Mastering Material Homogeneity: How Squeeze Pin Technology Eliminates Shrinkage Porosity in HPDC

This technical summary is based on the academic paper "THE EFFECT OF SQUEEZE PIN DIMENSION AND OPERATIONAL PARAMETERS ON MATERIAL HOMOGENITY OF ALUMINIUM HIGH PRESSURE DIE CAST PARTS" by Ferencz PETI and Gabriela STRNAD, published in Acta Marisiensis. Seria Technologica (2019). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Squeeze Pin Technology

- Secondary Keywords: High Pressure Die Casting, Material Homogeneity, Shrinkage Porosity, AlSi Alloy, Casting Defects, Cold Flow

Executive Summary

- The Challenge: Achieving material homogeneity and eliminating shrinkage porosity in thick-walled, massive-volume aluminum HPDC parts is a persistent industry challenge.

- The Method: The study systematically varied squeeze pin diameter, depth, and application time on an AlSi9Cu3(Fe) component and analyzed the internal structure using X-ray radiography.

- The Key Breakthrough: A squeeze time delay of 1.5 seconds with a 10 mm diameter pin at 15 mm depth successfully eliminated shrinkage porosity, but also created a distinct "dark line" phenomenon visible on radiographs.

- The Bottom Line: Effective porosity reduction using squeeze pins is directly correlated with the appearance of these "dark lines," suggesting they are a key indicator of successful material consolidation during solidification.

The Challenge: Why This Research Matters for HPDC Professionals

High Pressure Die Casting (HPDC) is a leading process for manufacturing complex and precise components. However, achieving perfect material homogeneity remains a significant challenge, especially in parts with large wall thicknesses or concentrated volumes of alloy. These massive areas are highly susceptible to defects like shrinkage porosity and internal cold flows, which compromise the structural, mechanical, and hydraulic integrity of the final component.

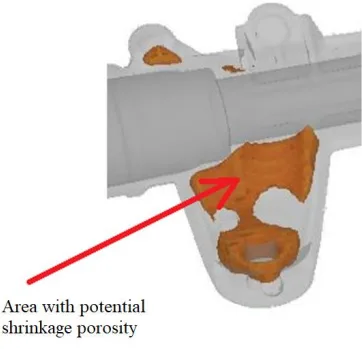

This research addresses the critical need to improve the die casting process for such parts, specifically focusing on an automotive gearbox suspension bracket where a large volume of alloy is functionally necessary. As predicted by solidification simulations (Figure 1), this area is prone to defects. The study investigates how Squeeze Pin Technology can be optimized to modify the structure and density during the solidification stage, directly tackling the root cause of these costly flaws.

The Approach: Unpacking the Methodology

The research team conducted a rigorous experimental study on a suspension bracket area produced from AlSi9Cu3(Fe) alloy.

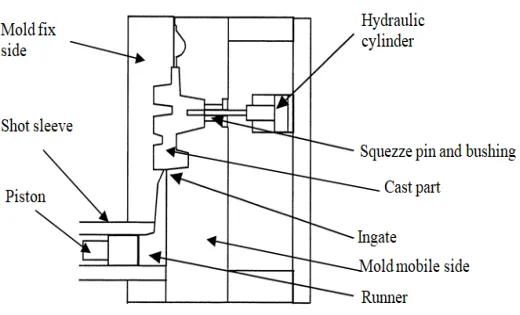

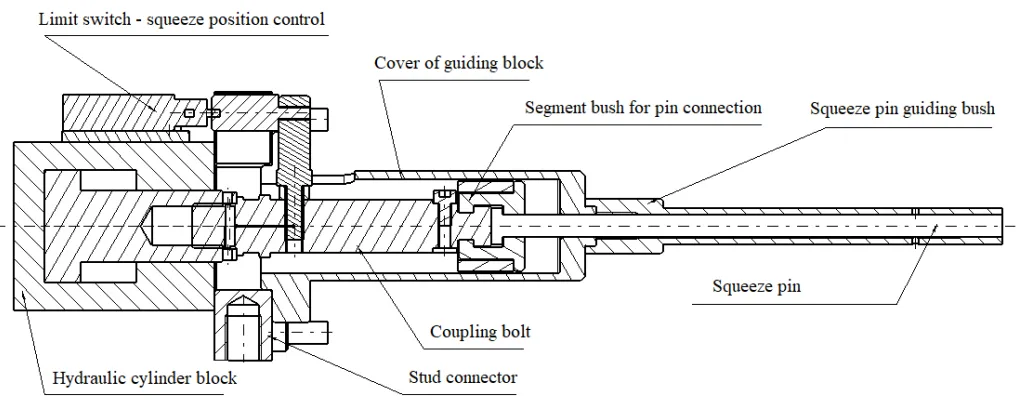

- Equipment: The tests were performed using an Italpresse 1650 Tn HPDC machine equipped with a specialized mold featuring a squeeze pin, guiding bush, and a connected hydraulic cylinder. This setup allowed for precise control and monitoring of the squeeze parameters.

- Analysis: Samples were analyzed using a MU2000 Yxlon X-ray machine to inspect the internal structure and assess material homogeneity. Results were interpreted against the ASTM E505 standard for aluminum die castings.

- Key Variables: The experiment was designed to isolate the effects of three critical squeeze pin parameters, as detailed in Table 1 of the paper:

- Squeeze Pin Diameter: 10 mm, 9 mm, and 8 mm.

- Squeeze Depth (Active Length): 15 mm and 7.5 mm.

- Squeeze Time (Delay): 0 s, 0.5 s, 1 s, 1.5 s, 2 s, and 2.5 s.

By systematically varying these parameters while keeping all other process variables constant, the study provides a clear understanding of their individual and combined effects on casting quality.

The Breakthrough: Key Findings & Data

The study produced 360 samples across all test conditions, yielding clear, data-driven insights into the effectiveness of Squeeze Pin Technology.

Finding 1: Squeeze Time is the Critical Factor for Eliminating Shrinkage

The data clearly shows that a minimum squeeze time delay is required to achieve the desired material homogeneity. Applying pressure too early or not at all is ineffective.

As shown in Table 2, for Test 1 (10 mm pin diameter, 15 mm depth), the shrinkage level was rated "NOK" (Not OK) for squeeze times of 0, 0.5, and 1 second. However, at a squeeze time of 1.5 seconds, the shrinkage level improved to "OK", meeting the ASTM E505 standard. This demonstrates a clear threshold for the effective application of the squeeze pin.

Finding 2: The "Dark Line" Phenomenon as an Indicator of Success

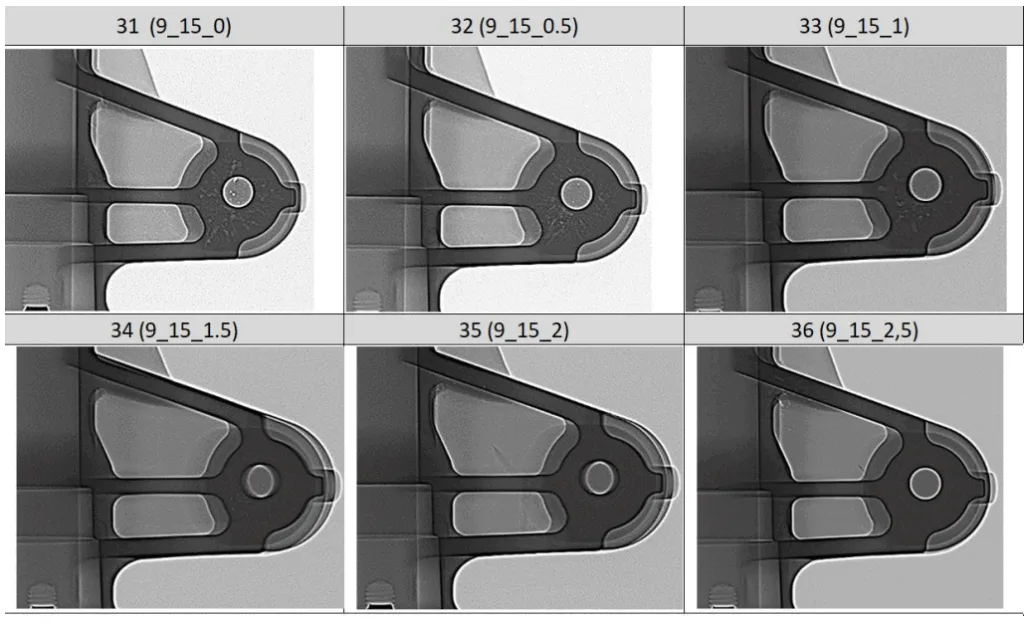

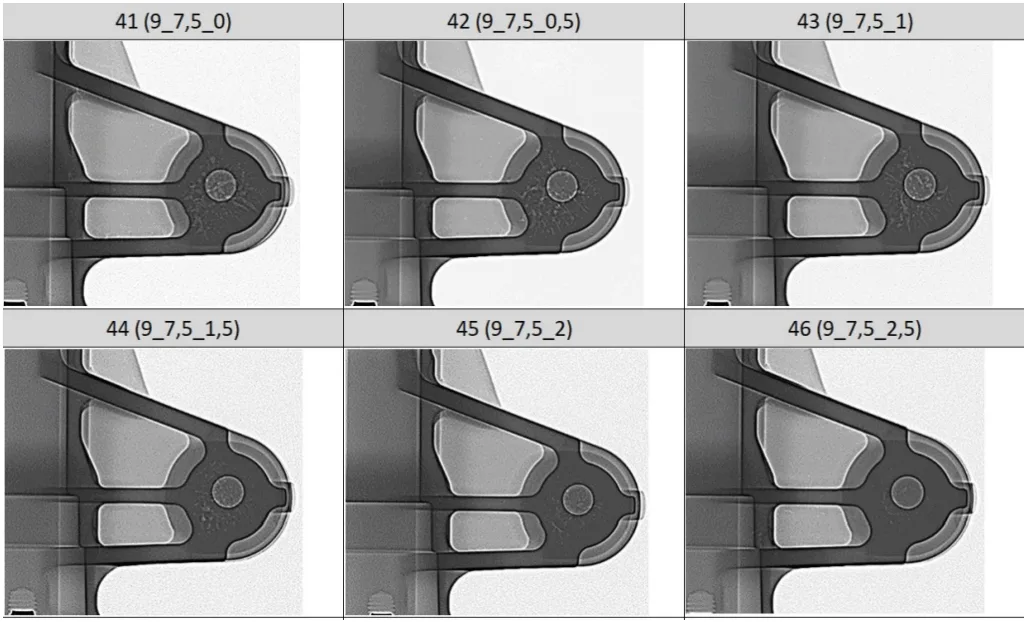

A significant secondary effect was observed: the appearance of a compact "dark line" in the X-ray images. The presence and prominence of this line are directly correlated with the successful reduction of porosity.

Referencing Table 2 for Test 1 again, the "Dark line presence" column shows "no line" for the ineffective squeeze times (0-1s). At the 1.5-second mark, where the shrinkage result becomes "OK", the result changes to "Line present". This pattern holds true across other successful tests, such as Test 3 (9 mm pin, 15 mm depth), where the line appears at 1.5 seconds, coinciding with the first "OK" rating. The paper concludes that "When squeeze pin effect is better, dark lines appear naturally but only in this situation porosity level requested can be achieved."

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the squeeze time delay is the most critical parameter for optimizing material homogeneity. For a part with a massive section requiring a 10 mm diameter pin, a delay of at least 1.5 seconds is a viable starting point to eliminate shrinkage porosity.

- For Quality Control Teams: The data in Figure 4 and Table 2 of the paper illustrates the effect of squeeze time on the internal structure. The appearance of the "dark line" on radiographs, while not currently evaluated by standards like ASTM E505, could serve as a valuable indirect indicator of successful porosity reduction and material consolidation.

- For Design Engineers: The findings indicate that for components with large, concentrated material volumes, incorporating a squeeze pin into the die design is a practical and effective method to counteract shrinkage. The pin's dimensions (diameter and depth) must be calculated to adequately compensate for the material volume deficit during solidification.

Paper Details

THE EFFECT OF SQUEEZE PIN DIMENSION AND OPERATIONAL PARAMETERS ON MATERIAL HOMOGENITY OF ALUMINIUM HIGH PRESSURE DIE CAST PARTS

1. Overview:

- Title: THE EFFECT OF SQUEEZE PIN DIMENSION AND OPERATIONAL PARAMETERS ON MATERIAL HOMOGENITY OF ALUMINIUM HIGH PRESSURE DIE CAST PARTS

- Author: Ferencz PETI, Gabriela STRNAD

- Year of publication: 2019

- Journal/academic society of publication: Acta Marisiensis. Seria Technologica, Vol. 16 (XXXIII) no. 2

- Keywords: high pressure die casting, AlSi alloy, squeeze pin, shrinkage, cold flow, porosity

2. Abstract:

The present paper is an experimental study on the squeeze pin effect on the high pressure die cast aluminium parts, as a way of improvement of material homogenity on various and big wall thickness castings. Squeeze is used in high pressure die casting technology for optimizing homogenity of big wall thicknesses of die cast parts working as structural, mechanical and hydraulic components, made of different aluminium alloys such AlSi alloys. The objective of this research is to highlight the primary and secondary effects of squeezing on the structural homogenity of high pressure die cast aluminium parts, as well as the dependence of the effects on the squeeze pin dimensions and the operating parameters.

3. Introduction:

High pressure die-casting is a common manufacturing process, but achieving material homogeneity is a challenge influenced by parameters like speeds, pressures, and temperatures. This research focuses on improving material homogeneity by reducing porosity, internal cold flow, and shrinkage porosity in aluminum HPDC parts using squeeze pin technology. The goal is to apply a squeeze pin in a massive area to modify the part's structure and density during solidification, with results analyzed against current standards.

4. Summary of the study:

Background of the research topic:

The study addresses the challenge of achieving material homogeneity in high-complexity, precise parts manufactured via high pressure die-casting. Specifically, it targets defects like porosity and shrinkage that occur in castings with large wall thicknesses or concentrated volumes of material.

Status of previous research:

Previous published results by the authors identified causes affecting the homogeneity of certain aluminum HPDC parts, leading to process improvements for automotive gearbox suspension brackets. This work builds upon that foundation.

Purpose of the study:

The objective is to highlight the primary and secondary effects of squeezing on the structural homogeneity of HPDC aluminum parts and to understand the dependence of these effects on the squeeze pin's dimensions (diameter, depth) and operating parameters (squeeze time).

Core study:

The core of the study is an experimental test plan involving an automotive suspension bracket made from AlSi9Cu3(Fe). The researchers systematically varied the squeeze pin's diameter, active depth, and the time delay of its application. The resulting internal quality of the cast parts was then analyzed using X-ray radiography to determine the optimal parameters for reducing shrinkage porosity.

5. Research Methodology

Research Design:

The experiment was designed to test the effect of different squeeze pin dimensions (diameters of 10, 9, and 8 mm; depths of 15 and 7.5 mm) and squeeze times (0 to 2.5 seconds in 0.5s increments) on a specific massive area of a suspension bracket known to have porosity issues. A full factorial test plan was executed, as detailed in Table 1.

Data Collection and Analysis Methods:

Ten samples were produced for each test code under serial conditions. These samples were analyzed on a MU2000 Yxlon X-ray machine. The resulting radioscopy pictures were captured and evaluated against the ASTM E505 standard for inspection of aluminum die castings to determine the level of shrinkage porosity.

Research Topics and Scope:

The research focuses on the application of squeeze pin technology to improve material homogeneity in AlSi alloy HPDC parts. The scope is limited to an automotive gearbox suspension bracket and investigates the interplay between squeeze pin diameter, depth, and application time on the reduction of shrinkage porosity and the appearance of secondary effects like cold flow.

6. Key Results:

Key Results:

- The effectiveness of the squeeze pin is highly dependent on the squeeze time delay. For a 10 mm diameter pin with 15 mm depth, a delay of 1.5 seconds was required to achieve an "OK" rating for shrinkage porosity.

- Smaller pin diameters and reduced squeeze depths were less effective. An 8 mm pin with 7.5 mm depth failed to meet the standard even at a 2.5-second delay.

- A secondary effect, the appearance of a "dark line," was observed. This line's presence correlates directly with successful porosity reduction. When the squeeze pin effect is sufficient to eliminate porosity, the dark line appears naturally.

- The study concludes there is an "indirect" relation between the dark lines and porosity: the absence of dark lines indicates an insufficient squeeze pin effect and a higher level of porosity.

Figure Name List:

- Fig. 1: Solidification simulation with Flow 3D software

- Fig. 2: Schematic solution of the mold with squeeze pin

- Fig. 3: Details of the squeeze design

- Fig. 4: Representative radioscopy pictures captures of Test 3

- Fig. 5: Representative radioscopy pictures captures of Test 4

7. Conclusion:

The use of squeeze pins is a practical and effective method for improving material homogeneity in HPDC parts with high-risk, high-volume areas. The additional pressure from the squeeze pin increases material density and directly causes the appearance of "dark lines" during the solidification phase. The tests performed demonstrate a clear relationship: when the squeeze pin effect is strong enough to achieve the required porosity level, these dark lines naturally appear. Conversely, if no dark lines are present, the squeeze effect was insufficient, and the porosity level remains high.

8. References:

- [1] Bellisario, D., Boschetti, A., Constanza, G., Tata Maria, E., Quadrini, F., and Santo, L. (2012), Squeeze Casting of Al-Si Alloys, in Recent Researches in Metallurgical Engineering - From Extraction to Forming, Ed. Mohammad Nusheh, InTech Open, pp. 161-186.

- [2] Reikher, A., Barkhudarov, M.R. (2007), Casting: An analytical approach, in Series: Engineering Materials and Processes, Ed. Springer-Verlag London.

- [3] Adamane, A.R., Arnberg, L., Fiorese, E. et al. (2015), Influence of Injection Parameters on the Porosity and Tensile Properties of High-Pressure Die Cast Al-Si Alloys: A Review, International Journal of Metalcasting, vol. 9(1), pp. 43-53.

- [4] Dong, X., Yang, H., Zhu, X, Ji, S.,(2019), High strength and ductility aluminium alloy processed by high pressure die casting, Journal of Alloys and Compounds, vol. 773, pp. 86-96.

- [5] Jiao, X.Y, et. Al, (2019), Influence of slow-shot speed on PSPs and porosity of AlSi17Cu2.5 alloy during high pressure die casting, Journal of Materials Processing Technology, vol. 268, pp. 63-69.

- [6] Apparao, K.c., Birru, A.K, (2017), Optimization of Die casting process based on Taguchi approach, Materials Today, vol. 4(2A), pp.1852-1859.

- [7] Jahangiri, A., Marashi, S.H.P., Mohammadaliha, M, Ashofte, V., (2017) The effect of pressure and pouring temperature on the porosity, microstructure, hardness and yield stress of AA2024 aluminum alloy during the squeeze casting process, Journal of Materials Processing Technology, vol. 245, pp. 1-6.

- [8] Battaglia, E., Bonollo, F., Timelli, G., Fiorese, E., Kral, G., (2016), Correlation between process, microstructure and properties in high pressure die casting aluminium-silicon alloys, Advances in Materials and Processing Technologies, vol. 3(1), pp. 111-124.

- [9] Peti, F., Grama, L., (2011), Analyse of the possible causes of porosity type defects in aluminium high pressure die cast parts, Scientific Bulletin of the „Petru Maior" University of Târgu Mureş, vol. 8 (XXV), no. 1, pp. 41-44.

- [10] Peti, F., Grama L., (2012), Researches concerning constructive and technological improvements of automotive gearbox suspension brackets, Proceedings of the 6th Interdisciplinarity in Engineering International Conference InterEng-2012, "Petru Maior" University Press, pp. 87-92.

- [11] SR EN 1706 – Aluminium and aluminium alloys, (2000).

- [12] DIN 1688 – Tolerances for pressure die casting, (1986).

- [13] ASTM E505 – Reference Radiographs for Inspection of Aluminium and Magnesium die castings, 2002.

- [14] VDG Specification P201 – Porosity of Metal Castings, 2002.

- [15] Company documentation CATIA, 2012.

- [16] Fundamentos de la fundicion a presion, CIE C. Vilanova, Spain, 2008.

- [17] Revision Tecnica del Producto, CIE C. Vilanova, Spain, 2008.

- [18] Company documentation Bühler, 2010.

- [19] Company documentation Idra, 2011.

- [20] Company documentation Italpresse, 2011.

- [21] Procedimiento IDT 05/1: Cuaderno de cargas de moldes, rev05, CIE Inyectametal, Spain, 2007.

- [22] Norma Ingenieria NCV21006C–Tiempo llenado del molde, CIE C. Vilanova, Spain, 2006.

- [23] Norma Ingenieria NCV21007B–Velocidad en el ataque, CIE C. Vilanova, Spain, 2006.

Expert Q&A: Your Top Questions Answered

Q1: Why were different squeeze pin diameters and depths chosen for the experiment?

A1: The paper explains that the scope of the squeeze pin is to compensate for volume shrinkage in a massive area. By testing different diameters (10, 9, 8 mm) and depths (15, 7.5 mm), the researchers were able to study how different compensated volumes of alloy affect the final material homogeneity. The results showed that larger compensation volumes (e.g., 10 mm diameter pin) were more effective than smaller ones.

Q2: What is the suspected cause and significance of the "dark line" seen in the X-ray images?

A2: The paper suggests the dark line is a secondary effect of the applied pressure and temperature changes during squeezing. It is described as looking "compact, but different as the rest of the area nearby" and might be a "macro segregation of the alloying elements." Its significance is critical: the study found it to be a direct indicator of an effective squeeze process. As stated in the conclusion, when the requested porosity level is achieved, these dark lines appear naturally.

Q3: Based on the data, is a longer squeeze time delay always better for reducing porosity?

A3: Not necessarily. The data in Table 2 shows there is an optimal window. For the 10 mm pin at 15 mm depth (Test 1), the quality level changed from "NOK" to "OK" at 1.5 seconds. While longer times of 2 and 2.5 seconds also yielded "OK" results, the necessary improvement was already achieved at 1.5 seconds. This suggests that process engineers can optimize cycle time by identifying this threshold rather than simply maximizing the delay.

Q4: Can Squeeze Pin Technology be applied to any HPDC part?

A4: The paper specifically focuses on the application of squeeze pins for "big wall thickness castings" and parts with a "massive area (big alloy volume)." The technology is intended to solve problems of shrinkage porosity that are common in these specific geometric features. Therefore, it is most beneficial for structural, mechanical, and hydraulic components where such features are unavoidable due to functional design reasons.

Q5: The paper mentions ASTM E505. How was this standard used in the study?

A5: ASTM E505 provides reference radiographs for the inspection of aluminum and magnesium die castings. It serves as an industry-standard visual guide for grading the severity of defects like porosity. In this study, ASTM E505 was used as the reference standard to interpret the X-ray results and objectively classify the shrinkage level of each sample as acceptable ("OK"), unacceptable ("NOK"), or borderline ("Limit OK").

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides clear, actionable evidence that Squeeze Pin Technology, when correctly optimized, is a powerful tool for overcoming material homogeneity issues in challenging HPDC components. The key takeaway is the direct relationship between squeeze parameters—particularly time delay—and the successful elimination of shrinkage porosity. Furthermore, the identification of the "dark line" phenomenon provides a new potential process indicator for quality control teams. By understanding and applying these principles, manufacturers can produce stronger, more reliable parts, even in designs with massive material sections.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "THE EFFECT OF SQUEEZE PIN DIMENSION AND OPERATIONAL PARAMETERS ON MATERIAL HOMOGENITY OF ALUMINIUM HIGH PRESSURE DIE CAST PARTS" by "Ferencz PETI and Gabriela STRNAD".

- Source: https://doi.org/10.2478/amset-2019-0010

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.