Beyond the Die: How Advanced Cooling in Lost Foam Casting Unlocks Superior Aluminum Casting Properties

This technical summary is based on the academic paper "Influence of Sand Fluidization on Structure and Properties of Aluminum Lost Foam Casting" by P. Kaliuzhnyi, published in ARCHIVES of FOUNDRY ENGINEERING (2020). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Aluminum Casting Properties

- Secondary Keywords: Lost Foam Casting, Sand Fluidization, AlSi9 Alloy, Microstructure Refinement, Mechanical Properties, Gravity Die Casting

Executive Summary

- The Challenge: Lost Foam Casting (LFC), despite its advantages for complex geometries, typically produces aluminum parts with mechanical properties inferior to those made by gravity die casting.

- The Method: The study introduced compressed air into the sand mold post-pouring, creating a "fluidized bed" to accelerate and unify the cooling of AlSi9 alloy castings.

- The Key Breakthrough: This sand fluidization technique dramatically refined the alloy's microstructure, increasing tensile strength by up to 50% and hardness by nearly 20%.

- The Bottom Line: By enhancing the cooling rate, LFC can produce aluminum castings with mechanical properties that meet or exceed those of gravity die castings, offering a high-performance alternative for intricate components.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of metal casting, the trade-off between geometric complexity and mechanical performance is a constant challenge. While methods like High Pressure Die Casting (HPDC) excel at producing strong, reliable parts, they can be limited by tooling costs and complexity. Lost Foam Casting (LFC) offers a compelling alternative, enabling the production of highly intricate parts without cores and with excellent dimensional accuracy. However, LFC has historically faced a significant drawback: the mechanical properties of its aluminum castings are often lower than those cast in metal molds.

This performance gap has limited LFC's application in more demanding scenarios. As stated in the paper, "the mechanical properties of aluminum alloys [from LFC] are lower than those cast in metal mold." This research directly confronts this limitation, exploring an innovative method to elevate the performance of LFC castings to rival their die-cast counterparts, a development that holds important lessons for the entire casting industry about the power of thermal management.

The Approach: Unpacking the Methodology

The researchers investigated the effects of accelerated cooling on AlSi9 aluminum alloy castings produced via the LFC process.

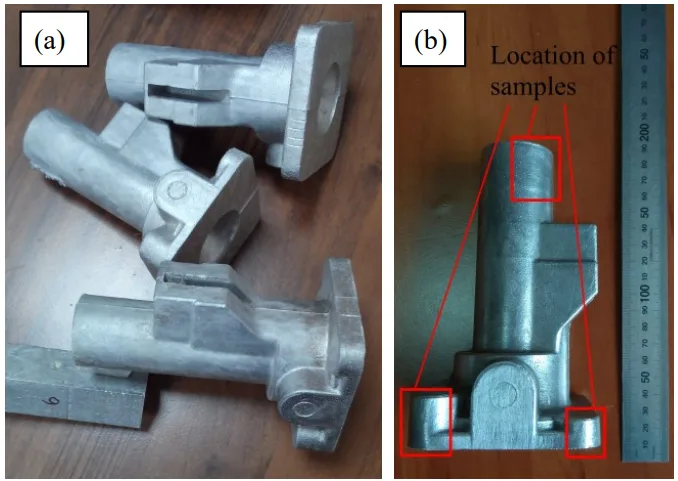

- Material & Casting: An industrial casting ("body") with varying wall thicknesses (10, 20, and 40 mm) was produced using AlSi9 aluminum alloy. The patterns were made from expanded polystyrene foam (25 kg/m³ density).

- Molding & Pouring: The patterns were coated with a refractory slurry and placed in a metal container filled with 0.16 mm silica sand. The mold was compacted by vibration and a vacuum of 0.035 MPa was applied during pouring at 730±5 °C.

- Experimental Conditions: After pouring, the castings were cooled under three distinct modes:

- Mode A (Conventional LFC): Cooled in static sand with no intervention.

- Mode B (Fluidization 1): After 60 seconds, compressed air was supplied at 0.064 m/s for 180 seconds to fluidize the sand.

- Mode C (Fluidization 2): Same as Mode B, but with a higher air flow rate of 0.080 m/s.

- Analysis: Samples were cut from different sections of the castings for microstructural analysis (examining Secondary Dendrite Arm Spacing (SDAS), eutectic silicon, and iron-rich phases) and mechanical testing (tensile strength, elongation, and Brinell hardness).

The Breakthrough: Key Findings & Data

The application of sand fluidization during solidification yielded significant, measurable improvements in both the microstructure and the final mechanical properties of the AlSi9 castings.

Finding 1: Dramatic Microstructure Refinement

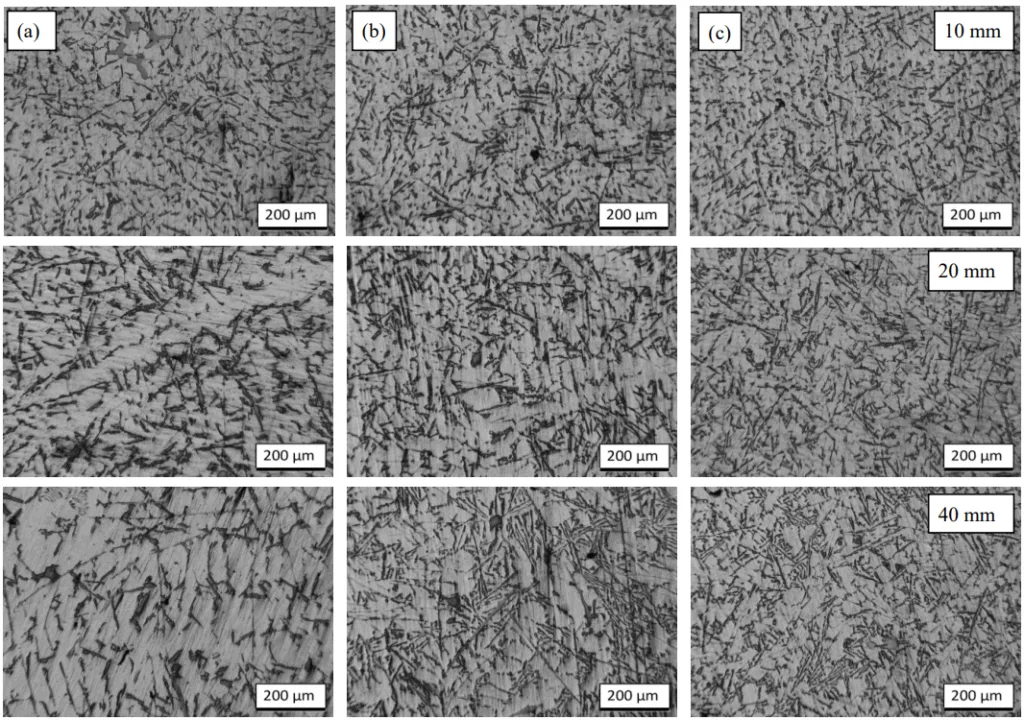

The accelerated cooling induced by sand fluidization resulted in a much finer and more uniform microstructure across all wall thicknesses. The primary microstructural components—SDAS, eutectic silicon, and iron-rich (Al₅FeSi) needles—were all significantly reduced in size.

- As shown in Table 2, for the thickest 40 mm wall section, the average SDAS was reduced from 66.9 µm in conventional LFC (Mode A) to just 31.3 µm with the highest fluidization rate (Mode C), a reduction of over 53%.

- Similarly, the length of the brittle Al₅FeSi needles in the 40 mm section decreased from 268.8 µm to 150 µm, a 44% reduction that lessens their negative impact as stress concentrators.

Finding 2: Mechanical Properties Elevated to Die Casting Levels

The refined microstructure translated directly into superior mechanical performance, elevating the LFC parts to a level competitive with gravity die castings.

- According to Table 3, the ultimate tensile strength of the alloy surged from 148 MPa in conventional LFC to 223 MPa in Mode C. This 50% increase surpasses the ≥196 MPa requirement for gravity die cast parts with a T1 heat treatment.

- Hardness also saw a significant boost, increasing from 69 HB to 82 HB, a nearly 19% improvement. The elongation to fracture improved from 0.8% to 1.2%, indicating enhanced ductility despite the high iron content.

Practical Implications for R&D and Operations

While this study focuses on LFC, the fundamental principle—the direct link between controlled cooling, microstructure, and performance—offers valuable insights for HPDC professionals.

- For Process Engineers: This study underscores the critical role of thermal management. It suggests that innovations in die cooling technology, such as conformal cooling channels or advanced spray applications, can be a powerful lever for refining grain structure and enhancing mechanical properties in HPDC parts, especially in thick-walled sections.

- For Quality Control Teams: The data in Table 2 and Table 3 of the paper clearly correlates reduced SDAS with increased tensile strength. This reinforces the value of using microstructural analysis as a predictive tool for mechanical performance, potentially allowing for faster and more accurate quality validation in HPDC processes.

- For Design Engineers: The findings show that sand fluidization created a more uniform structure across different wall thicknesses. This suggests that advanced, targeted cooling strategies in HPDC could enable the design of components with greater variations in section thickness without creating zones of weakness, expanding design freedom.

Paper Details

Influence of Sand Fluidization on Structure and Properties of Aluminum Lost Foam Casting

1. Overview:

- Title: Influence of Sand Fluidization on Structure and Properties of Aluminum Lost Foam Casting

- Author: P. Kaliuzhnyi

- Year of publication: 2020

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 20, Issue 1/2020

- Keywords: Innovative foundry technologies, Lost foam casting, Aluminum alloy, Sand fluidization

2. Abstract:

The article presents investigation results of the effect of sand fluidization on the structure and mechanical properties of AlSi9 aluminum alloy. Castings were made by lost foam casting process with sand fluidization in mold at the stages of their solidification and cooling. Sand fluidization was achieved by blowing sand bed with compressed air in a foundry container. The metallographic study was carrying out on samples cut from different sections of the castings. Mechanical properties were determined on specimens made from cast samples. Microstructural analysis showed that sand fluidization increases the cooling rate, as a result, the main microstructural components of the alloy - SDAS, eutectic silicon and needles of the rich-iron phase - decrease. Moreover, in different sections of the casting structure is more uniform. With an increasing the air flow rate, a greater refinement of the structure is observed. Through the use of sand fluidization, the mechanical properties of LFC aluminum alloys increase to the level of gravity die castings.

3. Introduction:

Castings from aluminum alloys are widely used in the automotive industry, often being a replacement for heavy steel and iron cast parts for lightweight and more economical cars. It is well known that the properties of castings from aluminum alloys obtained in metal molds are higher than those cast in sand molds [1]. The gravity die casting, having a number of drawbacks (the high cost of the die mold, the impossibility of making castings of complex configuration, etc.), is superseded by other, more progressive casting methods, one of which is lost foam casting (LFC). With all its advantages (castings of complex configuration are obtained without using of cores, high geometric accuracy and low roughness of castings) LFC has one drawback the mechanical properties of aluminum alloys are lower than those cast in metal mold. In this regard, many investigations of recent years are aimed at developing methods to improve the properties of aluminum castings obtained by LFC.

4. Summary of the study:

Background of the research topic:

Lost Foam Casting (LFC) is a progressive method for creating complex aluminum castings, but it traditionally yields lower mechanical properties compared to gravity die casting. Improving these properties is a key area of research to expand LFC's applications.

Status of previous research:

Previous methods to improve aluminum alloy properties in casting include pressure application, vibration, or a combination of both during solidification. Another approach involves accelerating solidification and cooling. It has been shown that the cooling rate in a fluidized bed of silica sand is 20 times higher than in a static one, which presented an opportunity for investigation in LFC.

Purpose of the study:

The aim of the work was to establish the laws of the influence of sand fluidization on the structure and mechanical properties of aluminum castings obtained by LFC, given that Al-Si alloys are sensitive to cooling rate.

Core study:

The study compared AlSi9 castings made with conventional LFC to those made with two different levels of sand fluidization applied during the cooling stage. The researchers analyzed the resulting microstructure (SDAS, eutectic silicon, Al₅FeSi needles) and mechanical properties (tensile strength, elongation, hardness) in casting sections of 10, 20, and 40 mm thickness.

5. Research Methodology

Research Design:

A comparative experimental study was designed to evaluate three cooling modes for LFC: one conventional (static sand) and two with sand fluidization at different air flow rates (0.064 m/s and 0.080 m/s).

Data Collection and Analysis Methods:

- Casting: An industrial casting "body" (0.95 kg) was produced using LFC.

- Microstructure: Samples were cut from 10, 20, and 40 mm thick walls, prepared with standard metallographic techniques, and examined with an optical microscope.

- Mechanical Testing: Tensile tests were performed on specimens cut from cast samples according to DSTU EN 10002-1: 2006. Hardness was measured using the Brinell method according to DSTU ISO 6506-1: 2007.

Research Topics and Scope:

The research focused on the AlSi9 aluminum alloy. The scope included fabricating castings, applying sand fluidization, and quantifying the effects on microstructural features and mechanical properties (tensile strength, elongation, hardness).

6. Key Results:

Key Results:

- Sand fluidization significantly increases the cooling rate of LFC aluminum castings.

- This leads to a finer microstructure: SDAS decreases by 1.5-1.8 times, eutectic silicon size by 1.3-1.6 times, and the length of iron intermetallic needles by 1.4-1.8 times.

- The microstructure becomes more uniform across different sections of the casting.

- Mechanical properties are substantially improved: tensile strength increases by 25-40%, while ductility and hardness increase by 10-20%.

- The resulting properties of LFC castings with sand fluidization are comparable to more expensive gravity die castings.

Figure Name List:

- Fig. 1. Casting "body"

- Fig. 2. Container with pattern block

- Fig. 3. Microstructure of different wall thickness of castings obtained by conventional LFC technology (a), technology with sand fluidization mode B (b) and mode C (c)

7. Conclusion:

The sand fluidization in the mold at the casting stage allows to increase the cooling rate of the aluminum alloy. As a result, the size of SDAS decreases by 1.5-1.8 times, the size of eutectic silicon by 1.3-1.6 times, the length of the needles of iron intermetallic 1.4-1.8 times. Sand fluidization also contributes to a more uniform structure in different sections of the casting. The strength of aluminum LFC due to sand fluidization was increased by 25-40%, ductility and hardness by 10-20%. This allows the use of such castings instead of the more expensive die castings. The results of the work showed that the LFC technology has the potential to improve the properties of aluminum alloys due to sand fluidization in the mold.

8. References:

- [1] Totten, G.E., MacKenzie, D.S. (Eds.). (2003). Handbook of Aluminum: Vol. 1: Physical Metallurgy and Processes. New York: Marcel Dekker Inc.

- [2] Niakan, A.A., Idris, M.H., Karimian, M. & Ourdjini, A. (2012). Effect of Pressure on Structure and Properties of Lost Foam Casting of Al-11Si Cast Alloy. Applied Mechanics and Materials. 110-116, 639-643. DOI: 10.4028/www.scientific.net/AMM.110-116.639.

- [3] Jiang, W., Chen, X., Wang, B., Fan, Z. & Wu, H. (2016). Effects of vibration frequency on microstructure, mechanical properties, and fracture behavior of A356 aluminum alloy obtained by expendable pattern shell casting. The International Journal of Advanced Manufacturing Technology. 83, 167-175. DOI: 83. 10.1007/s00170-015-7586-0.

- [4] Zhao, Z. & Fan, T. (2014). Influence on the Microstructures and Properties of A356 with Vibration Pressure in Lost Form Casting. Applied Mechanics and Materials. 685, 7-10. DOI: 10.4028/www.scientific.net/AMM.685.7.

- [5] Kaliuzhnyi, P., Holofaiev, A. & Hutko, Y. (2015). UA Patent No. 97151. Kyiv.

- [6] Ragab, Kh. A., Samuel, A.M., Al-Ahmari, A.M.A., Samuel, F.H. & Doty, H.W. (2011). Influence of fluidized sand bed heat treatment on the performance of Al-Si cast alloys. Material and Design. 32, 1177-1193. DOI: 10.1016/j.matdes.2010.10.023.

- [7] Shalevska, I. & Kaliuzhnyi, P. (2015). Fluidized bed application in technological process of casting production in vacuumized molds. Metal and casting of Ukraine. 4, 19-21. (In Russian).

- [8] Hren, I., Svobodova, J., Michna, Š. (2018). Influence of Al5FeSi Phases on the Cracking of Castings at Al-Si Alloys. Archives of Foundry Engineering. 18(4), 120-124. DOI: 10.24425/afe.2018.125180.

Expert Q&A: Your Top Questions Answered

Q1: Why was sand fluidization chosen as the cooling method for this study?

A1: Sand fluidization was chosen because it uniquely leverages the core materials of the LFC process—binderless silica sand. As noted in the introduction, a fluidized sand bed has significantly higher thermal conductivity than a static one. This allows for a controlled, accelerated cooling rate directly within the mold, avoiding the extreme thermal shock and potential cracking associated with methods like water quenching.

Q2: The paper mentions the alloy had a high iron content (0.94%). How did this impact the results?

A2: The paper explicitly states that the high iron content resulted in "rather long needles of iron intermetallic" (β-phase Al₅FeSi) in the conventional LFC castings. These needles act as stress concentrators and reduce plasticity. The key breakthrough was that sand fluidization significantly shortened these needles—by up to 44% in the 40mm section (Table 2). This reduction in the size of the harmful β-phase was a major contributor to the observed increase in mechanical properties.

Q3: How significant was the increase in mechanical properties compared to industry standards?

A3: The increase was highly significant. The tensile strength of the fluidization-cooled casting (Mode C) reached 223 MPa. As shown in Table 3, this not only far exceeds the standard for as-cast parts (≥157 MPa) but also surpasses the more stringent requirement for gravity die cast parts that have undergone T1 heat treatment (≥196 MPa). This effectively elevates the performance of an as-cast LFC part to that of a heat-treated die casting.

Q4: What is the primary mechanism that drives the improvement in the alloy's structure?

A4: The primary mechanism is the increased cooling rate. The paper explains that when the sand bed is fluidized, "the heat exchange mechanism changes, and the thermal conductivity of the sand layer increases significantly." This rapid heat extraction from the solidifying casting restricts the growth of dendritic arms (reducing SDAS), limits the coarsening of eutectic silicon particles, and shortens the formation time for the iron-rich needles, resulting in an overall finer and more robust microstructure.

Q5: The results show improvement across different wall thicknesses. How uniform were these improvements?

A5: A key finding was that sand fluidization leads to a "more uniform" structure in different sections. While all sections saw improvement, the effect was more pronounced in thicker sections. For example, in Mode C, the SDAS in the 40 mm wall was reduced by 53%, while in the 10 mm wall it was reduced by 28% compared to conventional LFC (Table 2). This demonstrates the method's powerful ability to mitigate the slow cooling typically associated with heavy sections, leading to more consistent properties throughout a complex casting.

Q6: Is this sand fluidization technique applicable only to AlSi9 alloy?

A6: While this study focused specifically on AlSi9, the underlying principle of accelerated cooling to refine microstructure is applicable to a wide range of casting alloys sensitive to cooling rates. The paper's conclusion suggests "the need to conduct a more advanced study of the effect of sand fluidization on the properties of aluminum alloys of various grades," indicating the technology has broader potential.

Conclusion: Paving the Way for Higher Quality and Productivity

This research demonstrates a powerful and innovative method for overcoming the primary limitation of Lost Foam Casting. By integrating sand fluidization into the cooling stage, it is possible to dramatically enhance the Aluminum Casting Properties of LFC components, elevating them to a level of performance previously reserved for die casting. The key takeaway is the profound impact of controlled, accelerated thermal management on microstructure refinement and, consequently, on final part strength and reliability. This principle holds immense value not just for LFC, but for all casting processes, including HPDC.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Influence of Sand Fluidization on Structure and Properties of Aluminum Lost Foam Casting" by "P. Kaliuzhnyi".

- Source: 10.24425/afe.2020.131293

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.