Paper Title From Simulation to Suspension: Optimizing Aluminum Casting for Heavy-Duty Performance

This technical summary is based on the academic paper "Development and optimization of casting technology on part of the suspension of a heavy vehicle used in difficult environmental wetland conditions" by Marcin Małysza, Robert Żuczek, Stanisław Pysz, Andrzej Gil, Piotr Wieliczko, Piotr Kowalski, and Krzysztof Wańczyk, published in Transactions of Foundry Research Institute (2016).

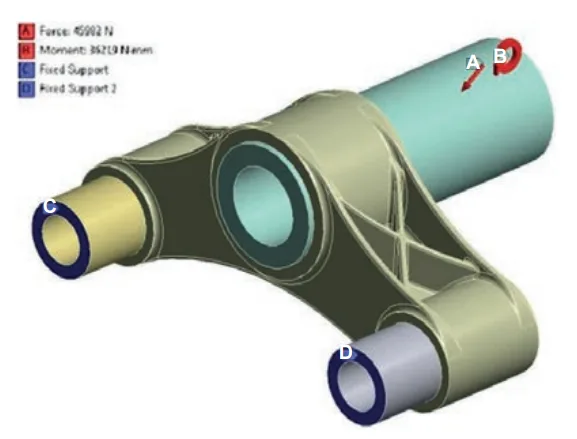

B ≈ 36 000 N∙mm and two fix points C, D

Keywords

- Primary Keyword: Casting Optimization

- Secondary Keywords: Integrated Computational Material Engineering (ICME), Casting Simulation, Aluminum Alloy Casting, Prototype Casting, Suspension Component Design

Executive Summary

- The Challenge: Developing new, complex cast components is a time-consuming process with significant risks related to design flaws and manufacturing defects.

- The Method: The researchers employed an Integrated Computational Material Engineering (ICME) approach, using computer simulation for shape optimization, material selection, and casting process verification for a heavy vehicle suspension arm.

- The Key Breakthrough: The ICME methodology enabled a 15% reduction in the component's weight while maintaining structural integrity and localizing potential casting defects to non-critical areas like risers and gating systems.

- The Bottom Line: A systematic, simulation-driven approach significantly shortens prototype development time, reduces material costs, and increases the probability of producing a sound, high-performance casting on the first attempt.

The Challenge: Why This Research Matters for HPDC Professionals

Developing new components, especially for demanding applications like heavy vehicle suspensions, is a complex dance between design engineering and manufacturing reality. The traditional cycle of design, prototype, test, and redesign is often slow and expensive. Each iteration consumes valuable time and resources, and unforeseen manufacturing issues can derail project timelines.

This paper addresses a core industry pain point: the need for a more efficient, predictable, and integrated procedure for creating new cast parts. The authors highlight that modern design trends require a logical chain of events where computer-aided design, manufacturing, and simulation work in concert. This integrated approach is essential for de-risking the entire process, from initial concept to final production, which is a universal goal for all advanced casting manufacturers.

The Approach: Unpacking the Methodology

The research team adopted an Integrated Computational Material Engineering (ICME) methodology to develop and optimize a swing arm for a heavy vehicle. This systematic approach integrated several key stages:

- Initial Design & Load Simulation: The process began with an initial geometry of the swing arm. Using ANSYS software, the team simulated the exploitation loads, assuming a vehicle weight of 6000 kg and a dynamic surplus ratio of 1.3. This analysis identified high-stress areas in the initial design.

- Iterative Shape Optimization: Based on the stress analysis, the component's shape was iteratively optimized. The goal was to reduce weight and minimize stress concentrations while ensuring the part could withstand the assumed loads. This resulted in a series of design versions, each numerically tested for performance.

- Material Selection: A comparative analysis was conducted for several aluminum alloys (A201, A355, A356, and ENAC-43300). The final material, ENAC-43300, was selected based on its strength index and the calculated safety factor under the simulated exploitation conditions.

- Casting Process Simulation: With the final optimized geometry, the team developed the casting technology. They simulated the entire process, including mold filling and solidification, using Flow3D and MAGMAsoft software. This allowed them to design and verify different gating and feeding system concepts to ensure a sound casting, free of critical defects.

- Prototyping: Based on the validated simulation, tooling was manufactured using rapid prototyping (FDM technique), and a physical prototype was cast and machined.

The Breakthrough: Key Findings & Data

The study yielded several significant results, demonstrating the power of a simulation-first approach.

Finding 1: Significant Weight Reduction without Compromising Strength

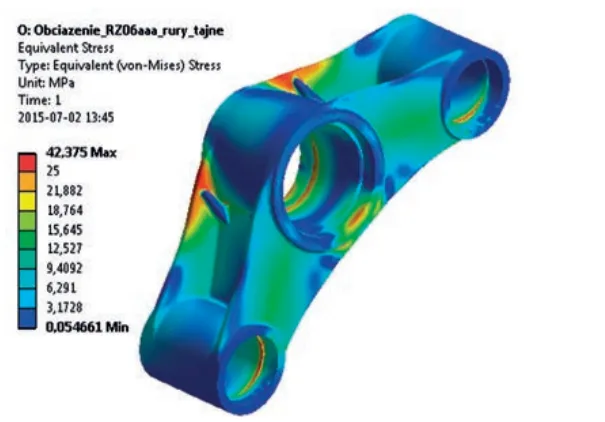

The iterative shape optimization process was highly effective. The team successfully reduced the component's weight while managing stress levels. As shown in Table 1, the initial design had a mass of 48.3 kg with a maximal equivalent stress of 45.6 MPa. The final optimized design achieved a mass of 41 kg (a 15% reduction) with a comparable maximal stress of 42.3 MPa, demonstrating a more efficient use of material.

Finding 2: Proactive Defect Management Through Process Simulation

By simulating the mold filling and solidification, the researchers could predict the location of potential defects. Figure 9 shows the results of porosity prediction from both Flow3D and MAGMAsoft simulations. The analysis confirmed that with the proposed gating and riser system, porosities were confined to the non-critical feeding system, ensuring the final casting would be sound. This proactive approach prevents costly trial-and-error on the foundry floor.

Practical Implications for R&D and Operations

The findings from this paper offer valuable, actionable insights for casting professionals.

- For Process Engineers: This study suggests that using multiple simulation tools (like Flow3D and MAGMAsoft) can provide a more robust verification of the casting process. The detailed visualization of mold filling (Figure 8) allows for the optimization of gating systems to prevent air entrainment and ensure complete cavity fill, directly contributing to reduced scrap rates.

- For Quality Control Teams: The safety factor distribution map (Figure 5) clearly identifies the most and least critical areas of the component under load. This data can be used to develop more intelligent and efficient quality inspection plans, focusing non-destructive testing efforts on the areas with the lowest safety factors.

- For Design Engineers: The iterative process detailed in Table 1 provides a clear roadmap for topology optimization. It shows how simulation can be used to systematically remove material from low-stress areas, leading to lighter, more efficient designs without sacrificing performance—a critical goal in the automotive and aerospace sectors.

Paper Details

Development and optimization of casting technology on part of the suspension of a heavy vehicle used in difficult environmental wetland conditions

1. Overview:

- Title: Development and optimization of casting technology on part of the suspension of a heavy vehicle used in difficult environmental wetland conditions

- Author: Marcin Małysza, Robert Żuczek, Stanisław Pysz, Andrzej Gil, Piotr Wieliczko, Piotr Kowalski, Krzysztof Wańczyk

- Year of publication: 2016

- Journal/academic society of publication: PRACE INSTYTUTU ODLEWNICTWA (TRANSACTIONS OF FOUNDRY RESEARCH INSTITUTE)

- Keywords: ICME, simulation, aluminum alloy, rapid prototyping, casting optimization

2. Abstract:

The development of a new element is a very complex procedure requiring a combination of many factors related to the design and manufacture phases. The most efficient way is to use computer simulation which allows for verification of the whole design and production process. Over the years, the development of computer technologies has allowed for the development of an Integrated Computational Material Engineering (ICME). This method in logical sequence makes it possible to integrate the project activities, to develop new manufacturing methods, to select suitable materials and to verify the final process. Such multi-threaded operations significantly shorten the time required for the production of the prototype which speeds up the implementation of the planned production of the designed casting. The additional advantage of such work is the possibility of ongoing monitoring of the changes and their impact on the final product.

3. Introduction:

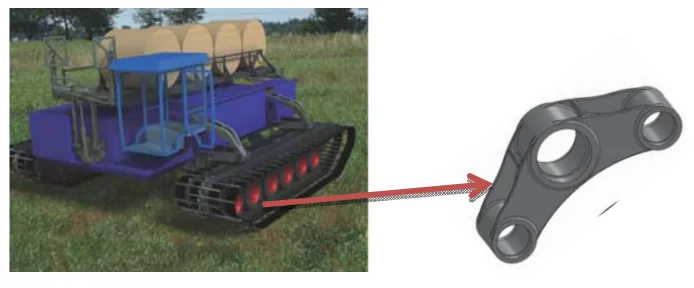

Modern techniques for the production of prototype castings include advanced design technologies. The design process must be considered as a logical chain of events. Using computer aided design, manufacturing and computer simulation supports that process. Such a solution allows to take into consideration a number of risks associated with the manufacturing process of the prototype casting part. Established methodology includes the optimization of the initial geometry of the swing arm of the heavy vehicle used in difficult wetland environmental conditions.

4. Summary of the study:

Background of the research topic:

The development of new cast components is a highly complex procedure that requires integrating multiple design and manufacturing steps. Traditional methods can be slow and inefficient.

Status of previous research:

The paper builds on the established trend of using computer simulation to evaluate design assumptions and analyze numerical phenomena during manufacturing. It formalizes this trend into an Integrated Computational Material Engineering (ICME) system.

Purpose of the study:

The study aimed to develop and optimize the design and casting technology for a heavy vehicle suspension swing arm using an ICME approach. The goal was to shorten the development time for a functional prototype, reduce weight, and ensure a high-quality final product.

Core study:

The core of the study involved a multi-stage, simulation-driven process. It began with optimizing the component's geometry based on strength criteria under simulated operational loads. This was followed by selecting a suitable aluminum alloy. Finally, the casting process itself, including gating and feeding systems, was designed and verified through numerical simulation to predict and mitigate potential defects like porosity. The process concluded with the rapid prototyping of tooling and the production of a physical cast part.

5. Research Methodology

Research Design:

The research followed an Integrated Computational Material Engineering (ICME) framework. This involved a logical sequence of:

1. Numerical analysis of exploitation conditions and shape optimization (using ANSYS).

2. Material selection based on comparative analysis.

3. Development and simulation of the casting technology (using Flow3D and MAGMAsoft).

4. Manufacturing of a prototype using rapid prototyping for tooling.

Data Collection and Analysis Methods:

Data was generated through computer simulations. Stress, deformation, and safety factor analyses were conducted on the component's design. Mold filling and solidification simulations were used to analyze temperature distribution, solidification paths, and predict porosity. The results were compared across different design iterations (Table 1) and between different simulation software packages (Figure 9).

Research Topics and Scope:

The research focused on the design and casting of a single component: a swing arm for a heavy vehicle. The scope included the entire development cycle from initial concept optimization to the simulation of the final manufacturing process and the creation of a physical prototype. The chosen material was an aluminum alloy (ENAC-43300), and the process involved casting into a mold bonded with CO2.

6. Key Results:

Key Results:

- The optimization process resulted in a 15% weight reduction for the final casting compared to the initial design (from 48.3 kg to 41 kg).

- Numerical analysis allowed for the design of a component where localized stress values did not exceed 42.3 MPa, well within the material's limits.

- Casting process simulation successfully guided the design of a gating and feeding system that localized predicted porosities within the non-functional riser and gating areas, ensuring a sound casting.

- The use of a comprehensive ICME approach was shown to significantly shorten the time required to produce a functional prototype.

Figure Name List:

- Fig. 1. Prototype vehicle and the swing arm

- Fig. 2. Optimization steps of the design changes of the swing arm shape

- Fig. 3. The load schematic used in the exploitation simulation with the force – A ≈ 4600 N, moment - B ≈ 36 000 N-mm and two fix points C, D

- Fig. 4. Stress distribution in the swing arm during the exploitation simulation

- Fig. 5. Distribution of the safet factor in the final desingn of the rocker arm for the chosen material

- Fig. 6. The natural solidification in the casting geometry with highlighted hot spots

- Fig. 7. Concepts of the casting technologies

- Fig. 8. Visualisation of the filling process

- Fig. 9. Predicted porosities in the casting results in a) Flow3D, b) MAGMAsoft

- Fig. 10. Pouring of the liquid metal (a) and the final casting (b)

- Fig. 11. Final swing arm casting

7. Conclusion:

- The use of computer optimization for geometrical purposes lowers stress levels occurring in the nodes of the element and reduces the weight.

- The computer simulation of the casting process allows designing appropriate casting technology, which can be used in the rapid prototyping of casting tooling.

- The use of computer simulation in a logical sequence allows for quick and accurate design of prototype casting.

8. References:

- Kowalski P., K. Wańczyk, M. Małysza, A. Gil. 2015. „Numerical Analysis of Casting Process of the Diesel Engine Compressor Rotor". Archives of Foundry Engineering 15 (sp.is. 2): 51-54.

- Gwiżdż A., M. Małysza, M. Nowak. 2013. „Use of Flow-3D Program for simulation of pouring and solidification process of ductile cast iron castings. Part I". Transactions of Foundry Research Institute 53 (1): 35-53.

- Pysz S., R. Żuczek, E. Czekaj, A. Karwiński, M. Małysza, P. Sprawka. 2014. „Integration of numerical procedures in the design and manufacturing technology on the example of a cast component for the automotive industry". Foundry Trade Journal International 188 (3711): 26-29.

- Pysz S., J. Piekło. 2013. „The application of Integrated Computational Materials Engineering (ICME) in foundry practice". Transactions of Foundry Research Institute 53 (4): 57-70.

- Pysz S., J. Piekło, M. Małysza. 2014. „The Use of Topology Optimization in Shaping the Strength of Castings". Solid State Phenomena 223 : 62-69.

- Zachura A., R. Żuczek. 2014. „Innovative design of a longwall shearer's haulage system with highly loaded components of a tribological pair manufactured according to the precise casting technology". Solid State Phenomena 223: 171-180.

Expert Q&A: Your Top Questions Answered

Q1: Why was the Integrated Computational Material Engineering (ICME) methodology chosen for this project?

A1: The paper states that the ICME method was chosen because it creates a "logical sequence" that integrates all project activities, from design and material selection to manufacturing process verification. This multi-threaded approach "significantly shorten the time required for the production of the prototype," which speeds up the implementation of planned production and allows for ongoing monitoring of how changes impact the final product.

Q2: What were the specific load conditions used in the exploitation simulation for the swing arm?

A2: The simulation conditions were based on a total vehicle weight of 6000 kg. It was assumed that one swing arm supports 1/6 of this total weight. A dynamic surplus ratio of k = 1.3 was also applied to account for real-world operating forces. As shown in the caption for Figure 3, this translated to a simulated force of approximately 4600 N and a moment of 36,000 N·mm.

Q3: How was the final material, ENAC-43300, selected over other aluminum alloys?

A3: The selection was a data-driven process. The paper mentions that a "comparison analysis was conducted for the material A201, A355, A356 and ENAC-43300." The final choice was based on the calculated safety factor for the assumed exploitation conditions and the material's strength index, with ENAC-43300 being identified as the "best suitable material" from the candidates.

Q4: The paper shows porosity predictions from two different software packages, Flow3D and MAGMAsoft (Figure 9). What was the reason for using both?

A4: The text indicates this was a step to improve confidence in the results. After the initial simulation, the paper states, "In order to increase the probability of manufacturing good quality casting the analysis was conducted in additional simulation software – MAGMAsoft." This suggests the second simulation served as a cross-verification, ensuring the predicted outcome was robust before committing to physical tooling and production.

Q5: What was the primary driver for the shape changes seen during the optimization process in Figure 2?

A5: The optimization was driven by the strength criterion. The initial stress analysis (Figure 4) revealed how stress was distributed across the component. The subsequent design changes aimed to reduce mass while ensuring that stress concentrations in critical areas were minimized and kept within the acceptable limits of the chosen material. The iterative results in Table 1 show how different shapes performed in terms of stress, deformation, and mass.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a powerful demonstration of how a systematic approach to Casting Optimization can yield superior results. By integrating design simulation, material science, and process verification, the team was able to solve the core challenge of developing a complex component efficiently and effectively. The key breakthrough—achieving a 15% weight reduction while simultaneously designing a defect-free manufacturing process—highlights the immense value of a simulation-first methodology. These principles of upfront analysis and digital prototyping are directly applicable to reducing lead times and improving part quality across the casting industry.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Development and optimization of casting technology on part of the suspension of a heavy vehicle used in difficult environmental wetland conditions" by "Marcin Małysza, et al.".

- Source: https://doi.org/10.7356/iod.2016.24

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.