The Giga-Casting Challenge: Key Factors for Defect-Free Ultra-Large Aluminum Parts

This technical summary is based on the academic paper "Ultra-Large Aluminum Castings in Automobiles" by Qigui Wang, Andy Wang, and Jason Coryell, published in The 75th World Foundry Congress (2024).

![Fig.1. Six mega Al castings in Cadillac Celestiq [3].](https://castman.co.kr/wp-content/uploads/image-3094.webp)

Keywords

- Primary Keyword: Ultra-Large Aluminum Castings

- Secondary Keywords: HPDC, Giga Casting, Automotive Lightweighting, Die Casting Quality, Aluminum Alloy

Executive Summary

- The Challenge: The automotive industry's shift to ultra-large "giga" castings presents significant manufacturing difficulties in maintaining dimensional stability, quality, and mechanical performance.

- The Method: The research reviews the key factors impacting the quality of ultra-large castings, including alloy selection, melt cleanliness, gating system design, and casting process parameters.

- The Key Breakthrough: An optimized shot profile, specifically a delayed plunger fast speed stage, combined with an improved gating design, can significantly reduce the amount of trapped air—a primary cause of casting defects.

- The Bottom Line: Successfully manufacturing high-quality ultra-large aluminum castings requires a holistic, systems-based approach that integrates advanced process simulation with meticulous control over every stage of production.

The Challenge: Why This Research Matters for HPDC Professionals

The automotive industry is undergoing a structural revolution. Automakers like Tesla, GM, and Toyota are aggressively adopting ultra-large aluminum castings—often called "mega" or "giga" castings—to replace assemblies of tens or even hundreds of individual parts. As noted in the paper, this approach offers massive benefits: over 60% part reduction, 40% lower tooling costs, and 30% savings in mass and energy. The Cadillac Celestiq, for example, uses six such castings to form its entire lower body structure.

However, these components are not simple brackets; they are critical structural parts subjected to static, dynamic, and cyclic loads. This places immense pressure on manufacturers to deliver castings with exceptional quality, high mechanical properties, and predictable performance. The sheer size and complexity of these parts make this a formidable challenge. Achieving defect-free castings depends on a complex interplay between alloy composition, melt treatment, gating design, and the casting process itself. Getting it wrong is not just a quality issue—it's a significant economic risk.

The Approach: Unpacking the Methodology

This paper provides a comprehensive review of the critical factors that determine the success or failure of producing ultra-large aluminum castings. The authors evaluated the entire manufacturing chain, focusing on five key areas that directly influence final part quality:

- Cast Aluminum Alloy: Analyzing the properties of different alloys (C611, Aural 5, Tesla's AA386, and GM's UniCAST) to assess their castability, including fluidity, shrinkage, hot tearing tendency, and solidification behavior.

- Melt Cleanliness Control: Investigating the importance of removing inclusions and gases from the liquid metal before it enters the mold cavity, as these are primary sources of defects.

- Gating System Design: Examining how the design of runners and ingates influences turbulent flow. While HPDC requires extremely high melt velocities (around 40 m/s) to fill thin walls, this is 80 times greater than the critical velocity (0.5 m/s) for avoiding turbulence, making optimal design essential.

- Mold Surface Treatment: Assessing the impact of mold surface condition and texture on the casting's surface finish and the integrity of the crucial outer "skin layer," which is critical for fatigue performance.

- Casting Process: Optimizing key process parameters—mold temperature, melt pouring temperature, and the shot profile—and aligning them with the gating system design to achieve the best possible combination of casting quality and die life.

The Breakthrough: Key Findings & Data

The research highlights several critical relationships between process variables and casting quality, with two findings standing out for their immediate practical relevance.

Finding 1: Alloy Composition Directly Impacts Solidification and Defect Susceptibility

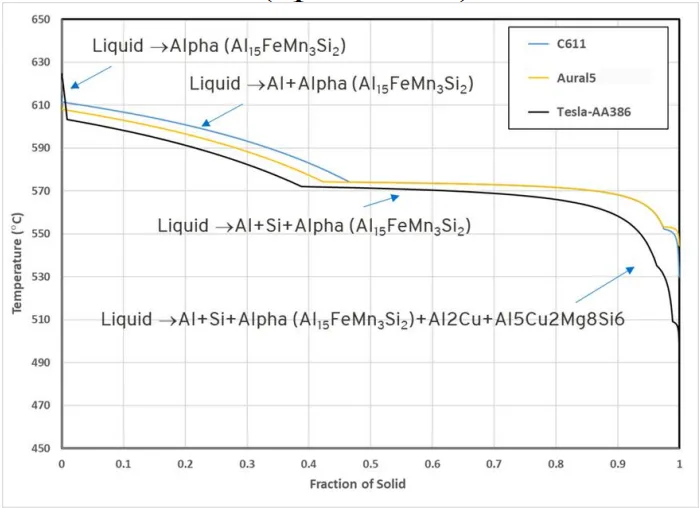

The choice of alloy has a profound effect on the casting's solidification behavior, which in turn influences the likelihood of defects like porosity and hot tearing. The paper uses calculated solidification curves to illustrate this. As shown in Figure 2, the addition of copper (Cu) to an alloy, such as in Tesla's AA386 (up to 0.8% Cu), increases the alloy's freezing range. A wider freezing range is directly linked to increased porosity and a higher crack susceptibility coefficient, as well as reduced corrosion resistance. This data underscores the critical trade-offs that must be considered during alloy selection for large, complex structural parts.

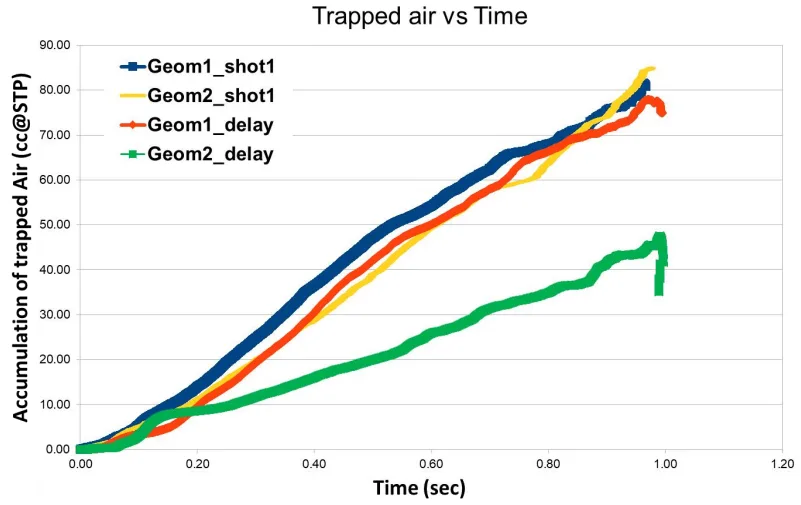

Finding 2: Optimized Shot Profile Dramatically Reduces Trapped Air

In HPDC, the shot profile is a powerful tool for controlling mold filling and minimizing defects. The paper demonstrates this with a simulation comparing trapped air accumulation for four different combinations of gating designs and shot profiles. As shown in Figure 3, the combination of an optimized gating system (Geom2) and a modified shot profile with a delayed plunger fast speed stage and pressurization (Geom2_delay) resulted in the lowest amount of trapped air. This finding is significant because it provides a clear, actionable strategy for process engineers to reduce gas porosity, a common and debilitating defect in large castings.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the shot profile, specifically by delaying the fast shot stage, may contribute to significantly reducing trapped air and related porosity defects, especially in castings with long flow paths.

- For Quality Control Teams: The data in Figure 2 of the paper illustrates the effect of alloy composition (specifically Cu content) on the freezing range, which could inform new material-specific quality inspection criteria focused on identifying porosity and micro-cracking.

- For Design Engineers: The findings in Figure 3, which show a strong interaction between gating design and shot profile, indicate that early-stage collaboration between part designers and manufacturing engineers is critical to creating geometries that are inherently easier to cast without defects.

Paper Details

Ultra-Large Aluminum Castings in Automobiles

1. Overview:

- Title: Ultra-Large Aluminum Castings in Automobiles

- Author: Qigui Wang*, Andy Wang, Jason Coryell

- Year of publication: 2024

- Journal/academic society of publication: The 75th World Foundry Congress

- Keywords: Ultra-Large Castings; Aluminum; Light-weighting; Quality; Microstructure; Materials Properties

2. Abstract:

Ultra-large aluminum castings are increasingly used in automobiles, particularly in electric vehicles for light-weighting and manufacturing cost reduction. As most of them are structural components subject to both quasi-static, dynamic and cyclic loading, the quality and quantifiable performance of the ultra-large aluminum castings is critical to their success in both design and manufacturing. This paper reviews applications of ultra-large aluminum castings in automotive industry and outlines their advantages and benefits as well as challenges. Factors affecting quality, microstructure and mechanical properties of the ultra-large aluminum castings are evaluated and discussed.

3. Introduction:

According to Ducker [1], applications of aluminum castings in automobiles have grown up by more than 300 pounds per vehicle (100%) in past twenty years. Recently, automakers have introduced ultra-large aluminum castings in critical structures to integrate tens or hundreds of different parts into a single piece casting. For instance, Tesla uses front and rear aluminum giga castings in the model Y vehicles [2]. GM has used 6 mega aluminum castings to form the entire lower body structure for the Cadillac Celestiq vehicle, Fig. 1 [3]. Toyota plans to implement giga castings to significantly reduce the number of parts used in its front and rear body frames [4]. Many other automakers are taking the similar approach. Ultra-large aluminum castings require good quality, high properties, and predictable performance. These goals are made more challenging by the complexity of ultra-large casting geometry and subsequent processing. The aluminum casting quality and final product performance is determined by alloy composition, melt treatment, casting and gating system design, and particularly casting process. Therefore, it is critical and economically important to design and manufacture the ultra-large castings correctly.

4. Summary of the study:

Background of the research topic:

The use of ultra-large aluminum castings is rapidly increasing in the automotive sector, especially for electric vehicles, to achieve lightweighting and reduce manufacturing costs. These castings often serve as critical structural components.

Status of previous research:

Automakers like Tesla, GM, and Toyota have already begun implementing "giga" or "mega" castings in their vehicles to consolidate parts. The paper cites existing applications and industry reports on this trend.

Purpose of the study:

This paper aims to review the applications, benefits, and challenges of ultra-large aluminum castings in the automotive industry. It evaluates and discusses the key factors that affect the quality, microstructure, and mechanical properties of these castings.

Core study:

The study focuses on five key factors affecting the quality of ultra-large aluminum castings: 1) Cast aluminum alloy selection and its impact on castability and solidification. 2) The importance of melt cleanliness control to prevent defects from inclusions and gases. 3) The design of the gating system to manage high-velocity turbulent flow. 4) Mold surface treatment to improve surface quality and fatigue performance. 5) Optimization of casting process parameters like temperature and shot profile.

5. Research Methodology

Research Design:

The paper is a review and evaluation of existing technologies, materials, and processes relevant to the manufacturing of ultra-large aluminum castings. It combines industry application examples with analysis of key manufacturing variables.

Data Collection and Analysis Methods:

The authors use thermodynamic calculations to model the solidification sequences of different aluminum alloys (presented in Figure 2). They also employ casting process simulation to calculate the accumulation of trapped air under different gating and shot profile conditions (presented in Figure 3).

Research Topics and Scope:

The scope covers the opportunities and challenges of ultra-large aluminum castings, and a detailed discussion of the factors influencing their quality: cast alloy, melt cleanliness, gating system design, mold surface treatment, and casting process control.

6. Key Results:

Key Results:

- The addition of Copper (Cu) to aluminum alloys, such as in AA386, increases the freezing range, which in turn increases the susceptibility to porosity and cracking.

- For high-pressure die casting (HPDC), a delayed plunger fast speed stage and pressurization (shot profile) combined with an optimized gating design can significantly reduce the amount of trapped air in the final casting.

- Melt velocity at the ingates for HPDC is typically around 40 m/s, which is 80 times greater than the critical velocity (0.5 m/s) to avoid turbulent flow, making gating design paramount.

- Unique surface patterns or textures on the mold/die surface can help peel off the oxide film from the melt front during filling, improving surface quality.

Figure Name List:

- Fig.1. Six mega Al castings in Cadillac Celestiq [3].

- Fig.2. Calculated fraction of solid and solidification sequences of three alloys.

- Fig.3. Accumulation of the trapped air calculated for different shot profiles.

7. Conclusion:

Application of ultra-large aluminum castings in automobiles has brought great opportunities and posed challenges that can be addressed with the advanced metal casting technologies and virtual casting tools.

8. References:

- [1] Ducker Frontier, North America Light Vehicle Al Content and Outlook. Final Report Summary: July 2020.

- [2] https://www.theautopian.com/how-tesla-made-gigacasting-the-most-important-word-in-the-car-industry/ (Sept 14, 2023)

- [3] https://insideevs.com/news/617108/cadillac-takes-page-from-tesla-book-uses-mega-castings-on-celestiq/ (Oct 18, 2022)

- [4] https://www.linkedin.com/pulse/what-do-toyotas-announcements-battery-technologies-giga-castings/ (Aug. 2023)

- [5] Zhan, H., G. Zeng, Q. Wang, C. Wang, P. Wang, Z. Wang, Y. Xu, D. Hess, P. Crepeau, J. Wang, Unified Cast (UniCast) Aluminum Alloy Journal of Materials Science & Technology, 154 (2023) 251-268

- [6] Wang, Q., D. Gerard, US Patent 9574252 (Feb 21, 2017)

Expert Q&A: Your Top Questions Answered

Q1: Why is a melt velocity of 40 m/s used in HPDC if the critical velocity to avoid turbulence is only 0.5 m/s?

A1: The paper explains that this extremely high velocity is a necessity in HPDC to ensure the mold is filled completely within a very short window of 100-200 milliseconds. This rapid filling is required to produce parts with very thin walls before the metal begins to solidify. This trade-off—accepting turbulent flow to achieve complete filling—is why the design of the gating system is so vital to manage the turbulence and avoid defects like converging melt fronts.

Q2: Figure 2 shows Tesla's AA386 alloy has a wider freezing range due to its copper content. What are the practical trade-offs of using this alloy for a giga-casting?

A2: According to the paper, the wider freezing range associated with the copper in AA386 directly increases the "porosity and crack susceptibility coefficient." It also "decreases corrosion resistance." While the alloy may have other desirable properties not detailed in this paper, these findings suggest that manufacturers using it must implement very tight process controls to mitigate the higher intrinsic risk of these specific solidification-related defects.

Q3: What specific recommendation does the paper make regarding mold surface treatment to improve quality?

A3: The paper suggests that the mold or die surface should be treated with "unique surface patterns or texture." The purpose of this is to create a surface that helps the oxide film on the leading edge of the molten metal front to be "peeled off" during mold filling. This improves the surface quality of the final casting, which is especially important for fatigue life since cracks often initiate at the surface.

Q4: Based on Figure 3, which combination of geometry and shot profile resulted in the least amount of trapped air?

A4: The graph in Figure 3 clearly shows that the combination labeled "Geom2_delay" resulted in the lowest accumulation of trapped air. This corresponds to using the second gating design ("Geom2") along with the delayed shot profile ("delay"). This demonstrates that optimizing the shot profile is not enough; it must be developed in conjunction with the gating system for maximum effect.

Q5: The paper mentions GM's UniCAST alloy. What advantages does it offer for structural castings?

A5: The paper states that GM developed UniCAST as a "sustainable alloy which is good for structure casting." While it doesn't provide a detailed compositional or mechanical property breakdown, the description implies it was formulated specifically to meet the demanding requirements of large, structural components while also considering sustainability, which is an increasingly important factor in automotive manufacturing.

Conclusion: Paving the Way for Higher Quality and Productivity

The transition to Ultra-Large Aluminum Castings is one of the most significant shifts in automotive body construction in decades. While the benefits are clear, the manufacturing challenges are substantial. This research from GM's technical team reinforces that success hinges on a deep, scientific understanding of the entire casting process. The key breakthrough—that an optimized, delayed shot profile matched with the right gating system can drastically cut down on trapped air—provides a tangible strategy for improving quality and yield. By holistically addressing alloy selection, melt quality, and process parameters, manufacturers can overcome the hurdles of giga-casting and unlock its full potential.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Ultra-Large Aluminum Castings in Automobiles" by "Qigui Wang, Andy Wang, and Jason Coryell".

- Source: The 75th World Foundry Congress, October 25-30, 2024, Deyang, Sichuan, China. Part 10: Die-Casting Technology.

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.