Optimizing Surface Finish: The Critical Role of Pouring Temperature in LM4 Aluminum Die Casting

This technical summary is based on the academic paper "Effect of Pouring Temperature on Surface Roughness of LM4 Aluminium Alloy using Die Casting Process" by Deepak Singh, Aman, and Tarang Vardhan Gupta, published in MIT International Journal of Mechanical Engineering (2015). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Pouring Temperature in Die Casting

- Secondary Keywords: Surface Roughness, LM4 Aluminium Alloy, Die Casting Process, Casting Quality, Process Optimization

Executive Summary

- The Challenge: To determine how adjusting the pouring temperature affects the final surface roughness of components cast from LM4 aluminum alloy.

- The Method: LM4 aluminum alloy was cast using a gravity die casting process at four distinct pouring temperatures: 703°C, 723°C, 743°C, and 763°C.

- The Key Breakthrough: The research demonstrated a clear inverse relationship between pouring temperature and surface roughness; as the temperature increased, the surface finish improved significantly.

- The Bottom Line: Increasing the pouring temperature from 703°C to 763°C reduced the average surface roughness (Ra) from 4.84 µm to 2.18 µm, achieving the best surface finish at the highest temperature tested.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of 'near net shape' manufacturing, surface finish is not just an aesthetic concern—it's a critical quality attribute. For components used in automotive, electronics, and aerospace applications, surface roughness can directly impact performance, durability, and the ability to form effective seals or joints. While die casting is renowned for producing high-quality products, achieving the desired surface texture consistently remains a key process challenge. This research addresses a fundamental question: How does one of the most critical process variables, the pouring temperature, directly influence the surface roughness of a widely used material like LM4 aluminum alloy? Understanding this relationship is vital for minimizing secondary finishing operations and producing higher-quality parts straight from the die.

The Approach: Unpacking the Methodology

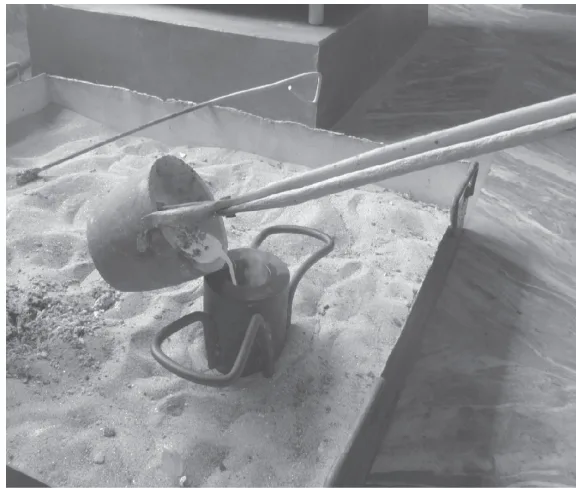

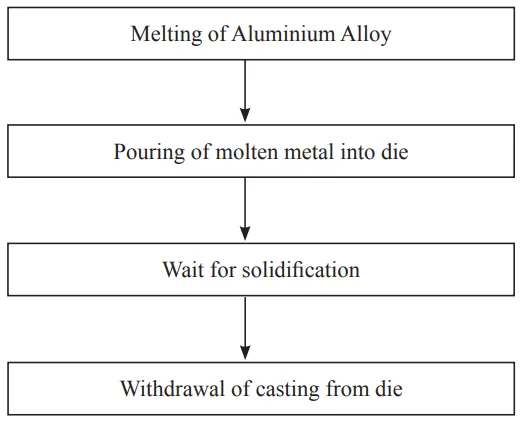

The researchers conducted a systematic investigation using a gravity-fed permanent mold (die) casting process.

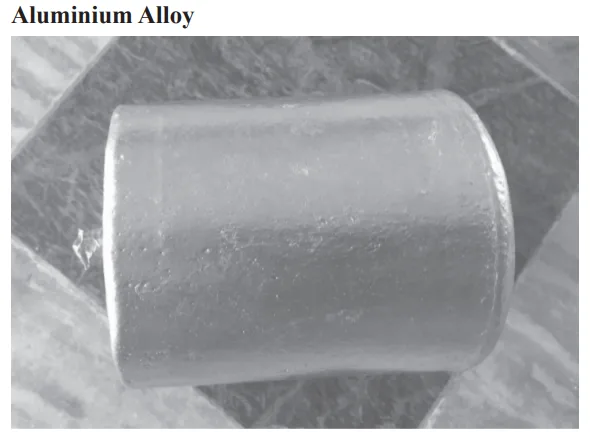

- Material: The study focused on LM4 aluminum alloy. The specific elemental composition is detailed in the paper's Table 1, with major components being Silicon (5.24%) and Aluminum (93.5%).

- Process: Ingots of LM4 alloy were melted in a resistance furnace. The molten metal was then poured into a permanent die mold made of heat-resistant cast iron, filling the cavity under the force of gravity.

- Key Variable: The core of the experiment was the variation of a single parameter: the pouring temperature. Four distinct temperatures were used for casting: 703°C, 723°C, 743°C, and 763°C.

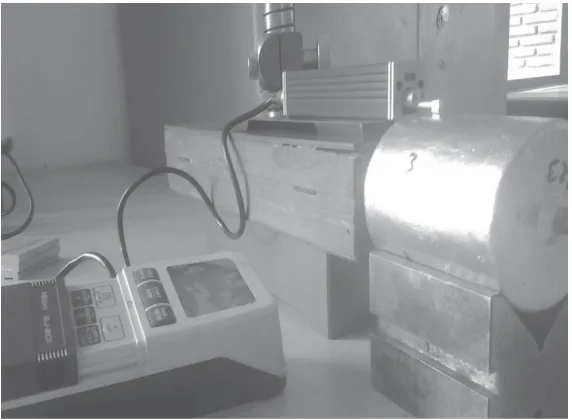

- Measurement: After solidification and withdrawal from the die, the surface roughness of each cast component was measured using a Mitutoyo SJ-201P surface roughness tester. The evaluation was based on ISO4287 norms, using the average Ra value (the arithmetical mean of the profile deviations) to quantify the surface texture.

The Breakthrough: Key Findings & Data

The experimental results revealed a direct and quantifiable correlation between the pouring temperature and the resulting surface finish.

Finding 1: Higher Pouring Temperature Leads to Lower Surface Roughness

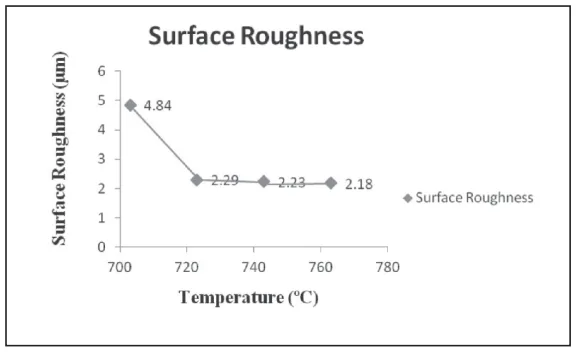

The study's primary finding is that surface finish improved as the pouring temperature was increased. The paper attributes this phenomenon to the interplay between adhesion forces (between the molten alloy and the mild steel die) and cohesion forces (between particles of the molten alloy). As shown in Figure 6, the trend line clearly indicates a decrease in surface roughness with an increase in temperature across the tested range.

Finding 2: A 55% Improvement in Surface Finish Was Achieved

The data presented in Table 2 quantifies the significant improvement in surface quality.

- At the lowest pouring temperature of 703°C, the mean surface roughness (Ra) was 4.84 µm.

- As the temperature was increased to 723°C and 743°C, the roughness dropped to 2.29 µm and 2.23 µm, respectively.

- At the highest pouring temperature of 763°C, the best surface finish was achieved, with a mean roughness of 2.18 µm.

This represents a greater than 55% reduction in surface roughness by optimizing the pouring temperature within the tested range. Importantly, the paper notes that sound castings were obtained at all four temperatures.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the pouring temperature upwards may contribute to directly improving the as-cast surface finish for LM4 aluminum alloy, potentially reducing the need for costly and time-consuming post-processing steps.

- For Quality Control Teams: The data in Table 2 and Figure 6 of the paper illustrates the direct effect of a specific process condition (pouring temperature) on a key quality attribute (surface roughness). This relationship could inform the development of more precise process control limits and new quality inspection criteria.

Paper Details

Effect of Pouring Temperature on Surface Roughness of LM4 Aluminium Alloy using Die Casting Process

1. Overview:

- Title: Effect of Pouring Temperature on Surface Roughness of LM4 Aluminium Alloy using Die Casting Process

- Author: Deepak Singh, Aman, Tarang Vardhan Gupta

- Year of publication: 2015

- Journal/academic society of publication: MIT International Journal of Mechanical Engineering, Vol. 5, No. 2, August 2015, pp. 118-121

- Keywords: Die Casting, aluminium alloy, Surface Roughness.

2. Abstract:

This paper focus on a research work in which an attempt has been made to investigate the effect of pouring temperature of die casting on surface roughness of LM4 aluminium alloy. In the present investigation LM4 aluminium has been considered in order to determine the effect of pouring temperature on surface roughness of LM4 aluminium alloy using die casting process. For the experimentation, four different pouring temperatures 703°C, 723°C, 743°C and 763°C has been considered.

3. Introduction:

The paper introduces gravity die casting as a permanent mould process where molten metal fills a mold cavity under the force of gravity. This process is commonly used for cast iron and non-ferrous castings. The introduction reviews previous studies on the effects of alloy additions (iron, strontium) and casting parameters (temperature, solidification time) on the mechanical properties of various aluminum and zinc alloys in both gravity and squeeze casting processes. This prior research established that casting parameters significantly influence properties like strength, ductility, and density, setting the stage for the current study's focus on surface roughness.

4. Summary of the study:

Background of the research topic:

Die casting is a 'near net shape' manufacturing process used extensively for producing quality products for technical and non-technical applications. Surface roughness is a critical quality attribute for cast components, especially those requiring good contact surfaces.

Status of previous research:

Previous research by Dong et al. [1], Yang [2], and Yang [3] investigated the effects of alloy additions and casting parameters like temperature on the mechanical properties (yield strength, ductility, density) of aluminum and zinc alloys using gravity and squeeze casting. These studies found that casting temperature and solidification time significantly affect the final properties of the cast parts.

Purpose of the study:

The purpose of this investigation was to specifically determine the effect of pouring temperature on the surface roughness of LM4 aluminum alloy when using a die casting process.

Core study:

The core of the study involved melting LM4 aluminum alloy and pouring it into a permanent die at four different temperatures (703°C, 723°C, 743°C, and 763°C). The surface roughness of the resulting castings was then measured and analyzed to establish a relationship between the pouring temperature and the surface finish.

5. Research Methodology

Research Design:

The study employed an experimental research design where a single process parameter, pouring temperature, was varied across four levels to observe its effect on a single output variable, surface roughness.

Data Collection and Analysis Methods:

LM4 aluminum was melted in a resistance furnace. The molten metal was poured into a die mold. The surface roughness of the cast components was measured using a surface roughness tester (SJ-201P) from Mitutoyo Corporation, based on ISO4287 norms. The average Ra value was calculated from multiple observations for each of the four temperature conditions. The results were then tabulated and plotted to analyze the trend.

Research Topics and Scope:

The research was limited to the LM4 aluminum alloy and a gravity-fed die casting process. The investigation focused exclusively on the effect of four specific pouring temperatures on the surface roughness of the final product.

6. Key Results:

Key Results:

- There is an inverse relationship between pouring temperature and surface roughness; as temperature increases, roughness decreases.

- The mean surface roughness at 703°C was 4.84 µm.

- The mean surface roughness at 723°C was 2.29 µm.

- The mean surface roughness at 743°C was 2.23 µm.

- The mean surface roughness at 763°C was 2.18 µm, which was the best result obtained.

- Sound castings were produced at all tested temperatures.

Figure Name List:

- Fig. 1: Die Casting Process

- Fig. 2: Steps involve in Die casting

- Fig. 3: Resistance furnance used for melting

- Fig. 4: Outline describing the preparation of casting

- Fig. 5: Surface roughness testing of specimen

- Fig. 6: Variation of Surface Roughness with Temperature

7. Conclusion:

Surface finish was improved with the increase in pouring temperature. Best value of surface finish (2.18µm) was obtained at pouring temperature 763°C. Sound Casting was obtained at all pouring temperature.

8. References:

- Dong, J., Karnezis P.A., The effect of Sr and Fe additions on the microstructure and mechanical properties of a direct squeeze cast Al-7Si-0.3Mg alloy, Metallurgical and Materials Transactions A, Volume 30, Issue 5, pp. 1341-1356, 1999.

- Yang, L.J., The effect of casting temperature on the properties of squeeze cast aluminium and zinc alloys. Journal of Materials Processing Technology, 140, pp. 391-396, 2003.

- Yang L.J., The effect of solidification time in squeeze casting of aluminium and zinc alloys. Journal of Materials Processing Technology, 192–193. pp. 114–120, 2007.

- Maleki, A., Shafyei, Niroumand, "Effects of squeeze casting parameters on the microstructure of LM13 alloy" J. Mater. Process. Technol. 209, pp. 3790-3797, 2009.

- Senthil, K.S.A., "Optimization of squeeze casting parameters for non-symmetrical AC2A aluminium alloy castings through Taguchi method" Journal of Mechanical Science and Technology 26 (4), pp. 1141-1147, 2012.

- Jatinder Madan and Ravindra Kumar Saxena, "Process Simulation Of Die Casting" Lecture On Process Simulation Of Die Casting, IIM Delhi Chapter, New Delhi (07-11-2011).

- ASM Handbook (Vol. 15) Casting.

- ASM Handbook (Vol. 8) Material Testing and Evaluation.

- ASM Metals Handbook (Vol. 17) Non Destructive Evaluation and Quality Control.

- ASM Metal Handbook (Vol. 2) Properties and Selection: Non-ferrous Alloys and Special-Purpose Materials.

Expert Q&A: Your Top Questions Answered

Q1: What were the specific pouring temperatures investigated in this study?

A1: The researchers selected four distinct pouring temperatures for the experimentation. As stated in the abstract, these temperatures were 703°C, 723°C, 743°C, and 763°C. This range allowed them to observe a clear trend in how temperature variation impacts surface finish.

Q2: How was surface roughness measured to ensure the data was reliable?

A2: The paper states that surface roughness was measured using a Mitutoyo Corporation surface roughness tester (model SJ-201P). The tests were performed according to ISO4287 norms, and the reported value is the average Ra value, which is the arithmetical mean of the roughness profile's deviations. To ensure reliability, the final value for each temperature condition was the average of multiple observations.

Q3: What was the most significant finding regarding the relationship between temperature and surface roughness?

A3: The most significant finding was the clear inverse relationship: as pouring temperature increased, surface roughness decreased. The data in Table 2 and the trend shown in Figure 6 confirm this. The best surface finish (a Ra value of 2.18 µm) was achieved at the highest tested temperature of 763°C, a significant improvement over the 4.84 µm roughness seen at 703°C.

Q4: What explanation did the paper offer for why higher temperatures lead to a better surface finish?

A4: The paper provides a brief explanation in the "Results and Discussions" section. It attributes the variation in surface roughness to the interplay between "adhesion forces between the molten aluminium alloy and die material (mild steel) and cohesion forces between the particles of the molten aluminium alloy." It suggests that increasing the temperature alters these forces in a way that leads to a smoother surface.

Q5: Were any negative effects, like casting defects, observed at the higher pouring temperatures?

A5: The paper's conclusion explicitly states, "Sound Casting was obtained at all pouring temperature." This indicates that within the tested range of 703°C to 763°C, the increase in temperature did not introduce any observable defects and successfully produced viable components at each level.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides clear, actionable data on a fundamental challenge in aluminum casting: controlling surface finish. The key takeaway is that for LM4 aluminum alloy, optimizing the Pouring Temperature in Die Casting is a direct lever for improving surface quality. By increasing the temperature from 703°C to 763°C, the researchers achieved a smoother, higher-quality surface without compromising the integrity of the casting. These findings empower engineers to make more informed decisions about process parameters to meet stringent quality requirements and reduce reliance on secondary finishing operations.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Effect of Pouring Temperature on Surface Roughness of LM4 Aluminium Alloy using Die Casting Process" by "Deepak Singh, Aman, and Tarang Vardhan Gupta".

- Source: MIT International Journal of Mechanical Engineering, Vol. 5, No. 2, August 2015, pp. 118-121, ISSN 2230-7680

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.