From Blueprint to Reality: Using FEA to Perfect Magnesium Alloy Wheel Casting

This technical summary is based on the academic paper "Magnesium Alloy Wheel Structure Design and Wheel Casting Process Performance Analysis" by Xin Jiang and Xinwei Lan, published in Journal of Materials Science and Engineering B (2022).

Keywords

- Primary Keyword: Magnesium Alloy Wheel Casting

- Secondary Keywords: Finite Element Method, Casting Process Simulation, Lightweight Wheel Design, Sand Casting, Solidification Analysis

Executive Summary

- The Challenge: The automotive industry's demand for lightweight magnesium alloy wheels is high, but the casting process is prone to defects like porosity and shrinkage.

- The Method: Researchers used finite element theory to create a numerical simulation of the sand casting process for a lightweight magnesium alloy wheel.

- The Key Breakthrough: The simulation precisely identified how temperature differentials and changes in molten metal flow velocity during mold filling lead to the formation of shrinkage defects.

- The Bottom Line: Finite element analysis is a powerful predictive tool that allows engineers to optimize casting process parameters and wheel design to prevent defects before production begins.

The Challenge: Why This Research Matters for HPDC Professionals

In the push for greater fuel efficiency and environmental protection, lightweighting has become a top priority in the automotive industry. Magnesium alloys, as the lightest structural metals, are an ideal choice for components like wheels. However, manufacturing these wheels is not without its challenges.

Casting, a fundamental manufacturing process, is often plagued by defects such as sand washing, sand inclusion, and porosity. For a critical safety component like a wheel, which bears the vehicle's weight and endures constant road forces, such defects are unacceptable. The core problem for engineers is how to leverage the benefits of casting—such as efficiency and adaptability—while mitigating its inherent risks. This research tackles that problem head-on by seeking a method to analyze and predict the casting process performance, making it more reliable and useful for mass production.

The Approach: Unpacking the Methodology

To understand the complex dynamics inside the mold, the researchers developed a comprehensive numerical simulation based on finite element theory. This approach provides a clear window into the filling and solidification process without the cost and time of physical trials.

Method 1: Digital Modeling and Simulation Setup

The study began with a lightweight wheel model designed to meet market safety and engineering standards. The chosen material was Magnesium alloy AZ91, with its specific thermal and mechanical properties (Table 1) programmed into the simulation. The sand casting process was simulated using a model with a grid size of 2, resulting in a highly detailed mesh of approximately 10 million grids to ensure accuracy.

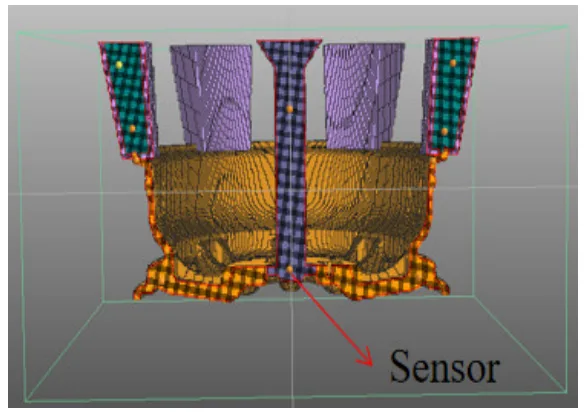

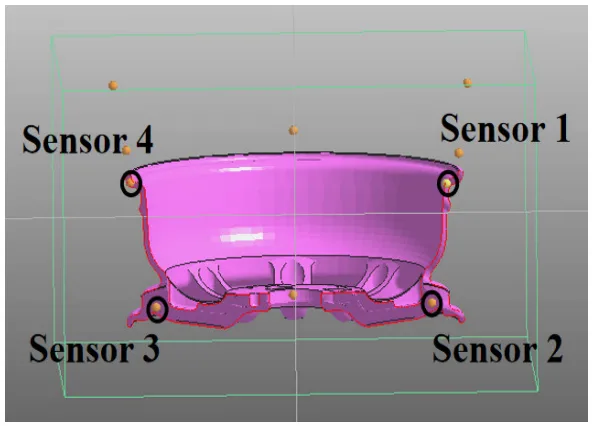

Method 2: Thermal Process Monitoring

To capture critical data, four virtual temperature sensors were strategically placed in the wheel model. These sensors were located at the junctions between the rim and spokes, a common area for defects to form. This setup allowed the researchers to record the precise evolution of temperature throughout the entire filling and solidification process, providing crucial insights into the thermal dynamics at play.

The Breakthrough: Key Findings & Data

The simulation yielded precise data on the thermal behavior and fluid dynamics of the molten magnesium alloy as it filled the mold. These findings directly correlate to the formation of common casting defects.

Finding 1: Significant Thermal Gradients During Mold Filling

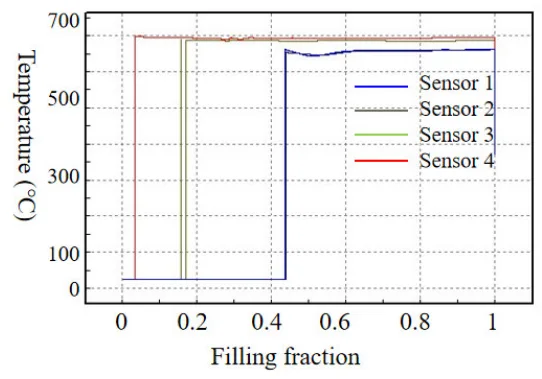

The simulation revealed a notable temperature difference within the mold as it was being filled. As shown in the data analysis, the alloy temperature at the bottom of the rim is approximately 700°C. Critically, the temperature difference between the top and the bottom of the rim was about 50°C. This thermal gradient can lead to non-uniform cooling, creating internal stresses and potential weak points in the final product. The temperature evolution at all four sensor points is detailed in Figure 4, which tracks temperature against the filling fraction.

Finding 2: Flow Velocity Reduction Causes Shrinkage Defects

A key insight from the study was the behavior of the molten metal as it flowed through the wheel's spokes. The simulation showed that as the metal front reaches the middle of the spokes, its flow velocity slows down significantly. This slowdown is a primary cause of shrinkage defects. When the flow is too slow, premature solidification can occur, preventing liquid metal from feeding the solidifying sections and leading to voids or shrinkage porosity within the casting.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the gating system or mold temperature to minimize the 50°C thermal gradient between the top and bottom of the rim may contribute to reducing internal stress and defects. The identified slowdown in the spokes highlights a need to optimize filling velocity.

- For Quality Control Teams: The data in Figure 4 illustrates the thermal signature of the casting process. This information can be used to identify areas with the highest risk of shrinkage defects (e.g., the middle of the spokes), allowing for more targeted and efficient quality inspection protocols.

- For Design Engineers: The findings indicate that the geometry of the spokes directly influences molten metal flow and defect formation during solidification. This suggests that incorporating casting simulation early in the design phase is a valuable consideration to create designs that are not only lightweight but also optimized for manufacturability.

Paper Details

Magnesium Alloy Wheel Structure Design and Wheel Casting Process Performance Analysis

1. Overview:

- Title: Magnesium Alloy Wheel Structure Design and Wheel Casting Process Performance Analysis

- Author: Xin Jiang¹ and Xinwei Lan²

- Year of publication: 2022

- Journal/academic society of publication: Journal of Materials Science and Engineering B 12 (7-9)

- Keywords: Magnesium alloy wheel, casting process, finite element method.

2. Abstract:

Recently, as the automotive industry is increasingly demanding on energy saving and environmental protection, people are paying more attention to the lightweight design and comfort of automobiles. Casting is a very important part of wheel manufacturing. Casting method includes centrifugal casting, sand casting, high pressure casting, low pressure casting and so on. In this research, magnesium alloy wheel casting numerical simulation was carried out. Analysis of casting process was researched based on finite element theory, filling and solidification data at the end of the simulation were obtained for guidance of produce.

3. Introduction:

With global development, there is a growing focus on environmental and energy issues. Magnesium alloys are the lightest metal structural materials, making them crucial for the aircraft and automobile industries. Reducing automobile weight significantly impacts the environment and energy consumption, making lightweighting an inevitable trend. Wheels are critical vehicle components, bearing the vehicle's weight and impact forces from the road, directly affecting driving stability and smoothness. While there are many methods for casting wheels, this research focuses on sand casting. The advantages of sand casting include the abundance and low cost of clay, short mold cycles, high efficiency, and wide adaptability. However, it is prone to defects like sand washing, sand inclusion, and porosity. This research analyzes the wheel casting process performance to make the study of this process more useful.

4. Summary of the study:

Background of the research topic:

The research is driven by the increasing demand in the automotive industry for energy saving and environmental protection, which has made the lightweight design of automobiles an inevitable trend. Magnesium alloys are the lightest structural metals, making them ideal for manufacturing lightweight components like wheels.

Status of previous research:

Previous research acknowledges that various casting methods exist for wheel manufacturing, including centrifugal, sand, high-pressure, and low-pressure casting. It is also known that sand casting, while efficient and adaptable, has disadvantages such as a propensity for defects like sand washing, inclusion, and porosity.

Purpose of the study:

The purpose of this research is to analyze the performance of the magnesium alloy wheel casting process. By using numerical simulation based on finite element theory, the study aims to obtain filling and solidification data to provide guidance for production and make the study of the wheel casting process more useful.

Core study:

The core of the study involved conducting a numerical simulation of the sand casting process for a lightweight magnesium alloy wheel. The simulation focused on analyzing the filling and solidification stages to understand the temperature evolution and fluid dynamics within the mold. Four test points were selected on the wheel model to record temperature data, which was then used to identify potential causes of casting defects.

5. Research Methodology

Research Design:

The research was designed as a numerical simulation study. A lightweight vehicle wheel model was designed based on market safety and engineering standards. The simulation was set up to model the sand casting process for this wheel using magnesium alloy AZ91.

Data Collection and Analysis Methods:

Data was collected through virtual sensors placed within the finite element model. Four test points were selected at the rim and spoke junctions to record the temperature evolution throughout the simulated casting process. The collected data, including temperature at different locations and filling fractions, was analyzed to understand the thermal dynamics and fluid flow, and to identify conditions leading to defects.

Research Topics and Scope:

The research topic is the performance analysis of the casting process for a magnesium alloy wheel. The scope is limited to a numerical simulation of the sand casting method. The analysis focuses on the filling and solidification phases, using temperature data to infer process performance and potential defect formation.

6. Key Results:

Key Results:

- A rational casting model was established for the magnesium alloy wheel casting process through simulation.

- The alloy temperature at the bottom of the rim during filling is approximately 700 °C.

- The temperature difference between the top and bottom of the rim is about 50 °C.

- During filling, the molten metal flow velocity slows down when it reaches the middle of the spokes.

- This slowing of flow velocity is identified as a cause of shrinkage defects.

Figure Name List:

- Fig. 1 Wheel model.

- Fig. 2 Wheel casting sensor.

- Fig. 3 Wheel casting sensor related to rim.

- Fig. 4 Wheel casting filling fraction.

7. Conclusion:

The casting of magnesium alloy wheels is a complicated process. This study successfully established a rational casting model by simulating the process. The lightweight design of the magnesium alloy wheel and the casting model were verified. Through simulation analysis, distribution data of different parts of the wheel at different times were obtained. The simulation of the actual wheel casting provided a good casting model, which is very meaningful for engineering applications.

8. References:

- [1] Kim, K. J., and Lee, J. W. 2022. "Light-Weight Design and Structure Analysis of Automotive Wheel Carrier by Using Finite Element Analysis." International Journal of Precision Engineering and Manufacturing 23 (1): 79-85.

- [2] Sharma, A., Yadav, R., and Sharma, K. 2021. "Optimization and Investigation of Automotive Wheel Rim for Efficient Performance of Vehicle." Materials Today: Proceedings 45: 3601-4.

- [3] Naim, A., Kumar, R., and Bhatia, S. 2021. "A Review Paper on Materials Used for Manufacturing of Alloy Wheels." IOP Conference Series: Materials Science and Engineering 1136 (1): 012006.

- [4] Blawert, C., Hort, N., and Kainer, K. U. 2004. "Automotive Applications of Magnesium and Its Alloys." Trans. Indian Inst. Met. 57 (4): 397-408.

- [5] Jiang, X., Lyu, R., Fukushima, Y., Otake, M., and Ju, D Y. 2018. “Lightweight Design and Analysis of Automobile Wheel Based on Bending and Radial Loads." IOP Conference Series: Materials Science and Engineering 372 (1): 012048.

- [6] Leister, G. 2018. Passenger Car Tires and Wheels: Development-Manufacturing-Application. New York: Springer.

- [7] Rui, X., Zeng, Z., Zhang, Y., Li, Y., Feng, H., Huang, X. J., and Sha, Z. 2019. "Design and Experimental Investigation of a Self-tuning Piezoelectric Energy Harvesting System for Intelligent Vehicle Wheels." IEEE Transactions on Vehicular Technology 69 (2): 1440-51.

- [8] Gadwala, W. K. 2022. "Modeling and Analysis of Car Wheel Rim for Weight Optimization to Use Additive Manufacturing Process." Materials Today: Proceedings 62: 336-45.

- [9] Campbell, J. 2012. "Stop Pouring, Start Casting." International Journal of Metalcasting 6 (3): 7-18.

- [10] Leister, G. 2018. Wheels: Passenger Car Tires and Wheels. Cham: Springer, pp. 157-242.

- [11] Maryani, E., Purba, H. H., and Sunadi, S. 2020. "Process Capability Improvement through DMAIC Method for Aluminium Alloy Wheels Casting." Journal of Industrial Engineering & Management Research 1 (4): 19-26.

- [12] Nejad, R. M. 2014. “Using Three-Dimensional Finite Element Analysis for Simulation of Residual Stresses in Railway Wheels." Engineering Failure Analysis 45: 449-55.

- [13] Yang, L. M., Zhao, L. L., Zhang, Q. Q., and Zhou, T. Т. 2013. "Numerical Simulation Analysis of Aluminium Alloy Wheels Casting Defects and Casting Process Optimization." Materials Science Forum. Trans Tech Publications Ltd 749: 125-32.

- [14] Chen, L., Li, J., Zhao, Y., Li, M., Li, L., Chen, L., and Hou, H. 2020. "Numerical Simulation and Optimization of Indirect Squeeze Casting Process." Engineered Science 13 (2): 65-70.

- [15] Reddy, K. S. 2014. "Casting Simulation of Automotive Wheel Rim Using Procast." Journal of Mechanical and Civil Engineering 11 (6): 11-4.

- [16] Hsu, Y. L., and Yu, C. C. 2006. "Computer Simulation of Casting Process of Aluminium Wheels—A Case Study." Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 220 (2): 203-11.

Expert Q&A: Your Top Questions Answered

Q1: Why did the study focus on sand casting when other, more precise methods exist?

A1: The paper highlights the practical advantages of sand casting: the raw material (clay) is inexpensive and abundant, the mold production cycle is short, and the process offers high work efficiency and wide adaptability. The research aimed to analyze and improve this widely used industrial process by understanding and mitigating its known disadvantages, such as a tendency for porosity and inclusions.

Q2: What specific magnesium alloy was used, and why are its properties important for the simulation?

A2: The study used magnesium alloy AZ91. The paper lists its specific properties in Table 1, including specific heat (1.02 kJ/(kg·k)), coefficient of thermal expansion (26.0 µm/(m·k)), Poisson ratio (0.35), and yield strength (0.16 GPa). These specific material parameters are essential inputs for the finite element analysis, as they govern how the material behaves thermally and mechanically during the simulated filling and solidification, ensuring the accuracy of the results.

Q3: How was the temperature monitored during the simulation to get such precise data?

A3: The researchers embedded four virtual test points, or "sensors," into the digital wheel model. As shown in Figures 2 and 3, these sensors were strategically placed at the junctions of the rim and spokes. During the simulation, these points recorded the temperature evolution throughout the entire process, providing a detailed timeline of thermal changes at critical locations.

Q4: The paper mentions "shrinkage defects." What part of the simulation specifically pointed to this risk?

A4: The simulation revealed that as the molten metal front travels to the middle of the spokes, the flow velocity decreases. This slowdown is a direct indicator of a high risk for shrinkage defects. When the flow is too slow, it can lead to premature solidification in thinner sections, cutting off the supply of liquid metal needed to compensate for volume reduction (shrinkage) as the casting cools, thus forming voids.

Q5: What is the practical value of knowing the temperature difference between the top and bottom of the rim is about 50°C?

A5: This 50°C thermal gradient is a critical piece of data for process control. A significant temperature difference across the casting can cause non-uniform cooling and solidification, which in turn creates internal stresses and can lead to distortion or cracking. By quantifying this gradient, engineers can redesign the gating and riser system or adjust mold cooling strategies to promote more uniform solidification, directly improving the structural integrity and quality of the final wheel.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing defect-free, lightweight components is a constant in the automotive industry. This research demonstrates that numerical simulation is an indispensable tool for perfecting the Magnesium Alloy Wheel Casting process. By providing a detailed view of what happens inside the mold, finite element analysis allows engineers to move from a reactive, trial-and-error approach to a proactive, predictive one, optimizing designs and process parameters to eliminate defects before the first part is ever cast.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Magnesium Alloy Wheel Structure Design and Wheel Casting Process Performance Analysis" by "Xin Jiang and Xinwei Lan".

Source: https://doi.org/10.17265/2161-6221/2022.7-9.001

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.