – Fixe side of the mould – mounted on the adjusting press

- Fig. 14 – Grouping of samples in function of categories

- Fig. 15 – Samples inside the RX machine

- Fig. 16 – Analyze of samples on the RX machine

- Fig. 17 – Interpretation of filling simulations results

- Fig. 18 – Interpretation of solidification simulations results

- Fig. 19 - Representation of the obtained porosity level in function of parameters

7. Conclusion:

The research successfully demonstrated a correlation between digital simulation results and physical outcomes from workbench and laboratory analysis. The areas with the highest risk of porosity, identified in simulations, were confirmed in the manufactured samples. The study determined the optimal process conditions—a changeover point of 320mm, a second stage velocity of 3.24-3.26 m/s, and an intensification pressure of 280 bar—to produce gearbox suspension brackets that meet the required material health standards (porosity level 2, ASTM E 505). The main contributions include correlating digital and physical results, correlating simulation-estimated porosity with RX analysis, and determining the influence of key parameters on the internal material health of the samples.

8. References:

- [1] MONTES, J., (2008), Fundamentos de la fundicion a presion, CIE C. Vilanova, Spain

- [2] MONTES, J., (2008), Revision Tecnica del Producto, CIE C. Vilanova, Spain

- [3] Company documentation Bühler, 2010

- [4] Company documentation CATIA, 2012

- [5] Company documentation Idra, 2011

- [6] Company documentation Italpresse, 2011

- [7] Introduction to Fluid Dynamics, Engineering Materials and Processes, (2007), Casting: An Analytical Approach, Pages 13-41

- [8] Norma Ingenieria NCV21006C Tiempo llenado del molde, (2006), CIE C. Vilanova, Spain

- [9] Norma Ingenieria NCV21007B – Velocidad en el ataque, (2006), CIE C. Vilanova, Spain

- [10] Part Design, Engineering Materials and Processes, (2007), Casting: An Analytical Approach, Pages 43-96

- [11] Procedimiento IDT 05/1: Cuaderno de cargas de moldes, rev05, (2007), CIE Inyectametal, Spain

- [12] Process Design, Engineering Materials and Processes, (2007), Casting: An Analytical Approach, Pages 97-155

- [13] Specification SR EN 1706

- [14] Specification ASTM E505- Reference Radiographs for Inspection of Aluminium and Magnesium die castings, 2002

- [15] Specification DIN 1688

- [16] VDG Specification P201- VEREIN DEUTCHER GIESSEREIFACHLEUTE

- [17] http://www.buhlergroup.com

- [18] http://www.diecasting.org/faq/

- [19] http://www.diecastingengineer.org

- [20] http://www.flow3d.com/

- [21] http://www.idracasting.com

- [22] http://www.springerlink.com

- [23] http://www.wikipedia.org

Expert Q&A: Your Top Questions Answered

Q1: What was the primary purpose of the Flow 3D simulations in this research?

A1: The primary purpose was to conduct digital experiments before manufacturing the physical mould. The simulations for flow and solidification were used to identify the areas of the bracket most likely to suffer from defects like gas porosity (from trapped air in last-to-fill regions) and shrinkage porosity. This predictive analysis guided the design of the runner system and overflows to minimize these potential issues from the outset.

Q2: The study tested seven categories of parameters (A-G). Which one yielded the best results and why?

A2: Category B produced the best parts. The samples from this category achieved a porosity level of 2 according to the ASTM E 505 standard, which satisfied the customer's material health requirements. This superior result was achieved with a specific combination of parameters: a changeover point of 320 mm, a second stage velocity between 3.22 and 3.30 m/s, and an intensification pressure of approximately 280 bar.

Q3: How was the internal quality of the cast brackets evaluated?

A3: The internal material health, specifically the presence and percentage of porosity, was analyzed non-destructively using an RX machine (model YXLON MU2000/160 kV). This X-ray inspection allowed researchers to see inside the cast parts and identify any voids. The results were then formally classified using the reference radiographs from the ASTM E 505 standard.

Q4: Did the physical experiments confirm the predictions from the digital simulations?

A4: Yes, there was a strong correlation. The paper states that the areas identified with the highest risk of porosity in the digital filling and solidification simulations—specifically the fixing hole areas—were proven to be the actual locations of porosity found during the RX analysis of the manufactured samples. This validates the use of simulation as a reliable predictive tool in the HPDC process.

Q5: What were the three main process parameters modified during the experiments?

A5: The research focused on modifying the main factors known to have a major influence on the internal health of the castings. As detailed in Table 2, these were: the "Changeover point" between the first and second injection phases, the "2nd stage velocity," and the "Contra pressure" (intensification pressure).

Q6: What specific aluminum alloy was used for these brackets?

A6: The alloy used for manufacturing the samples was AlSi9Cu3(Fe), as specified by the SR EN 1706 standard. The detailed chemical composition of this alloy is provided in Table 1 of the paper.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and effective roadmap for tackling one of the most persistent challenges in high pressure die casting. By systematically combining predictive digital simulation with rigorous physical experimentation, the study demonstrates a reliable method for achieving significant HPDC porosity reduction. The identification of an optimal process window for the gearbox suspension bracket not only solves a critical quality issue but also provides a methodology that can be applied to other complex automotive components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "RESEARCHES CONCERNING CONSTRUCTIVE AND TECHNOLOGICAL IMPROVEMENTS OF AUTOMOTIVE GEARBOX SUSPENSION BRACKETS" by "Ferencz PETI and Lucian GRAMA".

Source: The 6th edition of the Interdisciplinarity in Engineering International Conference “Petru Maior” University of Tîrgu Mureş, Romania, 2012.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.