Maximizing Recycled Content: Finding the Quality Sweet Spot for Circulating Scrap in HPDC

This technical summary is based on the academic paper "The Influence of the Proportion of Charge from Waste Materials on the Quality of High Pressure Castings" by P. Schlafka and A. W. Bydałek, published in ARCHIVES of FOUNDRY ENGINEERING (2019). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Circulating Scrap in HPDC

- Secondary Keywords: HPDC Quality Control, Al-Si Alloys, Casting Defects, Porosity in Die Casting, Mechanical Properties of Castings, Sustainable Casting

Executive Summary

- The Challenge: While using circulating scrap in High Pressure Die Casting (HPDC) is vital for cost reduction and sustainability, there is a critical need to define the safe upper limit before it compromises casting quality and mechanical integrity.

- The Method: The study systematically varied the proportion of new AlSi9Mg alloy and circulating scrap (from 0% to 80%) in a cold-chamber die casting process, keeping all casting parameters constant.

- The Key Breakthrough: A mix of 40% new metal and 60% circulating scrap was identified as the optimal configuration, delivering the highest tensile strength without introducing detrimental porosity.

- The Bottom Line: Increasing circulating scrap up to 60% can enhance mechanical strength; however, exceeding this threshold to 80% causes a sharp increase in porosity and a significant reduction in the casting's strength.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of HPDC, Al-Si alloys are the material of choice for automotive components due to their light weight, high strength-to-mass ratio, and corrosion resistance. To make production economical and environmentally responsible, reusing internal scrap (circulating scrap) is standard practice. However, this process is not without risk.

Improper alloy preparation, including the wrong ratio of new material to scrap, can introduce numerous casting defects like gas porosity, shrinkage porosity, and oxide inclusions. These defects directly impact the final quality and structural integrity of the component. This research addresses a critical question for every foundry: How much circulating scrap can be used before negatively impacting the quality of high-pressure castings? The study aims to define a data-driven limit to maximize scrap usage without compromising performance.

The Approach: Unpacking the Methodology

The researchers conducted a controlled experiment to isolate the effect of scrap proportion on casting quality.

- Material: The study used a hypereutectoid silumin alloy, Silafont 36 (AlSi9Mg), a common material in the automotive industry. The precise chemical composition is detailed in the paper's Table 1.

- Equipment: A FRECH DAK350-40 RC cold-chamber die casting machine was used for production. The alloy was melted at 700°C in a double-chamber shaft furnace.

- Experimental Variables: The core of the study involved creating six distinct batches of material with varying proportions of new metal input and circulating scrap, as detailed in Table 2 of the paper:

- Sample 1: 100% new metal, 0% scrap

- Sample 2: 80% new metal, 20% scrap

- Sample 3: 60% new metal, 40% scrap

- Sample 4: 50% new metal, 50% scrap

- Sample 5: 40% new metal, 60% scrap

- Sample 6: 20% new metal, 80% scrap

- Process Control: To ensure only the scrap ratio was being tested, all die casting parameters were held constant across all batches. Key parameters included injection piston velocities and compressing phase pressure of 1050 bar (Table 3).

- Quality Analysis: Produced castings were subjected to two primary quality checks:

- Porosity Inspection: A YXLON Y.MU2000-D Wheel X-ray system was used to assess internal porosity.

- Mechanical Testing: A universal testing machine was used to determine the maximum tensile force (Fmax) and other strength properties.

The Breakthrough: Key Findings & Data

The study delivered clear, actionable data on how circulating scrap affects both internal soundness and mechanical performance.

Finding 1: Porosity Increases Sharply Above a 60% Scrap Threshold

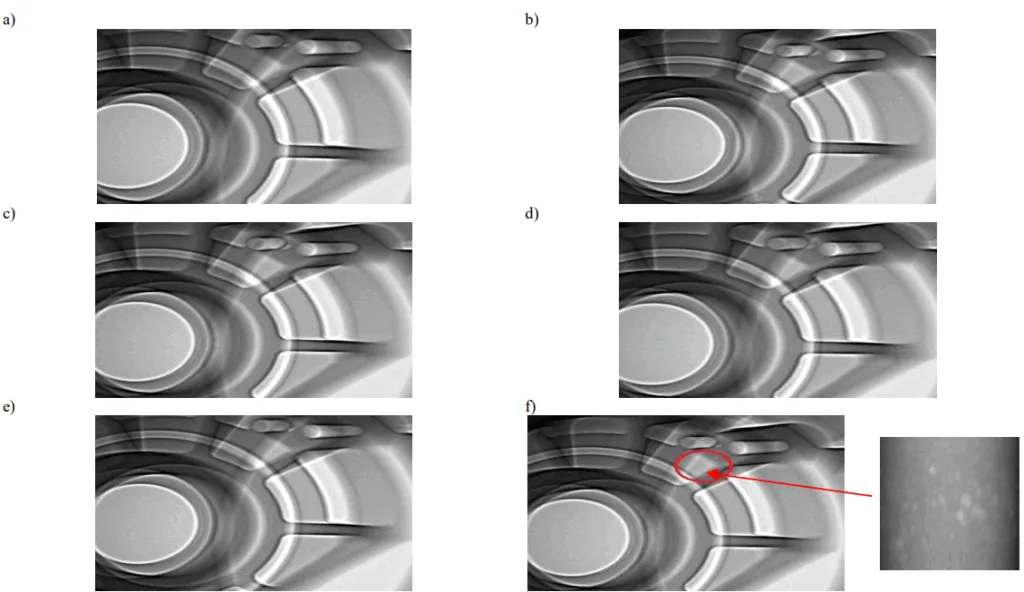

X-ray inspections revealed a distinct correlation between the percentage of circulating scrap and the presence of porosity.

- As shown in Table 4, castings made with 0% to 40% scrap (Samples 1, 2, and 3) showed no detectable porosity.

- At 50% and 60% scrap (Samples 4 and 5), a "little porosity" was detected (marked as "xx" in Table 4), but the size, distribution, and location of these pores were deemed acceptable for the component.

- However, at 80% scrap (Sample 6), the castings exhibited significant porosity ("xx" and "xxx" in Table 4), which "exceeded the permissible value for the detail." The porosity was observed to occur on the thicker sides of the casting, as seen in Figure 2f.

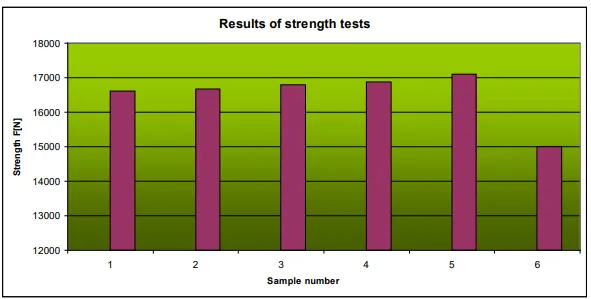

Finding 2: Mechanical Strength Peaks at 60% Scrap Before a Drastic Decline

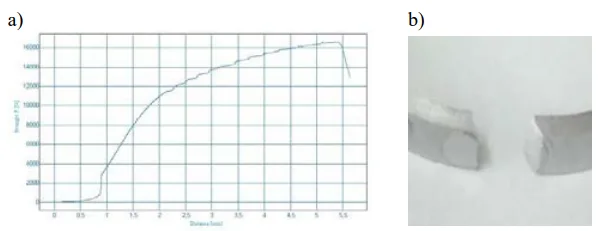

The tensile tests provided a surprising insight: a moderate amount of scrap actually improved the mechanical strength of the casting.

- The reference sample with 0% scrap (Sample 1) had a maximum tensile force of 16621 N.

- As detailed in Table 5, the maximum tensile force steadily increased with the addition of scrap, reaching a peak value of 17189 N for Sample 5 (40% metal / 60% scrap). This demonstrates that the "little porosity" found in this sample did not negatively influence the detail's strength.

- For Sample 6 (20% metal / 80% scrap), the tensile force plummeted to 14986 N. This result, directly linked to the high porosity, "does not fulfil the strength criterion for the detail given."

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that a circulating scrap proportion of up to 60% is not only safe but potentially beneficial for the mechanical strength of AlSi9Mg castings. Pushing the limit to 80% is a critical risk that leads to unacceptable porosity and part failure.

- For Quality Control Teams: The data in Table 4 and Figure 2 of the paper illustrates that while minor porosity may appear at 50-60% scrap levels, it does not necessarily correlate with a loss of strength. The key is to monitor for the significant porosity that appears at the 80% scrap level, particularly in thicker sections of the casting.

- For Design Engineers: The findings indicate that thicker sections of a part are more susceptible to porosity formation when high scrap ratios are used. This reinforces the importance of designing for uniform wall thickness to mitigate defect formation during solidification, especially when maximizing recycled material content.

Paper Details

The Influence of the Proportion of Charge from Waste Materials on the Quality of High Pressure Castings

1. Overview:

- Title: The Influence of the Proportion of Charge from Waste Materials on the Quality of High Pressure Castings

- Author: P. Schlafka, A. W. Bydałek

- Year of publication: 2019

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 19, Issue 2/2019

- Keywords: Die casting, Al-Si alloys, Circulation scrap, Environment protection, Castings defects

2. Abstract:

Nowadays, the most popular production method for manufacturing high quality casts of aluminium alloys is the hot and cold chamber die casting. Die casts made of hypereutectoid silumin Silafont 36 AlSi9Mg are used for construction elements in the automotive industry. The influence of the metal input and circulating scrap proportion on porosity and mechanical properties of the cast has been examined and the results have been shown in this article. A little porosity in samples has not influenced the details strength and the addition of the circulating scrap has contributed to the growth of the maximum tensile force. Introducing 80% of the circulating scrap has caused great porosity which led to reduce the strength of the detail. The proportion of 40% of the metal input and 60% of the circulating scrap is a configuration safe for the details quality in terms of porosity and mechanical strength.

3. Introduction:

The process of manufacturing high quality casts uses many casting methods [1-5]. Die casting is a popular production method applied to make details of the aluminium alloys [6,7]. Al-Si alloys are used to produce casts of details in the automotive industry due to their small weigh, high strength to mass relation, good mechanical properties and resistance to corrosion [8,9,10]. Die casting is the most economical and efficient process of producing details of Al-Si alloys. The production procedure, due to economic and quality reasons, should be characterised by appropriate preparation of an alloy for the casting [7, 11-13]. Details made by die casting with the wrong estimation of pouring parameters and inappropriate preparation of the alloy have numerous casting defects (gas porosity, shrinkage porosity, oxide inclusion etc.). These defects contribute to the appearance of scrap. This scrap is reused in the production process. In the article the results of examining the influence of the quantity of the metal input and the circulating scrap on the detail quality have been demonstrated. Due to the protection of environment it is crucial to use the scrap in high quality casts of various metal alloys production to the greatest extent possible [12,13].

4. Summary of the study:

Background of the research topic:

High-quality aluminum alloy casts, particularly for the automotive industry, are often produced using die casting. This method is economical and efficient but is sensitive to alloy preparation and casting parameters, which can lead to defects. Reusing circulating scrap is common for economic and environmental reasons, but its impact on final product quality needs to be carefully managed.

Status of previous research:

Previous research and industry practice have established that improper alloy preparation and pouring parameters in die casting lead to defects like porosity and oxide inclusions. The need to reuse scrap to the greatest extent possible for environmental protection is also a known imperative.

Purpose of the study:

The study aimed to examine the influence of varying proportions of new metal input and circulating scrap on the porosity and mechanical properties of high-pressure die casts made from AlSi9Mg alloy. The goal was to identify a safe and optimal configuration for scrap usage.

Core study:

The core of the study involved producing die casts with six different ratios of new metal to circulating scrap, ranging from 100% new metal (0% scrap) to 20% new metal (80% scrap). The resulting casts were then evaluated for internal porosity using X-ray inspection and for mechanical strength via tensile testing.

5. Research Methodology

Research Design:

The research was designed as a comparative experiment. Six distinct sample groups were created, with the only variable being the proportion of new metal input to circulating scrap. All other factors, including the alloy type (Silafont 36 AlSi9Mg), melting temperature (700°C), and die casting machine parameters, were held constant to isolate the effect of the scrap ratio.

Data Collection and Analysis Methods:

Data was collected through two primary methods:

1. X-ray Inspection: A YXLON Y.MU2000-D system was used to non-destructively inspect the internal structure of the castings for porosity. The results were qualitatively categorized as "no porosity" (x), "little porosity" (xx), and "porosity" (xxx).

2. Tensile Testing: A universal testing machine was used to perform static strength tests on the castings to measure the maximum tensile force (Fmax), elongation (AL), and tensile strength (Rm).

Research Topics and Scope:

The research focused on the quality of high-pressure die castings made from AlSi9Mg alloy. The scope was limited to investigating the effects of the charge material composition (new metal vs. circulating scrap) on two key quality metrics: internal porosity and mechanical (tensile) strength.

6. Key Results:

Key Results:

- Castings with 0-40% circulating scrap showed no porosity.

- Castings with 50-60% circulating scrap showed a small, acceptable amount of porosity that did not negatively impact strength.

- Castings with 80% circulating scrap showed great porosity that exceeded quality requirements and significantly reduced strength.

- Maximum tensile strength was achieved with a charge of 40% new metal and 60% circulating scrap (17189 N).

- The charge with 80% scrap produced the lowest tensile strength (14986 N), failing to meet the required strength criterion.

- The proportion of 40% metal input and 60% circulating scrap is a safe configuration for quality in terms of both porosity and mechanical strength.

Figure Name List:

- Fig. 1. FRECH Cold-chamber die casting machine: a) view from the front, b) view from the back

- Fig. 2. Exemplary results of the X-ray inspections for the details of various circulating scrap proportions: a) sample No. 1, b) sample No. 2, c) sample No. 3, d) sample No. 4, e) sample No. 5, f) sample No. 6

- Fig. 3. The result of the strength test of the detail: a) stress-strain curve of a sample, b) picture of a sample - the fracture

- Fig. 4. The diagram of the details strength for various circulating scrap proportions

7. Conclusion:

The research demonstrates that the proportion of circulating scrap has a significant influence on the final quality of Al-Si die castings. While no porosity was detected in samples with up to 40% scrap, a small and acceptable level of porosity occurred at 50% and 60% scrap. This minor porosity did not negatively affect the mechanical strength; in fact, strength increased up to the 60% scrap level. However, increasing the scrap proportion to 80% caused severe porosity, particularly in thicker sections, leading to a drastic reduction in strength below the acceptable criterion. The study concludes that a proportion of 40% new metal input and 60% circulating scrap is a safe and optimal configuration that balances material recycling with the high-quality demands for porosity and mechanical strength.

8. References:

- [1] Holtzer, M., Zych, J., Dańko, R. & Bobrowski, A. (2010). Reclamation of material from used ceramic moulds applied in the investment casting technology. Archives of Foundry Engineering. 10(3), 199-204.

- [2] Cha, G., Li, J., Xiong, S. & Han, Z. (2013). Fracture behaviors of A390 aluminum cylinder liner alloys under static loading. Journal of Alloys and Compounds. 550, 370-379. https://doi.org/10.1016/j.jallcom.2012.10.116

- [3] Ling, Y., Zhou, Y., Nan, H, Zhu, L. & Yin, Y. (2018). A shrinkage cavity model based on pressure distribution for Ti-6Al-4V vertical centrifugal castings. Journal of Materials Processing Technology, 251, 295-304. https://doi.org/10.1016/j.jmatprotec.2017.08.025.

- [4] Dumstorff, G., Pille, C., Tiedemann, R, Busse, M. & Lang, W. (2017). Smart aluminum components: Printed sensors for integration into aluminum during high-pressure casting. Journal of Manufacturing Processes. 26, 166-172. https://doi.org/10.1016/j.jmapro.2017.02.006.

- [5] Shangguan, H., Kang, J., Deng, C., Hu, Y. & Huang, T. (2017). 3D-printed shell-truss sand mold for aluminum castings. Journal of Materials Processing Technology. 250, 247-253. https://doi.org/10.1016/j.jmatprotec.2017.05.010.

- [6] Qi, M., Kang, Y., Qiu, Q., Tang, W. Li, J. & Li, B. (2018). Microstructures, mechanical properties, and corrosion behavior of novel high-thermal-conductivity hypoeutectic Al-Si alloys prepared by rheological high pressure die-casting and high pressure die-casting. Journal of Alloys and Compounds, In press, accepted manuscript, Available online 16 March 2018. https://doi.org/10.1016/j.jallcom.2018.03.178.

- [7] Lei, W.B., Liu, X.T., Wang, W.M., Sun, Q., Xu, Y.Z. & Cui, J.Z. (2017). On the influences of Li on the microstructure and properties of hypoeutectic Al-7Si alloy. J. Alloys Compd. 729, 703-709. https://doi.org/10.1016/j.jallcom.2017.04.295.

- [8] Eiken, J., Apel, M., Liang, S.M. & Schmid-Fetzer, R. (2015). Impact of P and Sr on solidification sequence and morphology of hypoeutectic Al-Si alloys: combined thermodynamic computation and phase-field simulation. Acta Mater. 98, 152-163. https://doi.org/10.1016/j.actamat.2015.06.056.

- [9] Favi, C., Germani, M. & Mandolini, M. (2017). Analytical Cost Estimation Model in High Pressure Die Casting Open access. Procedia Manufacturing. 11, 526-535. https://doi.org/10.1016/j.promfg.2017.07.146.

- [10] Zhang, P., Li, Z., Liu, B. & Ding, W. (2017). Tensile Properties and Deformation Behaviors of a New Aluminum Alloy for High Pressure Die Casting. Journal of Materials Science & Technology. 33(4), 367-378. https://doi.org/10.1016/j.jmst.2016.02.013.

- [11] Orłowicz, A.W., Mróz, M., Tupaj, M., Betlej, J. & Płoszaj, F. (2009). Influence of refining process on the porosity of high pressure die casting alloy Al-Si. Archives of Foundry Engineering. 9(2), 35-40.

- [12] Schlafka, P., Bydałek, A.W., Holtzer, M. & Wołczyński, W. (2016). The influence of the ionic reactions on the refining secondary raw materials. Metalurgija. 55(4), 609-612.

- [13] Janerka, K., Szajnar, J., Bartocha, D., Jezierski, J. (2010). Production of synthetic iron in the aspect of a smaller nuisance to the environment. Archives of Foundry Engineering. 10(SI 2), 77-82. (in Polish).

Expert Q&A: Your Top Questions Answered

Q1: Why was the Silafont 36 (AlSi9Mg) alloy chosen for this study?

A1: The paper specifies that die casts made of hypereutectoid silumin Silafont 36 AlSi9Mg are commonly used for construction elements in the automotive industry. This choice makes the research findings directly relevant to real-world industrial applications where a balance of weight, strength, and cost is critical.

Q2: The data shows that adding scrap up to 60% actually increased tensile strength. Does the paper explain the metallurgical reason for this?

A2: The paper factually reports this phenomenon, stating, "the addition of the circulating scrap has contributed to the growth of the maximum tensile force." As shown in Table 5, the force increased from 16621 N (0% scrap) to a peak of 17189 N (60% scrap). The paper does not offer a specific metallurgical explanation for this improvement, focusing instead on the empirical results and their practical implications for determining safe operating parameters.

Q3: What specific die casting parameters were held constant to ensure a fair comparison between the samples?

A3: According to Table 3 in the paper, several key parameters of the die casting process were unchanged for all proportions. These include the piston displacement for the first (250 mm) and second (270 mm) injection phases, the piston velocity for the first (0.30 m/s) and second (3.9 m/s) phases, and the compressing pressure in the third phase (1050 bar).

Q4: In the high-scrap samples that failed, where did the porosity tend to form in the casting?

A4: The paper's conclusion explicitly states that for the sample with 80% scrap (Sample No. 6), "The porosity occurred on the thicker sides of the cast picture." This is visually supported by Figure 2f and is a critical insight for quality control, as it suggests where inspections should be focused, especially on parts with variable wall thickness.

Q5: Did the study define a quantitative limit for "acceptable" vs. "unacceptable" porosity?

A5: The study uses a qualitative assessment from the X-ray inspection. The paper notes that for samples 6.2 and 6.3 (both with 80% scrap), "the porosity detected exceeded the permissible value for the detail." It does not provide a specific quantitative value (e.g., a percentage of void volume), but rather correlates the observed level of porosity directly with the failure to meet the mechanical strength criterion.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear, data-backed framework for managing Circulating Scrap in HPDC. The core challenge has always been balancing the economic and environmental benefits of recycling with the non-negotiable demand for high-quality, defect-free castings. This study's key breakthrough is the identification of a "sweet spot": a 60% scrap ratio that not only maintains quality but can actually enhance the mechanical strength of AlSi9Mg components.

For R&D and operations teams, these findings offer a practical guideline to maximize sustainability and cost-efficiency without risking product failure. By understanding that the limit is not a gradual decline but a steep drop-off after 60%, foundries can set more confident and effective process controls.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "The Influence of the Proportion of Charge from Waste Materials on the Quality of High Pressure Castings" by "P. Schlafka, A. W. Bydałek".

- Source: https://doi.org/10.24425/afe.2019.127110

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.