Ultrasonic Melt Treatment: A Breakthrough in Porosity and Inclusion Reduction for HPDC

This technical summary is based on the academic paper "An investigation on effect of rotary degassing-ultrasonic method on high pressure die casting products" by R. Haghayeghi, published in La Metallurgia Italiana (March 2022). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Ultrasonic Melt Treatment

- Secondary Keywords: Rotary Degassing, Porosity Reduction, Inclusion Removal, HPDC, Al-Si-Cu Alloys, Cavitation

Executive Summary

- The Challenge: Porosity formation in Al-Si-Cu alloys, a major problem in automotive applications, obstructs feeding channels and compromises the integrity of HPDC components.

- The Method: A new rotary degassing-ultrasound system was implemented on a large 400 kg aluminum melt and compared directly against a conventional Impeller+N₂ degassing process.

- The Key Breakthrough: The ultrasonic melt treatment enhanced hydrogen removal by 20% in just one-third of the time required by the impeller method and reduced inclusions by 3 to 6 times compared to impeller-treated and non-treated melts, respectively.

- The Bottom Line: This rotary-ultrasonic technique offers a faster, more effective solution for improving melt quality, significantly reducing defects, and enhancing the mechanical properties of final HPDC products.

The Challenge: Why This Research Matters for HPDC Professionals

For engineers working with Al-Si-Cu alloys in demanding automotive applications like ladder frames and engine blocks, porosity formation is a persistent and critical issue. This porosity is linked to several factors, including the obstruction of feeding channels by the β-Al₅FeSi phase and the segregation of copper, which leads to the formation of a eutectic mushy zone.

Furthermore, intermetallic compounds precipitating during the final stages of solidification—when feeding is most critical and permeability is at its lowest—exacerbate the problem. Previous research has confirmed the deleterious effect of Fe-Cu interaction on increasing porosity. Finding a reliable and efficient method to improve melt quality by addressing dissolved gasses and inclusions before casting is therefore essential for producing high-integrity, reliable HPDC components.

The Approach: Unpacking the Methodology

This investigation was conducted on an industrial scale, using approximately 400 kg of molten Al-9 wt.%Si-3 wt.%Cu-1.3 wt.%Fe alloy. The melt was heated to 700±5 °C and treated using two distinct methods for comparison:

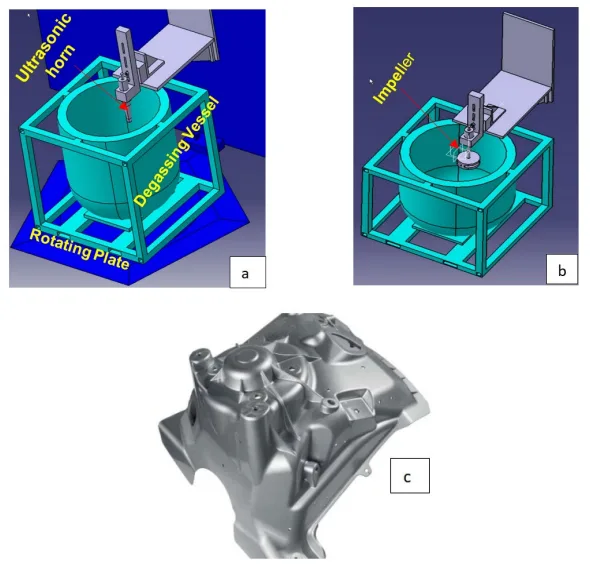

- Rotary Degassing-Ultrasonic System: An air-cooled piezoelectric transducer applied sonication at a frequency of 25 kHz with an input power of 1 KW for 3 minutes. Simultaneously, the vessel rotated at 2 rpm. The ultrasonic horn was strategically placed at 2/3 of the degassing tank's radius to optimize acoustic streaming and grain morphology.

- Impeller+N₂ System: A conventional impeller was used at a rotation speed of 750 rpm for 10 minutes, with nitrogen (N₂) gas blown from the bottom of the impeller at a rate of 5 Lit/min.

After treatment, the molten metal from each process was transferred to a 22 MN cold chamber HPDC machine to produce a 10 kg shock tower component. The quality of the melt was assessed using reduced pressure tests (RPT), density measurements (Archimedean method), and inclusion analysis via PoDFA.

The Breakthrough: Key Findings & Data

The study yielded compelling data demonstrating the superiority of the rotary-ultrasonic method in degassing, inclusion removal, and improving final part quality.

Finding 1: Superior Degassing Efficiency in One-Third the Time

The rotary-ultrasonic method proved significantly more efficient at removing hydrogen from the melt. As shown in Figure 2, the density index—a measure of gas porosity—decreased from 10.3% to just 2.6% after the 3-minute ultrasonic treatment. In contrast, the 10-minute impeller+N₂ treatment only reduced the density index from 10.5% to 4.6%. This represents a 20% higher degassing efficiency achieved in a fraction of the time. The improved performance is attributed to the high density of cavitation bubbles (1 × 10¹¹ m⁻³) with a large surface area, which enhances gas diffusion and removal.

Finding 2: Drastic Reduction in Harmful Inclusions

The PoDFA analysis revealed a dramatic improvement in melt cleanliness. As shown in Figure 3, the rotary-ultrasonic method was far more effective at removing inclusions compared to both the impeller+N₂ process and the non-treated melt. Specifically, with respect to the initial content, the amount of aluminium oxides (Al₂O₃) was decreased by 6 times using the ultrasonic treatment and by 3 times using the impeller+N₂ method. The study attributes this to the intense jet streams created by collapsing cavitation bubbles, which rupture oxide films and promote their attachment to bubbles for flotation.

Finding 3: Enhanced Mechanical Properties and Microstructure

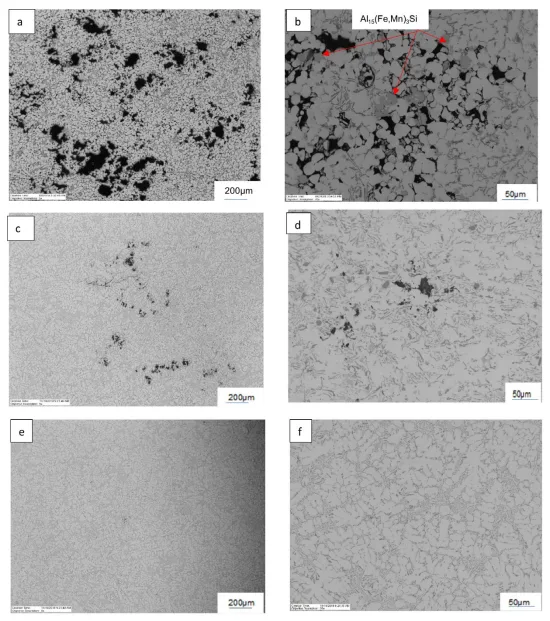

The improvements in melt quality translated directly to superior mechanical properties and a refined microstructure in the final die-cast part. The rotary vessel-ultrasonic system produced parts with a Yield Strength (YS) of 210 MPa, Ultimate Tensile Strength (UTS) of 303 MPa, and an elevated elongation of 6%. In comparison, the impeller+N₂ process yielded a YS of 180 MPa and UTS of 288 MPa with only 3% elongation, while the untreated melt achieved just 1% elongation. Microstructure analysis (Figure 4) confirmed that the ultrasonic process considerably decreased the size of intermetallic particles, which are potential sites for porosity formation.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adopting a rotary-ultrasonic system can reduce degassing cycle times by over 65% (from 10 minutes to 3 minutes) while achieving a 20% higher degassing efficiency. This contributes directly to increased throughput and reduced energy consumption.

- For Quality Control Teams: The data in Figure 2 (Density Index) and Figure 3 (PoDFA Analysis) of the paper illustrates the effect of ultrasonic treatment on reducing gas porosity and oxide inclusions. These results can inform new, more stringent quality inspection criteria for critical components.

- For Design Engineers: The findings indicate that the significant reduction in porosity and intermetallic size (Figure 4) achieved with ultrasonic melt treatment could allow for the design of more complex, lightweight components with thinner wall sections without compromising mechanical integrity.

Paper Details

An investigation on effect of rotary degassing-ultrasonic method on high pressure die casting products

1. Overview:

- Title: An investigation on effect of rotary degassing-ultrasonic method on high pressure die casting products

- Author: R. Haghayeghi

- Year of publication: 2022

- Journal/academic society of publication: La Metallurgia Italiana - International Journal of the Italian Association for Metallurgy

- Keywords: DIE CASTING, ROTARY DEGASSING-ULTRASONIC, CAVITATION;

2. Abstract:

A new rotary degassing-ultrasound system was implemented and compared with Impeller+N₂. The results suggest an enhanced hydrogen removal from the melt with a one third of required time for degassing by Impeller+N₂. The gas removal increased by 20% in comparison with rotary impeller. Inclusions reduced significantly by 3 and 6 times compared to impeller+N₂ and non-treated melt, respectively. Better cavitation dispersion, increased bubble surface area, less dross formation and better floatation rate contributed to better degassing and inclusion removal. For the first time, the ultrasonic melt treatment was performed on 400 Kg melt whereas the maximum volume ever been treated was 200 Kg.

3. Introduction:

Al-Si-Cu alloys are appropriate candidates for automotive applications. Many components such as ladder frame or engine block are produced from this group of aluminum alloys. A major problem in these alloys is porosity formation. This is related to various factors like the obstruction of feeding channels by β-Al₅FeSi phase as well as the segregation of copper by formation of constitutional undercooling ahead of the eutectic/liquid interface and establishment of eutectic mushy zone [1]. In addition, intermetallic compounds precipitate at last stages of solidification, that is when feeding is critical and permeability is the lowest [1]. This further could contribute to porosity formation. Alloying elements would have an effect on porosity formation. Previous researches [1-3] have shown the deleterious effect of Fe-Cu interaction on increasing the porosity content in Al-Si-Cu alloys. Hence, finding a solution to the above is required. In this research, the effect of rotary degassing ultrasonic process in a large pool of melt respecting previous researches [4,5] has been analyzed. It was compared with impeller degassing and its effects on porosity formation in a high pressure die casting (HPDC) process were discussed.

4. Summary of the study:

Background of the research topic:

The study focuses on Al-Si-Cu alloys used in automotive applications, where porosity formation is a major problem that compromises component quality.

Status of previous research:

Previous research identified factors causing porosity, such as the β-Al₅FeSi phase, copper segregation, and the interaction between iron and copper. Prior studies on ultrasonic degassing had been conducted, but this research aimed to analyze its effect on a large pool of melt (400 kg).

Purpose of the study:

The purpose was to analyze the effect of a rotary degassing ultrasonic process on a large melt pool, compare it with conventional impeller degassing, and discuss its effects on porosity formation in a high pressure die casting (HPDC) process.

Core study:

The core of the study is a direct comparison between a novel rotary degassing-ultrasound system and a standard impeller+N₂ system in treating a 400 kg melt of Al-Si-Cu alloy. The effects on hydrogen removal, inclusion content, microstructure, and mechanical properties of the resulting HPDC parts were evaluated.

5. Research Methodology

Research Design:

A comparative experimental design was used. Two separate processes (rotary-ultrasonic and impeller+N₂) were implemented to degas identical batches of Al-Si-Cu molten alloy. The treated melt was then used to produce a "shock tower" component via HPDC, and the resulting material properties were analyzed.

Data Collection and Analysis Methods:

- Melt Quality: Measured via reduced pressure test (RPT) and density measurement (Archimedean method).

- Inclusions: Measured by PoDFA (Porous Disc Filtration Apparatus) on 3 kg samples.

- Mechanical Properties: Tensile tests were performed on sub-size specimens according to ISO 6892-1 A standard.

- Microstructure: Examined using an image analyzer on samples from the castings.

Research Topics and Scope:

The research investigated the effect of two different melt treatment methods on degassing efficiency, inclusion removal, and porosity formation in HPDC products made from an Al-9 wt.%Si-3 wt.%Cu-1.3 wt.%Fe alloy. The study is notable for its industrial scale, treating a 400 kg melt, which is double the previously reported maximum volume for ultrasonic treatment.

6. Key Results:

Key Results:

- The rotary vessel-ultrasound method decreased the density index from 10.3% to 2.6%, while the impeller+N₂ method decreased it from 10.5% to 4.6%. This indicates a 20% higher degassing efficiency for the ultrasonic method.

- The ultrasonic treatment was performed in 3 minutes, one-third of the 10-minute time required for the impeller method.

- Dross formation was significantly lower with the rotary-sonication system (245 gr) compared to the rotary impeller (1300 gr).

- The amount of aluminium oxides was decreased by 6 times with ultrasonic treatment and 3 times with impeller+N₂ treatment compared to the initial content.

- The ultrasonic method resulted in superior mechanical properties: YS of 210 MPa, UTS of 303 MPa, and 6% elongation, compared to 180 MPa YS, 288 MPa UTS, and 3% elongation for the impeller method.

Figure Name List:

- Fig.1 - (a) The rotating furnace-sonication system; (b) Impeller with nitrogen degassing, (c) Shock tower.

- Fig.2 - Density index of molten metal before and after degassing with two different methods.

- Fig.3 - PoDFA analysis of untreated, impeller+N₂ and ultrasonically treated melts.

- Fig.4 - Microstructure of diecast AlSi₉Cu₃(Fe) alloy: (a,b) untreated; degassed with (c,d) impeller+N₂ and (e,f) rotary vessel-sonication.

7. Conclusion:

A rotary sonication-ultrasonic technique was offered for degassing and inclusion removal. The results suggest 20% improvement for degassing and 2 times enhancement in oxide removal compared with impeller+N₂. The YS, UTS and elongation was increased considerably. Moreover, 400 Kg of molten metal was treated whereas the maximum ever reported was 200 Kg. By the suggested technique the formation of undesired composition from the impeller decreases significantly and melt quality improves accordingly.

8. References:

- [1] Dinnis C.M, Taylor J.A, Dahle, A.K. Iron-related porosity in Al-Si-(Cu) foundry alloys. Mater. Sci. Eng. 2006; 425: 286-296.

- [2] Roy N., Samuel A.M. and Samuel F.H. Porosity formation in Al-9 Wt Pct Si-3 Wt Pct Cu alloy systems: Metallographic observations. Met Mater Trans A.1996; 27: 415-429.

- [3] Heiberg G., Nogita K., Dahle A.K., Arnberg L. Columnar to equiaxed transition of eutectic in hypoeutectic aluminium-silicon alloys. Acta Mater. 2002; 50:2537-46.

- [4] Haghayeghi R., Kapranos P. The Effect of Processing Parameters on Ultrasonic Degassing Efficiency. Mater Lett. 2014;116: 399-401.

- [5] Haghayeghi R., Heydari A., Kapranos P. Effect of ultrasonic vibrations prior to high pressure die-casting of AA7075. Mater Lett. 2015;153:175-8.

- [6] Lebon G.S.B, Abou-Jaoud G.S., Eskin D., Tzanakis I., Pericleous K., Jarry P. Numerical modelling of acoustic streaming during the ultrasonic melt treatment of direct-chill (DC) casting. Ultrason Sonochem. 2019; 54:171-182.

- [7] Samuel A.M., Samuel F.H. Various aspects involved in the production of low-hydrogen aluminium castings. J Mater Sci, 1992; 27: 6533-63

- [8] Eskin D.G., Tzanakis I., Wang F., Lebon G.S.B, Subroto T., Pericleous K., Mi J. Fundamental studies of ultrasonic melt processing. Ultra Sonochem. 2019; 52:455-467.

- [9] Doinikov A.A., Translational motion of two interacting bubbles in a strong acoustic field. Phys. Rev. E, 64 (2001), Article 026301.

- [10] Eskin D., Alba-Baena N., Pabel T. and Da Silva M. Ultrasonic degassing of aluminium alloys: basic studies and practical implementation. Mater Sci Techno. 2015; 31: 79-84

- [11] Eskin D.G, Al-Helal K., Tzanakis I. Application of a plate sonotrode to ultrasonic degassing of aluminum melt: Acoustic measurements and feasibility study. J. Mater. Process. Technol. 2015;222: 148-154.

- [12] Kang S., Shen M., Li C., Cold Model Experiments and Mechanism on Inclusion Removal by Ultrasonic Horn. Adv Mater Res, 2013; 750-752: 404-7.

- [13] Khalifa W., Samuel A.M., Samuel F.H., Doty H.W. & Valtierra S., Metallographic observations of β-AlFeSi phase and its role in porosity formation in Al-7%Si alloys. Int. J Cast Metal Res. 2006; 19:156-166.

- [14] Haghayeghi R., Depaula L.C, Zoqui E.J. Comparison of Si Refinement Efficiency of Electromagnetic Stirring and Ultrasonic Treatment for a Hypereutectic Al-Si Alloy. J Mater Eng Per. 2016; 29:1900-7.

Expert Q&A: Your Top Questions Answered

Q1: Why was the ultrasonic horn specifically placed at 2/3 of the degassing tank's radius?

A1: The paper states this position was "determined based on preliminary experiments which have evidenced how the sonotrode's position affects the acoustic streaming and the grain morphology of the solidified material [6]." This strategic placement is crucial for maximizing the effectiveness of the ultrasonic waves throughout the melt, ensuring uniform treatment and avoiding dead zones.

Q2: The paper notes that dross formation was much lower with the ultrasonic method (245 g vs. 1300 g). Why is this an important factor in degassing?

A2: This is a critical point for melt quality. The paper explains that dross acts as an "accumulator of hydrogen by adsorption of hydrogen molecules which is significant at above 600°C [10]." By generating significantly less dross, the ultrasonic method prevents a major source of hydrogen re-contamination, contributing to its overall higher degassing efficiency compared to the mechanical agitation of an impeller.

Q3: How exactly does the ultrasonic method remove inclusions more effectively than the impeller with N₂ gas?

A3: The mechanism is fundamentally different and more active. The paper explains that ultrasonic waves create intense acoustic pressure variations, causing cavitation bubbles to explode and release a powerful "jet stream." Inclusions collide with this jet stream, and the pressure changes rupture oxide films. This process makes it easier for the inclusions to attach to bubbles and float to the surface. One cited study [12] demonstrated that this cavitation effect can increase the flotation rate of inclusions by up to 6 times.

Q4: What is the industrial significance of successfully treating a 400 kg melt with this technology?

A4: This is a major step towards industrial-scale implementation. The abstract explicitly highlights, "For the first time, the ultrasonic melt treatment was performed on 400 Kg melt whereas the maximum volume ever been treated was 200 Kg." This successful scale-up demonstrates that the technology is not limited to laboratory settings and can be viably integrated into large-scale HPDC operations that require large volumes of high-quality molten metal.

Q5: The paper mentions the "Bjerknes force." What role does this force play in the ultrasonic degassing process?

A5: The Bjerknes force is key to maintaining a high density of active bubbles in the melt. According to the paper, this force attempts to bring bubbles together during each acoustic cycle. However, the bubbles also create a strong velocity field that pushes them apart. The paper describes this as a "steady state condition" where the distance between bubbles remains nearly constant [9]. This prevents bubbles from coalescing into larger, less effective bubbles and ensures that a high number of small bubbles are continuously available throughout the melt for efficient hydrogen diffusion.

Conclusion: Paving the Way for Higher Quality and Productivity

This research demonstrates a clear and compelling case for the adoption of rotary ultrasonic melt treatment in high-pressure die casting. By addressing the core challenges of hydrogen porosity and harmful inclusions more effectively and efficiently than conventional methods, this technology offers a direct path to higher quality components. The key breakthrough—achieving 20% better degassing in one-third the time while simultaneously removing up to 6 times more oxides—translates into tangible benefits for R&D and operations, including faster cycle times, reduced defects, and superior mechanical performance.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "An investigation on effect of rotary degassing-ultrasonic method on high pressure die casting products" by "R. Haghayeghi".

- Source: [https://www.aimnet.it/la-metallurgia-italiana/2022/MI_MAR22_Haghayeghi.pdf]

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.