Maximizing Component Durability: How Al-Si Alloy Casting and Anodization Impact Reflectivity in High-Temp Applications

This technical summary is based on the academic paper "Reflectivity of anodised Al-Si alloy surface of belt pulleys used in combustion engines" by Krzysztof LABISZ, published in Scientific Journal of Silesian University of Technology. Series Transport (2021).

Keywords

- Primary Keyword: Aluminium Alloy Anodization

- Secondary Keywords: High pressure die casting, Al-Si alloys, surface treatment, albedo, component durability, automotive casting

Executive Summary

- The Challenge: Optimizing the surface properties of aluminium alloy belt pulleys to minimize heat absorption and maximize durability in high-temperature combustion engines.

- The Method: Investigating the effects of two Al-Si alloys (AlSi12Cu1, AlSi9Cu3), two casting methods (HPDC, sand casting), and an anodization process on wear resistance, layer thickness, and surface reflectivity.

- The Key Breakthrough: The sand cast AlSi9Cu3 alloy, after anodization, exhibited the highest reflectivity (albedo of 0.8), significantly reducing potential energy absorption compared to other tested variants.

- The Bottom Line: The choice of casting method and alloy composition is critical for controlling the final surface properties of anodized aluminium components, directly impacting their thermal performance and lifespan.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive and transportation industries, the push for lighter, more efficient components is relentless. Aluminium-silicon (Al-Si) alloys have become a go-to material for parts like engine belt pulleys, offering an excellent combination of strength, low weight, and durability. To further enhance their performance, especially in high-temperature environments, a surface treatment called anodization is applied. This creates a hard, wear-resistant oxide layer.

However, a critical factor often overlooked is the surface's ability to reflect or absorb energy (light and heat), a property measured by "albedo." A surface with low albedo absorbs more energy, leading to higher operating temperatures and potentially reducing the component's service life. The core challenge addressed by this research was to identify the ideal combination of Al-Si alloy, casting method (High Pressure Die Casting vs. Sand Casting), and anodization parameters to create a surface with the highest possible reflectivity, thereby minimizing energy absorption and maximizing long-term durability.

The Approach: Unpacking the Methodology

The study was designed to systematically evaluate how different manufacturing variables influence the final surface properties of anodized Al-Si alloys.

Method 1: Material and Casting Selection

- Alloys: Two common casting alloys were used: AlSi12Cu1 and AlSi9Cu3. Their chemical compositions are detailed in Table 1 of the paper.

- Casting Processes: Each alloy was cast using two distinct methods: High Pressure Die Casting (HPDC) and traditional sand casting. This allowed for a direct comparison of how the initial manufacturing process affects the final anodized surface.

Method 2: Anodization Process

- All cast samples were subjected to a controlled anodization process to create a protective oxide layer.

- Electrolyte: Sulphuric acid (H₂SO₄) with a concentration of 295-315 g/l.

- Temperature: A cold process at -4 to -2 °C.

- Current: A pulse current was applied (2 A/dm² for 0.25 s, followed by 1 A/dm² for 0.1 s).

Method 3: Performance Testing

- Abrasive Wear Test: Conducted according to the ISO 8251 standard to measure the mass loss of both anodized and non-anodized samples, quantifying the improvement in wear resistance.

- Microstructural Analysis: The thickness and structure of the anodic layer were examined using light microscopy.

- Reflectivity (Albedo) Measurement: A light meter was used to measure the amount of incident light versus reflected light (in lux), allowing for the calculation of the albedo value for each surface.

The Breakthrough: Key Findings & Data

The research yielded clear, data-driven insights into how material and process choices dictate the functional surface properties of anodized aluminium parts.

Finding 1: Anodization Boosts Wear Resistance, but Casting Method Plays a Key Role

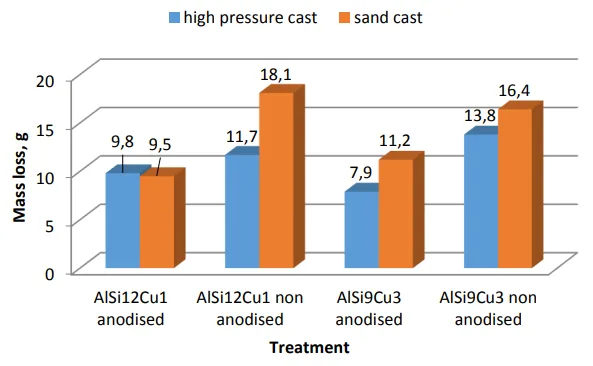

The study confirmed that anodization significantly reduces material loss from abrasive wear. However, the casting method had a notable impact. As shown in Figure 3, anodized samples consistently outperformed their non-anodized counterparts. For example, the anodized sand cast AlSi9Cu3 samples showed approximately half the mass loss (7.9 g) compared to the non-anodized version (16.4 g). Interestingly, sand cast alloys generally demonstrated higher abrasion resistance (lower mass loss) than the HPDC alloys in this specific test.

Finding 2: Sand Casting Produces a Thicker and Rougher Anodic Layer

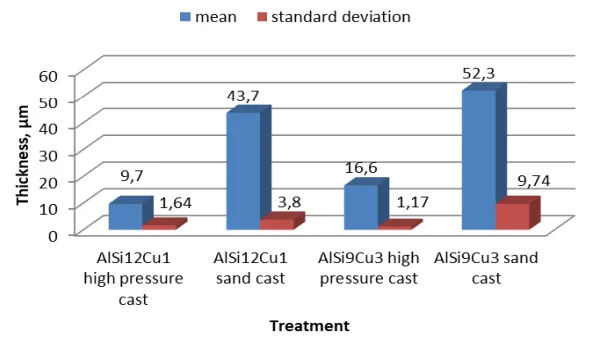

The choice of casting method directly influenced the physical characteristics of the anodic layer. The thickest layers were formed on the sand cast samples. As detailed in Figure 8, the anodized sand cast AlSi9Cu3 produced a layer with an average thickness of 52.3 µm, while its HPDC counterpart produced a much thinner layer of 16.6 µm. This corresponds with surface roughness data from Table 4, which shows that anodized sand cast surfaces were significantly rougher (Ra of 3.26 µm for AlSi9Cu3) than anodized HPDC surfaces (Ra of 1.93 µm for AlSi9Cu3).

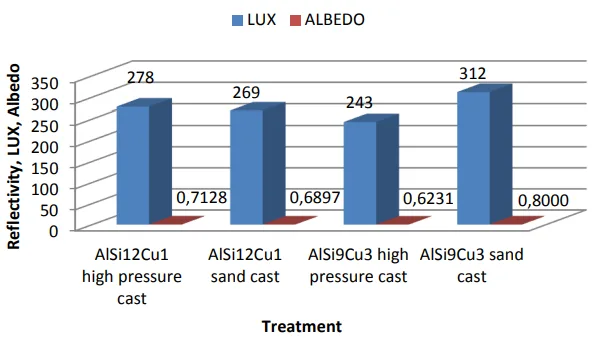

Finding 3: Sand Cast AlSi9Cu3 Achieves Superior Reflectivity

The ultimate goal was to maximize reflectivity, and the results pointed to a clear winner. As presented in Figure 9, the anodized sand cast AlSi9Cu3 alloy delivered the highest reflectivity, measuring 312 lux and achieving an albedo value of 0.8000. In contrast, the high pressure cast version of the same alloy had the lowest albedo at 0.6231. This 28% difference in reflectivity is a significant factor in determining how much energy a component will absorb during operation. The paper suggests this high reflectivity is partially linked to the high surface roughness achieved with the sand casting method.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for applications where minimizing heat absorption is critical, a process that yields higher surface roughness post-anodization, such as sand casting, may be advantageous. Adjusting anodizing parameters to influence layer thickness and structure is a key lever for controlling final surface properties.

- For Quality Control Teams: The data in Figure 8 and Table 4 of the paper illustrates the direct effect of the casting method on anodic layer thickness and surface roughness. These metrics could be incorporated as new quality inspection criteria for components requiring specific reflective or thermal properties.

- For Design Engineers: The findings indicate that the selection of both the alloy (e.g., AlSi9Cu3) and the manufacturing process (sand casting vs. HPDC) is a critical consideration in the early design phase. This interplay fundamentally determines the final surface performance, especially for parts exposed to significant thermal radiation in engines.

Paper Details

Reflectivity of anodised Al-Si alloy surface of belt pulleys used in combustion engines

1. Overview:

- Title: Reflectivity of anodised Al-Si alloy surface of belt pulleys used in combustion engines

- Author: Krzysztof LABISZ

- Year of publication: 2021

- Journal/academic society of publication: Scientific Journal of Silesian University of Technology. Series Transport

- Keywords: aluminium, reflectivity, adonisation, surface treatment, sand cast, high pressure cast, albedo

2. Abstract:

The recent trend of using aluminium alloys instead of steel has reached the transportation industry, where increasingly, more parts are made of aluminium. An example is the belt pulley, applied for combustion engines for energy transmission. This part should be strong, durable, and lightweight. Aluminium-silicon alloys are a good choice, moreover, even when the surface is anodised, also because of their moderate inertia control and excellent wear characteristic during mechanical operations. Since aluminium is lightweight yet mechanically durable and anodised, it is an ideal belt pulley to use, especially in high-temperature operations. However, the main question is what type of Al-Si alloy, casting method and anodisation method should be used in terms of energy adsorption, having long-term properties for a lifetime, has to be applied. For this reason, this paper presents the influence of the chemical composition, casting method and anodising parameters on the structure and thickness of the anodic layer produced on aluminium alloys, as well as on the albedo value as an ability to reflect or absorb light. The aluminium alloys, AlSi12Cu1 and AlSi9Cu3, were used as research materials, obtained using different casting methods. The goal of this work was to determine the optimal combination of the anodisation conditions and materials for maximising the reflectivity factor of the surface, as a very important factor, determining the energy amount absorbed by an anodised surface. For further improvement of these surface properties as well as for enhancement of the properties and strengthen the material produced with different aluminium alloys production methods, different alloying additives were added. In addition, the mechanical properties of the surface layer were measured, where a remarkable hardness increase was obtained, and the best combination in form of AlSi12Cu1 high pressure cast was found with the highest albedo factor among all tested surface variants.

3. Introduction:

In recent years, the use of aluminium alloys has continuously increased across various industries. Anodic coatings are applied for protective and decorative purposes on numerous products, and hard anodic coatings are utilized in the aviation and transportation sectors. These coatings, permanently bonded to the substrate, offer corrosion resistance, although this can be compromised by porosity or the presence of certain alloying elements like copper. A key issue concerning surface properties, beyond mechanical aspects, is reflectivity and albedo. Albedo is a measure of the percentage of light reflected from a surface. This property is crucial for the lifetime of engineering materials, as it determines the amount of energy absorbed, which influences temperature and durability. This study aims to investigate the albedo of coatings produced on cast aluminium alloys via anodisation, evaluating the effect of the alloy, casting method, and electrolyte on the anodic layer's reflectivity and durability.

4. Summary of the study:

Background of the research topic:

The research is situated within the context of the automotive industry's increasing substitution of steel with lightweight aluminium alloys for components such as belt pulleys in combustion engines. These components require a combination of strength, durability, and low weight, particularly for high-temperature operations. Anodisation is a common surface treatment to improve these properties.

Status of previous research:

The paper acknowledges existing knowledge regarding the benefits of anodic coatings for corrosion resistance and their application in various industries. It notes that alloying elements, particularly copper, can negatively affect the properties of the anodic layer. The concept of albedo is established as a critical factor in thermal management and material science, influencing the amount of energy a surface absorbs.

Purpose of the study:

The primary goal was to determine the optimal combination of Al-Si alloy type (AlSi12Cu1 and AlSi9Cu3), casting method (high pressure die casting and sand casting), and anodisation parameters to maximize the reflectivity (albedo) of the component surface. Maximizing reflectivity is directly linked to minimizing absorbed energy, which is expected to enhance the durability and working life of the part.

Core study:

The study is an experimental investigation into the influence of chemical composition, casting method, and anodising parameters on the structure, thickness, wear resistance, and reflectivity of the anodic layer produced on Al-Si alloys. Four distinct material-process combinations were created and subjected to a standardized anodisation treatment, followed by a series of characterization tests to compare their performance.

5. Research Methodology

Research Design:

The research employed a comparative experimental design. Two aluminium alloys, AlSi12Cu1 and AlSi9Cu3, were each produced using two methods: high pressure die casting and sand casting. This resulted in four distinct sample groups. These samples were then subjected to a standardized anodisation process. The properties of the resulting surfaces, including layer thickness, wear resistance, roughness, and reflectivity, were measured and compared to identify the optimal combination.

Data Collection and Analysis Methods:

- Material Characterization: The chemical composition of the alloys was pre-defined (Table 1).

- Anodisation: A controlled anodisation process was applied using parameters specified in Table 2 (H₂SO₄ electrolyte, -4 to -2 °C, pulse current).

- Metallography: An OLYMPUS BX60M light microscope was used to observe the structure and measure the thickness of the anodic layers.

- Abrasive Wear Testing: An ABR-8251 machine was used following the ISO 8251 standard, with mass loss being the measured output.

- Reflectivity Measurement: A light meter was used to measure direct and reflected light in lux. Albedo was calculated using the formula: albedo = reflected light [lux] / direct light [lux].

Research Topics and Scope:

The research focused on the reflectivity, wear resistance, and physical characteristics of anodised surfaces on Al-Si alloys. The scope was limited to two specific alloys (AlSi12Cu1, AlSi9Cu3), two casting methods (high pressure and sand), and a single set of anodising parameters. The primary objective was to evaluate the influence of these variables on the final surface properties relevant to energy absorption in combustion engine applications.

6. Key Results:

Key Results:

- Anodisation was found to reduce abrasive wear. As a result of an abrasive wear test, anodised samples of sand cast AlSi9Cu3 alloy demonstrated half the mass loss compared to their non-anodised counterparts.

- The casting method significantly influenced the thickness of the anodic layer. The thickest layers were produced on sand cast alloys, with the AlSi9Cu3 sample reaching an average thickness of 52.3 µm, compared to 16.6 µm for the high pressure cast version (Figure 8).

- The highest reflectivity was achieved by the anodised sand cast AlSi9Cu3 alloy, which measured 312 lux and corresponded to an albedo value of 0.8000 (Figure 9). This combination was identified as optimal for maximizing reflectivity.

- The difference in reflectivity between the best-performing sample (sand cast AlSi9Cu3) and the worst-performing sample (high pressure cast AlSi9Cu3) was 28%.

- Anodisation increased the surface roughness (Ra) for all samples. The effect was more pronounced on sand cast samples, with the Ra of AlSi9Cu3 increasing from 0.38 µm (non-anodised) to 3.26 µm (anodised) (Table 4).

Figure Name List:

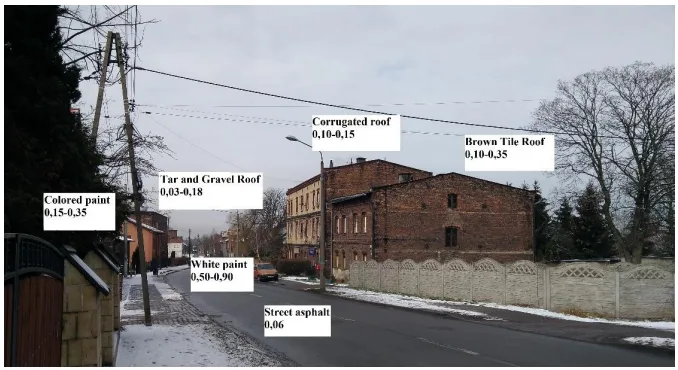

- Fig. 1. Albedos of different surfaces

- Fig. 2. Anodised Al-Si belt pulleys used in combustion engines

- Fig. 3. Comparison of abrasion of pressure castings

- Fig. 4. Anodic layer produced on the AlSi9Cu3 alloy, high pressure cast

- Fig. 5. Anodic layer produced on the AlSi9Cu3 alloy, sand cast

- Fig. 6. Anodic layer produced on the AlSi12Cu1 alloy, high pressure cast

- Fig. 7. Anodic layer produced on the AlSi12Cu1 alloy, sand cast

- Fig. 8. Comparison of anodic layer thickness

- Fig. 9. Reflectivity and albedo of the produced anodic layers

7. Conclusion:

The study determined that a proper anodisation method combined with a well-selected Al-Si alloy and casting process is critical for controlling the electromagnetic radiation adsorption of components like belt pulleys. A high albedo value leads to lower energy adsorption, which increases the durability and service life of anodised light materials. The optimal combination for achieving high reflectivity was found to be the sand cast AlSi9Cu3 alloy, which yielded an albedo value of 0.8. This high reflectivity is partially associated with the relatively high surface roughness resulting from this process. The 28% difference in reflectivity observed between the tested combinations highlights the importance of process and material selection for applications where thermal management is critical.

8. References:

- Nickel Daniela, Dagmar Dietrich, Roy Morgenstern, Ingolf Scharf, Harry Podlesak, Thomas Lampke1. 2016. “Anodisation of Aluminium Alloys by Micro-Capillary Technique as a Tool for Reliable, Cost-Efficient, and Quick Process Parameter Determination”. Advances in Materials Science and Engineering Article ID 1374897: 1-12. DOI: http://dx.doi.org/10.1155/2016/1374897.

- University of Calgary. „Energy education”. Available at: https://energyeducation.ca/encyclopedia/Albedo.

- HyperPhysics. “Albedo of the Earth”. Available at: http://hyperphysics.phy-astr.gsu.edu/hbase/phyopt/albedo.html.

- Gombar M., L. Sobotova, M. Badida, J. Kmec. 2014. “The comparison of possibilities at using of different electrolytes in the process of anodizing aluminium”. Metalurgija 53(1): 47-50.

- Curioni Michele, Tito Gionfini, Antonello Vicenzo, P. Skeldon, G. E. Thompson. 2013. “Optimization of anodizing cycles for enhanced performance”. Surface and Interface Analysis 45(10): 1485-1489.

- Yılmaza Demet, Ayşe Bayrakçeken, Yurtcanbe Tuba, Öznülüer Özercd, Fulya Memioğlub. 2021. “Albedo parameters and effective atomic numbers of PEDOT/Carbon black composites”. Radiation Physics and Chemistry 182: 109378.

- Jiang Tao, Chong Ji, Xin Wang, Ying Liu, Fuyin Gao, Yuxiang Sun, Kun Zhang, Lei Meng. 2021. “Experimental investigation on the damage effect of 6063-T5 aluminum alloy circular tubes subjected to blast after exposure to fire”. Thin-Walled Structures 159: 107290.

- Ahmetab Turşucu. 2021. “Albedo factor determination of some selected 3d alloy samples". Applied Radiation and Isotopes 169: 109505.

- Petrič M., J. Medved, P. Mrvar. 2011. “Effect of grain refinement and modification of eutectic phase on shrinkage of AlSi9Cu3 alloy”. Metalurgija 50(2): 127-131.

Expert Q&A: Your Top Questions Answered

Q1: Why were the AlSi12Cu1 and AlSi9Cu3 alloys chosen for this study?

A1: The paper identifies these as aluminium-silicon alloys commonly used for research materials obtained via different casting methods. Their differing silicon and copper contents (AlSi12Cu1 has higher Si and lower Cu, while AlSi9Cu3 has lower Si and higher Cu, as per Table 1) provide a basis for comparing how alloy composition influences the final properties of the anodized layer, such as hardness, thickness, and resistance to the anodizing process itself.

Q2: What is "albedo," and why is it a critical factor for belt pulleys in combustion engines?

A2: Albedo is a measure of how much light (and thus radiant energy) a surface reflects. A perfectly reflective surface has an albedo of 1.0 (or 100%), while a perfectly black, absorbent surface has an albedo of 0. For a belt pulley in a hot engine bay, a surface with a high albedo will reflect more radiant heat, absorbing less energy. This helps the component run cooler, which increases its durability and extends its working lifetime.

Q3: The study found that sand casting produced a thicker anodic layer. Why might this be the case?

A3: The paper does not explicitly state the metallurgical reason, but it directly correlates the casting method with the resulting surface roughness and layer thickness. Table 4 shows that sand cast parts had a higher initial and final roughness compared to HPDC parts. This rougher, more complex surface topography provides a larger surface area for the electrochemical reaction during anodization to occur, which likely contributes to the formation of a thicker oxide layer under the same process conditions.

Q4: According to the results, anodization increased surface roughness. Isn't a smoother surface generally better for wear resistance?

A4: While it's true that anodization increased roughness (Table 4), it also created a very hard aluminium oxide layer. The results in Figure 3 show that despite the increased roughness, the anodized samples had significantly better wear resistance (less mass loss) than the smoother, non-anodized samples. This indicates that the exceptional hardness of the anodic layer is the dominant factor in improving wear resistance, outweighing any potential negative effects of the increased surface roughness in this abrasive wear test.

Q5: The sand cast AlSi9Cu3 showed the best reflectivity. What were its specific performance metrics?

A5: The anodized sand cast AlSi9Cu3 sample achieved the highest albedo value of 0.8000, corresponding to a reflected light measurement of 312 lux (Figure 9). It also produced the thickest anodic layer at 52.3 µm (Figure 8) and demonstrated excellent wear resistance, with mass loss reduced from 16.4 g to 7.9 g after anodization (Figure 3).

Q6: How significant was the difference in reflectivity between the best and worst-performing samples?

A6: The difference was very significant from a thermal management perspective. The best performer (sand cast AlSi9Cu3) had an albedo of 0.8, while the worst performer (high pressure cast AlSi9Cu3) had an albedo of 0.6231. The paper states this difference in reflectivity reaches 28%, which is a substantial variation that would directly impact the amount of energy absorbed by the component during operation.

Conclusion: Paving the Way for Higher Quality and Productivity

This research underscores a fundamental principle in advanced component manufacturing: the final performance is a product of the entire process chain. For anodized aluminium parts, achieving optimal surface characteristics like high reflectivity is not just about the Aluminium Alloy Anodization process itself. It is an intricate interplay between the initial alloy selection and the casting method used. The finding that a sand cast AlSi9Cu3 alloy can yield a surface that reflects 28% more energy than its HPDC counterpart provides critical insight for engineers designing components for thermally demanding environments.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Reflectivity of anodised Al-Si alloy surface of belt pulleys used in combustion engines" by "Krzysztof LABISZ".

Source: https://doi.org/10.20858/sjsutst.2021.112.10

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.