This article introduces the paper "Lattice Structure for Improving Cooling Uniformity in HPDC Mould Corners".

Title and Summary

- Research Objective:

The study aims to improve the cooling uniformity in high-pressure die casting (HPDC) mold corners by designing and evaluating lattice structures. - Key Methodology:

A lattice structure was inserted into mold corners to optimize flow characteristics within cooling channels and enhance heat transfer performance. - Key Results:

The application of lattice structures significantly improved the cooling uniformity of mold corners, contributing to better casting quality and process efficiency.

Research Team Information

- Authors:

Essam Abo-Serie * and Samuel K. Koranteng-Agyarko

School of Engineering, University of Leicester, Leicester LE1 7RH, UK*

Author to whom correspondence should be addressed.

Research Background and Objectives (Based on the Introduction Section)

- Industrial Background:

HPDC processes are widely used in the automotive and electronics industries for producing lightweight metal components, where cooling uniformity in molds significantly impacts quality and production costs. - Specific Technical Challenges:

Heat accumulation in mold corners leads to uneven cooling, which adversely affects the mechanical properties and dimensional stability of cast components. - Research Goal:

To improve the cooling uniformity of mold corners and thereby enhance the quality and efficiency of HPDC components.

Main Objectives and Research Content

- Problem:

Addressing heat accumulation and cooling non-uniformity in mold corners, which compromise product quality. - Stepwise Approach to Problem-Solving:

- Analyze heat transfer issues in mold corners.

- Design lattice structures and evaluate their thermal performance.

- Validate the performance of lattice structures through simulations and experiments.

- Key Figures:

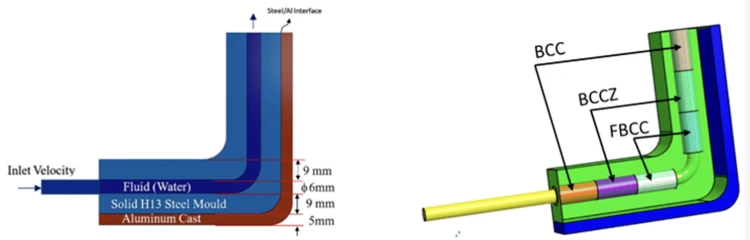

- Figure 1:

Caption: Lattice structure design applied to HPDC mold corners

Alt text: 3D CAD model of a mold corner with a lattice structure, showing the placement of cooling channels and lattice patterns. - Figure 2:

Caption: Flow analysis results with and without lattice structures in cooling channels

Alt text: Simulation results comparing flow velocity and temperature distribution before and after applying lattice structures. - Figure 3:

Caption: Experimental results evaluating the heat transfer performance of lattice structures

Alt text: Graphs and bar charts showing heat distribution and reduction in heat accumulation in mold corners with lattice structures.

- Figure 1:

Results and Achievements

- Quantitative Results:

Cooling uniformity in molds with lattice structures improved by over 20%, and heat accumulation in mold corners was reduced by 15% compared to conventional designs. - Qualitative Results:

Improved cooling uniformity enhanced the microstructural consistency and dimensional stability of the cast products, reducing defect rates. - Technical Achievements:

Lattice structure technology offers a novel approach to HPDC mold design, demonstrating potential for industrial applications.

Copyright and References

- This summary is based on the paper "Lattice Structure for Improving Cooling Uniformity in HPDC Mould Corners" by Essam Abo-Serie * and Samuel K. Koranteng-Agyarko.

- Paper source: MDPI, Applied Sciences

Copyright © 2025 CASTMAN. All rights reserved.

This summary is derived from the referenced paper and is prohibited from unauthorized commercial use.