Beyond Defect Detection: Using CT for Predictive Damage Modelling in HPDC

This technical summary is based on the academic paper "An innovative use of CT method in light metals development" by Christoph Angermeier and Amir M. Horr, published in iCT Conference 2014.

Keywords

- Primary Keyword: CT for Damage Modelling

- Secondary Keywords: Computed Tomography, Porosity, Damage Model, Mechanical Strength, Aluminium, HPDC, Squeeze Casting, Non-Destructive Testing

Executive Summary

- The Challenge: Accurately predicting component failure in light metal alloys requires understanding internal defects, but traditional methods are destructive and limited in scope.

- The Method: The study combined an emulated High Pressure Die Casting (HPDC) process with high-resolution Computed Tomography (CT) scanning to precisely quantify initial porosity in cast aluminum step plates.

- The Key Breakthrough: CT-derived porosity data was successfully integrated as an input for a numerical damage model, which then accurately predicted the material's stress-strain behavior and failure under load.

- The Bottom Line: This innovative approach transforms CT from a simple post-production inspection tool into a powerful predictive engineering instrument for designing more durable and reliable light metal components.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, engineers have sought reliable methods to understand and predict the mechanical strength of cast metal parts. Internal defects like porosity, inclusions, and cracks are primary drivers of component failure, yet their detection has traditionally relied on destructive methods like sectioning and microscopy. While these methods provide valuable information, they are sample-based and cannot give a complete, three-dimensional picture of a component's internal structure without destroying it.

Industrial CT scanning emerged as a powerful non-destructive tool, allowing us to see inside a part and identify flaws. However, its use has often been limited to quality control—a pass/fail check for defects. The research presented in this paper addresses a critical industry need: moving beyond simple defect detection to using this rich 3D data to proactively predict material behavior and component lifetime. The core challenge was to bridge the gap between CT imaging and predictive numerical simulation to create a more robust and efficient design and validation process.

The Approach: Unpacking the Methodology

The researchers devised a comprehensive methodology to validate the use of CT data in damage modelling, combining a modified casting process with advanced scanning and mechanical testing.

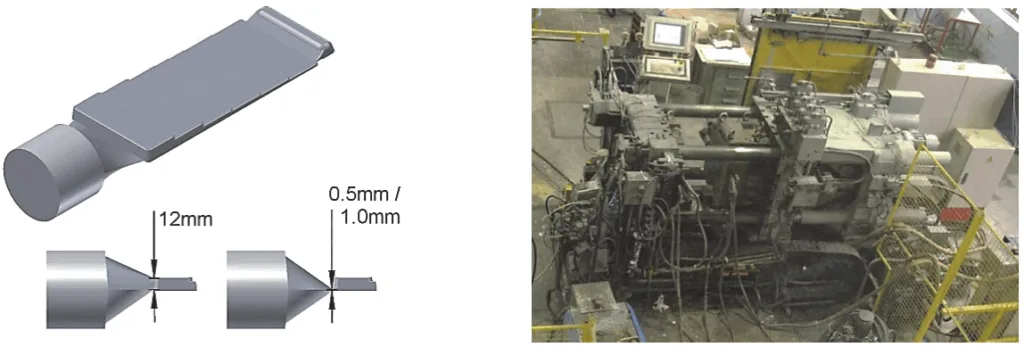

Method 1: Emulated HPDC Casting

To create test samples with realistic porosity, the team modified a squeeze casting process to emulate HPDC conditions. They replaced the standard 12mm nozzle with much narrower gates (0.5mm and 1.0mm). This change induced a high-turbulence, atomized flow regime with a melt velocity of approximately 50m/s, characteristic of HPDC. This approach allowed them to produce A226 (AlSi9Cu3) aluminum step plates with varying levels of porosity, ideal for subsequent analysis.

Method 2: High-Resolution CT Scanning and Porosity Quantification

The cast step plates were scanned using industrial CT at the University of Applied Sciences Upper Austria, Wels Campus. An identical "Region of Interest" (ROI) was defined for each sample across its different thicknesses (3mm to 14mm). The scans achieved a high resolution with a voxel size of 77µm. The resulting 3D data was analyzed to precisely measure the volume fraction of voids (porosity percentage) in each section. These CT-based measurements were also compared against traditional metallography to validate their accuracy.

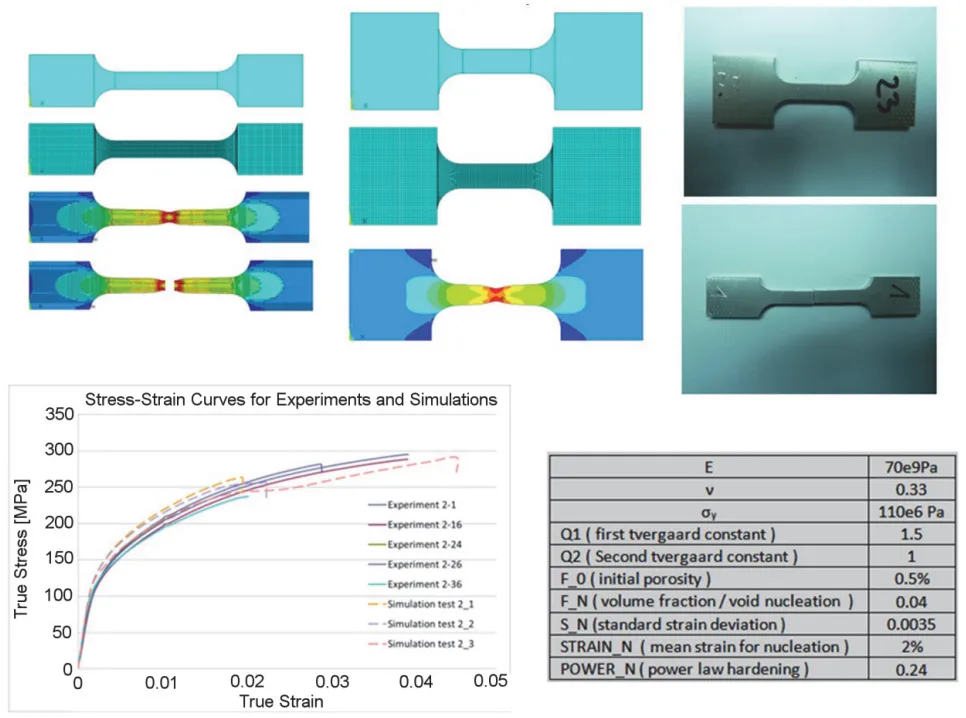

Method 3: Mechanical Testing and Numerical Simulation

To create a baseline for material behavior, a series of mechanical tests were performed on specimens machined from the cast plates. This included uniaxial tensile tests and Charpy impact tests. The experimental force-displacement data was recorded. In parallel, a numerical simulation was set up using a combined Gurson damage model in Ansys. Critically, the "initial porosity" parameter for the model was not an estimate but was taken directly from the CT scan results. The simulation then predicted the stress-strain behavior of the material, which was compared against the real-world experimental test data.

The Breakthrough: Key Findings & Data

The study yielded two significant findings that demonstrate the power of integrating CT scanning with damage modelling.

Finding 1: CT Provides Accurate, Spatially-Resolved Porosity Data

The research confirmed that CT scanning is a highly reliable method for quantifying porosity in cast aluminum. As shown in Figure 4, the porosity percentages measured by CT (blue bars) showed a strong correlation with those measured by traditional metallography (green bars) across various thicknesses of the step plate. For example, in the 14mm step, the CT-measured porosity for the 1.0mm nozzle was approximately 6.5%, closely matching the metallography results. This validation was crucial for establishing trust in the CT data as a direct input for simulation.

Finding 2: CT-Informed Models Accurately Predict Material Failure

The most significant breakthrough was the successful prediction of mechanical behavior using the CT-informed damage model. The simulation, which used an initial porosity value of 0.5% (F_O) derived from CT scans, generated stress-strain curves that closely matched the experimental results from the tensile tests. As seen in the graph from Figure 6, the simulation curves (e.g., "Simulation test 2_1") align almost perfectly with the experimental data curves (e.g., "Experiment 2-1"), demonstrating that the model could accurately predict both the elastic and plastic deformation phases leading to failure. This proves that incorporating real-world defect data from CT scans dramatically improves the accuracy of damage simulations.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that CT scanning can be used not just for final inspection but as a tool to validate and optimize casting process parameters. By correlating nozzle design and injection speeds with CT-measured porosity, processes can be fine-tuned to minimize defect formation from the start.

- For Quality Control Teams: The data in Figure 4 of the paper illustrates the effect of gating conditions on porosity distribution. This could inform new, more sophisticated quality inspection criteria that go beyond simple defect detection to quantify porosity volume fraction in critical areas of a component.

- For Design Engineers: The findings indicate that designers can use CT data from initial prototypes to run highly accurate failure simulations. This allows for the validation of component durability early in the design phase, reducing the need for extensive physical testing and potentially allowing for more lightweight and optimized designs without compromising safety.

Paper Details

An innovative use of CT method in light metals development

1. Overview:

- Title: An innovative use of CT method in light metals development

- Author: Christoph Angermeier, Amir M. Horr

- Year of publication: 2014

- Journal/academic society of publication: iCT Conference 2014

- Keywords: Computer Tomography, Porosity, Damage Model, Mechanical Strength, Aluminium

2. Abstract:

During the past two decades, the macrostructural characteriziation and its effects on material properties have been considered by many authors, and special attention has been devoted to the material strength and mechanical design. Varios methods have been proposed to investigate the material defects using microstructure characteriziation, e.g. ultrasonic scanning, macro etching, light microscopy, scanning electron microscopy and X-ray computer tomography (CT). Conventionally, determining component porosity would require destructive testing. However, industrial CT scanning can detect internal features and flaws without destroying the part. It can detect flaws inside a part such as porosity, an inclusion or a crack before a failure can occur. Studying porosity variation in different metals and alloys, while varying the percentage composition of the material (especially under different compressive and tensile loads), is an important consideration for the mechanical strength and design of metal parts. The industrial CT, depends on its resolution, can even detect and localized small defects in metals and casting parts in three dimensions. In recent years, in order to investigate component defects, the use of industrial CT has been emphasized in the Leichtmetallkompetenzzentrum Ranshofen (LKR). The macrostructural characterization and its effects on material strength are carried out using detection of material defects (in particular pores) by CT. One of the main contributions of this paper is to show the advantages of using CT in material characterization and damage modelling. The squeeze casting process (used to cast aluminium step plates) has been modified in order to achieve a high velocity/pressure casting quality parts using an atomized flow characteristic (atomized jet at inlet). Further experimental and simulation tasks have also been carried out to investigate the variation of porosity and its effects on accumulation of damage in light metal alloys using CT results.

3. Introduction:

CT is an innovative and ascending technology in non-destructive material testing. Many research studies about CT possible applications in material science have been carried out recently to deal with casting process optimization, fracture mechanics, fatigue life, damage modeling and also microstructural characterization. While scientific research improves the application potential of CT, the casting industry primarily uses it for pore detection to avoid rejections in serial production. The research herein focuses on the well-known advantage of CT in detecting pores and shrinkage voids in aluminum alloys to predict material behavior.

4. Summary of the study:

Background of the research topic:

The characterization of macrostructure and its effect on material properties, particularly strength, is a critical aspect of mechanical design for metal parts. Traditional methods for investigating material defects like porosity are often destructive (e.g., macro etching, microscopy) or lack three-dimensional detail. Industrial Computed Tomography (CT) offers a non-destructive method to detect and localize internal flaws in 3D.

Status of previous research:

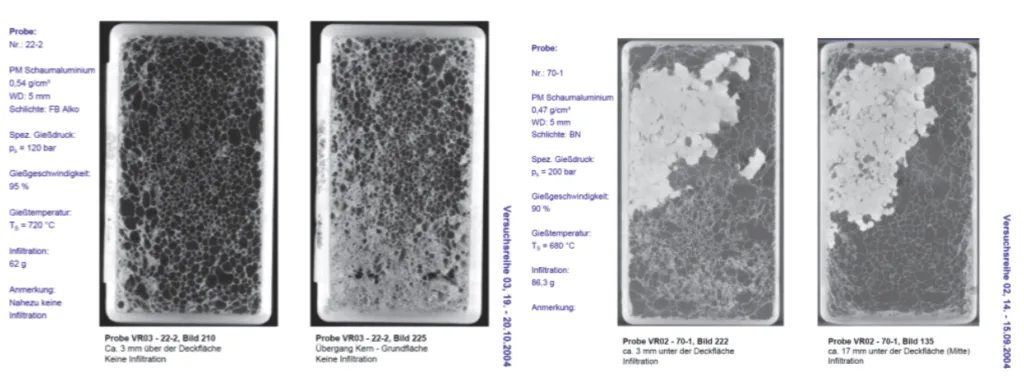

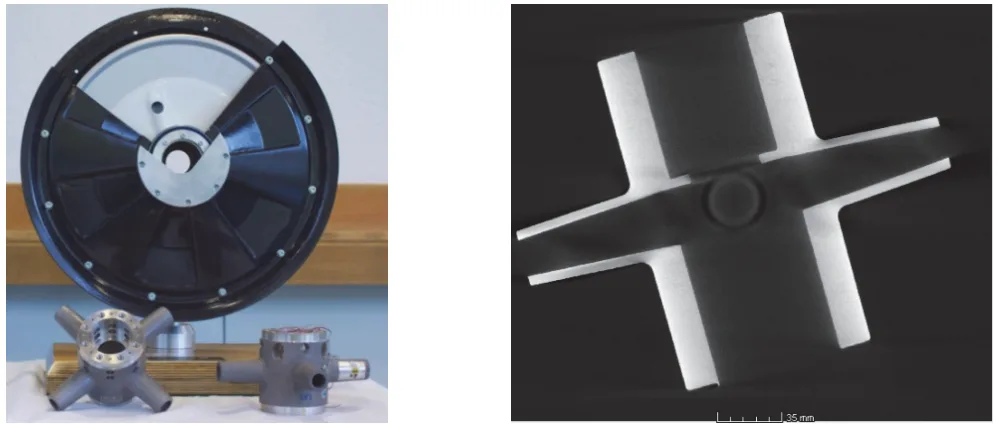

Previous work has demonstrated the power of CT in materials science, including high-resolution synchrotron CT for detecting nano-scale phases, in-situ CT for observing solidification, and using CT data to generate Finite Element (FE) models for stress concentration analysis. In industry, CT is mainly used for pore detection in serial production. Recent research at LKR has also used CT to investigate porosity distribution in High Pressure Die Casting (HPDC) and to characterize metal foams.

Purpose of the study:

The main contribution of this paper is to demonstrate the advantages of using CT in material characterization and, subsequently, in numerical damage modelling. The goal is to show how CT-derived data on internal defects (specifically porosity) can be used as a direct input for simulations to accurately predict the mechanical strength and durability of light metal alloy components.

Core study:

The study involved a multi-stage process. First, an HPDC process was emulated by modifying a squeeze casting machine with a narrow nozzle design to produce aluminum (AlSi9Cu3) step plates with significant porosity. Second, these plates were scanned using a high-resolution CT system to quantify the porosity volume fraction and distribution. Third, the CT results were validated against traditional metallography. Fourth, mechanical properties were determined through tensile and Charpy tests. Finally, the CT-measured porosity data was used as an initial condition in a numerical damage simulation (Gurson model) to predict the material's stress-strain behavior, and these simulation results were compared with the experimental test data for validation.

5. Research Methodology

Research Design:

The research followed a comparative experimental and numerical design. An emulated casting process was used to create test samples with controlled defects. These defects were then characterized non-destructively using CT. The material's actual mechanical response was measured experimentally. Finally, a numerical model, informed by the CT data, was used to simulate the same mechanical tests, and the results from the experiment and simulation were compared to validate the approach.

Data Collection and Analysis Methods:

- Casting: A UBE HVSC 350 squeeze casting machine was used with a modified step plate mold (nozzle widths of 0.5mm and 1.0mm) to cast A226 (AlSi9Cu3) alloy.

- CT Scanning: Samples were scanned at the University of Applied Sciences Upper Austria, Wels Campus. Key parameters included a tube voltage of 180 kV and a voxel size of 77µm. Porosity percentage was determined via grey value analysis within defined Regions of Interest (ROIs).

- Metallography: Micro-sections were analyzed using light microscopy, and the area percentage of pores was measured by the intersect line method for comparison with CT results.

- Mechanical Testing: Uniaxial tensile tests were conducted using a displacement control setup. Standard Charpy impact tests were performed on V-notched specimens at room temperature.

- Numerical Simulation: A combined Gurson damage model with power law plasticity was implemented in Ansys. A 2D quad, hex-dominated mesh with a 0.25mm element size was used. The initial porosity value for the simulation was taken from the CT scan results.

Research Topics and Scope:

The research focused on using industrial CT to quantify casting porosity in an AlSi9Cu3 alloy and applying this data to a numerical damage model to predict mechanical failure. The scope included modifying a casting process to emulate HPDC, comparing CT and metallographic porosity measurements, conducting mechanical tests, and validating a CT-informed damage simulation against experimental results.

6. Key Results:

Key Results:

- A squeeze casting process was successfully modified with narrow gating (0.5mm and 1.0mm) to emulate the high-velocity, high-turbulence flow of HPDC, enabling the creation of test samples with relevant porosity levels.

- CT scanning, with a voxel size of 77µm, proved to be an effective method for quantifying the porosity percentage in different sections of the cast aluminum step plates.

- The porosity values obtained from CT scans showed good agreement with measurements from traditional metallographic analysis, validating the accuracy of the CT data (Figure 4).

- The numerical damage simulation, which used the CT-derived porosity value (F_O = 0.5%) as an initial input, produced stress-strain curves that accurately matched the experimental data from tensile tests (Figure 6). This demonstrates that CT-informed models can reliably predict the mechanical behavior and failure of cast components.

Figure Name List:

- Figure 1: CT slices of cast integral aluminum foam cores, remained stable (left) and infiltrated (right)

- Figure 2: Exposition of wheel hub in Light Metal Technology (LMT) conference, Gmunden, 2012 and CT scan of the magnesium wheel hub

- Figure 3: Details of new nozzle designs for step plates and UBE HVSC 350 Squeeze Casting machine at LKR

- Figure 4: ROIs, their porosity percentage(CT – measured in computed tomography; MT – measured in metallography) and CT scanning parameters for step plate investigations

- Figure 5 - Experimental specimen, cast step plate and test machines

- Figure 6: Geometry, mesh, stress Intensity contour, true stress-strain curves and material card

7. Conclusion:

The study successfully demonstrated that the integration of CT scanning with numerical damage modelling provides a powerful tool for assessing the quality and predicting the failure of cast components. The comparative analyses between experimental and simulation results showed that numerical models, when supplied with an initial porosity input from CT scanning, generate reasonably accurate predictions for damage and failure in light weight alloys. This approach is attractive for industrial use due to its accuracy and affordable simulation time. The authors conclude that combining the scanning power of CT technology with advanced numerical damage models can streamline quality control procedures for industrial HPDC production and create a powerful method for material characterization and defect modelling.

8. References:

- [1] G. Requena, P. Cloetens, W. Altendorfer, C. Poletti, D. Tolnai, F. Warchomicka, and H. P. Degischer, “Sub-micrometer synchrotron tomography of multiphase metals using Kirkpatrick–Baez optics," Scr. Mater., vol. 61, no. 7, pp. 760–763, Oct. 2009.

- [2] D. Tolnai, P. Townsend, G. Requena, L. Salvo, J. Lendvai, and H. P. Degischer, “In situ synchrotron tomographic investigation of the solidification of an AlMg4.7Si8 alloy,” Acta Mater., vol. 60, no. 6–7, pp. 2568–2577, Apr. 2012.

- [3] G. Nicoletto, R. Konečná, and S. Fintova, “Characterization of microshrinkage casting defects of Al-Si alloys by X-ray computed tomography and metallography,” Int. J. Fatigue, vol. 41, pp. 39-46, Aug. 2012.

- [4] A. Staude, M. Bartscher, K. Ehrig, J. Goebbels, M. Koch, U. Neuschaefer-Rube, and J. Nötel, “Quantification of the capability of micro-CT to detect defects in castings using a new test piece and a voxel-based comparison method,” NDT E Int., vol. 44, no. 6, pp. 531–536, Oct. 2011.

- [5] J. Kastner, B. Harrer, G. Requena, and O. Brunke, “A comparative study of high resolution cone beam X-ray tomography and synchrotron tomography applied to Fe- and Al-alloys,” NDT E Int., vol. 43, no. 7, pp. 599–605, Oct. 2010.

- [6] Ambos, E., Neuber, D., Besser, W., Stuke, I., Teubner, S., Lux, H., and Brunke, O., “Einsatz der Schnellen Computertomographie zur Prorositätsbewertung an Druckgussteilen,” Gie, vol. 60, no. 1/2, pp. 14–22, 2013.

- [7] Chimani, C. M., Kretz, R., and Angermeier, C., “Investigations On Microstructure Effect Of Changing Fluid Flow Characteristic In High Pressure Die Casting," in 15th International Symposium on Metallography, Stara Lesna, 2013.

- [8] Chimani, C. M., Kretz, R., Schneiderbauer, S., Puttinger, S., and Pirker, S., “Studies on flow characeristics at high-pressure die-casting,” in Light Metals 2012, 2012.

- [9] Gurson, A.L., Continuum theory of ductile rupture by void nucleation and growth, Part I: Yield criteria and flow rule for porous ductile media. J. Eng. Mater. Technol., Vol. 99, pp. 1–15, 1977.

- [10] Johnson, G. R. and Cook, W. H., Fracture characteristics of three metals subjected to various strains, strain rates, temperature and pressure, J. Eng. Fracture Mechanics, Vol. 21. No. 1, pp. 31-48, 1985.

- [11] Needleman, A. & Tvergaard, V., Analysis of plastic flow localization in metals. Applied Mechanics Review, 45, pp. s3-s18, 1992.

- [12] Neukamm F., Feucht M. and Haufe A., Considering damage history in crashworthiness simulation, Ls-Dyna Anwenderforum, 2009.

- [13] Tresca, H.,, Mémoire sur l'écoulement des corps solides soumis à de fortes pressions. C.R. Acad. Sci. Paris, vol. 59, pp. 754, 1864.

Expert Q&A: Your Top Questions Answered

Q1: Why was the squeeze casting process modified to emulate HPDC instead of just using a standard HPDC machine?

A1: The paper states the goal was to achieve a "high velocity/pressure casting quality" using an "atomized flow characteristic." By scaling down the gating of the squeeze casting mold to 0.5-1.0mm, they could achieve a high melt velocity of ~50m/s. This modification induced the high turbulence and atomized flow typical of HPDC, which was necessary to generate the porosity required for the study, while likely using available equipment at LKR.

Q2: What specific numerical damage model was used in the simulation, and why was it chosen?

A2: The study employed a "combined Gurson damage model with power law plasticity." The Gurson model is specifically designed to describe ductile rupture in porous materials by accounting for void nucleation, growth, and coalescence. This makes it an ideal choice for this research, as the primary defect being studied and quantified by CT was porosity.

Q3: How was the critical "initial porosity" value for the simulation determined?

A3: The paper explicitly states that "the initial porosity for the whole sample has been taken from the CT scan results." This is the core innovation of the study. Instead of using an estimate or a theoretical value, they used a precise, empirically measured value (F_O = 0.5% as shown in the material card in Figure 6) from the non-destructive CT analysis of the actual cast parts.

Q4: What was the resolution of the CT scans, and was it sufficient to capture the relevant defects?

A4: The CT scanning parameters listed in Figure 4 show a "Voxelsize" of 77µm. This resolution was sufficient to detect and quantify the gas pores and shrinkage porosity that are characteristic of the HPDC process. The close correlation between the CT results and the metallography results confirms that this resolution was adequate for the goals of the study.

Q5: How did the researchers validate that the porosity measured by CT was accurate?

A5: The researchers validated the CT data by performing investigations on micro-sections of the same step plates using traditional metallography. As stated on page 4, "The area percentage of pores was measured by intersect line method and the results compared with CT." The bar chart in Figure 4 visually presents this comparison, showing a strong agreement between the porosity measured by CT and metallography (MT), which builds confidence in the CT results.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of predicting component failure based on internal defects has long been a hurdle in light metal casting. This research demonstrates a powerful solution: leveraging CT for Damage Modelling. By treating CT data not as a simple image but as a quantitative input for sophisticated numerical simulations, we can move from reactive quality control to predictive design and analysis. This approach allows engineers to understand the real-world impact of porosity on mechanical strength, leading to more robust components, optimized casting processes, and shorter development cycles.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "An innovative use of CT method in light metals development" by "Christoph Angermeier and Amir M. Horr".

Source: https://www.ndt.net/?id=15697

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.